Q345-grade hot-rolled weather-resistant large-scale steel angle for iron tower and preparation method thereof

A weather-resistant and iron tower technology, applied in the field of metallurgy, can solve problems such as cracking, weather-resistant cold-formed angle steel transmission towers that cannot be deployed on a large scale, and increase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0027] Embodiment 1-2 provides a Q345 grade hot-rolled weather-resistant large-scale angle steel for iron towers, the composition of which is shown in Table 1, and is specifically prepared according to the following steps:

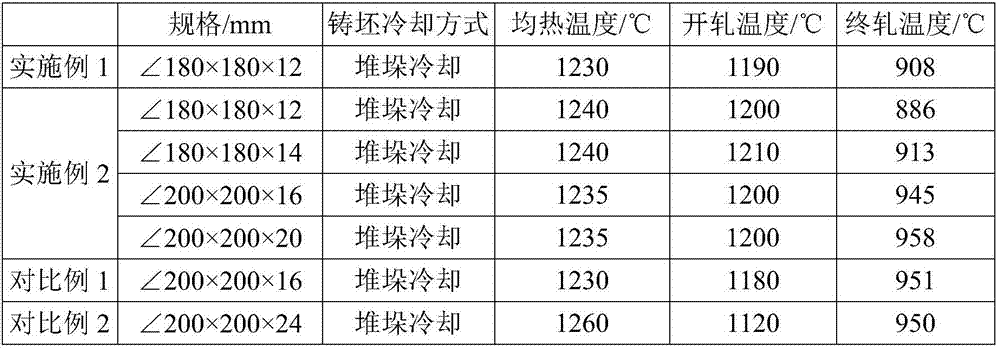

[0028] 1) The iron tower is smelted with various components of Q345 hot-rolled weather-resistant large-scale angle steel, and cast into slabs, and the slabs are cooled to room temperature by stacking; 2) The slabs are heated, wherein the soaking temperature As shown in table 2;

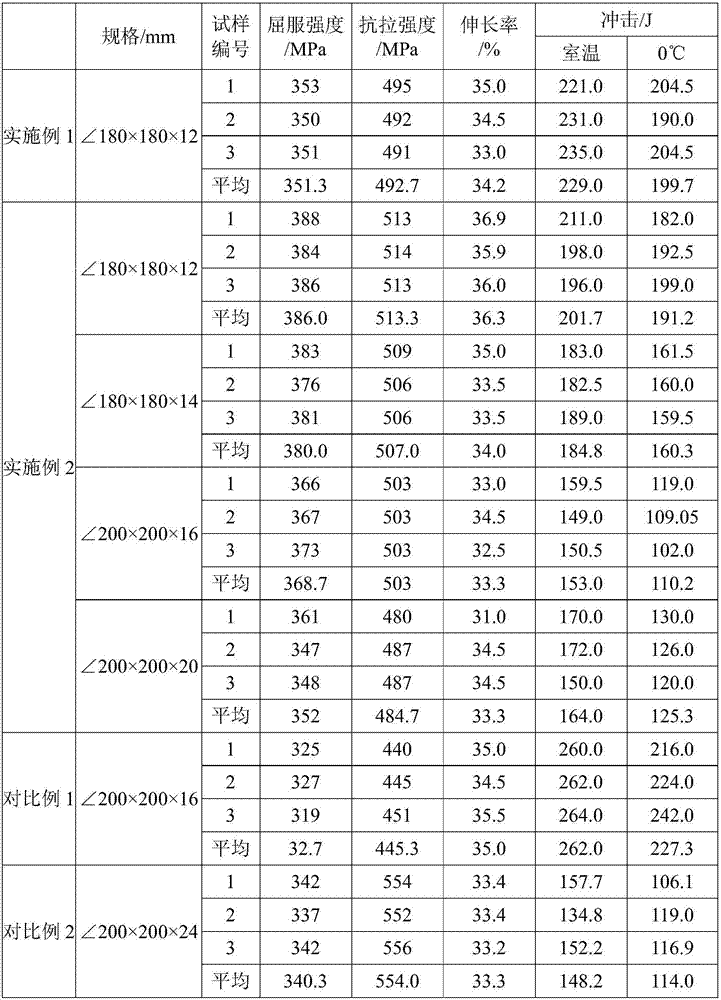

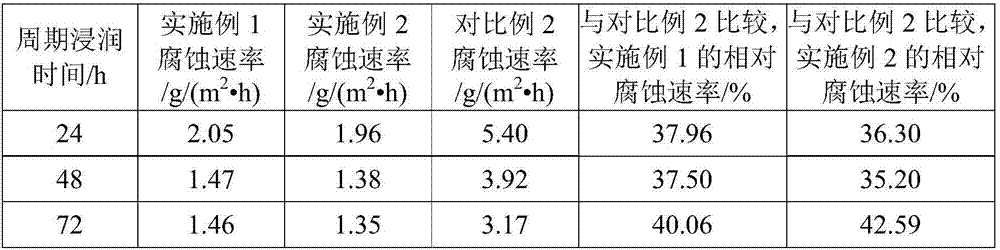

[0029] 3) rolling the heated slab, wherein the starting rolling temperature and the finishing rolling temperature are as shown in Table 2, and the total compression ratio of the slab is >5; 4) air-cooling the rolled angle steel to obtain Q345 iron tower Grade hot-rolled weather-resistant large-scale angle steel. The main process parameters in the preparation process are shown in Table 2, the mechanical properties are shown in Table 3, and the corrosion rate is shown in Table 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com