Electronic-grade glass fiber cloth with sealed edges

A glass fiber cloth, electronic grade technology, applied in the direction of fabric trimming, weaving, fabric, etc., can solve the problems of increasing the cost of feather edge cloth, adverse environmental impact, scrapping of prepreg, etc., achieve considerable market prospects, save costs, and improve products Yield effect

Inactive Publication Date: 2017-12-22

江春兰

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The resin taken away by the feathers causes a lot of waste, because the price of the resin is relatively high, and poor trimming during the manufacturing process will lead to the scrapping of the prepreg, which increases the cost of the feathers in the downstream production process, and the resin Added organic solvents, scrapped prepregs and cut resin-containing feathers contain dangerous chemicals, which also have adverse effects on the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

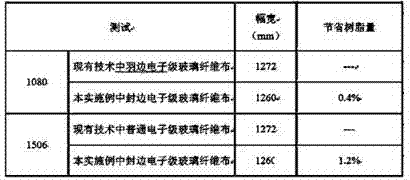

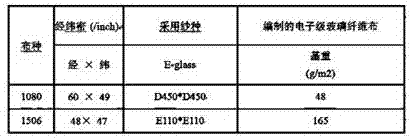

[0016] Example 1 Weaving 1080 and 1506 types of fabrics with electronic grade glass fiber warp and weft: see Table 1. Resin savings test results: See Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to electronic-grade glass fiber cloth with sealed edges, and is applicable to electronic-grade glass fiber cloth fabrics for high-frequency and high-speed copper-clad laminates. Warp yarns and weft yarns are interactively woven with one another to form the electronic-grade glass fiber cloth with the sealed edges and comprise monofilaments, and integral electronic-grade glass fiber cloth is of a plain weave structure. The electronic-grade glass fiber cloth with the sealed edges is characterized in that feather edges on two sides of the integral electronic-grade glass fiber cloth are cut to form the sealed edges with resin coating layers. The electronic-grade glass fiber cloth with the sealed edges has the advantages that electronic-grade glass fiber cloth products with cut edges can be provided for downstream CCL (copper-clad laminate) manufacturers, the electronic-grade glass fiber cloth with the sealed edges is favorable for reducing the costs for the CCL manufacturers, waste with dangerous chemicals can be reduced, and the purposes of energy conservation, emission reduction and green production can be achieved.

Description

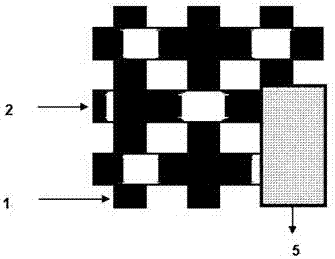

technical field [0001] The invention relates to an edge-sealing electronic-grade glass fiber cloth, which is an electronic-grade glass fiber cloth suitable for high-frequency and high-speed copper-clad laminates. Background technique [0002] The electronic-grade glass fiber cloths currently on the market are feather edge cloths (such as figure 1 As shown), that is, the electronic grade glass fiber cloth is used to prevent the edge of the cloth from detaching. On the air-jet loom, Leno (Leno) hemming device is used to hem both sides of the electronic grade glass fiber cloth in the length direction (warp direction) (Leno Leno hemming device) edge 3), and finally leave a feather edge 4 of about 4 to 6mm in the width direction (weft direction). [0003] After the electronic-grade glass fiber cloth is impregnated with resin and dried downstream, the feather edge of the prepreg formed is irregular, and an edge trimming device needs to be installed on the impregnation machine to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D15/00D03D13/00D06C25/00

CPCD03D13/00D06C25/00D10B2101/06D03D15/267

Inventor 江春兰

Owner 江春兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com