Target module and aerodynamic measurement system applicable to millinewton vacuum plume

A measurement system and a target target technology, which is applied in the field of millinewton-level vacuum plume aerodynamic measurement systems, can solve problems such as failure of target target force measurement equipment, influence on normal operation of sensors, influence on aerodynamic measurement, etc., so as to reduce influence and ensure Thermal insulation, effect of reducing thermal stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

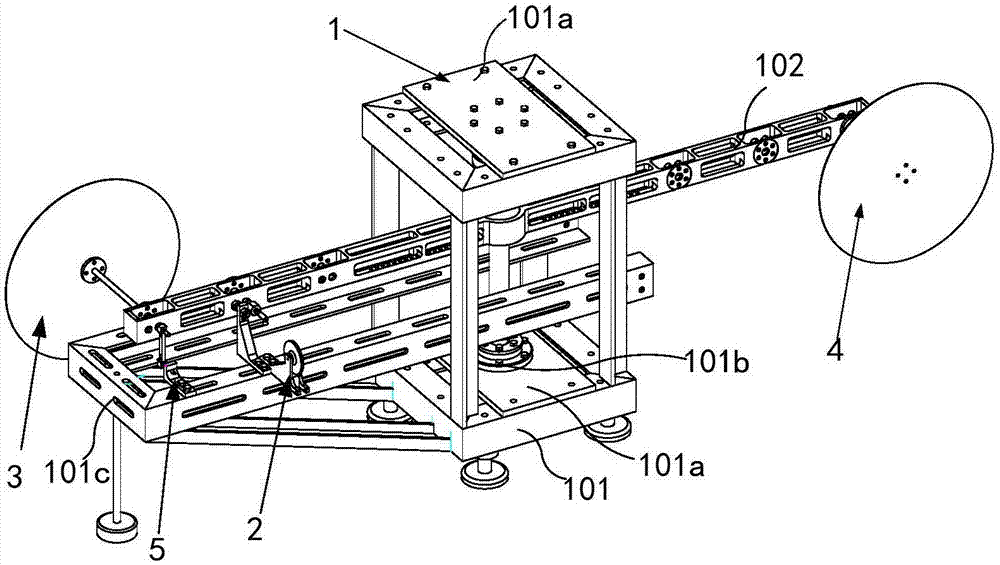

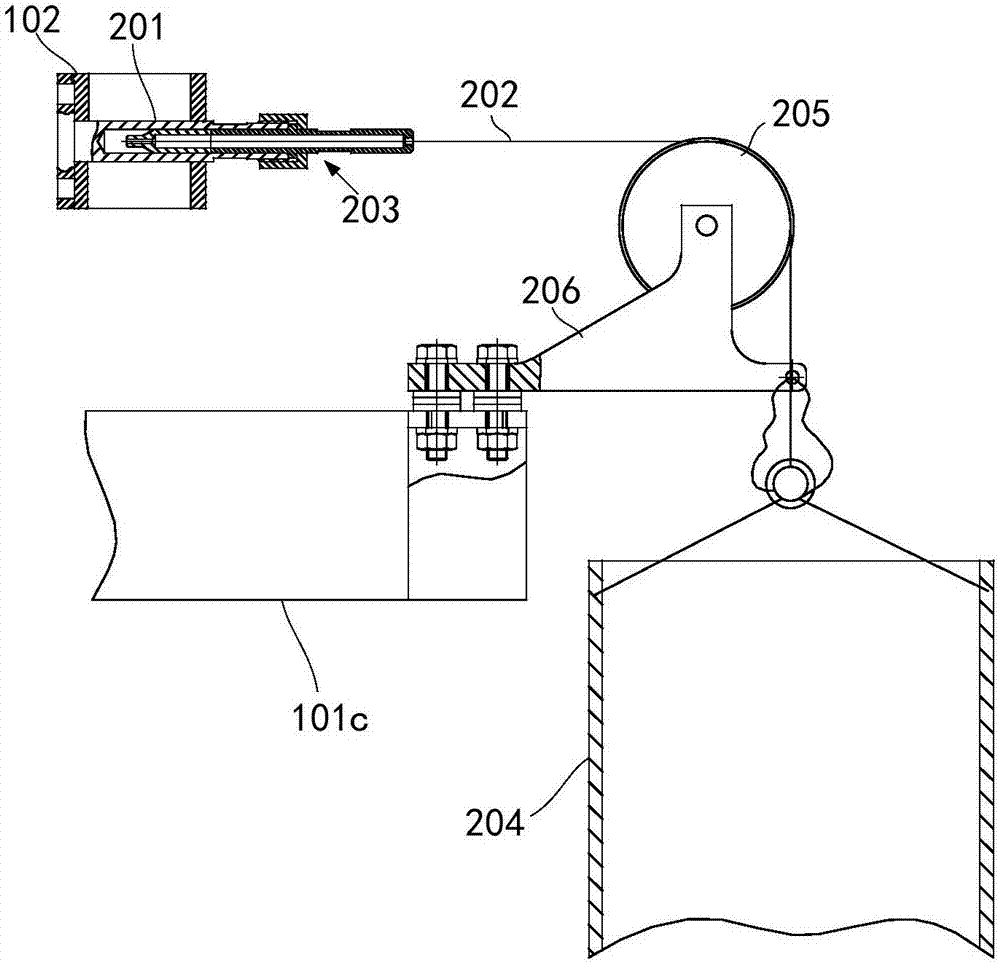

[0050] like Figure 1-9 As shown, the millinew level vacuum plume aerodynamic measurement system provided by the embodiment of the present invention includes a force measurement bench 1 , a force calibration component 2 , a force measurement component 5 , a target target component 3 and a balance target component 4 .

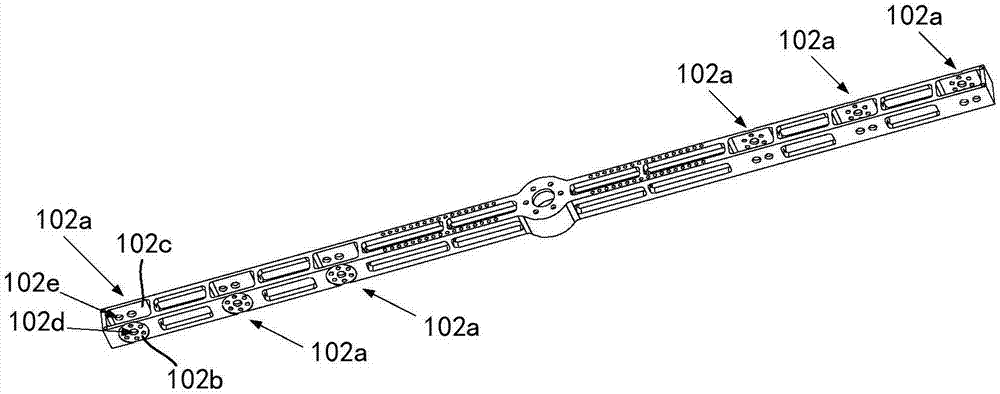

[0051] Wherein, the force measurement stand 1 includes a force measurement support platform 101, a force measurement beam 102 and a force measurement support 101c; the force measurement support platform 101 is a rectangular frame structure, and a connecting plate 101a is installed on the top surface and the bottom surface, and the top surface and the bottom surface A force measurement central axis 101b is vertically fixed between the connecting plates 101a for installing the force measurement beam 102 . The force measurement support platform 101 is fixed with a horizontally arranged rectangular frame structure force measurement bracket 101c, the force measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com