water mill

A technology of water mill and frame, which is applied in the direction of grain processing, etc. It can solve the problems of limitation, limitation of material storage space, and influence of material crushing effect, etc., and achieves the effects of simple structure, improved mixing and crushing effect, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

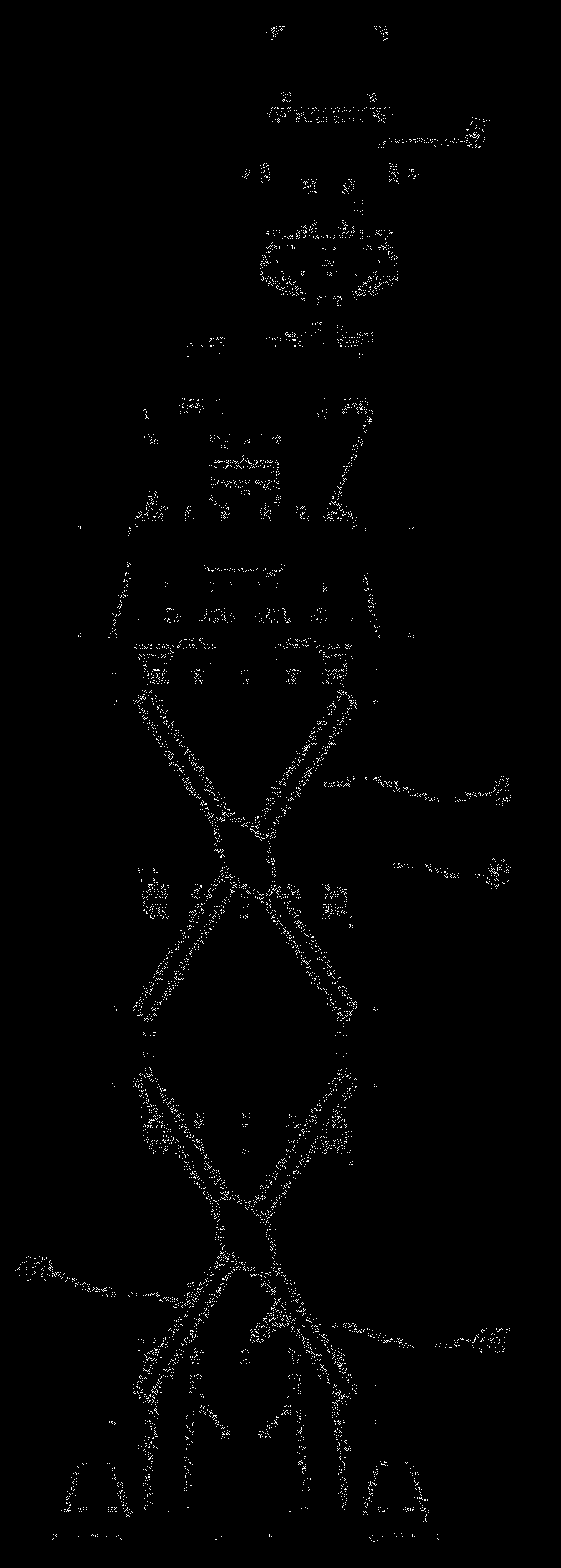

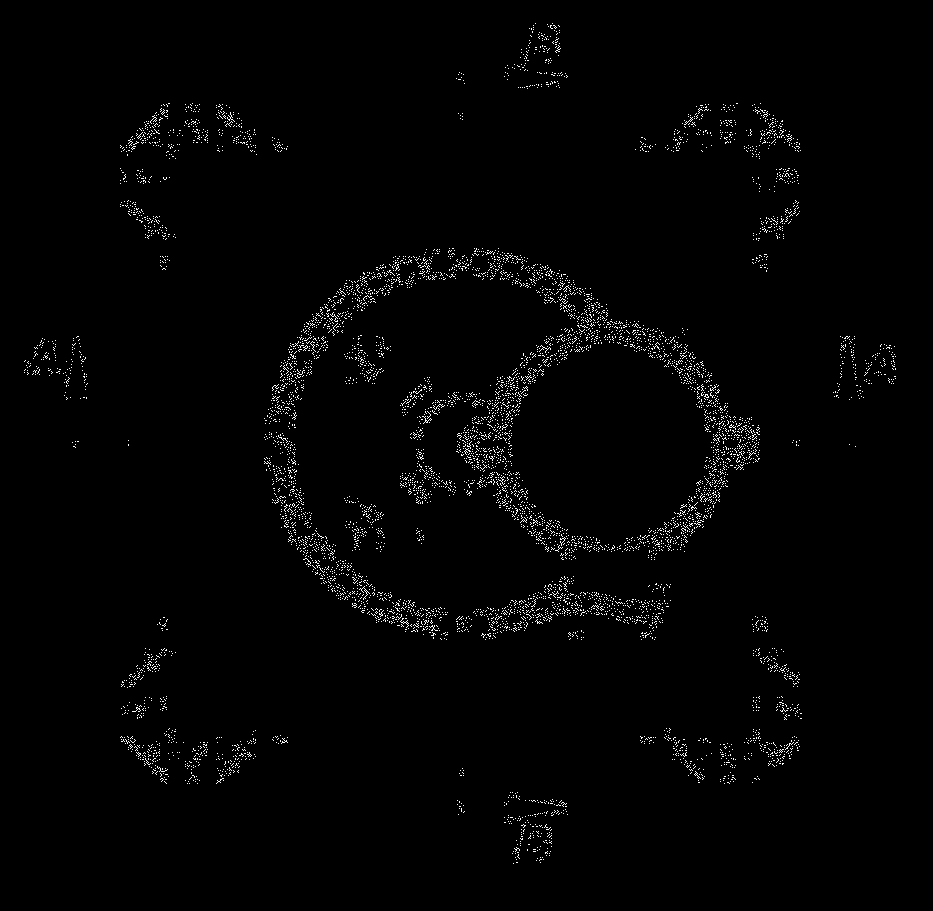

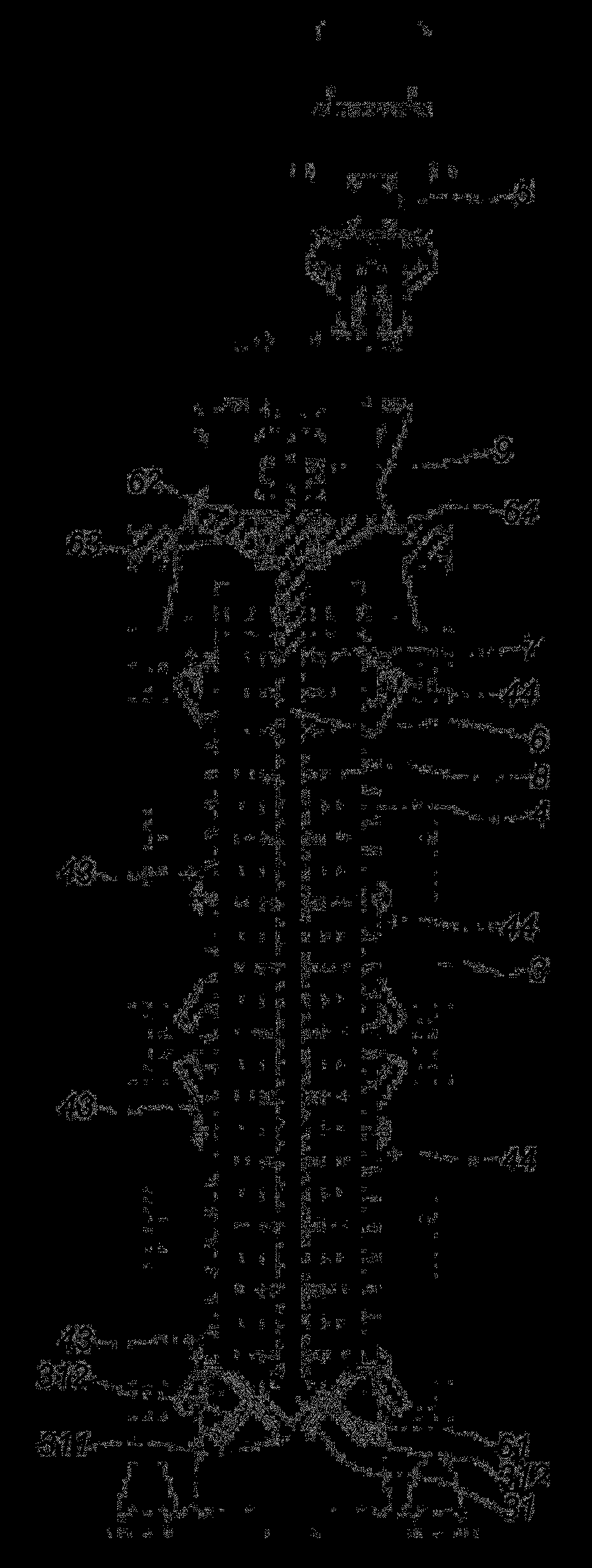

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , 2 , 3, and 4, the water mill comprises a frame 3, a stirring chamber 4 and a speed reducer 5, the stirring chamber 4 is vertically installed relative to the frame 3, and the bottom and top of the stirring chamber 4 are respectively provided with a feed port 41 and a Outlet 42, the outer wall of the stirring chamber 4 is provided with a cooling water inlet 43 and a cooling water outlet 44, the stirring chamber 4 is a cylindrical cavity, the cooling water inlet 43 and the cooling water outlet 44 are respectively located on the same longitudinal section of the stirring chamber, There are 3 cooling water inlets and 3 cooling water outlets, which are arranged at intervals. The cooling water inlet 43 and the cooling water outlet 44 are not on the same cross section of the stirring chamber 4 .

[0024] The stirring chamber 4 has a built-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com