Full-automatic mechanical high-pressure sterilization pot

A high-pressure sterilizer and fully automatic technology, applied in the field of high-pressure machinery, can solve the problems of physical injury of experimenters, no handle of the sterilizer, and affect the sterilization effect, so as to reduce safety hazards, protect the environment, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

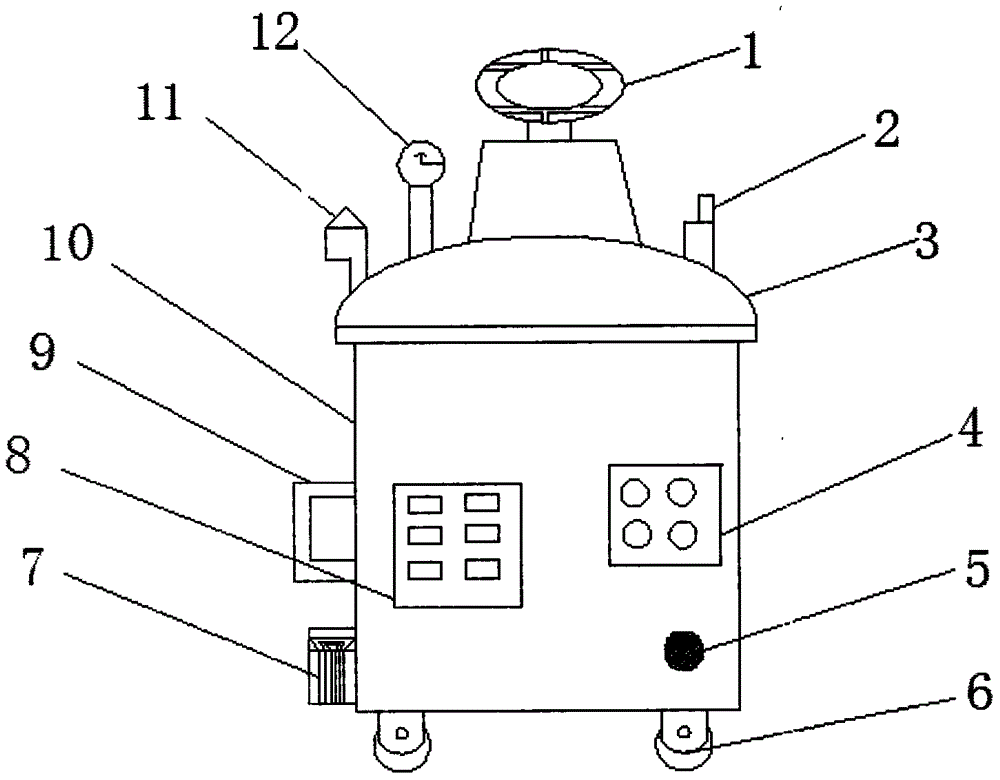

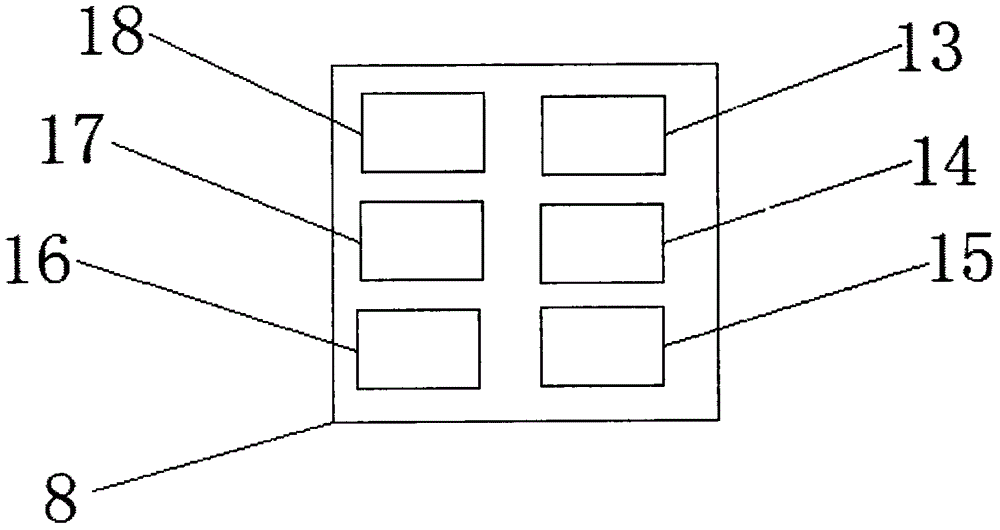

[0014] refer to Figure 1-2 , a fully automatic stainless steel autoclave, comprising a rotary valve 1, a pot cover 3, a working status indicator light 4, a power switch 5, an outer pot 10, a pressure sensor 11 and a pressure gauge 12, characterized in that the outer pot 10 A pot cover 3 is installed on the upper table wall, a pressure sensor 11 is arranged on the left side of the pot cover 3, a pressure gauge 12 is installed on the right side of the pressure sensor 11, and a control wheel 1 is installed on the right side of the pressure gauge 12, and the control wheel The right side of 1 is equipped with a venting valve 2, a power switch 5 is installed under the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com