Rearview mirror wiper for overall wiping and rearview mirror thereof

A rear-view mirror and wiper technology, which is applied to vehicle cleaning, vehicle maintenance, optical observation devices, etc., can solve the problems of blurred rear-view mirrors, poor controllability of wipers, and sweeping of rear-view mirrors, so as to improve the cleaning effect, Avoid re-blur effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

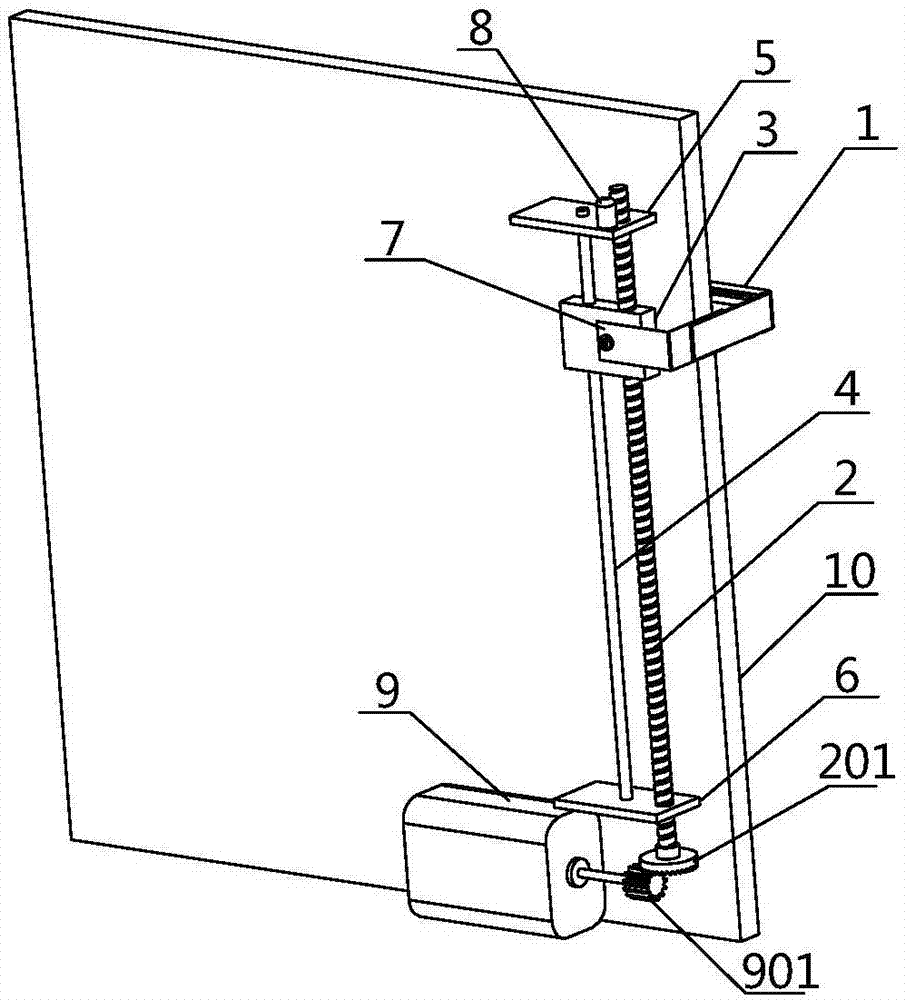

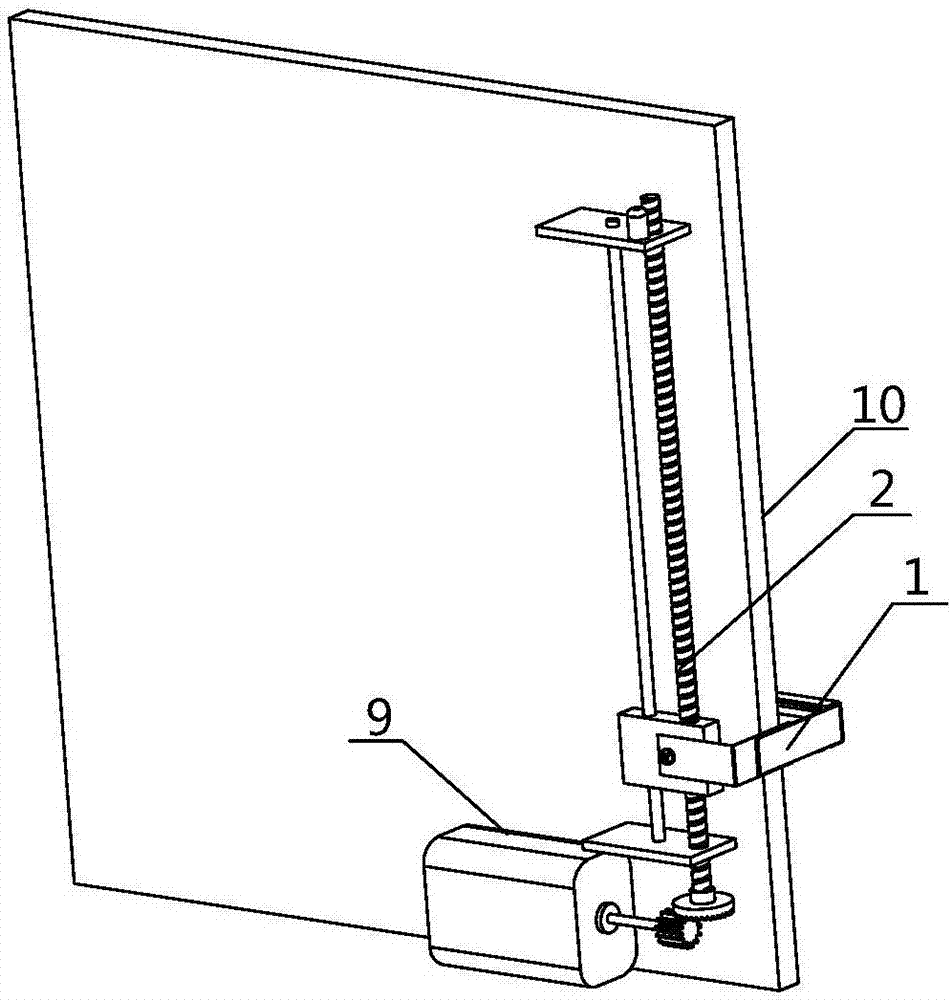

[0033] Such as Figure 1-3 As shown, the rearview mirror wiper convenient for comprehensive sweeping according to Embodiment 1 of the present invention, the rearview mirror wiper includes an elastic wiper portion 1 arranged on the outer surface of the mirror panel 10 and used for comprehensive sweeping. 10 is the sliding mechanism used to make the wiper unit 1 move up and down on the back, and the driving device used to drive the sliding mechanism.

[0034] First, further analysis of the sliding mechanism set above:

[0035] Described sliding mechanism has slide rail 4; Because can according to the demand of the shape of mirror panel 10 and the brushing mode, slide rail 4 is vertically set from top to bottom on mirror panel 10 backside and this slide rail 4 upper and lower ends pass through respectively The upper position positioning plate 5 and the lower position positioning plate 6 are fixed on the back of the mirror panel 10 or in the parts cavity on the inner side of the ...

Embodiment 2

[0044] Such as Figure 1-3 As shown, the rearview mirror wiper convenient for comprehensive sweeping described in Embodiment 2 of the present invention includes a wiper portion 1 arranged on the outer surface of the mirror panel 10 and used for comprehensive sweeping, and arranged on the back of the mirror panel 10 for use. The wiper unit 1 is a sliding mechanism for moving up and down, and a driving device for driving the sliding mechanism.

[0045] First, further analysis of the sliding mechanism set above:

[0046] The back side of the mirror panel 10 has a housing and the inside of the housing has a component cavity, and a sliding mechanism with a slide rail 4 is installed in the component cavity; a slide block 3 is sleeved on the slide rail 4, and the outer surface of the slide block 3 is Connect the connecting guide plate 7, because the slider 3 and the wiper portion 1 are separated by the mirror plate 10, therefore, the connecting guide plate 7 is an L-shaped structure...

Embodiment 3

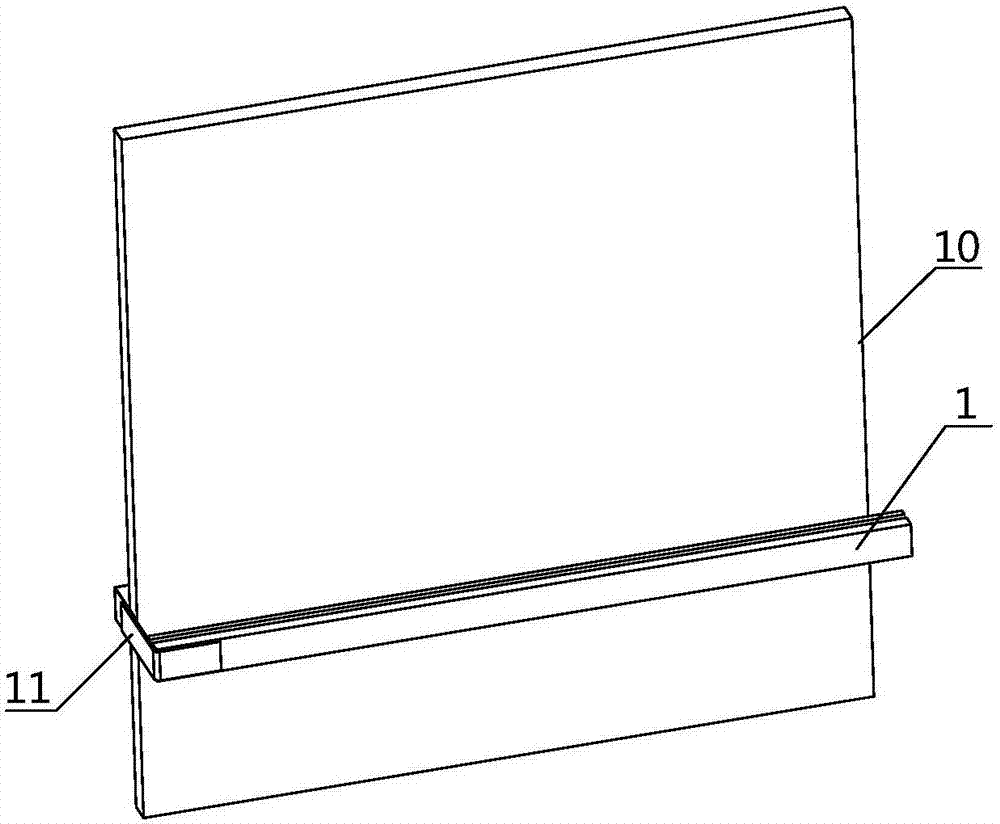

[0050] Such as Figure 1-3 As shown, a rearview mirror convenient for comprehensive sweeping described in Embodiment 3 of the present invention includes a mirror panel 10 of a rectangular structure and a housing for fixing the mirror surface. The mirror surface of the rectangular structure is provided with a wiper portion 1, and the mirror panel 10 A sliding mechanism for swiping the wiper unit 1 up and down is provided between the back surface and the casing, and a driving device for driving the sliding mechanism is provided below the sliding mechanism.

[0051] First, further analysis of the sliding mechanism set above:

[0052] The sliding mechanism is arranged in the housing on the back of the mirror panel 10, so that there is no need to additionally configure a wiper drive box to occupy the space outside the car body, which will neither affect the appearance of the car body nor hinder cleaning and maintenance;

[0053] Owing to can according to the demand of the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com