Process method for producing high-purity alumina polycrystal in graphite suspension cold crucible

A technology of high-purity alumina and a process method is applied in the field of producing high-purity alumina polycrystals from a graphite suspension type cold crucible, which can solve the problems of high temperature around the cold crucible, inconvenient operation, complicated structure of an automatic lifting mechanism, etc. The method is simple and easy to operate, easy to operate, and the effect of the process is rapid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

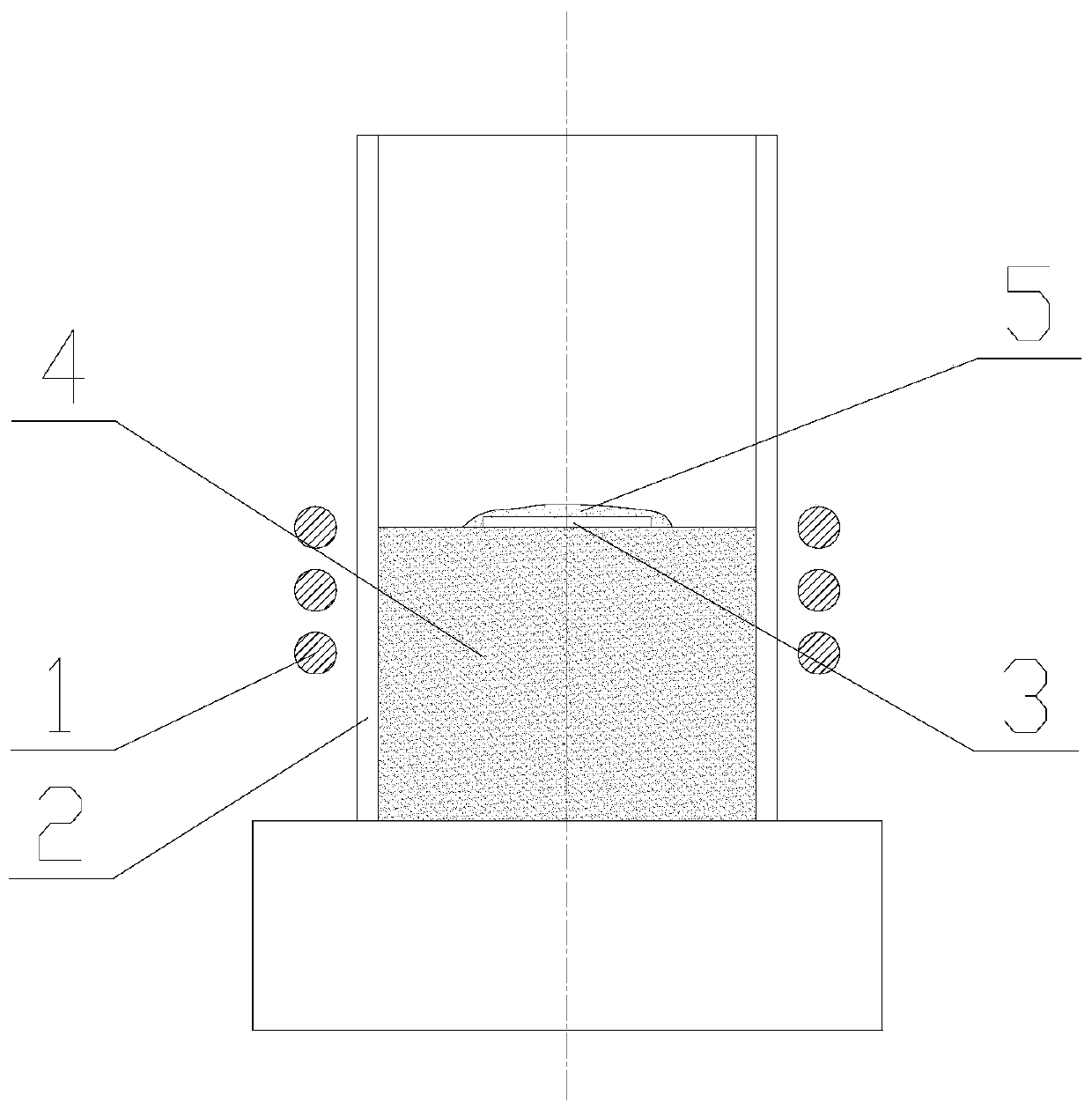

[0037] see figure 1 A method for producing high-purity alumina polycrystals in a graphite suspension type cold crucible, comprising the steps of:

[0038] 1) Fill the cold crucible with high-purity alumina raw material powder, the total height of the high-frequency induction coil is 10cm, and the height of the lower edge of the high-frequency induction coil is at 11cm, and the added raw material powder is compacted as a base material, so that after compaction The height of the high-purity alumina raw material powder is 16cm;

[0039] 2) Put a high-purity graphite sheet with a diameter of 12cm, a thickness of 0.5cm, and a purity greater than 99.99% on the above-mentioned base material, and then evenly cover a layer of 1cm-high uncompacted high-purity alumina on the high-purity graphite sheet Raw material powder;

[0040] 3) Start the water-cooling system of the cold crucible, turn on the power supply of the high-frequency induction coil, adjust the power supply frequency of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com