Heavy door and mounting method

An installation method and heavy-duty door technology, applied in windows/doors, door/window applications, door/window accessories, etc., can solve problems such as door leaf falling off, hidden safety hazards, etc., and achieve the goals of prolonging service life, saving cost, and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

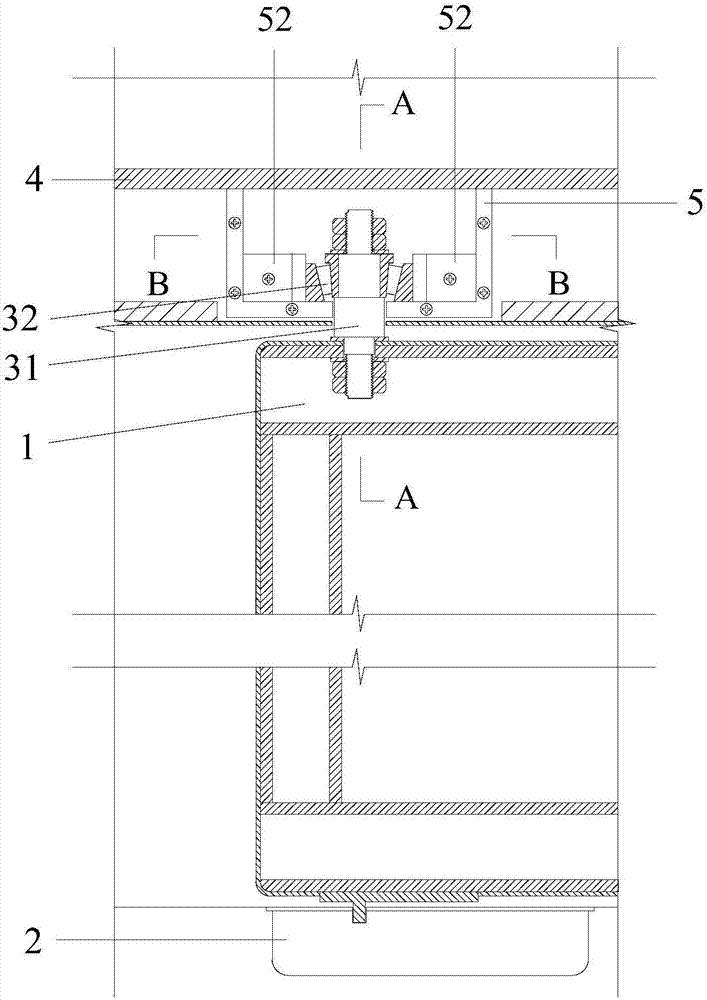

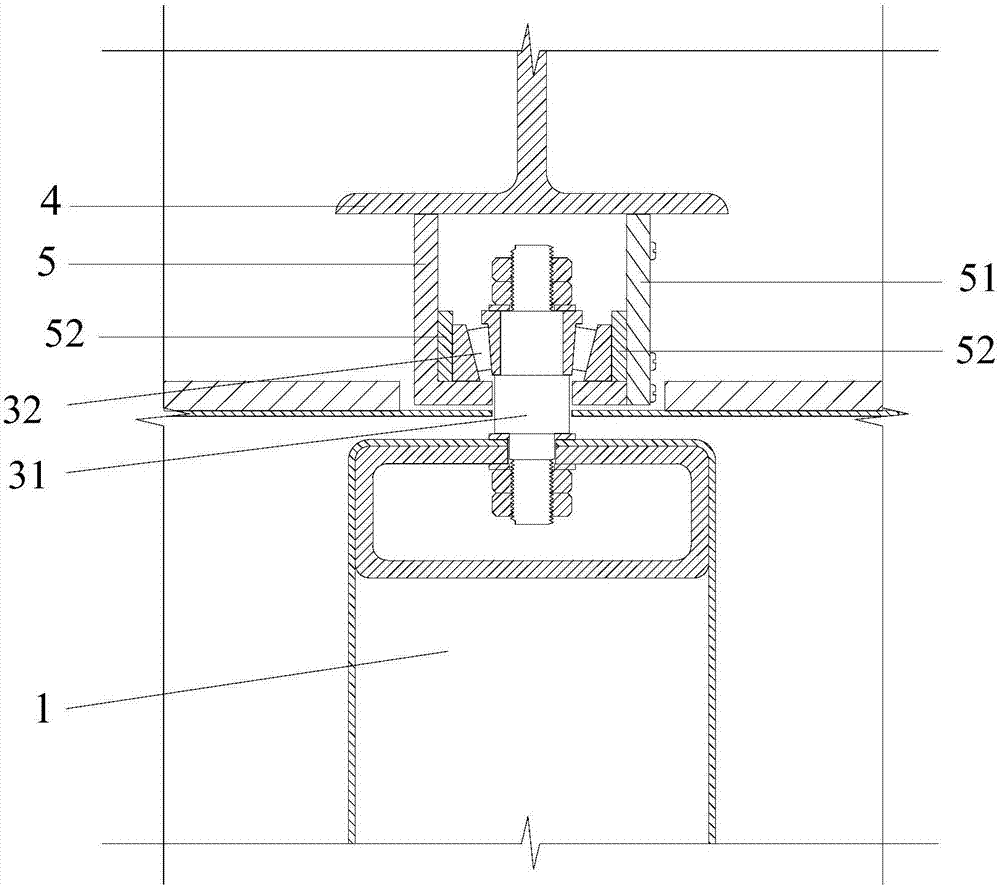

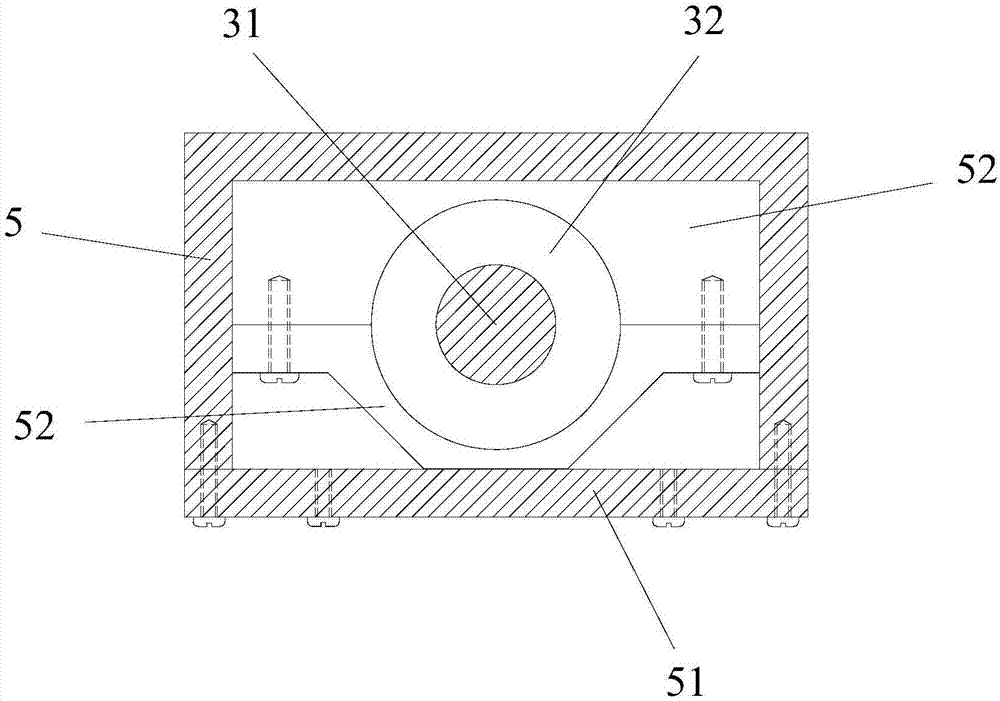

[0036] Such as Figure 1-3 As shown, a heavy-duty door includes a door leaf 1, and further includes an upper shaft and a floor spring 2. The ground shaft of the floor spring 2 is connected to the bottom of the door leaf 1, and the upper shaft includes a shaft 31 and a tapered roller bearing 32, The shaft 31 is rotatably connected to the tapered roller bearing 32, the lower end of the shaft 31 is connected to the frame on the top of the door leaf 1, the upper and lower ends of the shaft 31 are fixed by double nuts, and the double nut at the lower end is connected to the door leaf 1 to prevent the door leaf 1 from falling off. The tapered roller bearing 32 is arranged on a connecting piece for connecting to the door frame or beam 4. The sky shaft and the ground shaft are arranged coaxially, and the connecting piece includes The housing 5, the tapered roller bearing 32 is connected to the inside of the housing 5, the bottom of the housing 5 is provided with a through hole adapted ...

Embodiment 2

[0038] A method for installing a heavy door includes using a heavy door as in Example 1, such as Figure 4 , Its installation method includes the following steps:

[0039] Step 1. Pre-bury the floor spring 2;

[0040] Step 2: Connect the shaft 31 to the frame on the top of the door leaf 1;

[0041] Step 3: Connect the connecting piece to the door frame or beam 4;

[0042] Step 4: Connect the bottom of the door leaf 1 to the ground shaft of the floor spring 2;

[0043] Step 5: Connect the shaft 31 to the connecting piece, and then connect the tapered roller bearing 32.

[0044] The floor spring 2 is pre-embedded, the double nut is welded and connected to the inner side of the frame at the top of the door leaf 1, and then the shaft 31 is screwed into the double nut and tightened, and the shell 5 is welded to the The door frame or beam 4, and then lift the door leaf 1 so that the shaft of the floor spring 2 is inserted into the shaft hole under the door leaf 3, and then push the shaft 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com