Automobile sealing strip wear resistant test device and test method

A technology for automotive sealing strips and wear-resistant tests, which is applied to measuring devices, wear-resistant tests, instruments, etc., can solve the problem that glass friction heads and metal friction heads cannot completely simulate the customer's working conditions, so as to reduce the risk of failure, Low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the drawings, the same reference numerals represent the same or corresponding technical features.

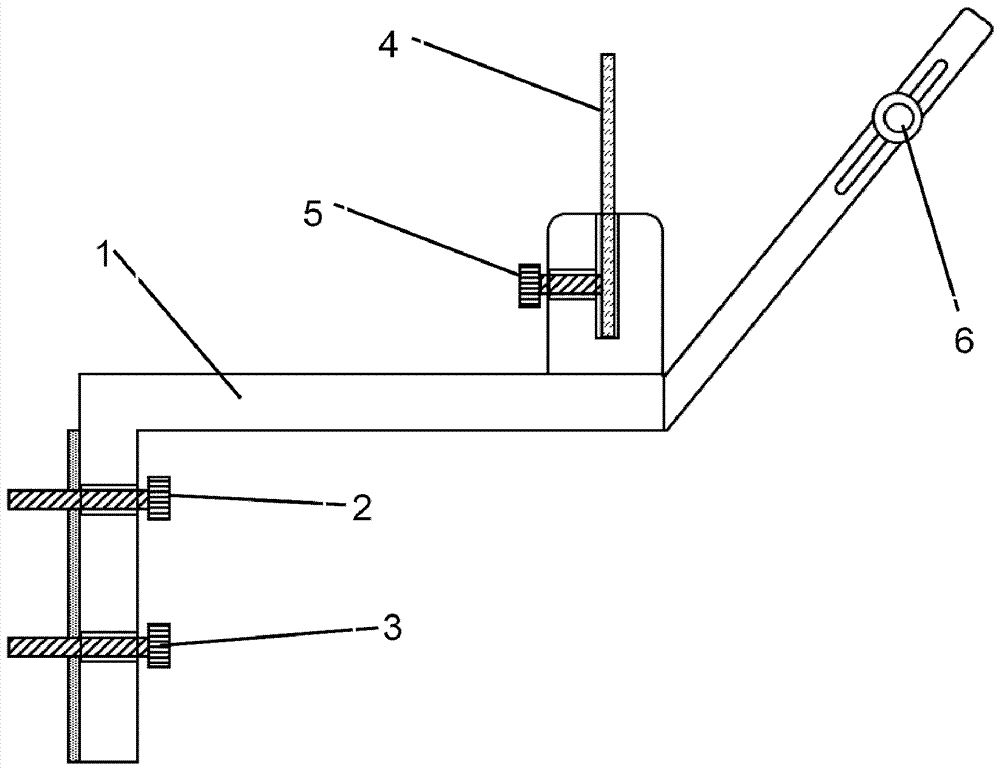

[0027] figure 1 It is a schematic side view of the main part of the tooling of the automobile weather strip abrasion test device according to the first embodiment of the present invention.

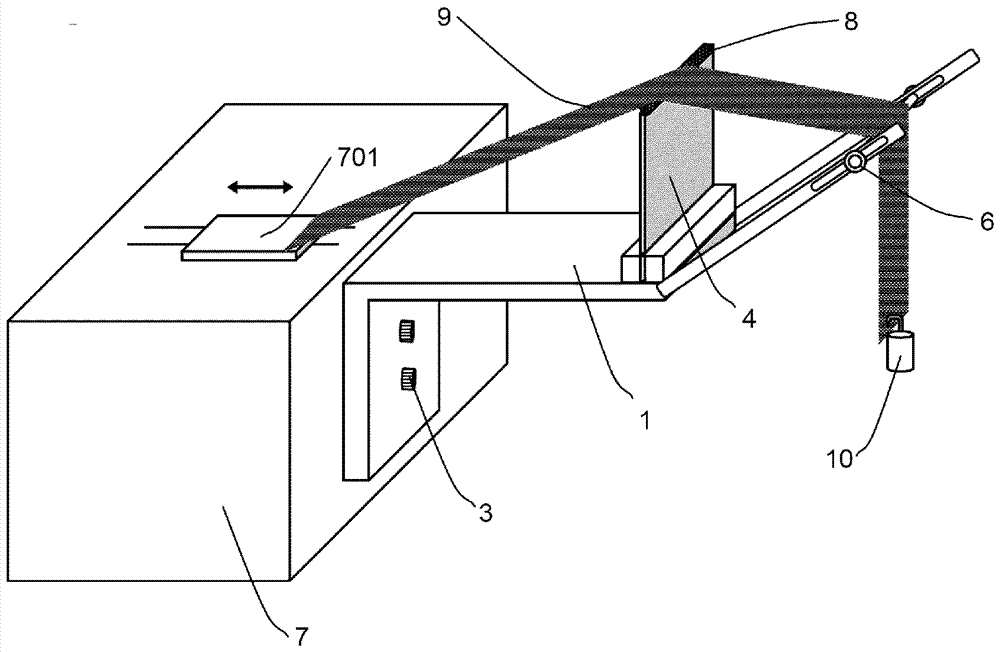

[0028] exist figure 1 It can be seen from the figure that the tooling main body 1 is fixed by fastening bolts 2 and 3 . combine figure 2 It can be seen that the tool body 1 can be fastened to the test bench 7 such as the glass friction head or metal friction head of the prior art to and from the side of the wear-resistant equipment.

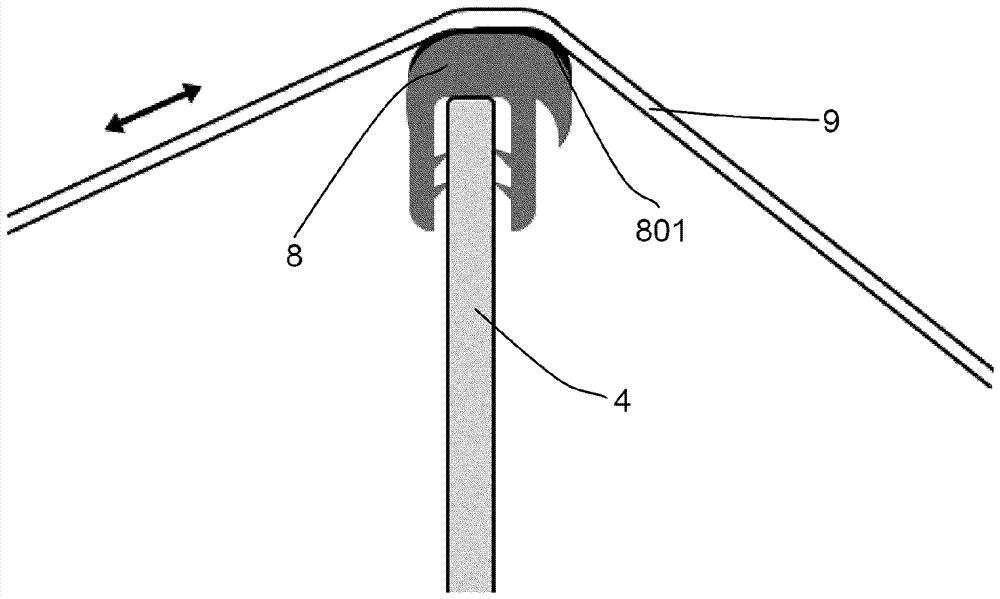

[0029] A vertical sealing strip support plate 4 is installed on the frock main body. Specifically, in the illustrated embodiment, a groove is provided on the tool body, and the size of the groove can ensure that the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com