Patents

Literature

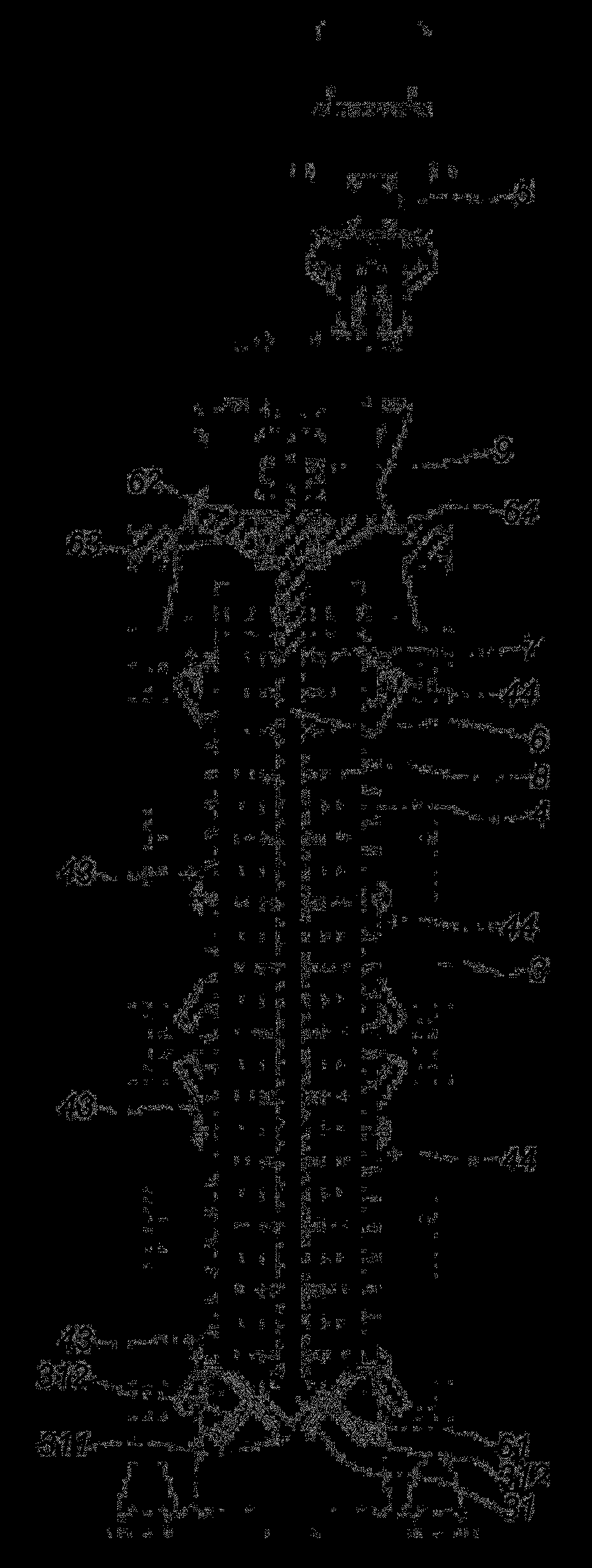

31results about How to "Improve mixing and crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

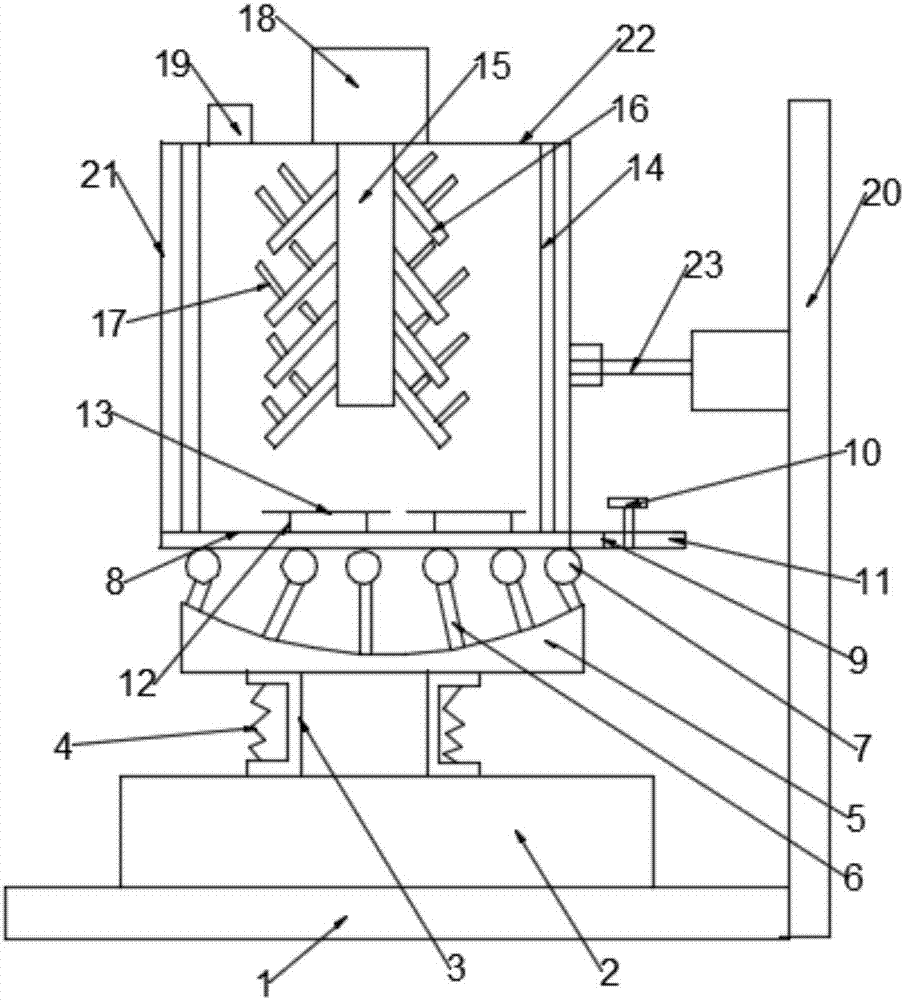

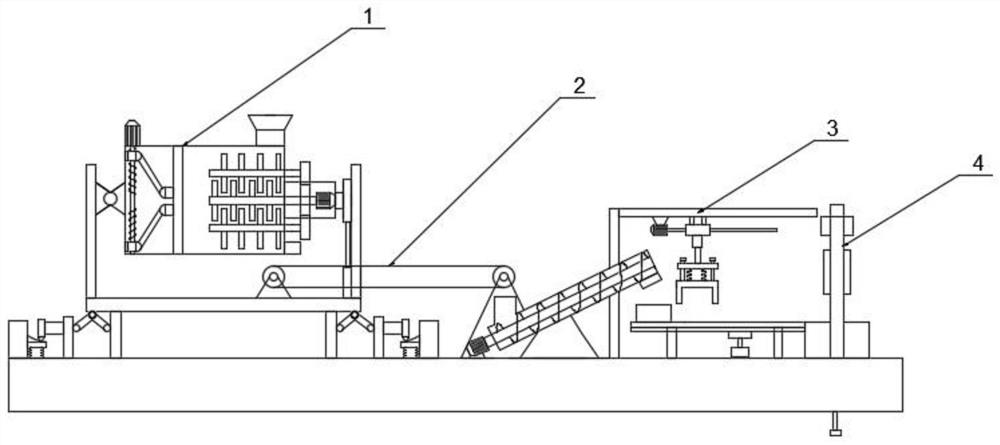

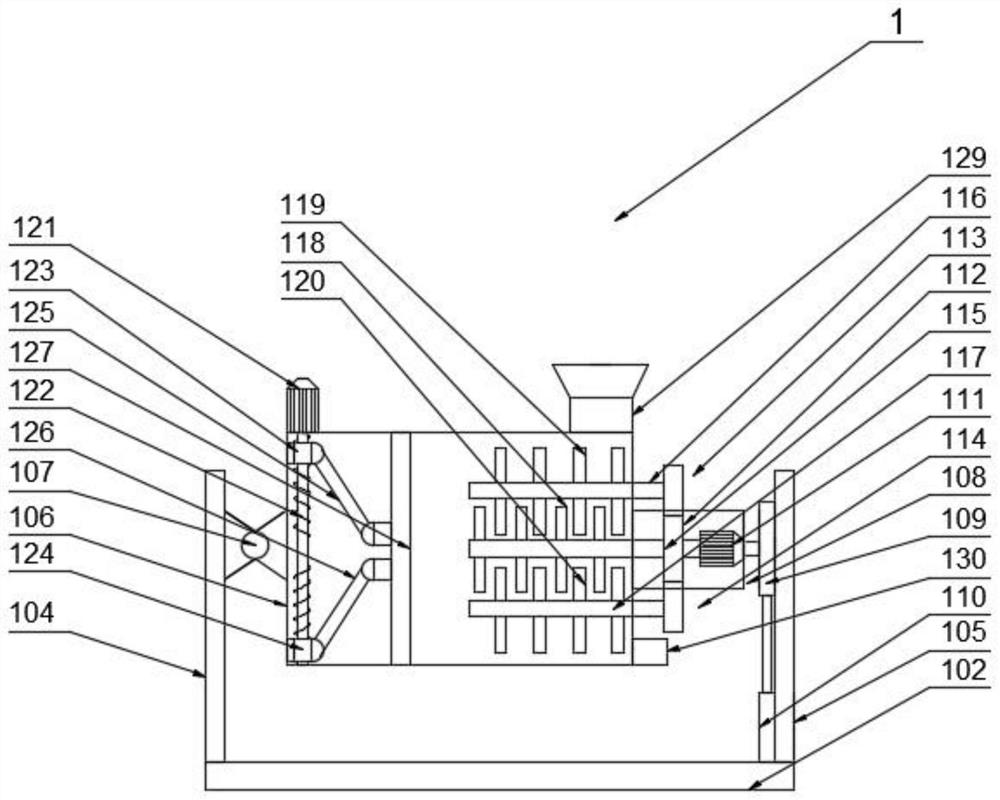

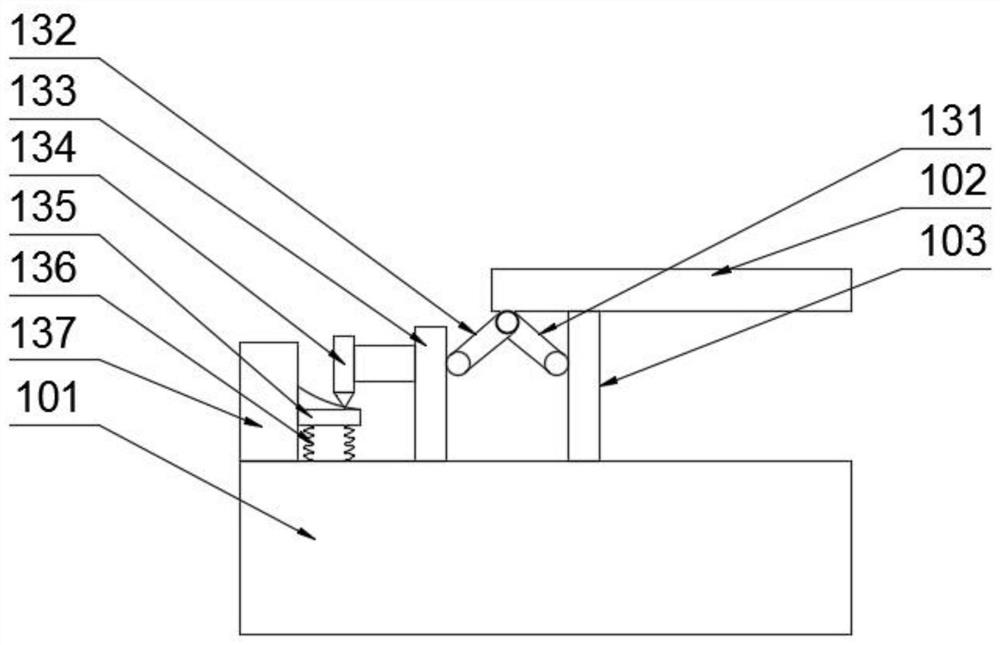

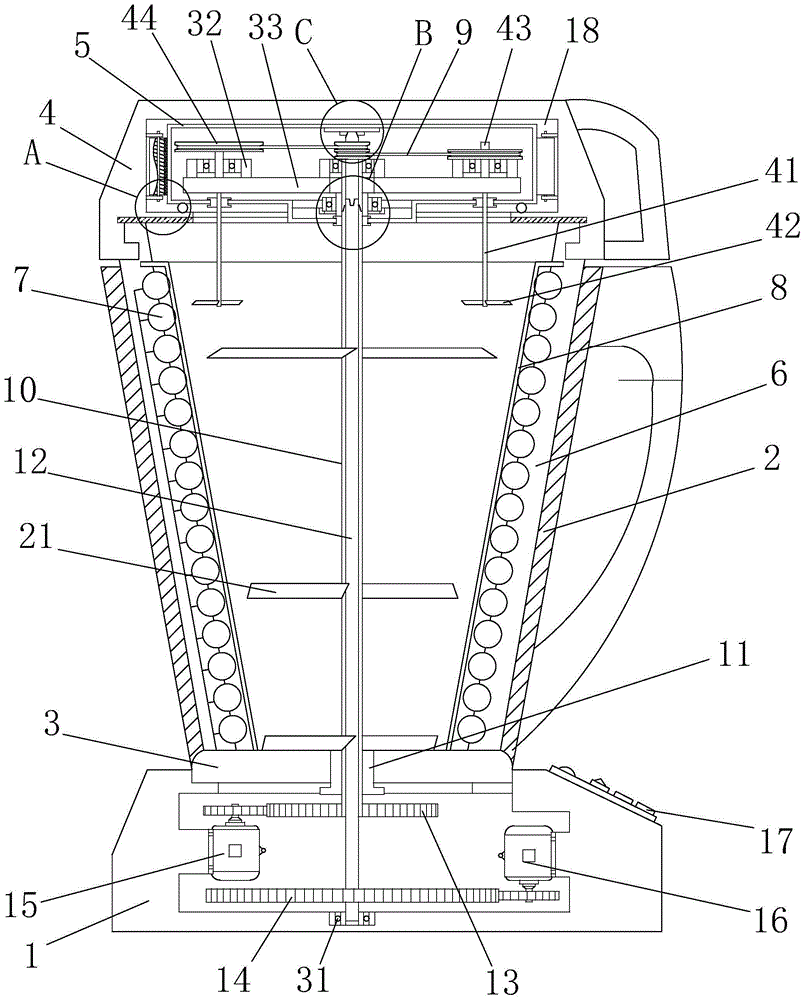

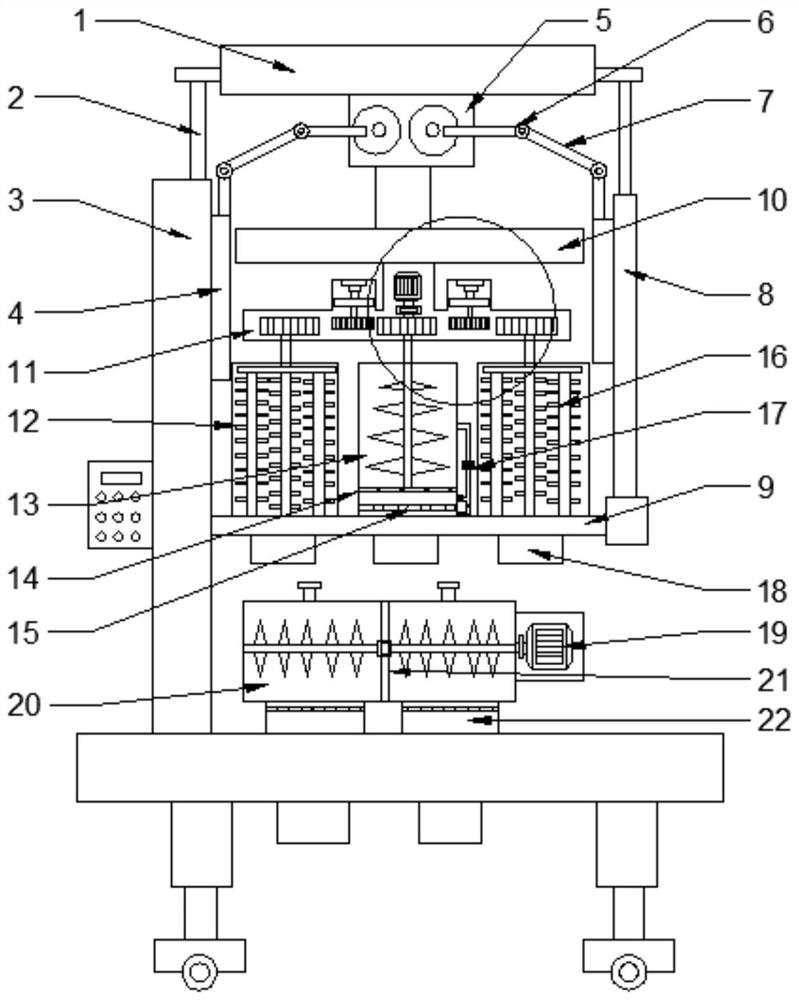

Contaminated soil ex-situ medicating, mixing and restoring system

InactiveCN104368595AQuick fixReduced Diffusion of DisorderContaminated soil reclamationContaminated soilsEngineering

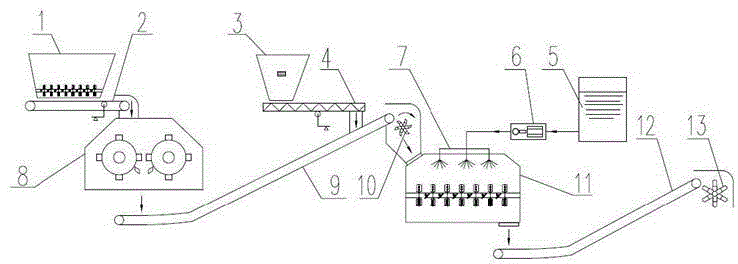

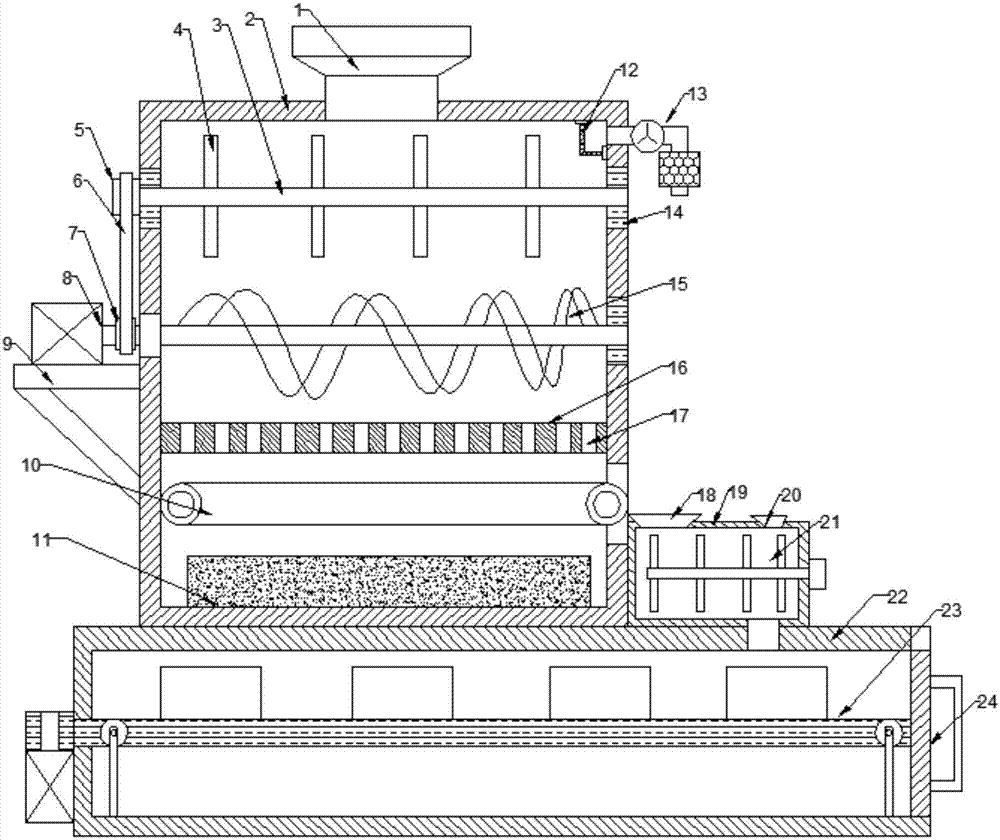

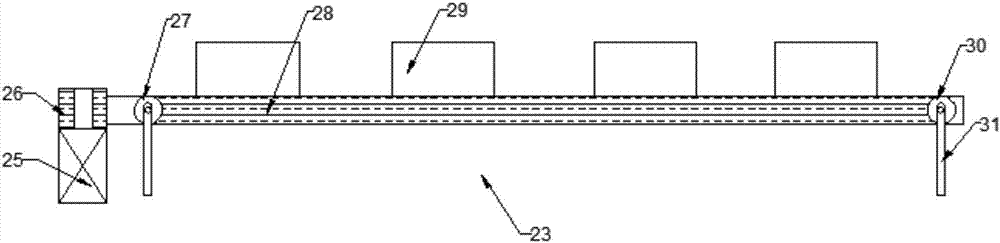

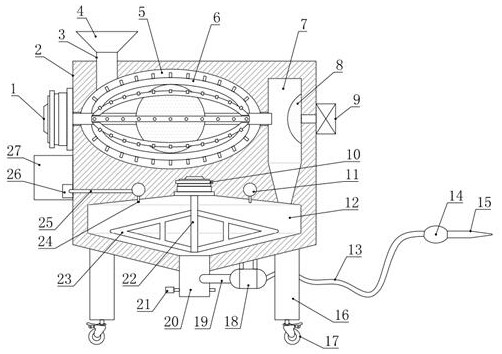

The invention relates to a contaminated soil ex-situ medicating, mixing and restoring system. The system consists of a soil warehouse, a quantitative feeder, a solid medicament bin, a weighing screw feeder, a liquid medicament box, a medicament pump, a spraying device, a soil crusher, a feeding belt machine, a cutting, crushing and mixing device, a soil stirrer, a discharge belt machine and a scattering, crushing and mixing device. Contaminated soil can be rapidly restored by adopting a solid or liquid remediation medicament according to different contaminated soil characteristics, and the contaminated soil ex-situ medicating, mixing and restoring system is mainly suitable for ex-situ remediation occasions of heavy metal or organic matter contaminated soil. The contaminated soil ex-situ medicating, mixing and restoring system is wide in application range, high in processing capacity and medicating and measuring precision, good in crushing and mixing effect, is high in automation degree for contaminated soil, can be used for solidification stability of heavy metal contaminated soil and chemical and oxidation remediation treatment of organic matter polluted soil, also can be used for the crushing and mediation mixing operation of other similar materials, and has favorable environment-friendly and social benefits.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

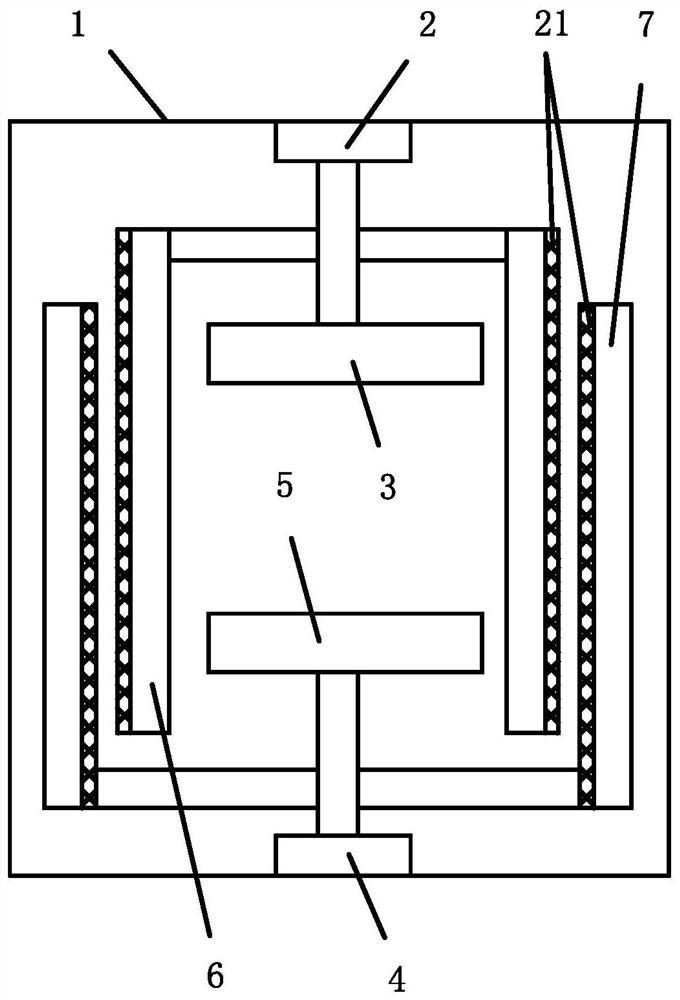

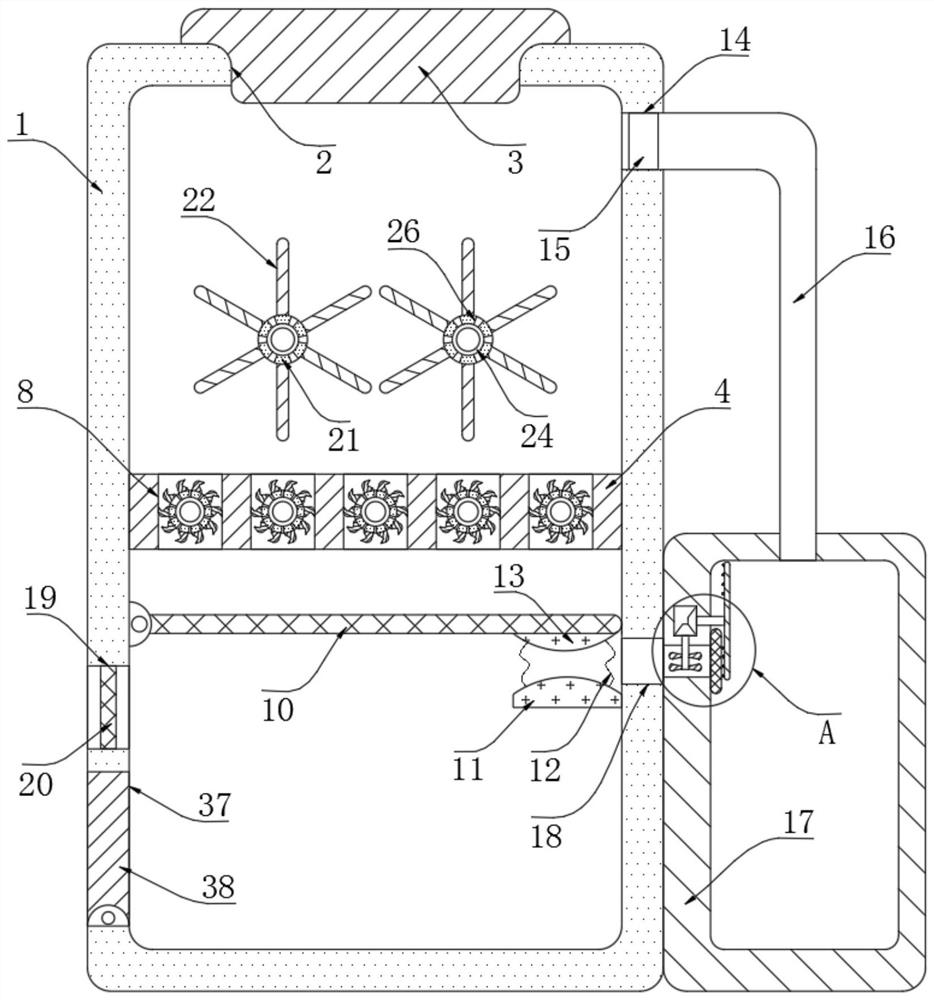

Vibration attenuating and noise lowering type soil restoration device

InactiveCN108296272AImprove repair effectAvoid cloggingSpadesNon-rotating vibration suppressionSprayerSpray nozzle

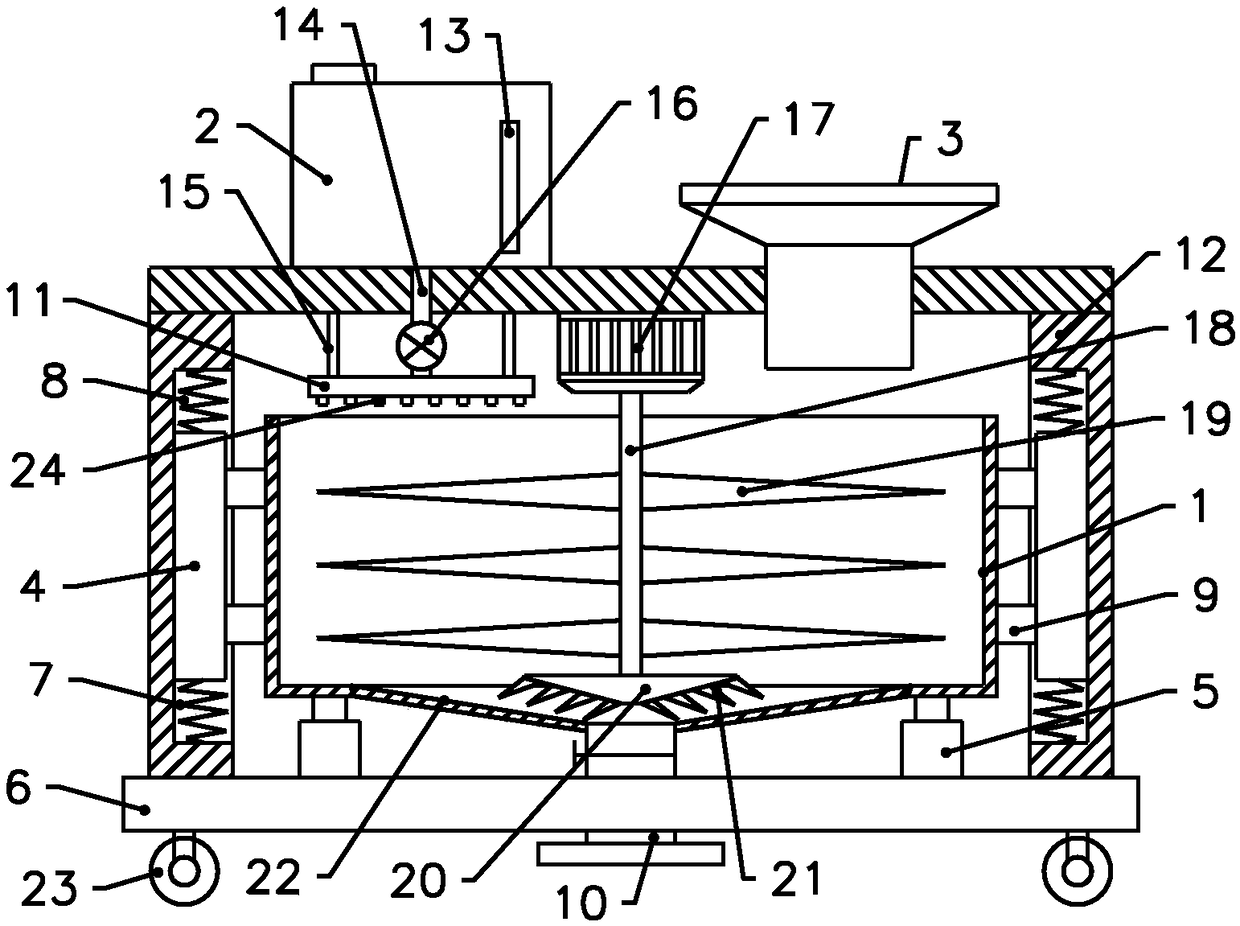

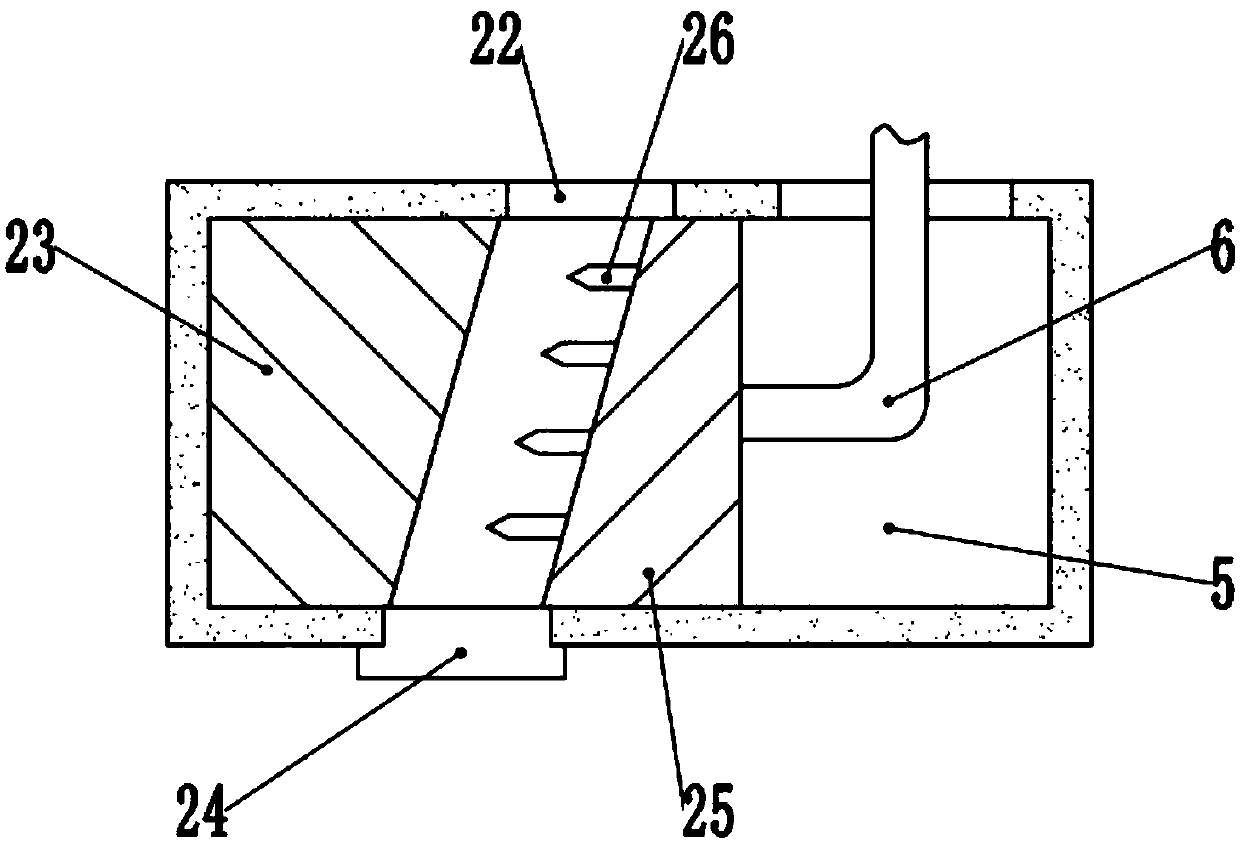

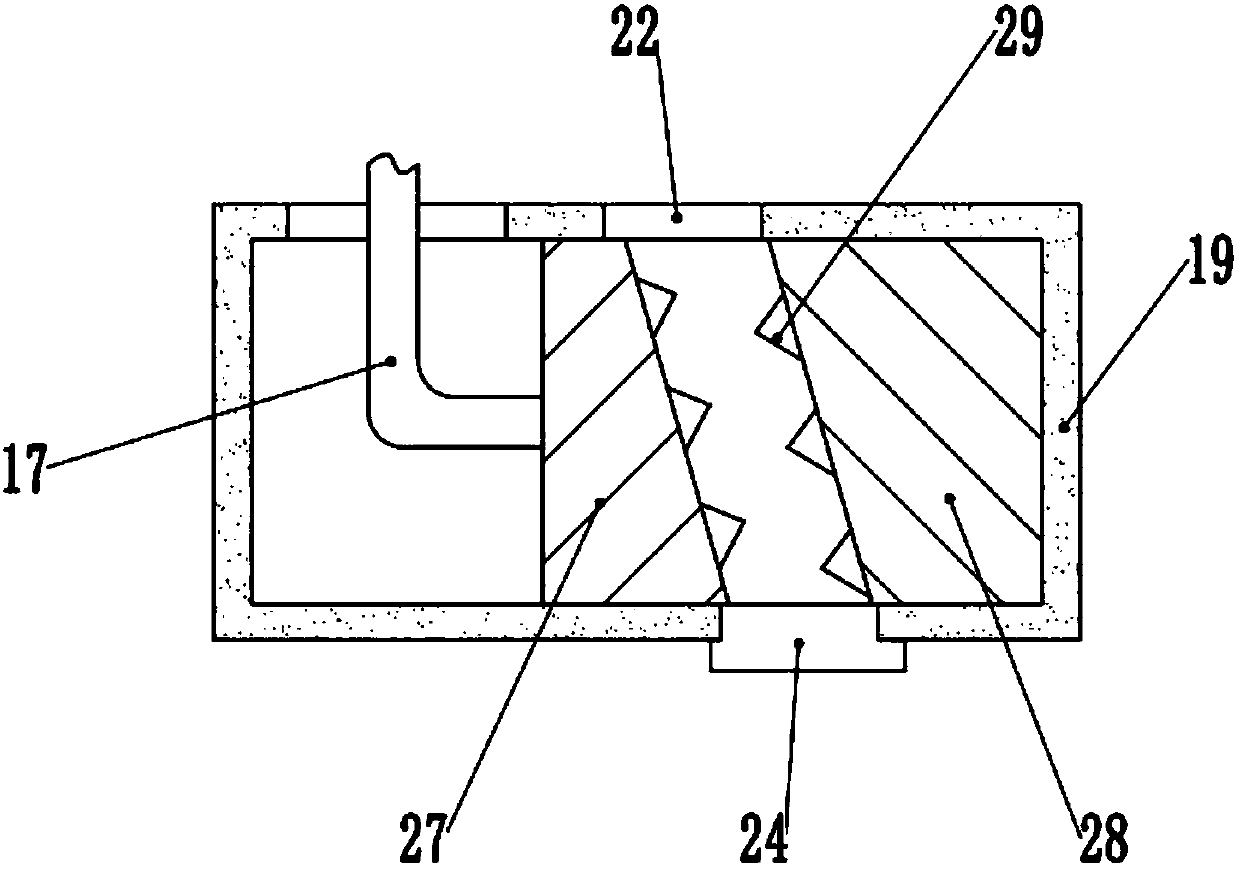

The invention discloses a vibration attenuating and noise lowering type soil restoration device. The vibration attenuating and noise lowering type soil restoration device comprises a box body, a chemical agent box, a vibration attenuating and noise lowering base, a supporting base, a liquid spraying pipe, crushing blades and crushing knife blades; two side plates of the box body are fixedly erected on two rising and falling sliders through supporting connection rods correspondingly; the box body is further erected on the top of the supporting base through the vibration attenuating and noise lowering base arranged at the bottom end of the box body; the liquid spraying pipe is further fixedly erected at the bottom of a top plate of a supporting framework through a supporting rod; a pluralityof sprayers with downward openings are uniformly distributed in the bottom of the liquid spraying pipe; a rotating rod is rotationally erected in an inner cavity of the box body; and the crushing blades are uniformly distributed and fixedly arranged on the periphery of the rotating rod. The vibration attenuating and noise lowering type soil restoration device is simple in structure, convenient touse, good in vibration attenuating and noise lowering effect, obvious in soil restoration effect and high in practicability, and chemical agents and soil are mixed sufficiently.

Owner:柳州弘蓝科技有限公司

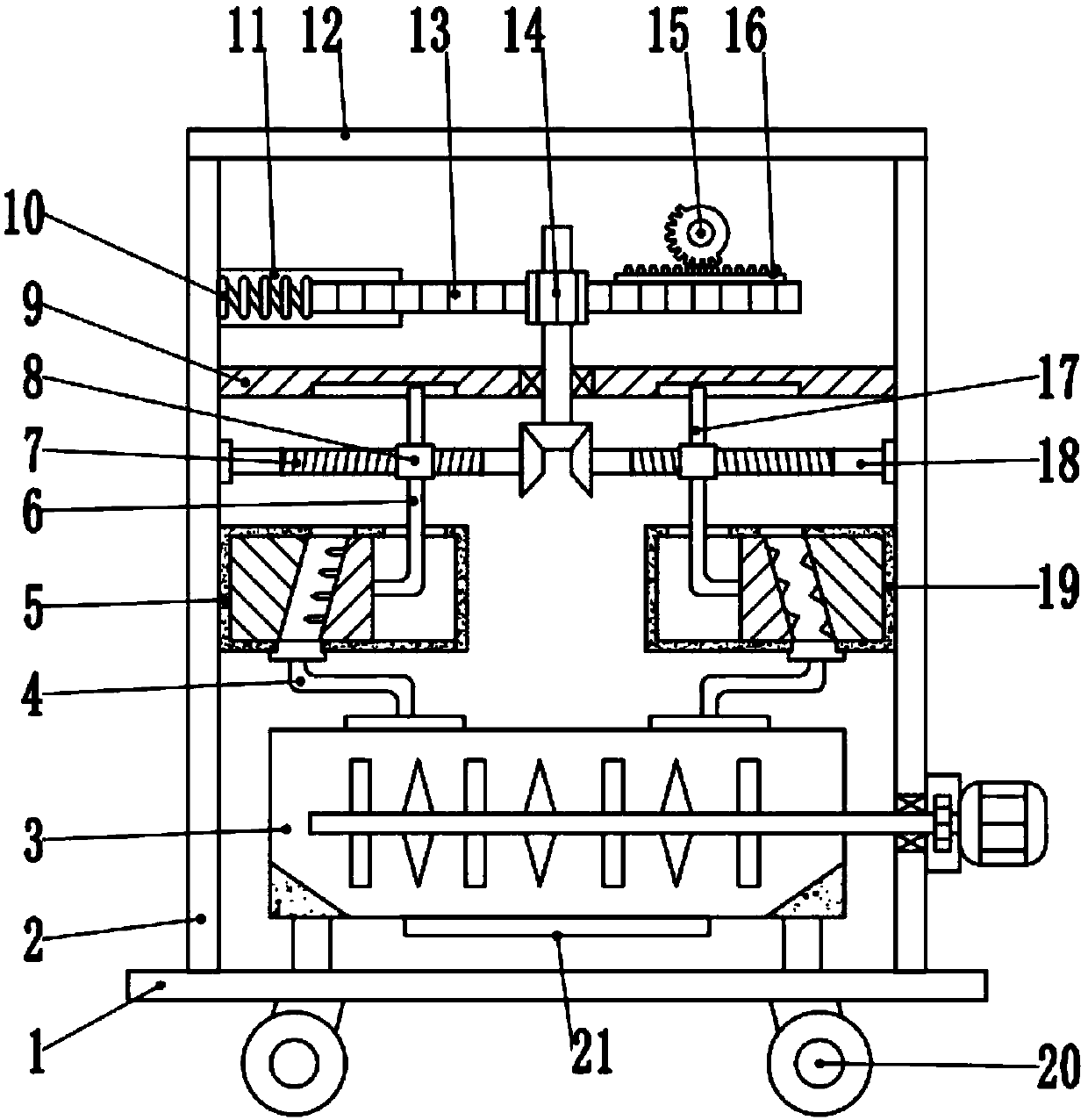

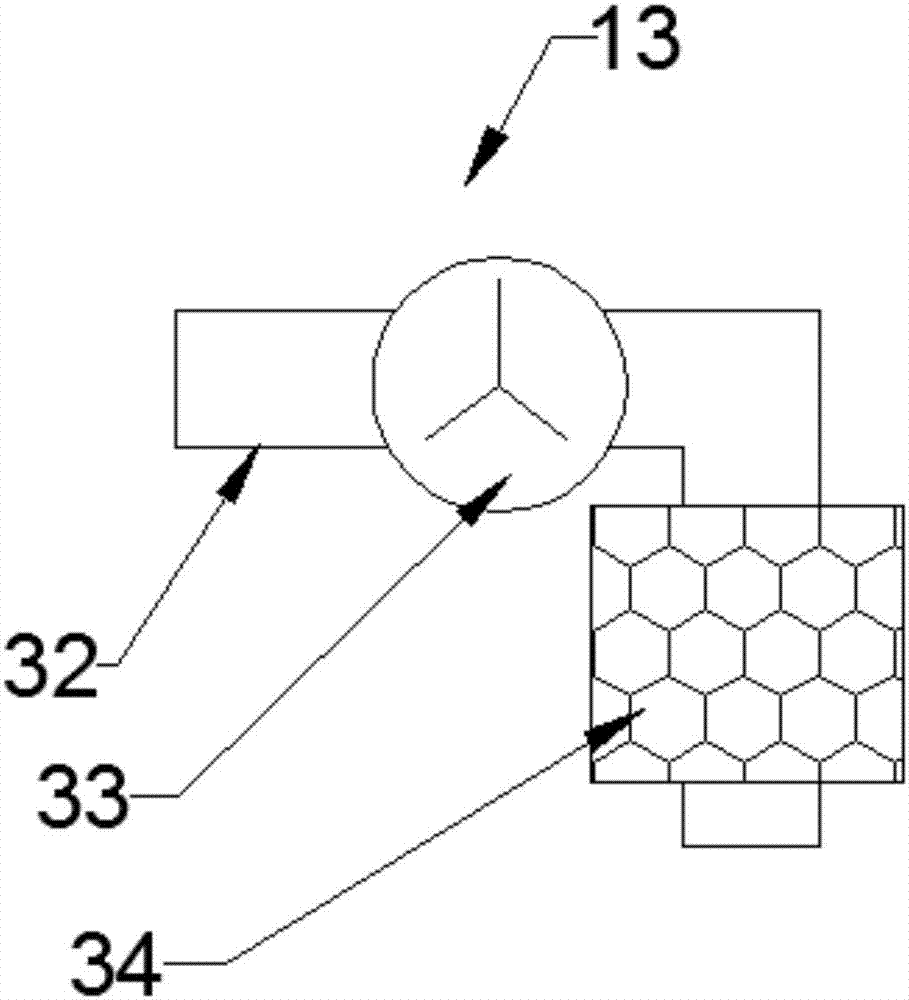

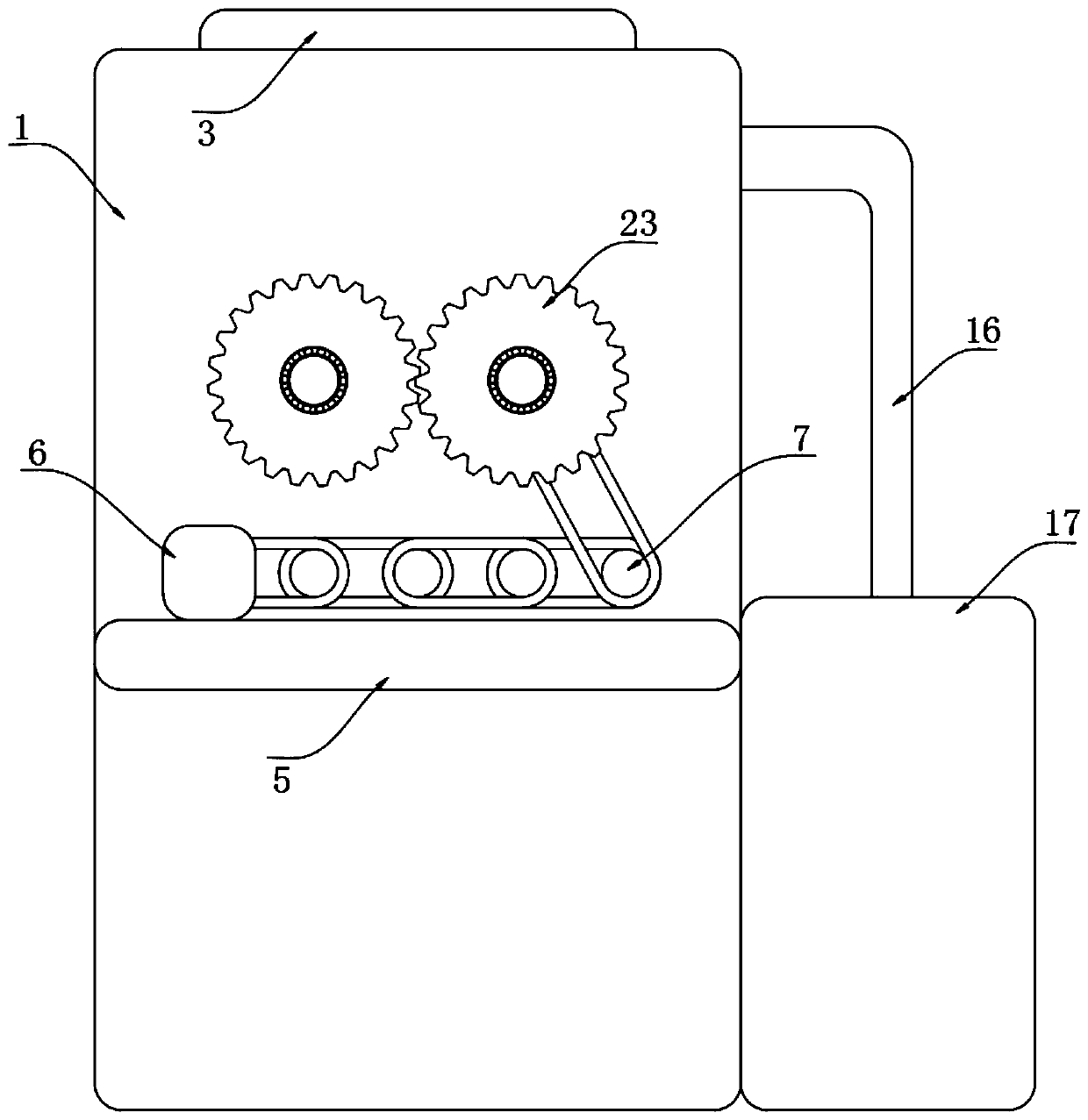

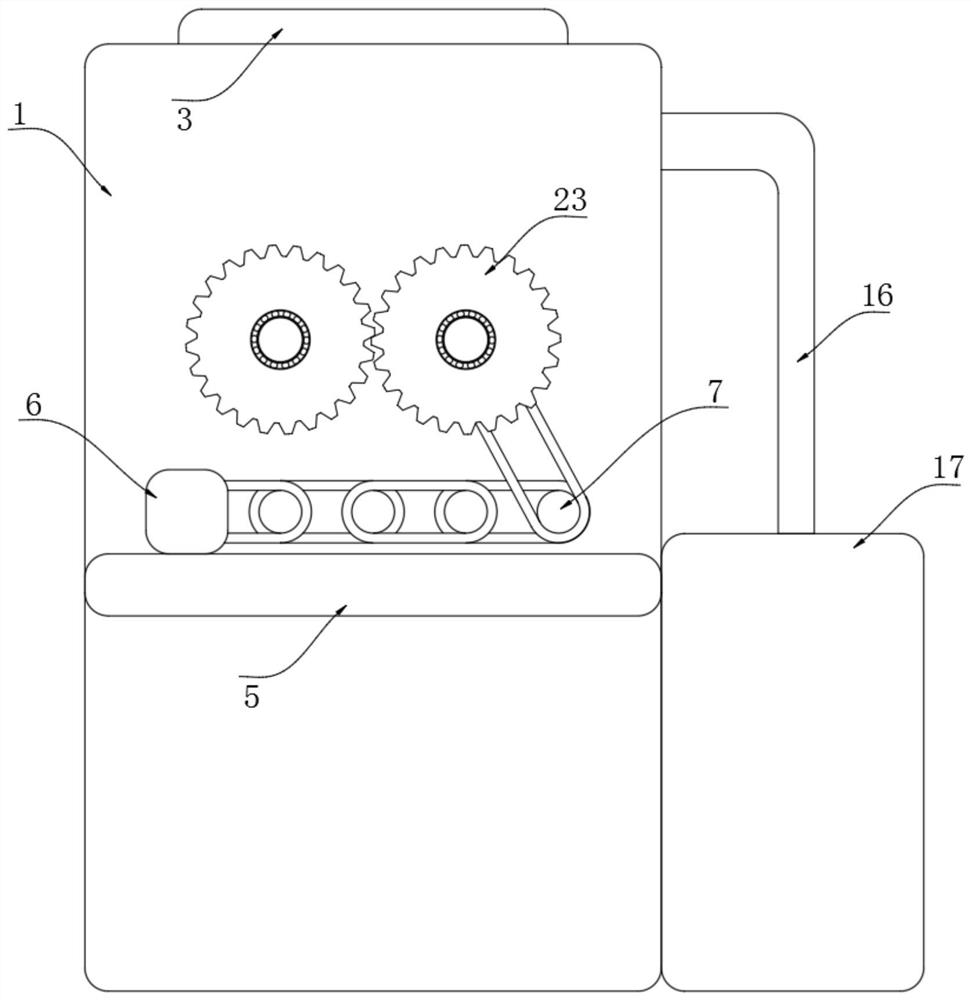

Moveable mixing machine for smashing and stirring

InactiveCN104801411AEasy to moveSimple structureTransportation and packagingRotary stirring mixersReduction driveReducer

The invention discloses a moveable mixing machine for smashing and stirring. A machine case is mounted on the base; the smashing and stirring bin is fixed at the upper right end of the machine case; an electromotor is mounted on the machine case, wherein the machine case is positioned on the right side of the smashing and stirring bin; the machine case is connected with the electromotor through a reducer; a rotation axis is mounted in the smashing and stirring bin; the rotation axis is connected with the reducer through a conveyer belt in a transmission way; smashing blades, a screw panel and stirring rods are mounted on the rotation axis; a feed hopper is arranged at the top left corner of the smashing and stirring bin; the feed hopper is fixedly connected with the smashing and stirring bin through a feed chute; a feed outlet is formed in the lower left corner of the smashing and stirring bin; road wheels are mounted at the bottom of the base. The moveable mixing machine for smashing and stirring is simple in structure and convenient to move; the smashing blades, the screw panel and the stirring rods are mounted on the rotation shaft, so that the smashing and mixing effect is improved, the efficiency is improved and a large amount of time is saved.

Owner:杜志刚

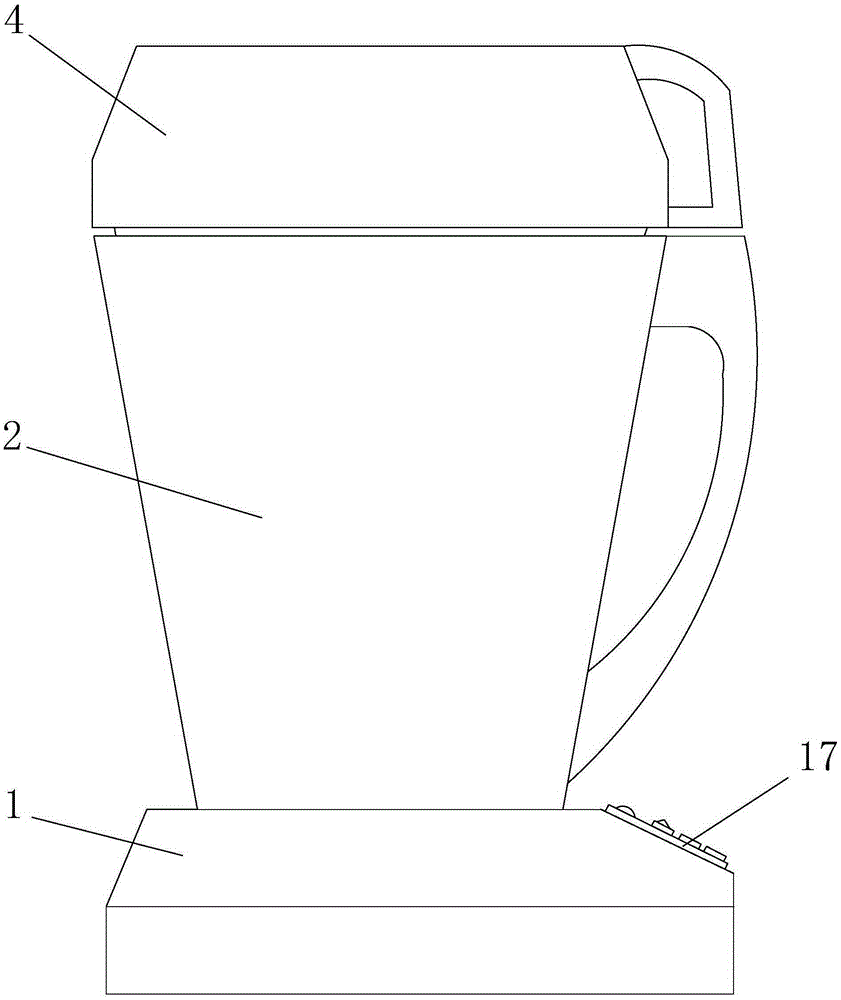

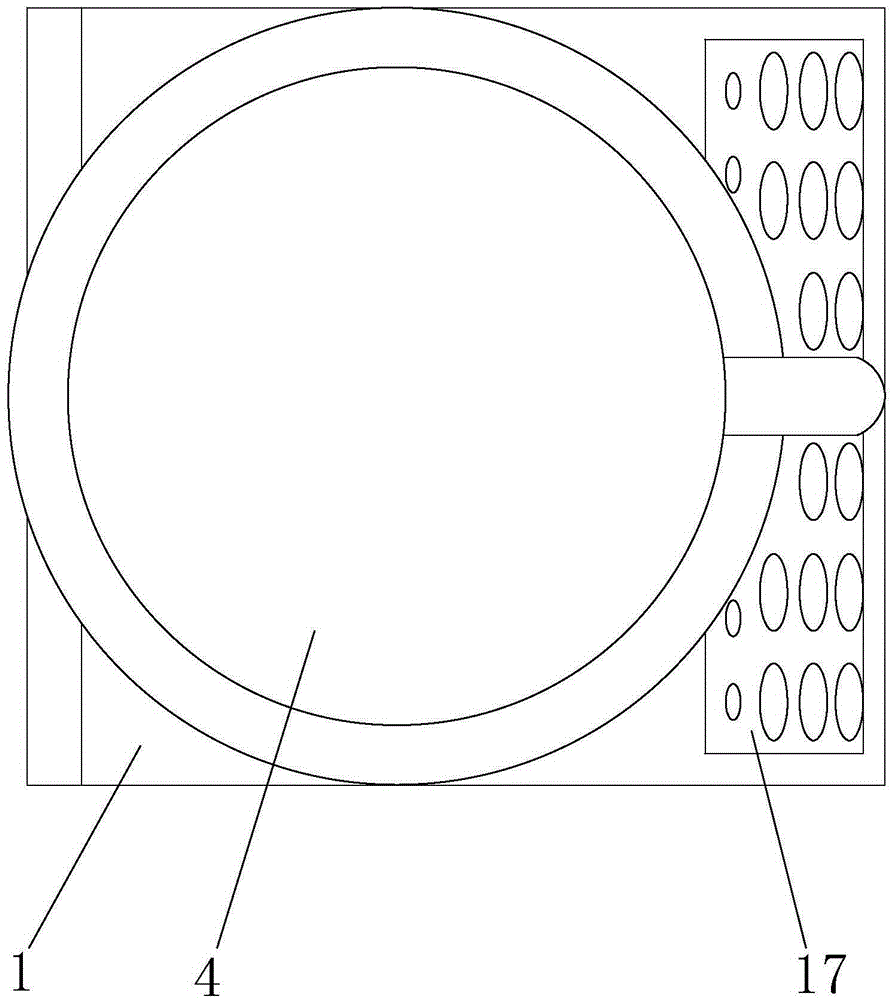

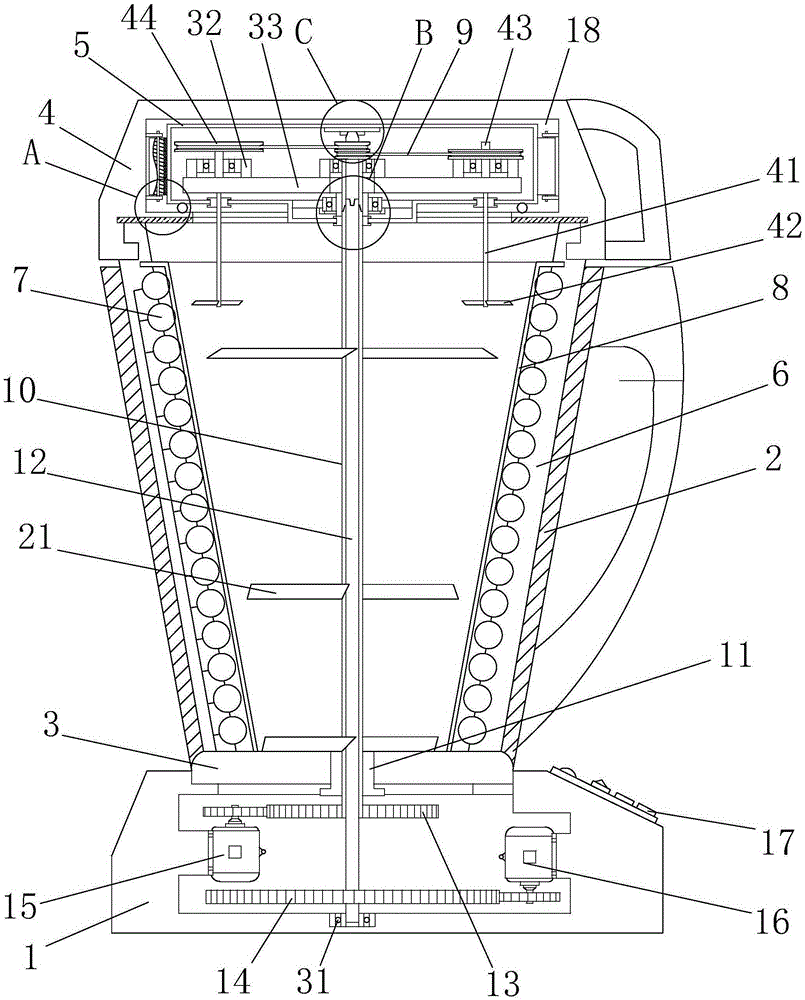

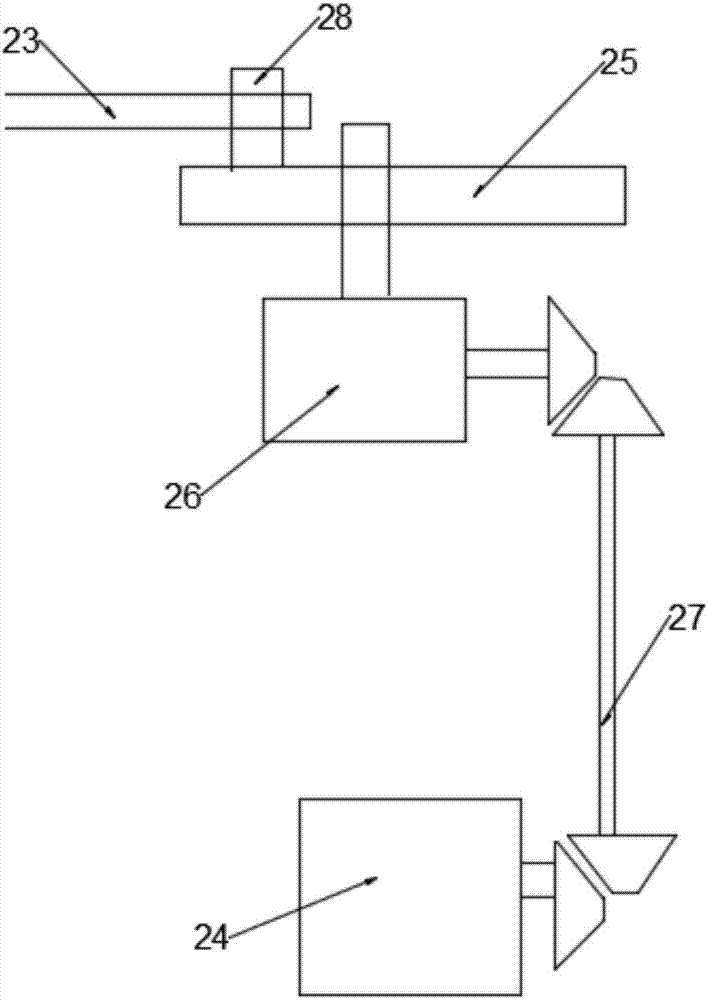

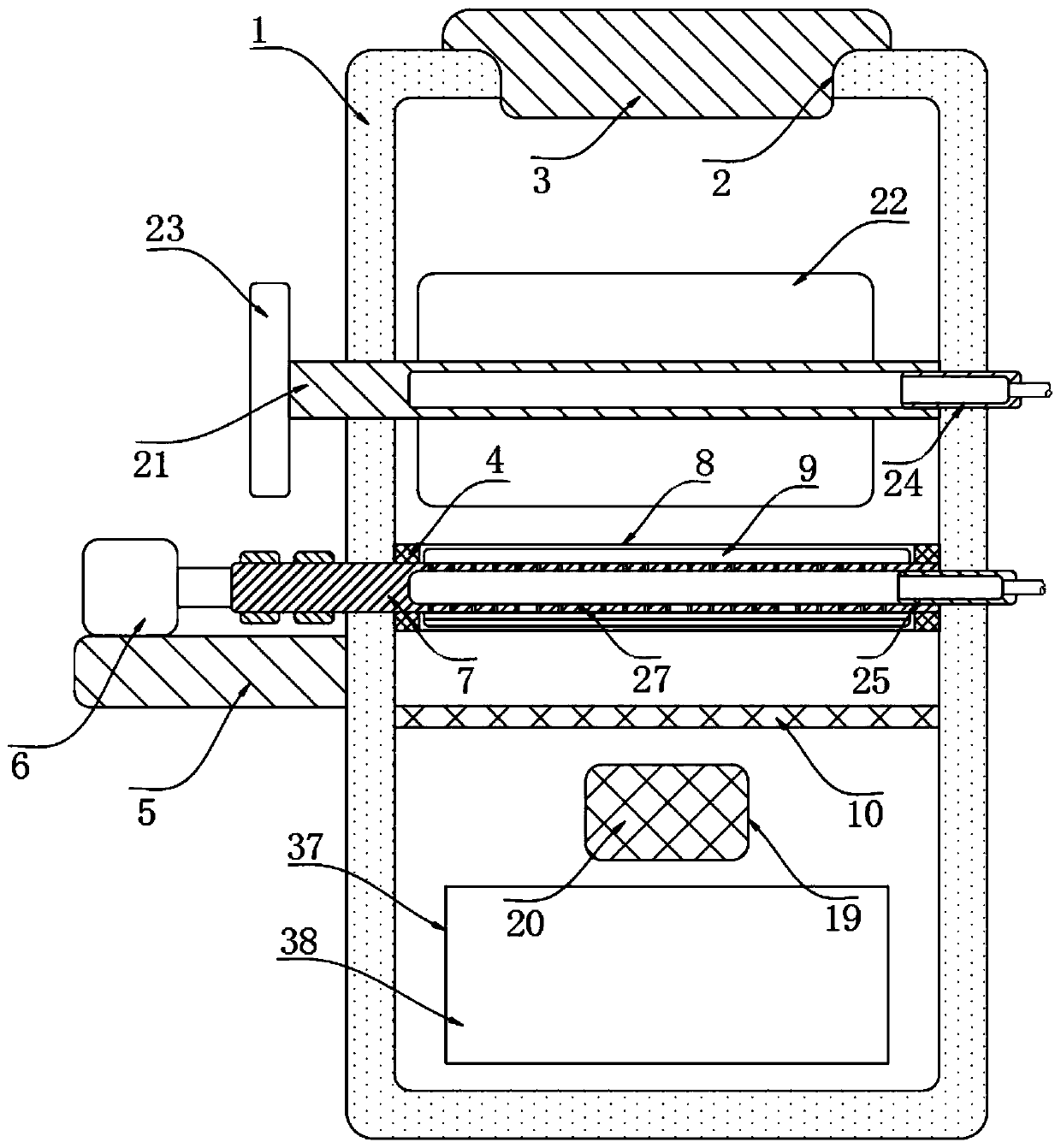

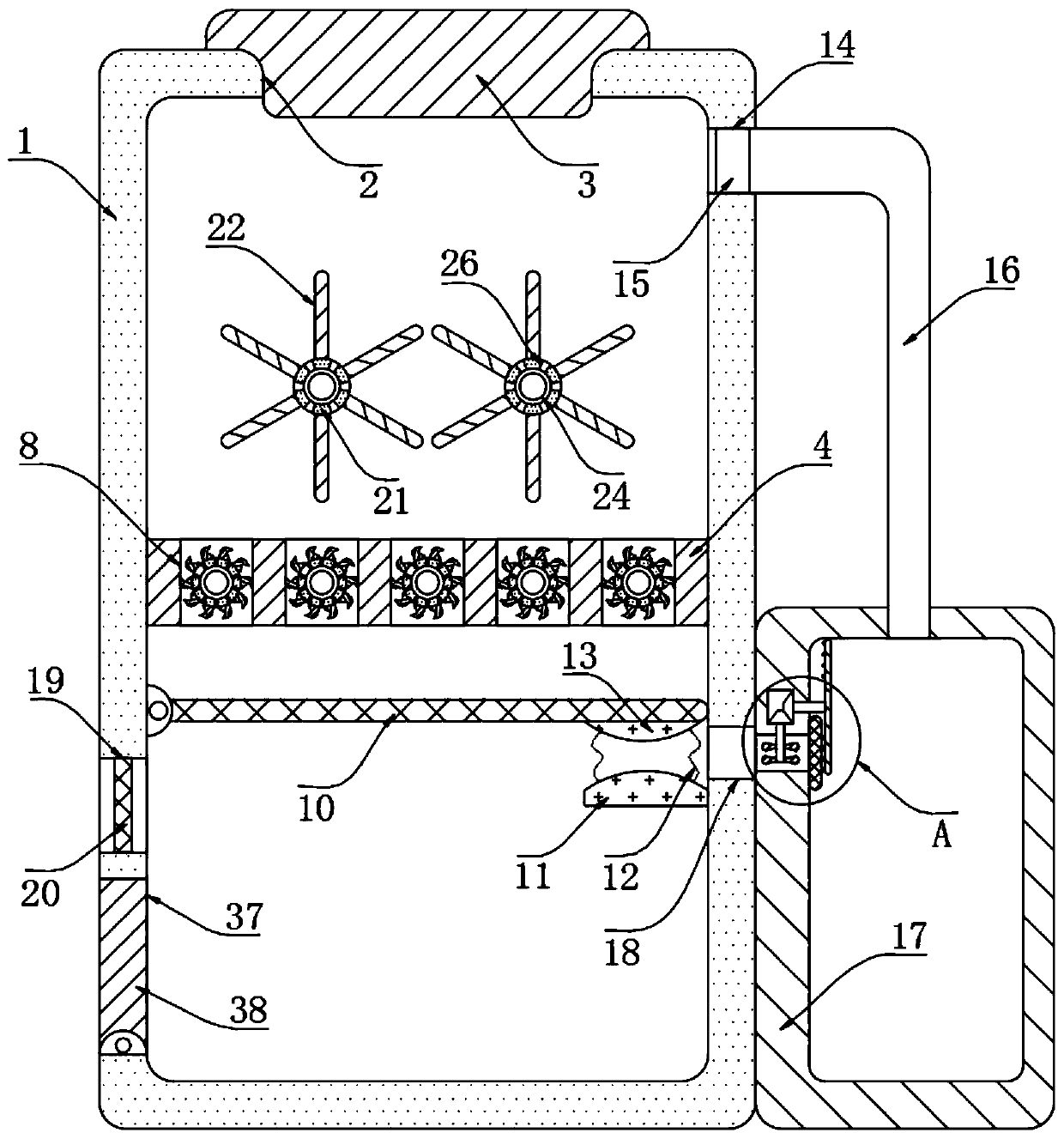

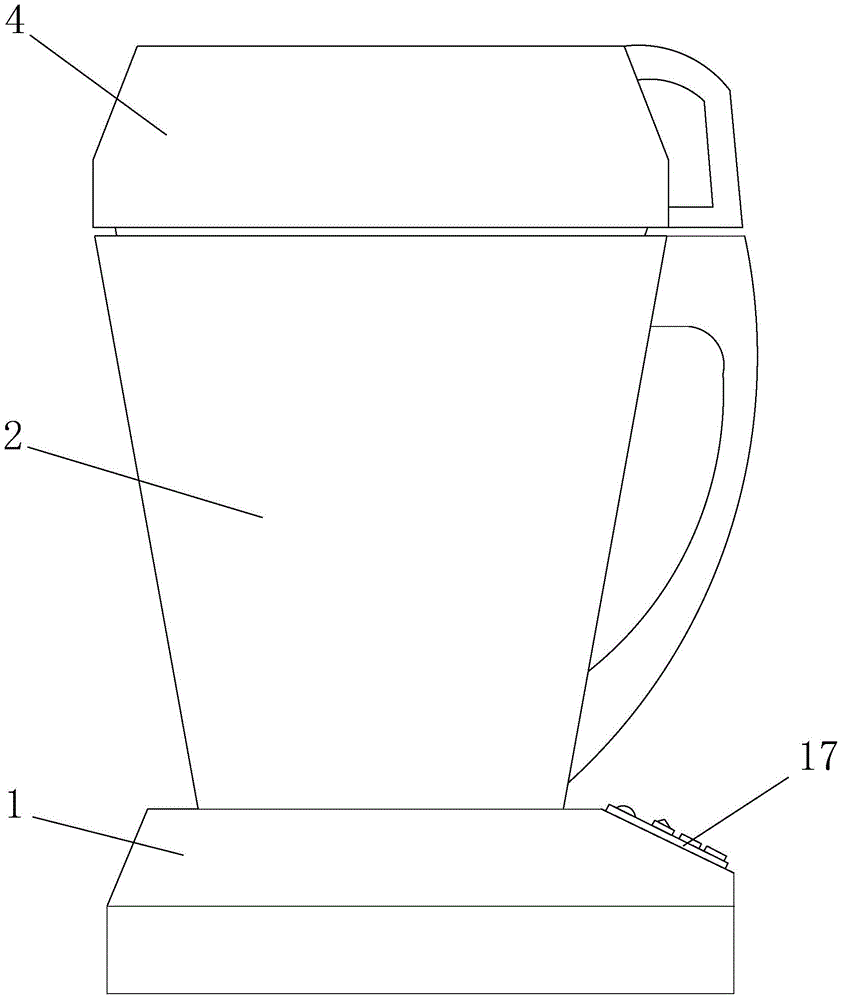

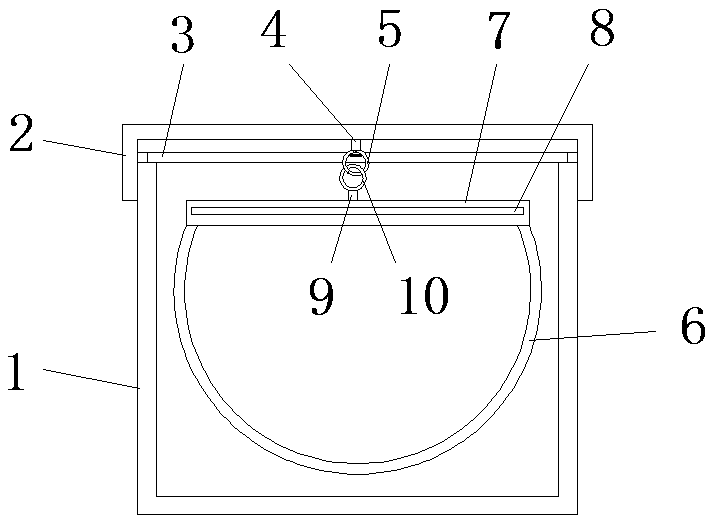

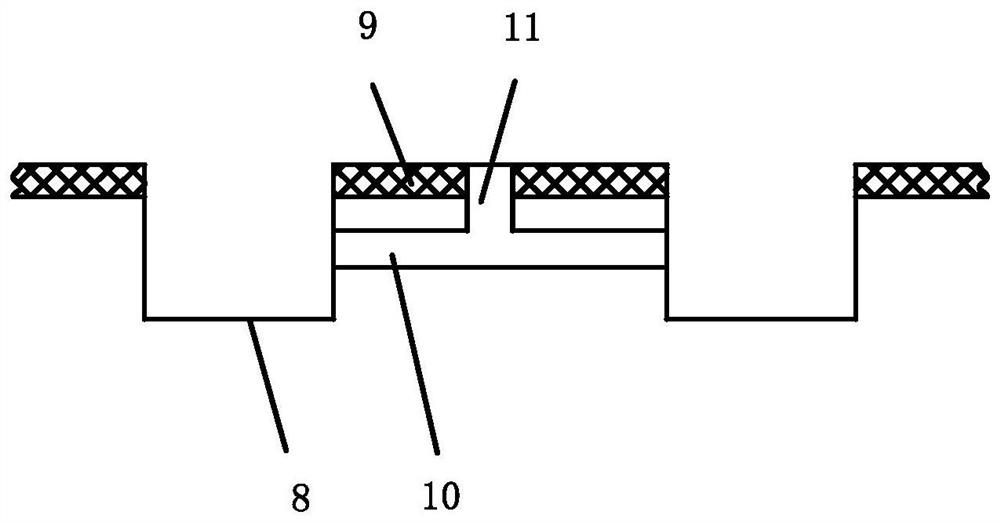

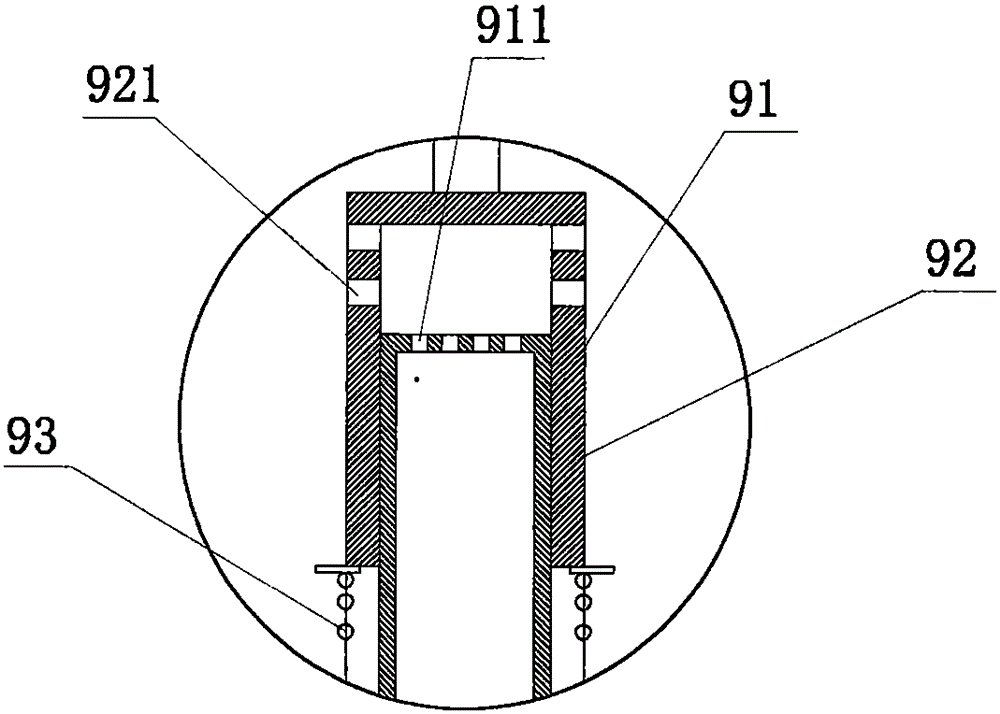

Mixed flow stirring soybean milk machine

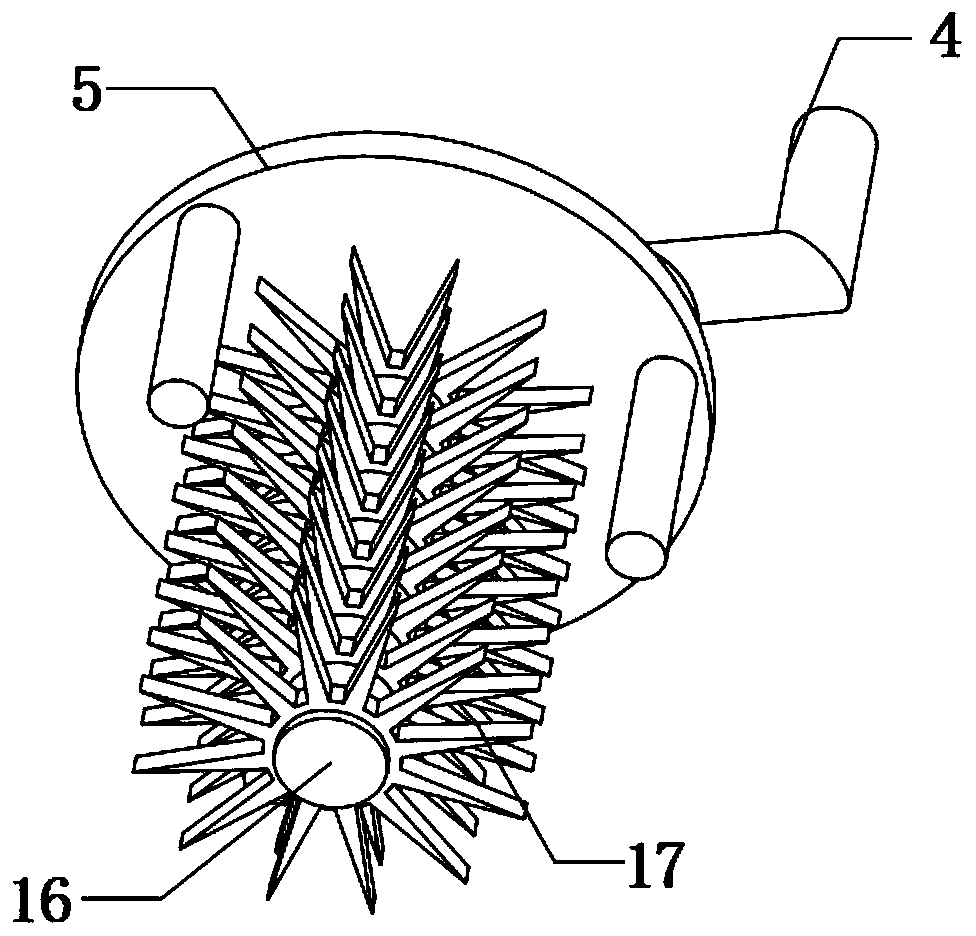

InactiveCN105310542AImprove mixing and crushing effectImprove efficiencyKitchen equipmentEngineeringContact mode

The invention discloses a mixed flow stirring soybean milk machine which comprises a base, an outer barrel body, a barrel body fixing plate, a barrel cover and a stirring rotary disc. A heat insulation barrel is arranged on the inner side wall of the outer barrel body. A plurality of circles of heating pipes are arranged inside the heat insulation barrel. The inner sides of the heating pipes are provided with a heating barrel in a tight contact mode. The bottoms of the outer barrel body, the heat insulation barrel and the heating barrel are fixed to the base through the barrel body fixing plate. An outer rotary sleeve shaft penetrates through the center of the barrel body fixing plate. The portion, penetrating through the barrel body fixing plate, of the outer rotary sleeve shaft is sleeved with a sealing ring. An inner rotary shaft penetrates into the outer rotary sleeve shaft. The bottom of the outer rotary sleeve shaft and the bottom of the inner rotary shaft are provided with an outer rotary sleeve shaft driving gear and an inner rotary shaft driving gear. During smashing and stirring, disordered turbulent flow is formed, and the smashing and stirring effect and efficiency are improved.

Owner:金庆新

Organic compound fertilizer mixing device for animal husbandry

InactiveCN107853737AGood crushing and mixing effectQuality assuranceFeeding-stuffGrain treatmentsEngineeringOrganic fertilizer

The invention discloses organic compound fertilizer mixing device for the animal husbandry. The device comprises a base, a mixing barrel, an organic raw material crushing tank, a left screw, a rack, aright screw and a mineral raw material crushing tank, wherein a first fixed block and a second fixed block are respectively fixedly arranged inside the organic raw material crushing tank and the mineral raw material crushing tank; a first movable block and a second movable block are respectively arranged inside the organic raw material crushing tank and the mineral raw material crushing tank in asliding manner; a plurality of cutters are arranged on the first movable block; a plurality of crushing teeth are uniformly arranged on the side of the second movable block and the side of the secondfixed block, which get close to each other; and the upper side of the mixing barrel is respectively communicated with the inside of the organic raw material crushing tank and the inside of the mineral raw material crushing tank. The organic compound fertilizer mixing device can be used for separately crushing organic raw materials and mineral raw materials of different materials at the same timedue to the organic raw material crushing tank and the mineral raw material crushing tank, and adding the organic raw materials and mineral raw materials into the mixing barrel at the same time for mixing.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

Livestock feed crushing and mixing device with transfer function

InactiveCN107876185ASimple structurePracticalFeeding-stuffRotary stirring mixersFeed processingLivestock

The invention provides a livestock feed crushing and mixing device with a transfer function, which belongs to the technical field of livestock feed processing. The device includes a crushing device and a mixture transfer device. The upper part of a driving wheel is provided with a driven wheel through a belt, the right end of the driven wheel is provided with a crushing shaft, and the upper part of the crushing shaft is welded and fixed with crushing blades. A delivery device is arranged on the lower side of a filter plate. A dryer is fixedly arranged at the lower end of the inner cavity of acrushing box. A dehumidification device is arranged on the upper right side of the crushing box. The upper left end of an auxiliary material box is provided with a receiving hopper. A collecting box is provided with a transfer device. The device of the invention has the function of mixing livestock and auxiliary materials by arranging a stirring device in the inner cavity of the auxiliary materialbox. The conveyor belt is uniformly provided with transfer hoppers, which is convenient for conveying and collecting the processed livestock. The device has the characteristics of simple structure, strong practicability and good crushing and mixing effect.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Chemical raw material stirring device

InactiveCN107570075AEasy to operateQuality assuranceMixer accessoriesEngineeringReciprocating motion

The invention discloses a chemical raw material stirring device, which comprises a base, a stirring body and a stirring device, wherein a first fixing block is arranged at the upper end of the base, and a buffer plate is arranged at the upper end of the first fixing block; a buffer spring is arranged in the buffer plate, and a second fixing block is arranged at the upper end of the buffer plate; rollers are arranged on the second fixing block, and the bottom of the stirring body is in contact with the rollers; a stirring device is arranged in the stirring body, and the stirring device comprises a stirring shaft, stirring wheels and stirring components; a bottom plate is arranged in the stirring body, and horizontal blades are arranged on the bottom plate; a first bracket is arranged on thebase, and a swinging mechanism is arranged on the first bracket; the swinging mechanism is hinged with the stirring body. The device can realize full stirring and crushing of raw materials through the cooperation of a stirring motor, the stirring shaft, the stirring wheels, the stirring components, the horizontal blades and vertical blades so as to ensure the quality of stirring; the swinging mechanism drives the stirring body to reciprocate horizontally, thus strengthening the stirring and crushing effects.

Owner:COMMON TECH DEV CO LTD

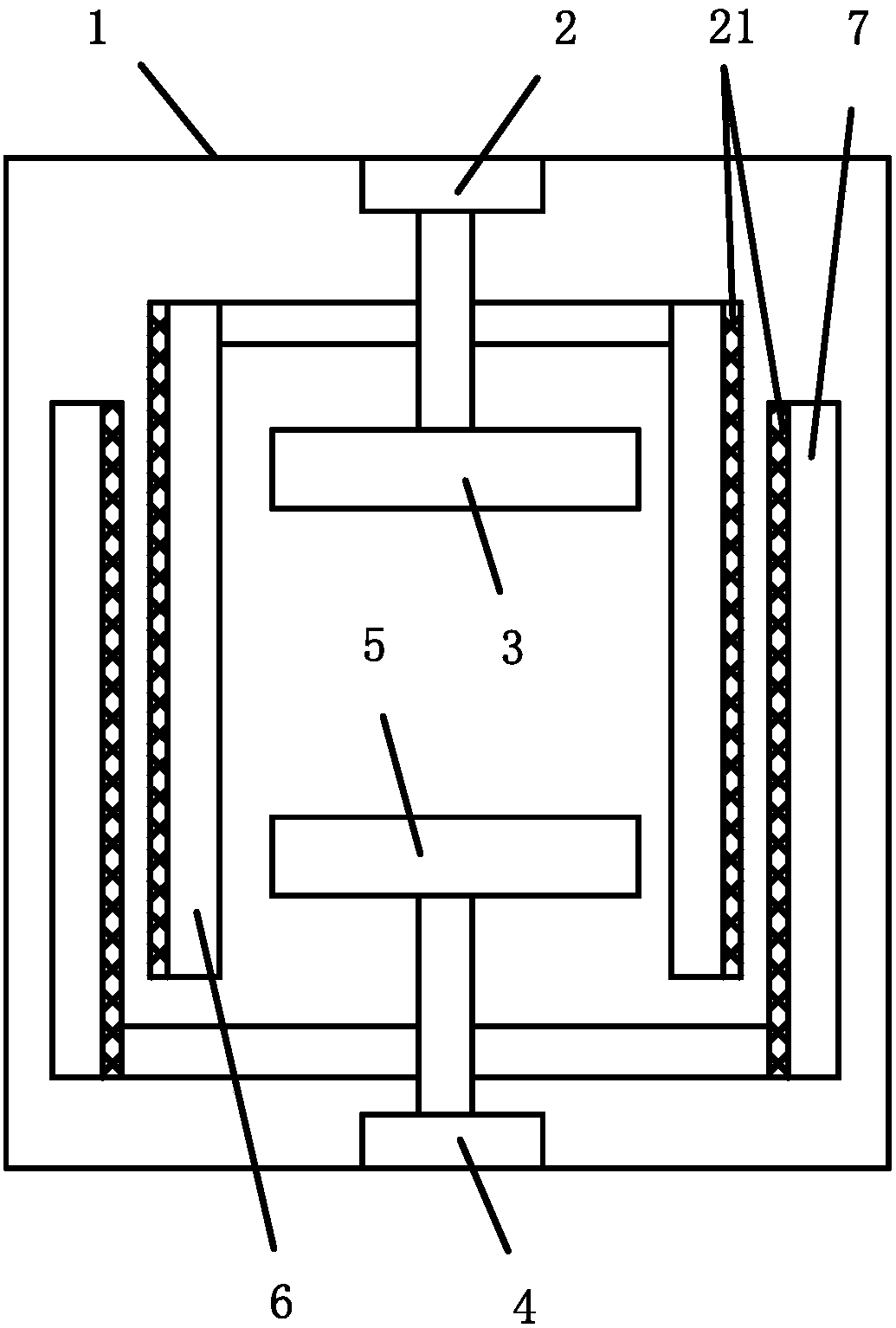

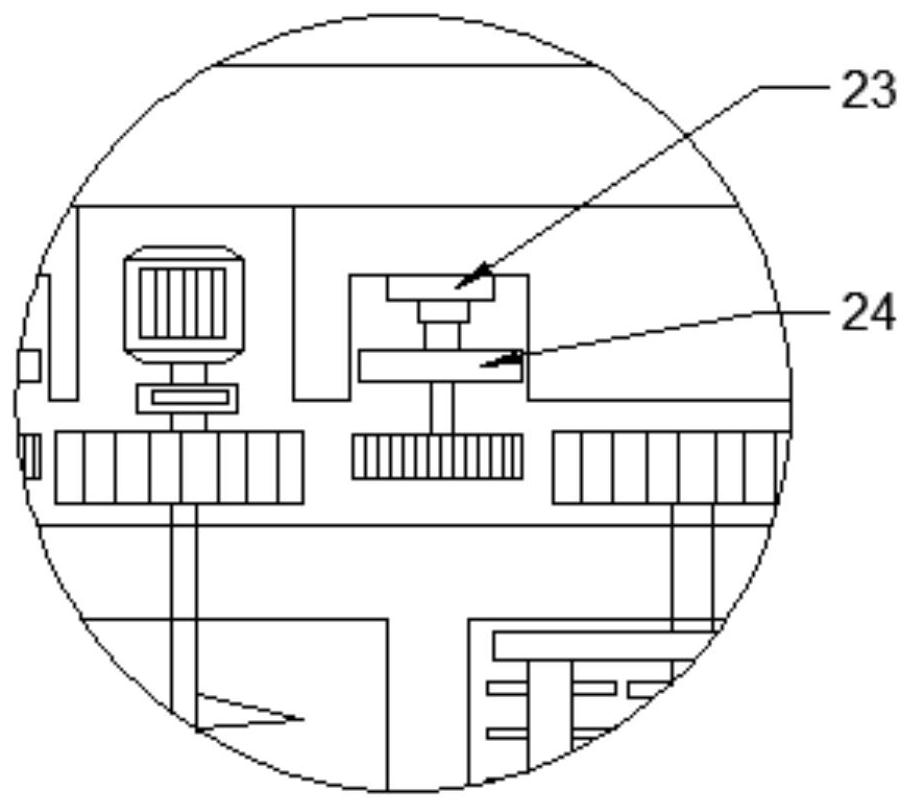

Mixing and stirring tank crushing mechanism

PendingCN108355781AGuaranteed uniformityImprove uniformityGrain treatmentsEngineeringMixed materials

The invention provides a mixing and stirring tank crushing mechanism. The crushing mechanism comprises a rotary crushing barrel and a crushing shaft, wherein the crushing shaft is coaxially and reversely rotationally connected with the crushing barrel; a plurality of rows of blades distributed in the circumference are arranged on the outer wall of the crushing shaft, conical teeth are arranged onthe inner wall of the crushing barrel, the part, far away from a feeding mechanism, of the side wall if the crushing shaft is provided with symmetrical stirring blades, and the bottom of the crushingbarrel is rotationally connected with a conical structure which is tightened inwards; and two rollers which rotate relatively are arranged in a discharging box, the parts, arranged outside the discharging box, of the two rollers are meshed with a second gear through a first gear, and the end of one of the rollers is connected to a second motor. According to the mixing and stirring tank crushing mechanism, through internal and external double-reverse rotation of the crushing mechanism, the crushing effect can be better guaranteed through the blades, the materials cannot be adhered and stacked on the wall, the waste is avoided, multiple crushing and filtering of the rollers are coordinated, so that the diameter of mixed particles can be ensured to be small on the basis that mixed materials are uniform, and a the better effect for subsequent use is provided.

Owner:TIANJIN XINYUAN GUANGTAI NEW MATERIAL TECH CO LTD

Screening device for soil remediation

ActiveCN111001470AEffective stirringHigh shear forceSievingDispersed particle filtrationSoil remediationElectric machinery

The invention discloses a screening device for soil remediation. A screening box is included. A feeding groove is arranged in an upper end of the screening box. An upper cover abuts against an inner wall of the feeding groove. A partition plate is fixed to the inner wall of the screening box. A plurality of dividing grooves are arranged in an upper end of the partition plate in a penetrating manner. The inner wall of each dividing groove is rotatably connected with a dividing pipe in a penetrating mode, a plurality of scraping plates are fixed to a circumferential side wall of each dividing pipe, a bearing plate is fixed to an outer wall of the screening box, a power mechanism is arranged at an upper end of the bearing plate, and an air outlet groove is arranged in the side wall of the screening box in the penetrating mode. The device has advantages that a motor drives rotating pipes to rotate so that the rotating pipes drive stirring plates on the rotating pipes to rotate, the stirring plates effectively stir soil at an upper end of the partition plate, the soil is stirred and smashed, and subsequent screening is facilitated; and rotating directions of the two rotating pipes are opposite, then the soil between the two rotating pipes is subjected to a larger shearing force, and a stirring and smashing effect of the soil is enhanced.

Owner:博思英诺科技(北京)有限公司

Detection method of radix angelicae dahuricae coumarins in veterinary drugs

ActiveCN108152392AImprove pulverization and dissolution rateIncrease contact areaComponent separationMedicineVeterinary Drugs

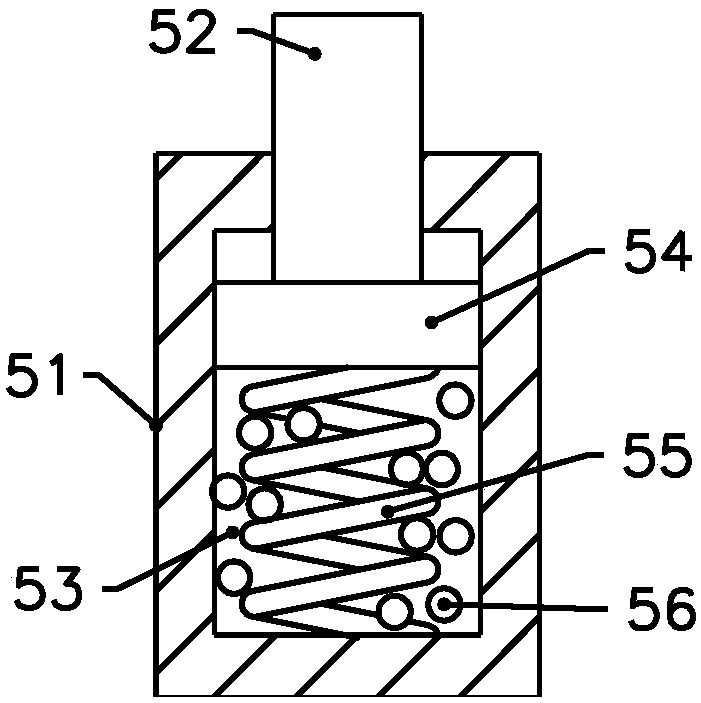

The invention discloses a detection method of radix angelicae dahuricae coumarins in veterinary drugs. The detection method comprises the following steps: A, adding a veterinary drug to be detected into a pulverizing mechanism, then injecting a 60wt% ethanol water solution and performing stirring and pulverizing; B, filtering the ethanol water solution containing the veterinary drug component to obtain filtrate; C, adding the filtrate to ether and performing extraction; and D, performing component separation on the extraction product by using a liquid chromatography column, and then determining the content of the radix angelicae dahuricae coumarins by chromatographic analysis. The detection method of radix angelicae dahuricae coumarins in the veterinary drugs can improve the defects of theprior art, improve the extraction accuracy of the radix angelicae dahuricae coumarins in the veterinary drugs, improve the accuracy of detection results and prolong the service life of the liquid chromatography column.

Owner:宋瑞

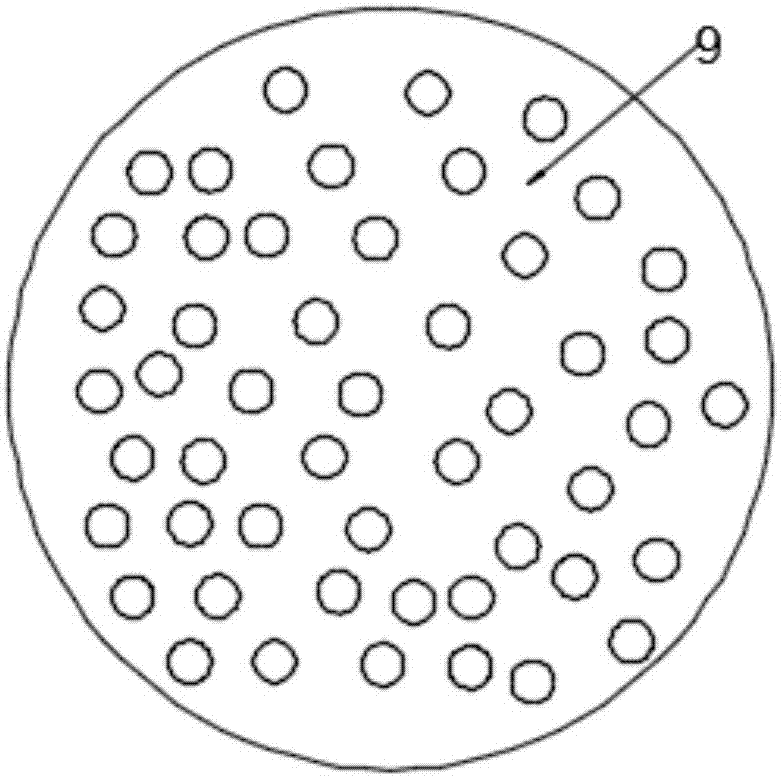

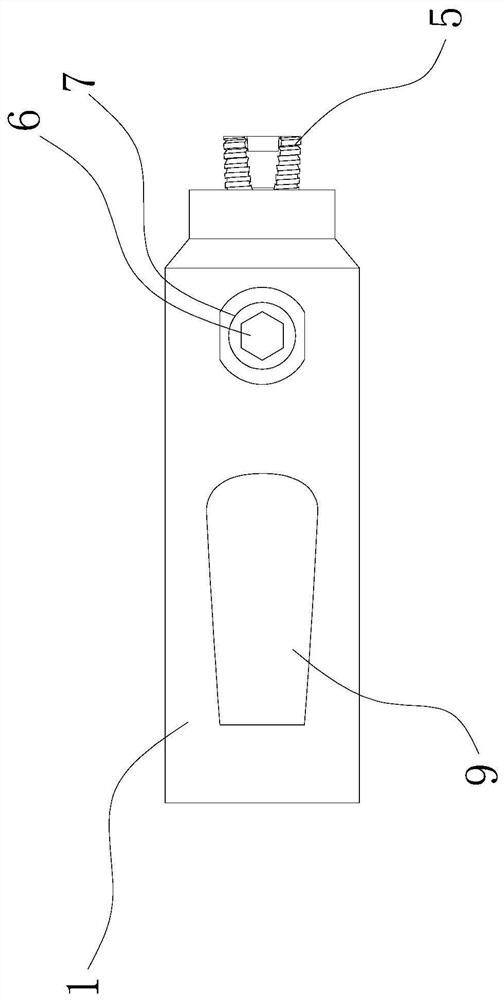

Feeding device for production of grinding tool

InactiveCN107362739AImprove crushing effectControl output rateTransportation and packagingRotary stirring mixersFeed tankDischarge rate

The invention relates to a feeding device for production of a grinding tool. The feeding device comprises a feeding tank and a stirring assembly, wherein the upper part and the lower part of the feeding tank are respectively provided with a feed inlet and a discharge outlet; the stirring assembly is arranged in the feeding tank and comprises a stirring shaft, stirring vanes and fixed stirring vanes; the stirring shaft is vertically arranged in the feeding tank and is in pin joint with the feeding tank; the stirring vanes are fixed at the central part of the stirring shaft; the fixed stirring vanes are fixed on the inner wall of the feeding tank; the stirring vanes and the fixed stirring vanes are arranged in a staggered way; the stirring assembly also comprises a spiral vane; and the spiral vane is fixed at the bottom of the stirring shaft and located at the discharge outlet of the feeding tank. According to the invention, the feeding tank and the stirring assembly are arranged, and the stirring vanes and the fixed stirring vanes are used for extruding and crushing materials together, so stirring and crushing effect is improved; and the spiral vane is arranged for further improvement of the crushing effect of the material and control of the discharging rates of materials.

Owner:台山市兰宝磨具有限公司

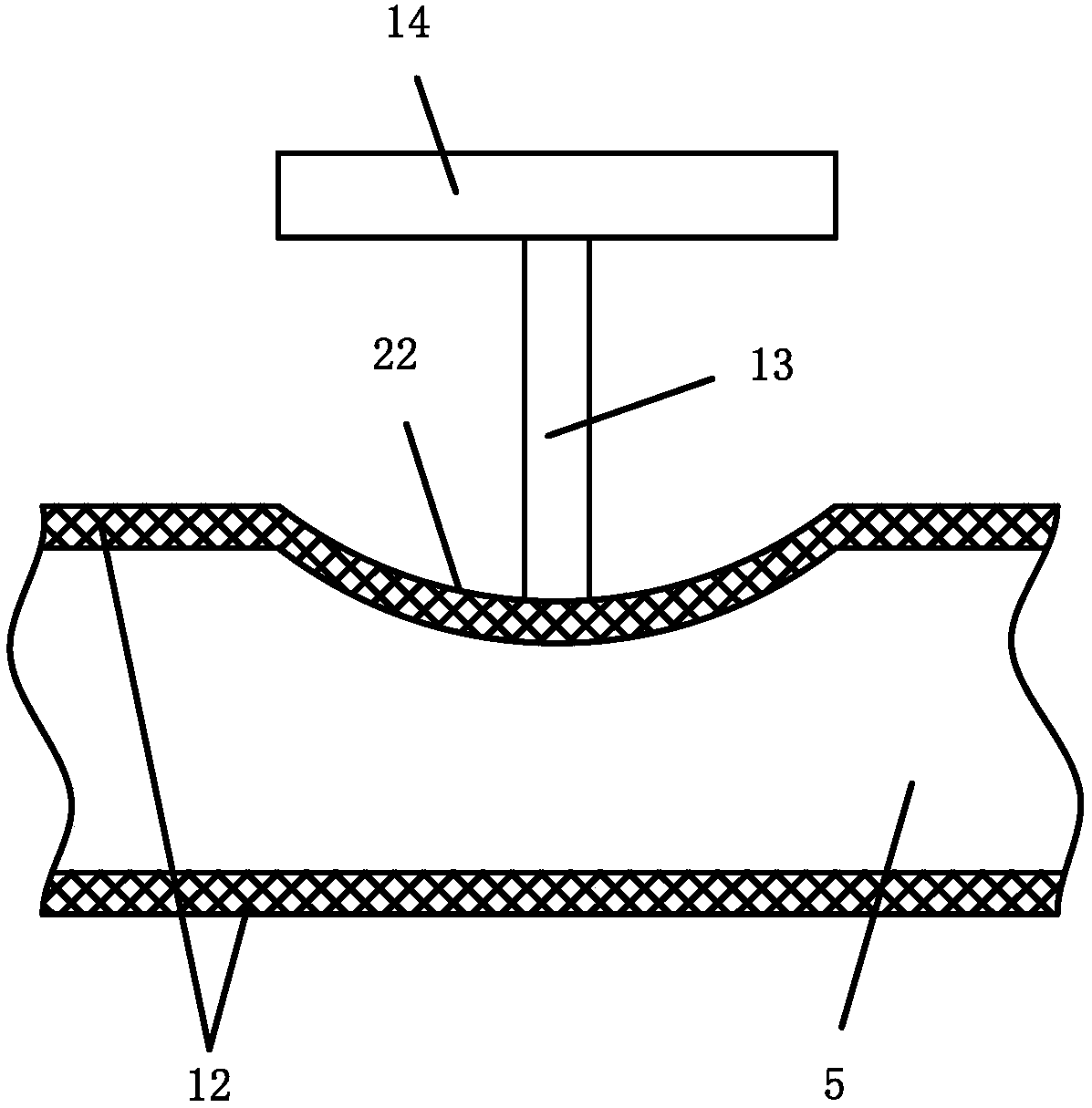

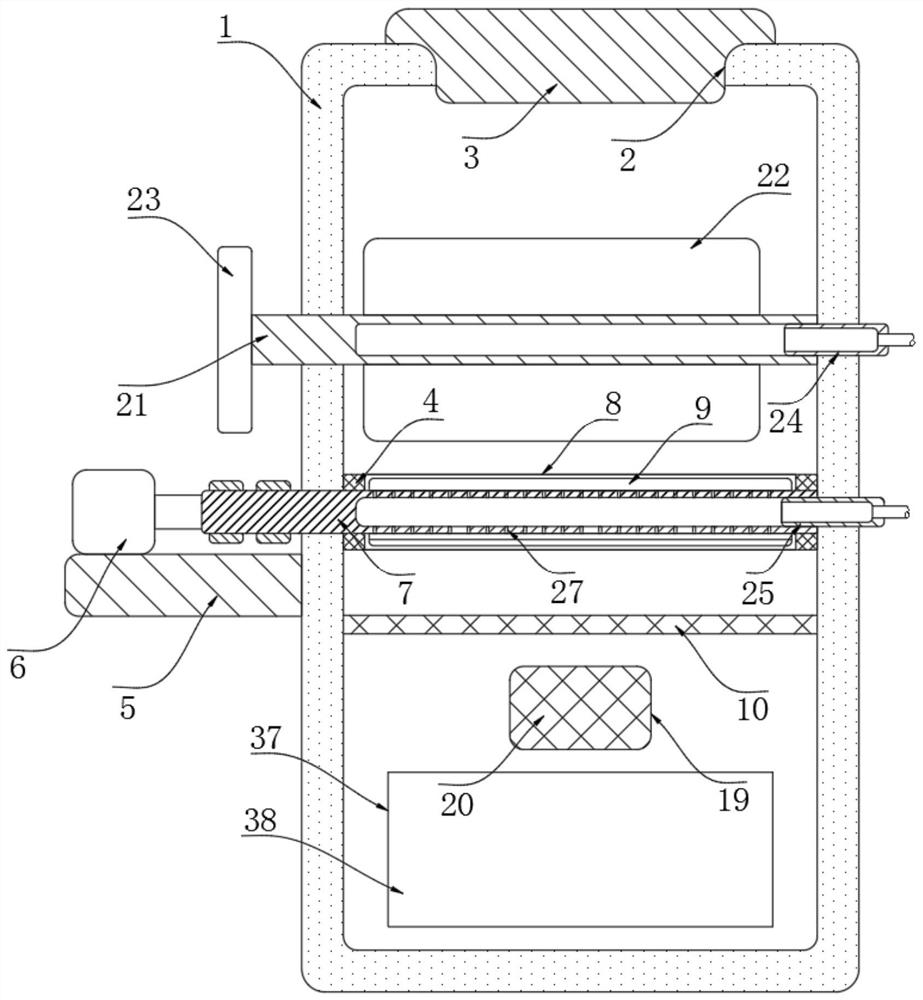

Brick pressing device used for flyash bricks

InactiveCN111791357AStir wellImprove mixing and crushing effectDischarging arrangementCeramic shaping plantsDrive wheelElectric machine

The invention discloses a brick pressing device used for flyash bricks. The brick pressing device comprises a crushing and stirring device. The crushing and stirring device comprises a substrate. A base is arranged above the substrate, and a first supporting rod and a second supporting rod are fixed to the left end and the right end of the upper surface of the base. A driving wheel on a first motor output shaft is driven through a first motor to rotate, the driving wheel drives a first stirring shaft to rotate, first stirring blades are driven to rotate, and raw materials of flyash bricks arecrushed and stirred; the driving wheel drives a first driven wheel and a second driven wheel to rotate, a second stirring shaft and a third stirring shaft are driven to rotate, and finally second stirring blades and third stirring blades are driven to rotate; due to the fact that the first stirring blades, the second stirring blades and the third stirring blades are arranged in a staggered manner,raw materials of flyash bricks can be stirred and can be crushed; and the multiple stirring shafts and stirring blades are arranged at the same time, and therefore crushing and stirring can be more insufficient.

Owner:涡阳县晟丰新型建材有限公司

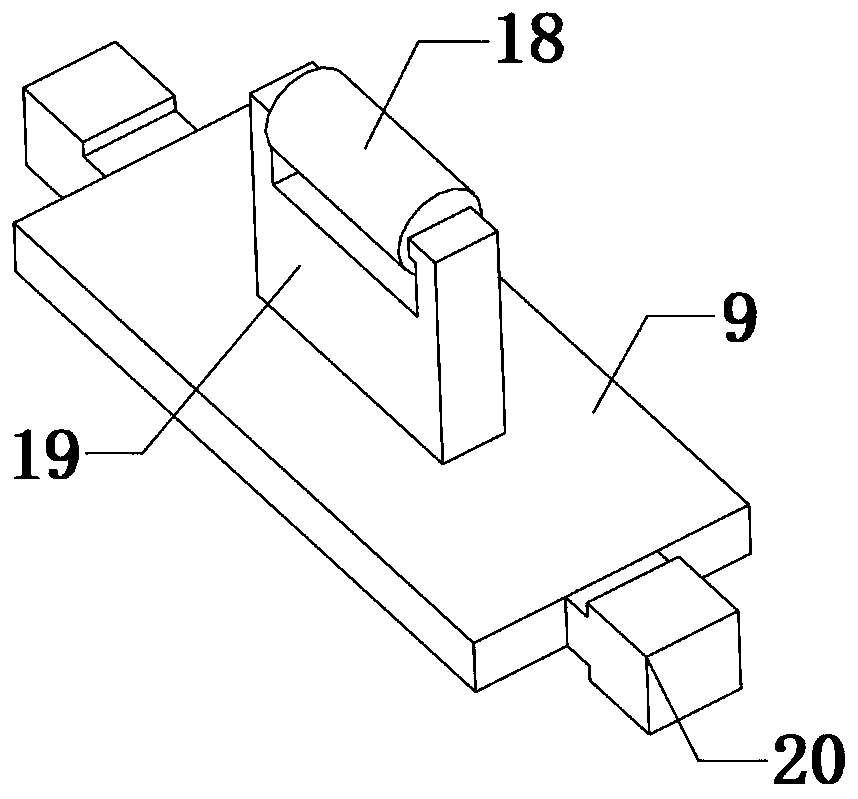

Medicine applicator special for traditional Chinese medicine dermatology department

InactiveCN111494787AImprove cleaning efficiencyImprove application progressMedical applicatorsCleaning using toolsDermatology departmentTraditional medicine

The invention belongs to the technical field of traditional Chinese medicines. The invention relates to a medicine applicator special for a traditional Chinese medicine dermatology department. A largeamount of medicine paste can be remained on a medicine coating plate, after one use process, the medicine coating plate needs to be cleaned, so that secondary smearing is conducted, but when the medicine coating plate is cleaned, due to the fact that the adhesiveness of medicine paste is high, the consumed time is long in the cleaning process, the medicine smearing efficiency is affected, and theoverall smearing progress is reduced, in order to solve the above problem, the following scheme is provided: the device comprises a bottom plate, and two supporting rods are fixedly connected to thetop outer wall of the bottom plate. By arranging a limiting groove and a scraping plate, when the medicine coating plate is cleaned, a sliding block on the medicine coating plate is slidably connectedto the inner wall of the limiting groove, and the medicine coating plate slides on the inner wall of the limiting groove, so that the scraping plate scrapes away residual medicine paste attached to the medicine coating plate and then washes the medicine coating plate with water, so that the medicine coating plate cleaning efficiency is improved, and then the overall medicine smearing progress isimproved.

Owner:李新

Crusher with joint filling function for traffic road and bridge construction

ActiveCN112048979AImprove discharge efficiencyPromote leachingRoads maintainenceArchitectural engineeringLiquid storage tank

The invention relates to traffic road and bridge construction equipment, in particular to a crusher with a joint filling function for traffic road and bridge construction. The crusher comprises a machine body, a crushing cavity is formed in the upper part of the inner side of the machine body, a crushing mechanism is mounted in the crushing cavity, and a settling cavity is formed in the right sideof the crushing cavity. A negative-pressure fan horizontally corresponding to the crushing mechanism and communicating with the settling cavity is mounted on the right side wall of the machine body,a mixing cavity is formed in the lower portion of the inner side of the crushing cavity, a rotating shaft is mounted in the middle of the mixing cavity, a plurality of mixing blades are further mounted on the rotating shaft in the circumferential direction, and a liquid spraying assembly is arranged at the top of the mixing cavity. The liquid spraying assembly is connected with a liquid storage tank arranged on the outer side wall of the machine body. The crusher is good in concrete crushing and mixing effect, can selectively humidify and uniformly mix concrete for later use, has the joint filling function with buffer protection, and is beneficial to popularization and application.

Owner:谢晓红

Cleaning and drying device for yam flour processing

InactiveCN112539603ATo achieve the purpose of grindingImprove fine qualityDrying solid materials with heatDrying chambers/containersElectric machineryAgricultural engineering

The invention belongs to the technical field of yam flour processing, particularly relates to a cleaning and drying device for yam flour processing, and provides the following scheme for solving the problem that many impurities are left in yam flour or part of yam blocks are not finely ground in the yam flour processing process. The cleaning and drying device comprises a box body, supporting feetare fixedly connected to the outer wall of the bottom of the box body, an electric control box is fixedly connected to the outer wall of one end of the box body, a first cover plate is rotatably connected to the top of the box body, a material guide plate is arranged at the bottom of the first cover plate, and the material guide plate is fixedly connected with the inner wall of the box body. According to the cleaning and drying device, a motor is arranged to drive a driving gear to rotate so as to drive a driven gear and a processing table connected with the bottom of the driven gear through aconnecting rod to rotate, the processing table can vibrate and screen yam flour through a vibration motor arranged on the outer wall of the processing table, the yam flour leaks out from filtering holes at the bottom of a bearing table after being processed by the processing table, and the fine quality of yam is improved.

Owner:朱南方

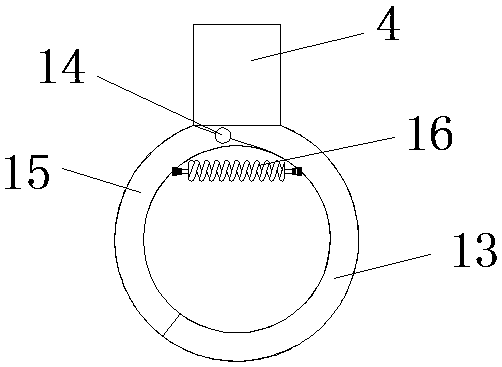

Water guiding structure of sludge precipitation tank

PendingCN106237673AImprove sedimentation efficiencyImprove mixing and crushing effectSettling tanks feed/dischargeSludgeEngineering

The invention relates to a water guiding structure of a sludge precipitation tank. The water guiding structure comprises a distribution tube arranged in the center of a precipitation tank body, the sidewall of the distribution tube is provided with water guiding tubes, the water guiding tubes are elastic telescoping structures, the end portion of every water guiding tube is provided with a roller, and the rollers are in rolling contact with guiding rings arranged on the inner wall of the precipitation tank body. Every water guiding tube comprises an inner guiding tube connected with the distribution tube and an outer guiding tube nested on the outer wall of the inner guiding tube in a sliding manner, a spring is arranged between the inner guiding tube and the outer guiding tube, the end portion of the inner guiding tube is provided with an axial through hole, and the end portion of the outer guiding tube is provided with a radial through hole. The guiding rings are fixedly connected with the inner wall of the precipitation tank body through supports, and the inner wall of every guiding ring is provided with a plurality of projections uniformly arranged at intervals. The elastic telescoping water guiding tubes adopted in the invention can guide sludge water and also can preliminarily crush the sludge water to assist dispersion of the sludge, so improvement of the later stirring and crushing effect is facilitated.

Owner:WUXI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY CO LTD

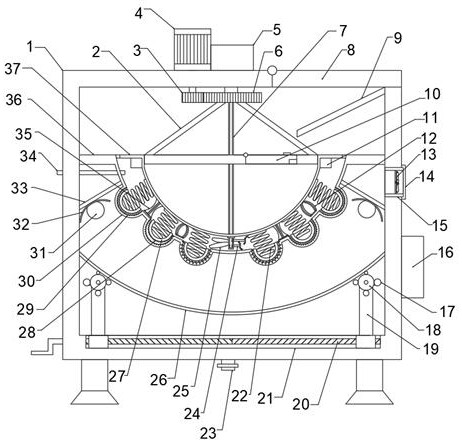

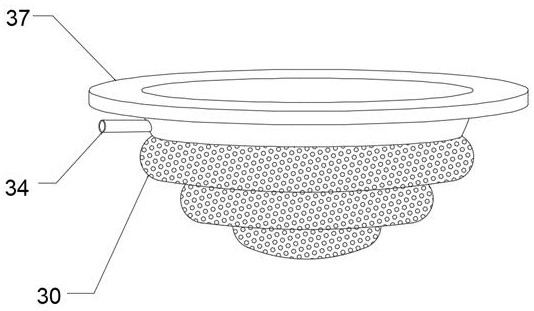

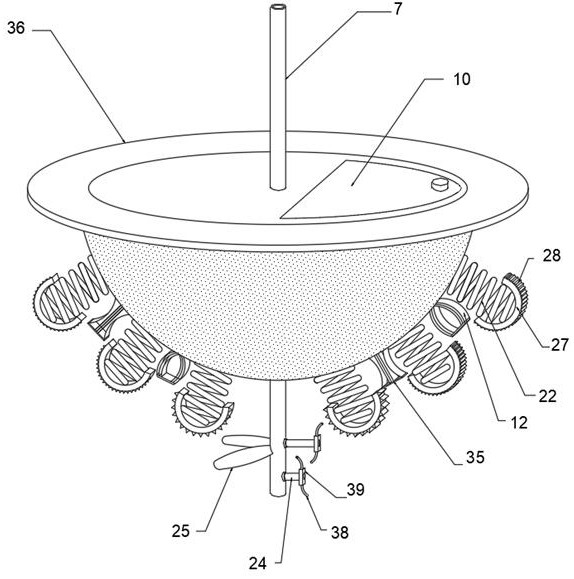

Mixed flow stirring soymilk machine

InactiveCN105310542BImprove mixing and crushing effectImprove efficiencyKitchen equipmentGear wheelEngineering

The invention discloses a mixed flow stirring soybean milk machine which comprises a base, an outer barrel body, a barrel body fixing plate, a barrel cover and a stirring rotary disc. A heat insulation barrel is arranged on the inner side wall of the outer barrel body. A plurality of circles of heating pipes are arranged inside the heat insulation barrel. The inner sides of the heating pipes are provided with a heating barrel in a tight contact mode. The bottoms of the outer barrel body, the heat insulation barrel and the heating barrel are fixed to the base through the barrel body fixing plate. An outer rotary sleeve shaft penetrates through the center of the barrel body fixing plate. The portion, penetrating through the barrel body fixing plate, of the outer rotary sleeve shaft is sleeved with a sealing ring. An inner rotary shaft penetrates into the outer rotary sleeve shaft. The bottom of the outer rotary sleeve shaft and the bottom of the inner rotary shaft are provided with an outer rotary sleeve shaft driving gear and an inner rotary shaft driving gear. During smashing and stirring, disordered turbulent flow is formed, and the smashing and stirring effect and efficiency are improved.

Owner:金庆新

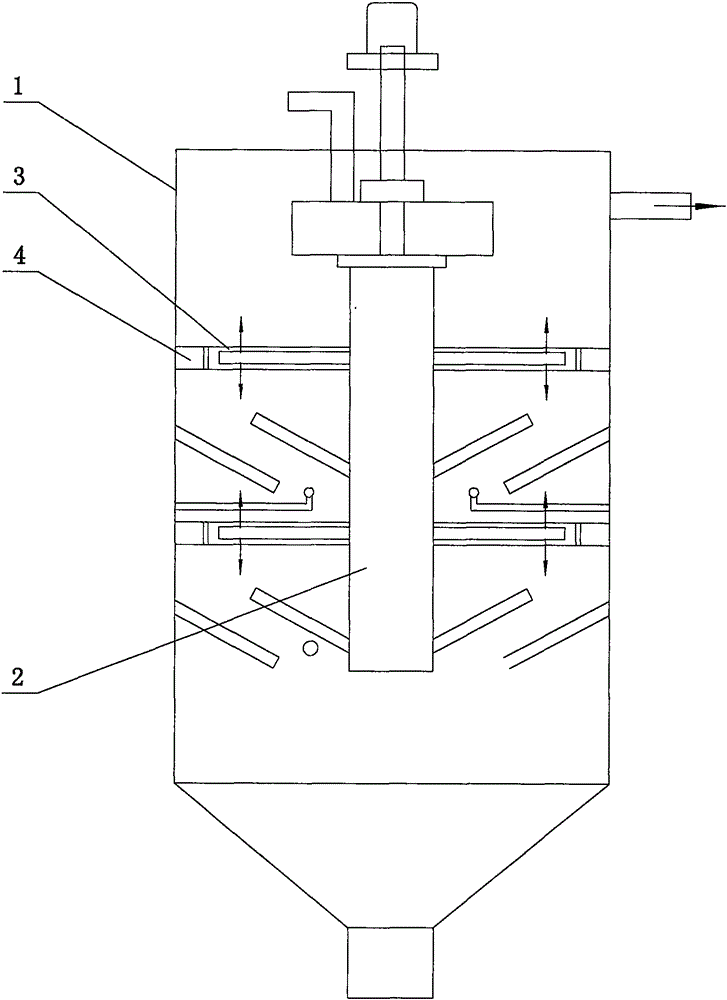

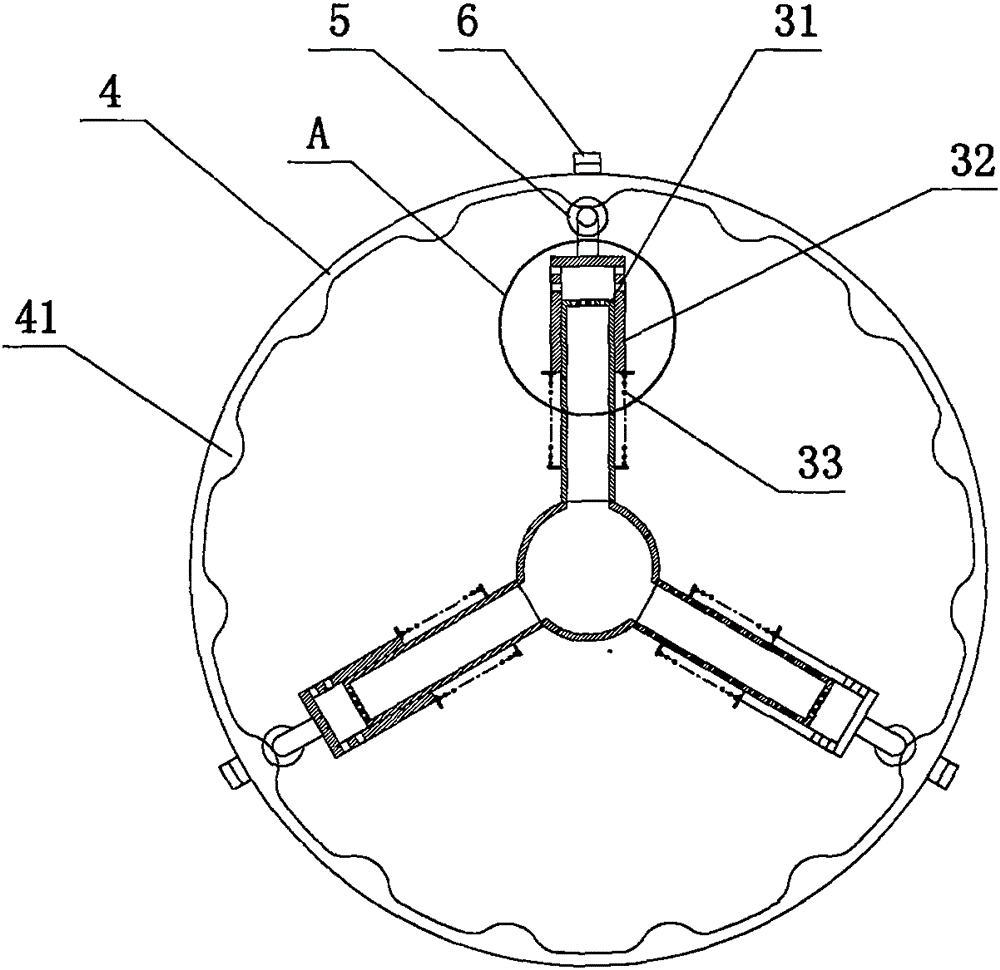

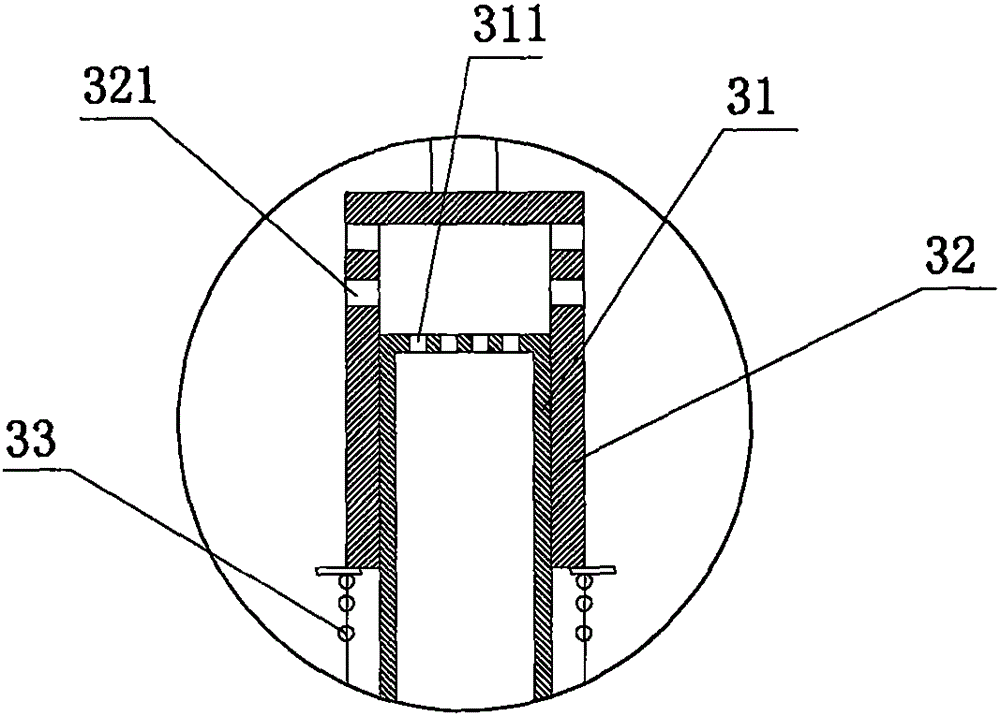

Novel sludge settling tank

PendingCN106310733AImprove sedimentation efficiencyReduce stirring resistanceCentrifugal force sediment separationSedimentation settling tanksSludgeSludge settling

The invention relates to a novel sludge settling tank which comprises a settling tank body, wherein the center of the settling tank body is provided with a distributing pipe; the upper end of the distributing pipe is provided with a motor through a rotating shaft; the motor is arranged on the outer top surface of the settling tank body; the upper end of the distributing pipe positioned in the settling tank body is provided with a water inlet distribution plate; the side wall is provided with movable stirring blades arranged up and down; the water inlet distribution plate is connected with a water inlet pipe; the upper and lower parts of the inner wall of the settling tank body are provided with fixed stirring blades; the upper and lower fixed stirring blades and the upper and lower movable stirring blades are arranged alternately at pulverizing intervals; and the side wall of the distributing pipe is provided with an elastic telescopic water guide pipe, the end of the elastic telescopic water guide pipe is provided with a roller wheel, and the roller wheel forms a rolling contact with a guide ring on the inner wall of the settling tank body.

Owner:WUXI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY CO LTD

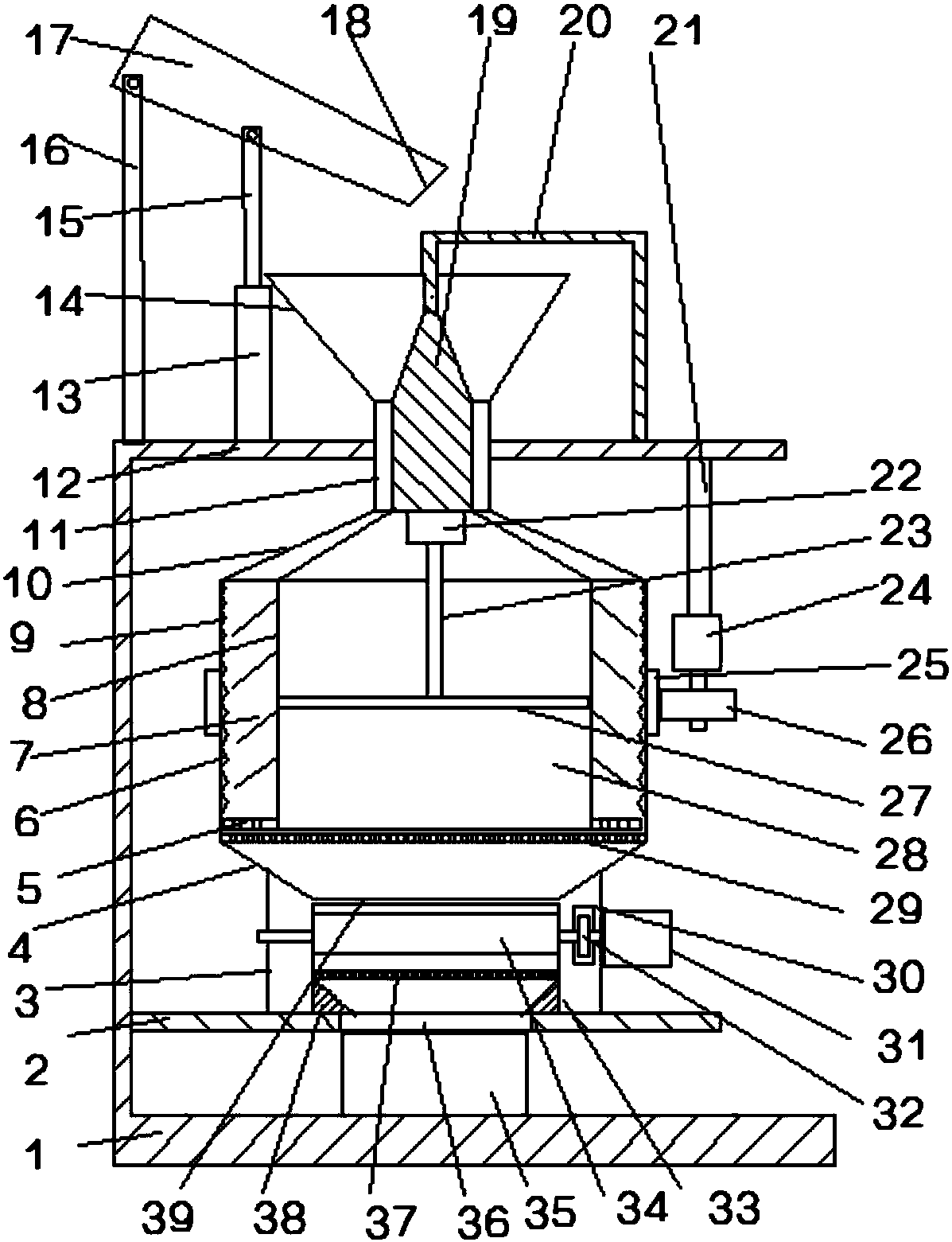

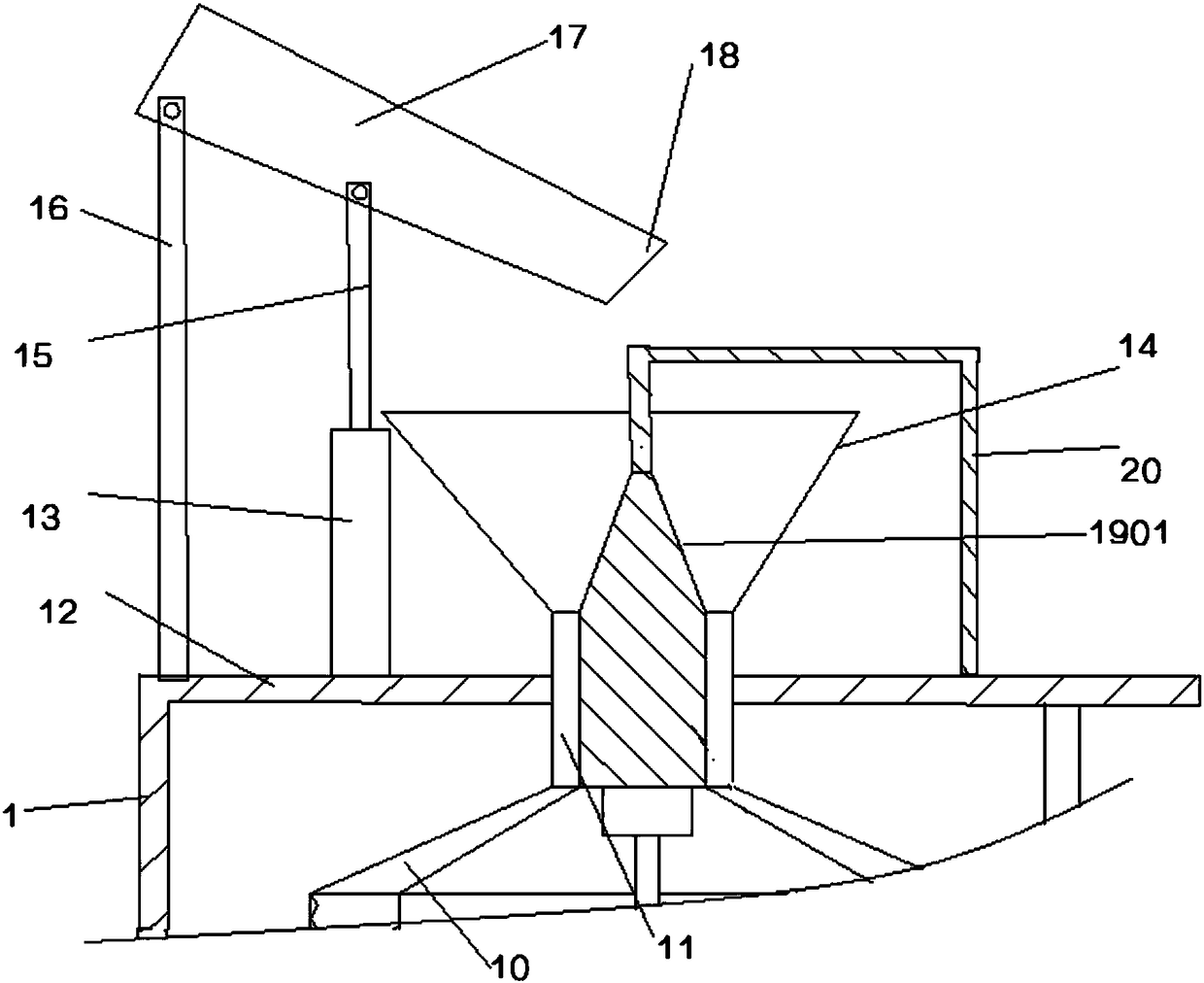

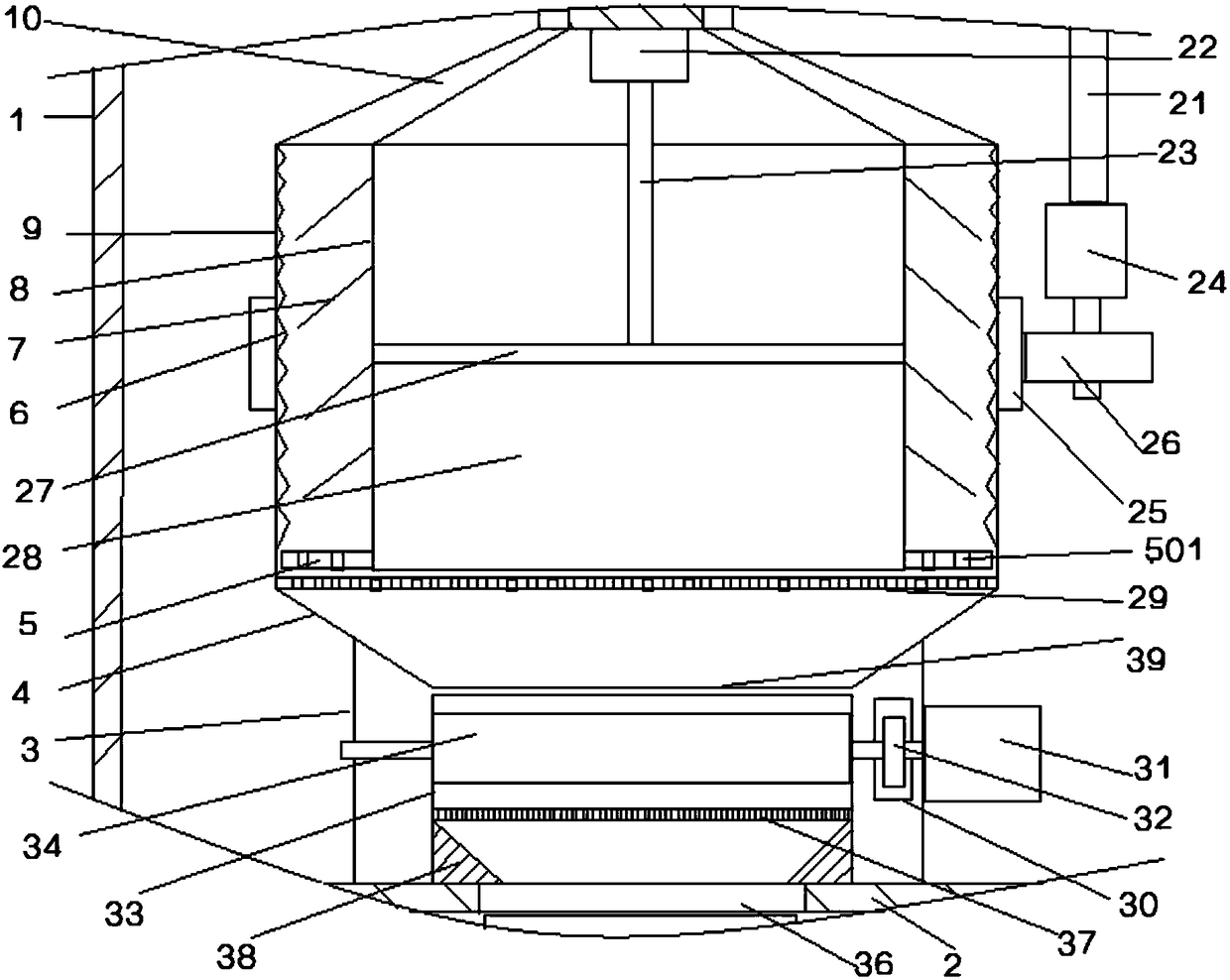

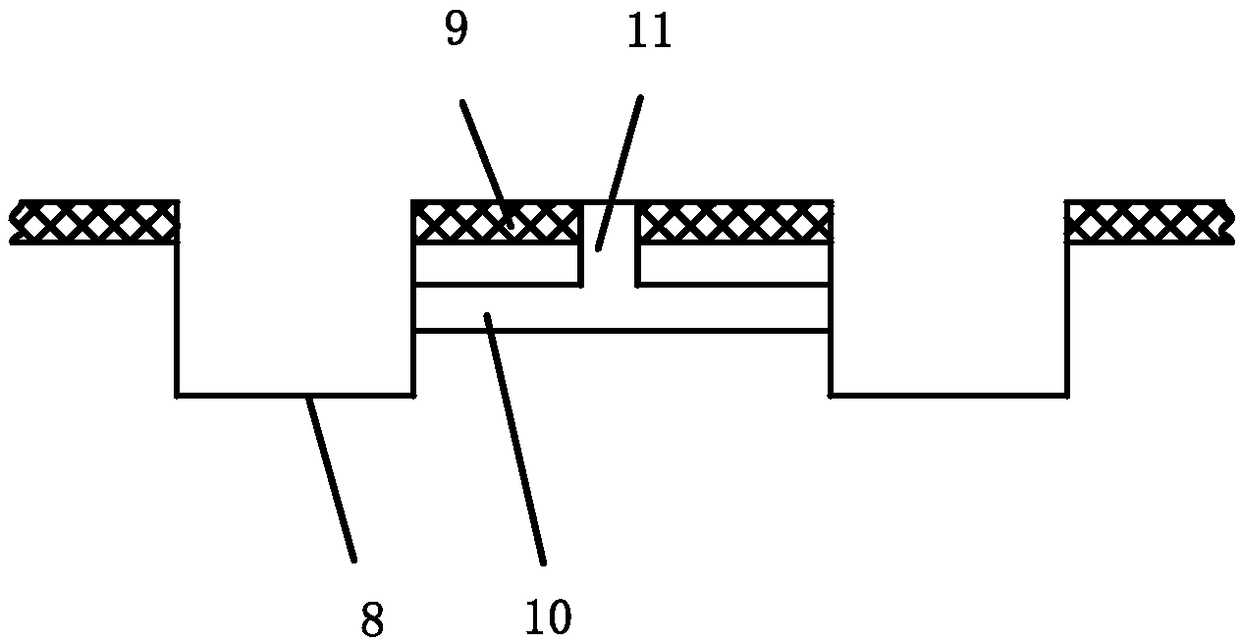

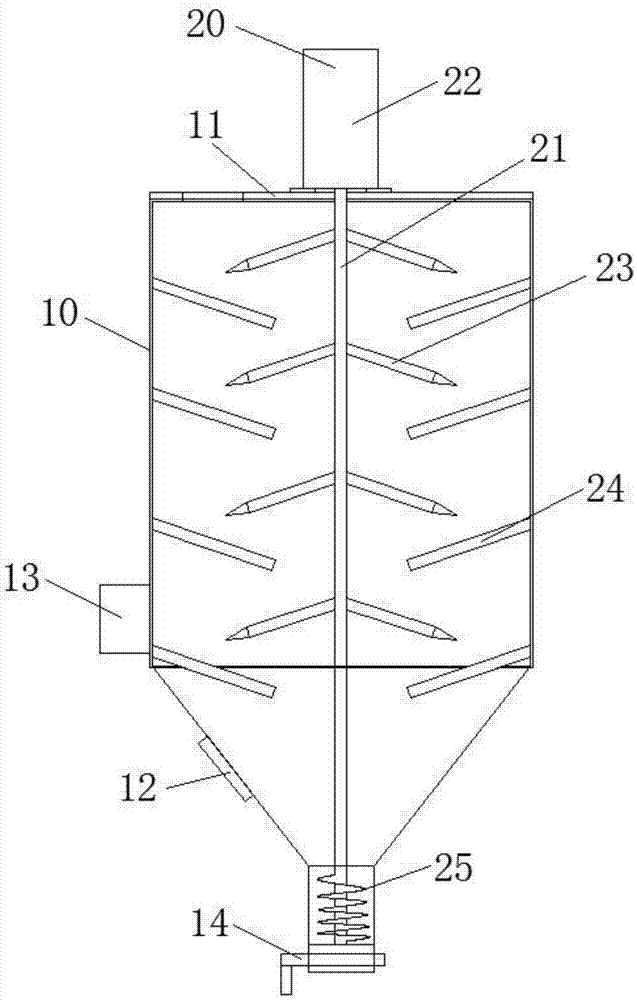

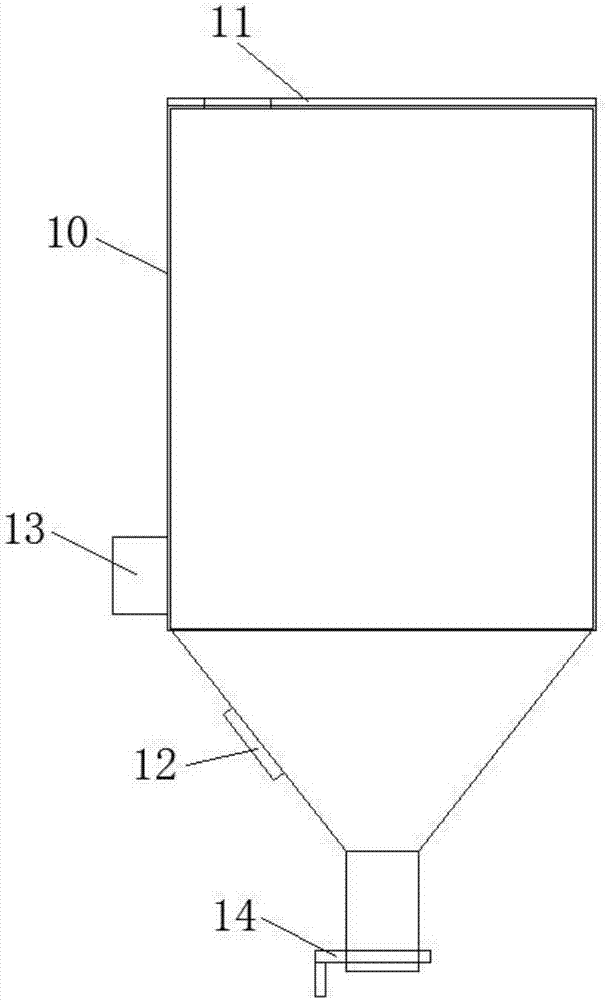

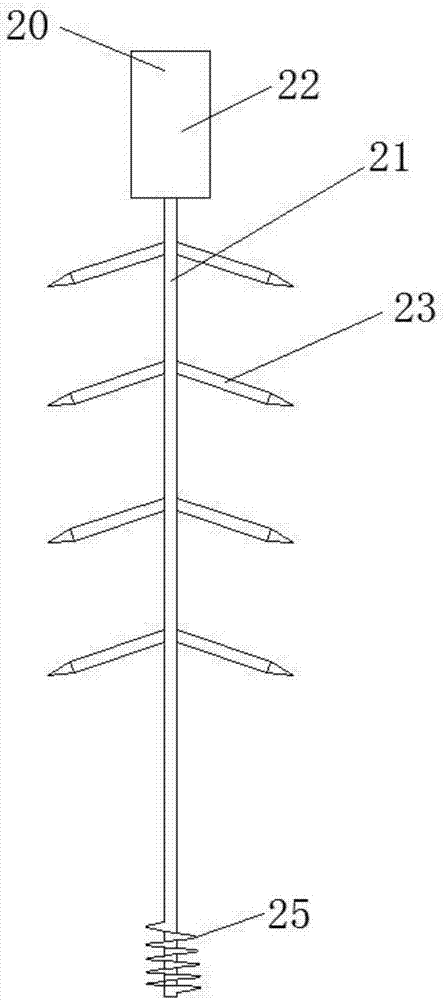

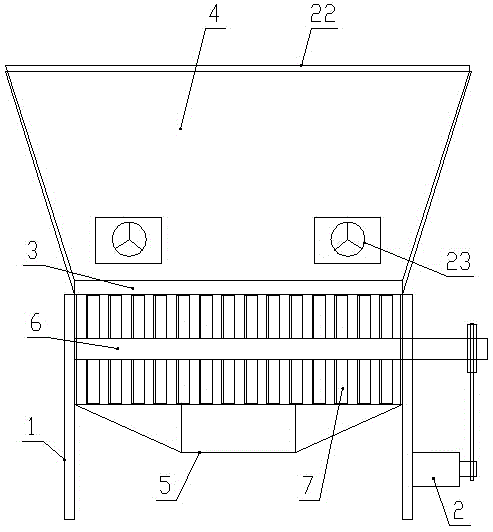

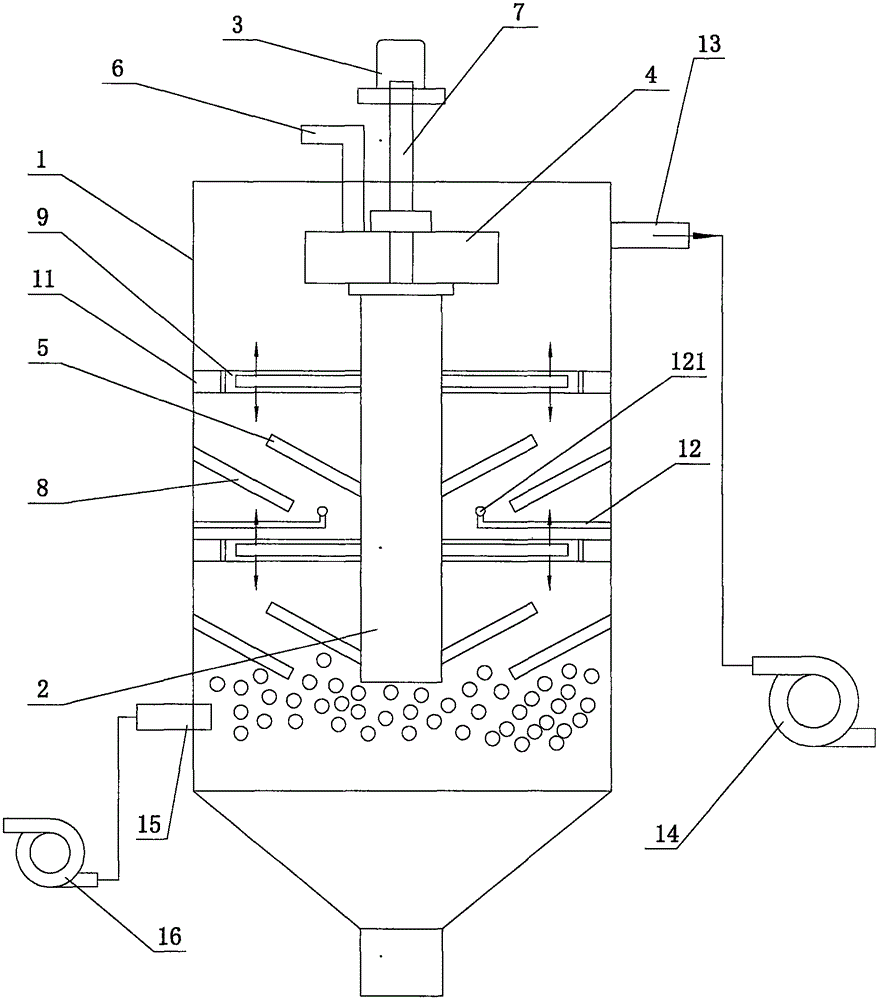

Material crushing mixer

InactiveCN104399379BReasonable designSimple structureRotary stirring mixersAlcoholic beverage preparationEngineeringMixing effect

A material pulverizing and agitating machine comprises a rack, wherein a motor is arranged on the left side or the right side of the rack, a pulverizing and mixing box with a top opening is arranged on the rack, a feeding hopper is arranged at the top of the pulverizing and mixing box, the feeding hopper is of a conical structure with a large top and a small bottom, a discharging slotted plate is arranged at the bottom of the pulverizing and mixing box, an agitating shaft is horizontally arranged in the pulverizing and mixing box in a rotating way, a plurality of agitating rods are uniformly and vertically arranged on the agitating shaft in the axial and peripheral directions, the motor is in transmission connection with one end of the agitating shaft, the agitating rods are made by angle irons, the two side edges of the angle irons are respectively perpendicular and parallel to the axial direction of the agitating shaft, cutting edges are arranged on the outer edges of the side edges of the angle irons, perpendicular to the axial direction of the agitating shaft, and two feeding quantity regulators positioned on the same plane are arranged at the upper end opening part of the pulverizing and mixing box. The material pulverizing agitator is reasonable in design and simple in structure and has the good pulverizing and mixing effects. The feeding quantity can be regulated according to the humidity of the raw material, so that blocking phenomena are prevented.

Owner:HENAN FUTAN WINE

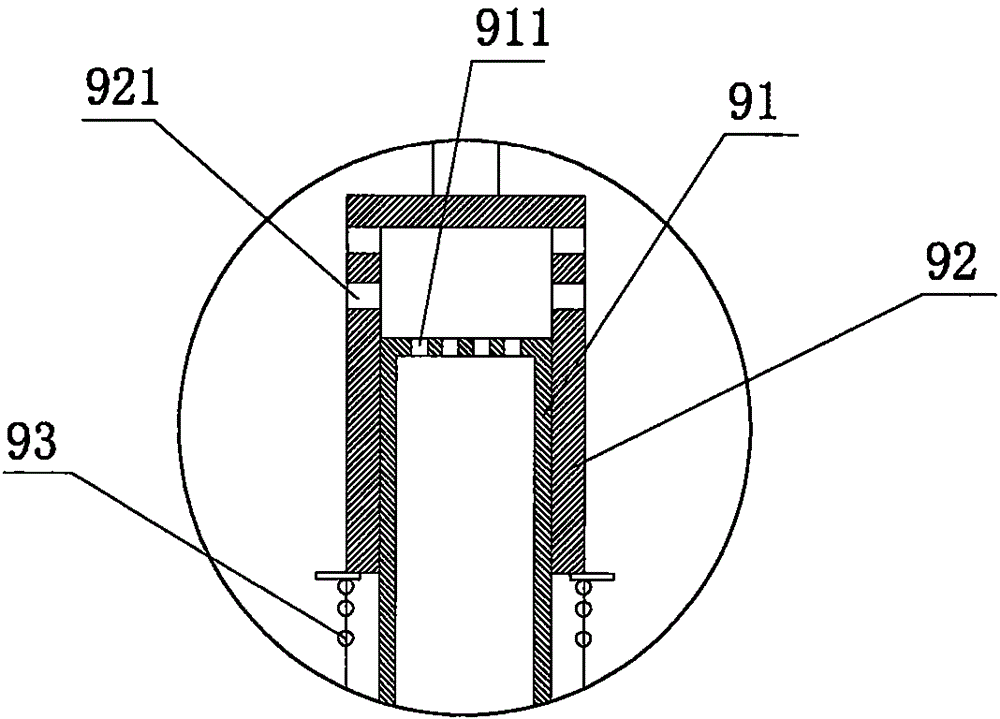

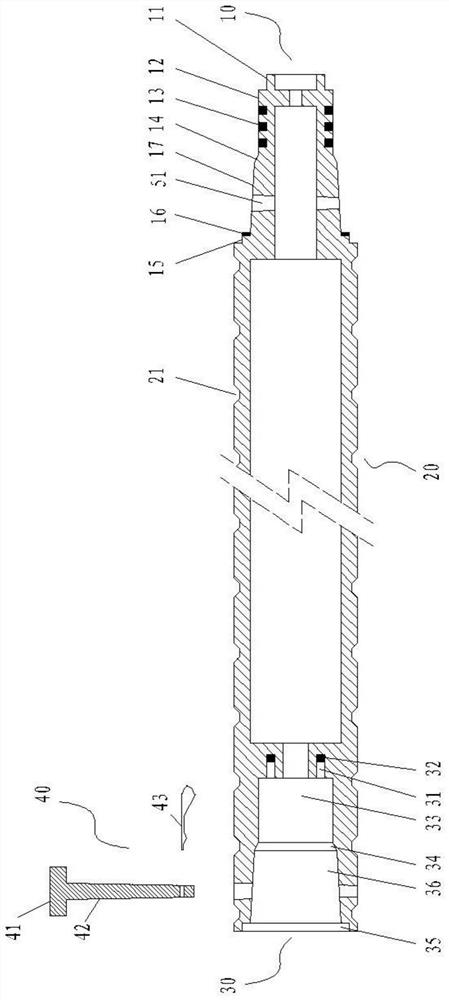

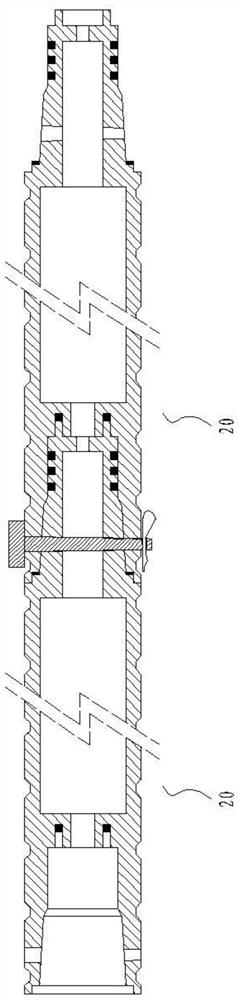

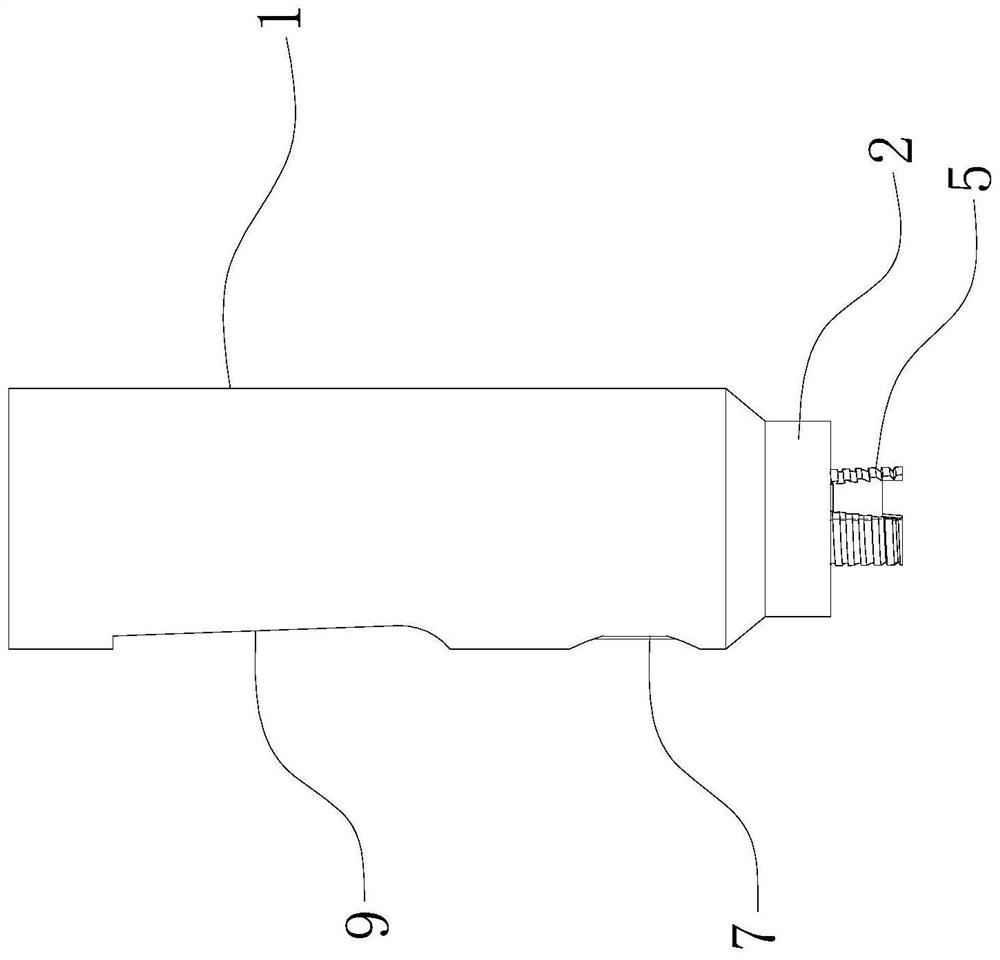

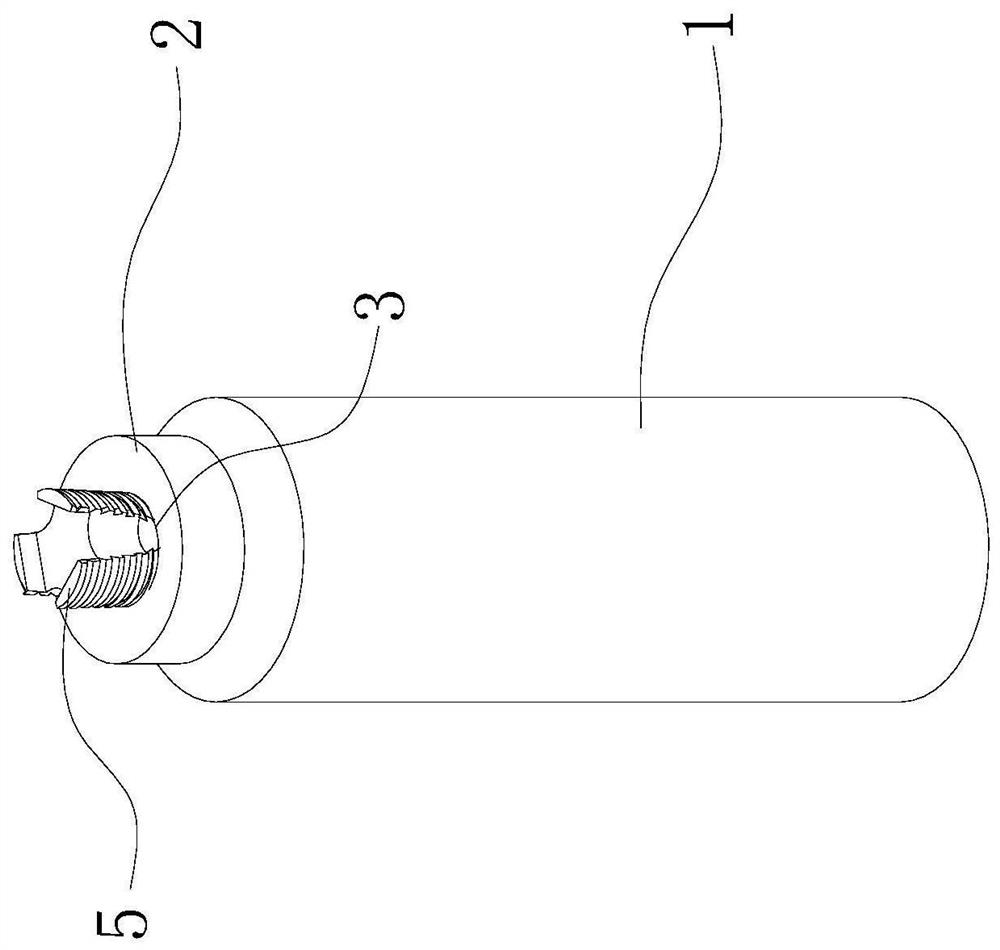

A hexagonal plug-in outer groove high-pressure compact drill pipe

ActiveCN111485832BImprove high pressure tightnessSufficient torqueDrilling rodsDrilling casingsSlagClassical mechanics

The invention discloses a hexagonal plug-in type external groove high-pressure compact drill pipe, which comprises a male joint, a drill pipe body and a female joint connected in sequence, and a connecting pin for connecting the male joint and the female joint. The drill pipe The body has a hexagonal structure, and the male joint and the female joint are radially provided with connection holes. When the male joint and the female joint are connected, the corresponding connection holes of the male joint and the corresponding connection holes of the female joint are formed radially opposite to each other for connecting pins. Passes radially through the pin hole that connects the pin and box. The wall of the drill pipe of the present invention adopts a hexagonal body design, and the drill pipe realizes a plug-in high-pressure resistant seal. The wall of the hexagonal drill pipe body can not only keep the drill clamping and prevent sliding during the drilling process, but also improve the drill pipe’s resistance to drilling. The mixing and crushing ability of coal cinder prevents faults such as hole plugging, drill sticking, and drill sticking, and ensures the safe construction of coal mine gas drainage drilling.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

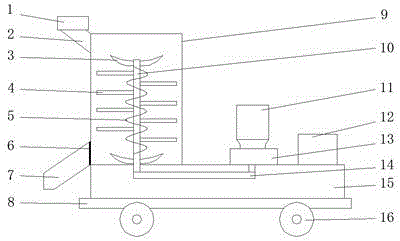

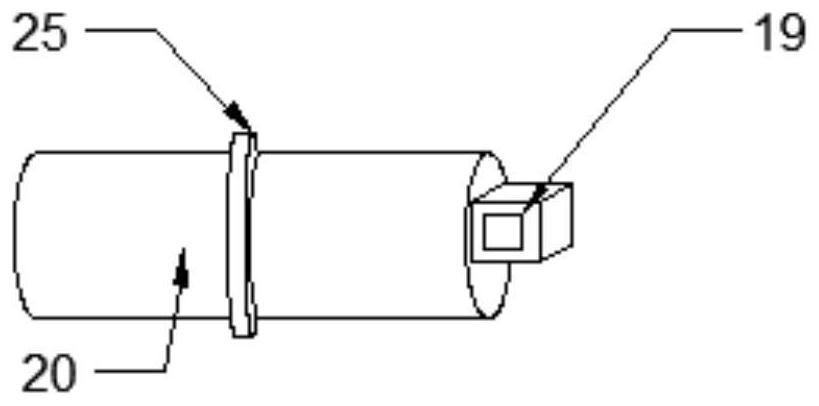

Corn stalk feed machine

The invention provides a corn stalk feed machine. The corn stalk feed machine comprises a cylinder, a discharge mould, a material delivery chamber, a crushing chamber and a second motor; the cylinderis installed at a left end of a top of a fixed base; a discharge tube is installed at a right end of the cylinder; the discharge mould is installed at a right end socket of the discharge tube; a low-speed motor is installed at a right end socket of a fixed frame; a rotating shaft is in transmission connection with the low-speed motor; the material delivery chamber is installed at a top of the cylinder; a spiral shaft is installed in the material delivery chamber, and is in transmission connection with a first motor via a first reduction gear; the crushing chamber is installed at a left end ofa top of the material delivery chamber; a crushing shaft is installed in the crushing chamber; and the crushing shaft is in transmission connection with the second motor via a second reduction gear. The corn stalk feed machine is capable of achieving better crushing and mixing effects. Cooperation of the cylinder, the discharge tube and the discharge mould is adopted so that a piston is driven toperform extruded discharging by the cylinder, and thus, good discharge effect and high efficiency are realized; moreover, large amount of material residues is also avoided.

Owner:FOSHAN KUIFENG BUSINESS CONSULTATION SERVICES CO LTD

A crusher for traffic road and bridge construction with the function of caulking

ActiveCN112048979BImprove discharge efficiencyPromote leachingRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to equipment for traffic road and bridge construction, in particular to a crusher for traffic road and bridge construction with the function of filling gaps, including a machine body. There is a settling chamber on the right side. A negative pressure fan corresponding to the level of the crushing mechanism and connected to the settling chamber is installed on the right side of the machine body. A mixing chamber is provided on the inner lower part of the crushing chamber, and a rotating shaft is installed in the middle of the mixing chamber. A plurality of mixing vanes are installed in circumferential distribution, and a liquid spraying assembly is arranged on the top of the mixing chamber, and the liquid spraying assembly is connected with a liquid storage tank provided on the outer wall of the machine body. The invention has a good crushing and mixing effect on concrete materials, can be selectively humidified and mixed for standby, and also has the function of filling joints with buffer protection, which is beneficial to popularization and application.

Owner:谢晓红

Novel bubble-separation/ultrasonic-penetration-separation stirring-type sludge settling tank

PendingCN106310731AAuxiliary dispersionImprove sedimentation efficiencySettling tanks feed/dischargeCentrifugal force sediment separationSludgeEngineering

The invention relates to a novel bubble-separation / ultrasonic-penetration-separation stirring-type sludge settling tank which comprises a settling tank body, wherein the center of the settling tank body is provided with a distributing pipe; the upper end of the distributing pipe is provided with a motor through a rotating shaft; the upper end of the distributing pipe positioned in the settling tank body is provided with a water inlet distribution plate; the side wall is provided with movable stirring blades arranged up and down; the water inlet distribution plate is connected with a water inlet pipe; the upper and lower parts of the inner wall of the settling tank body are provided with fixed stirring blades; the upper and lower fixed stirring blades and the upper and lower movable stirring blades are arranged alternately at pulverizing intervals; the side wall of the distributing pipe is provided with an elastic telescopic water guide pipe, the end of the elastic telescopic water guide pipe is provided with a roller wheel, and the roller wheel forms a rolling contact with a guide ring on the inner wall of the settling tank body; and an ultrasonic generator is also arranged in the settling tank body, an upper water outlet pipe of the settling tank body is connected with a vacuum water pump, and the lower side wall of the settling tank body is provided with an air guide pipe connected with a blower.

Owner:WUXI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY CO LTD

A kind of detection method of Angelica dahurica coumarin in veterinary medicine

ActiveCN108152392BImprove pulverization and dissolution rateIncrease contact areaComponent separationFluid phaseAqueous ethanol

The invention discloses a detection method of radix angelicae dahuricae coumarins in veterinary drugs. The detection method comprises the following steps: A, adding a veterinary drug to be detected into a pulverizing mechanism, then injecting a 60wt% ethanol water solution and performing stirring and pulverizing; B, filtering the ethanol water solution containing the veterinary drug component to obtain filtrate; C, adding the filtrate to ether and performing extraction; and D, performing component separation on the extraction product by using a liquid chromatography column, and then determining the content of the radix angelicae dahuricae coumarins by chromatographic analysis. The detection method of radix angelicae dahuricae coumarins in the veterinary drugs can improve the defects of theprior art, improve the extraction accuracy of the radix angelicae dahuricae coumarins in the veterinary drugs, improve the accuracy of detection results and prolong the service life of the liquid chromatography column.

Owner:宋瑞

Vitamin tablet raw material smashing-stirring production equipment

InactiveCN111760653AImprove mixing effectImprove work efficiencyTransportation and packagingMixersBLENDER/MIXEREngineering

The invention discloses vitamin tablet raw material smashing-stirring production equipment. The vitamin tablet raw material smashing-stirring production equipment comprises a mounting frame, wherein abottom plate is arranged on one side of the mounting frame; a side plate is fixedly arranged at the end, far away from the mounting frame of the bottom plate; a No. 1 mixing box, a coating liquid mixing box and a No. 2 mixing box are arranged sequentially from far to near on the top of the bottom plate according to the distances away from the mounting frame; a stirring-adjusting mechanism is arranged on the mounting frame and the side plate; a stirring mechanism is arranged at the bottom end of the stirring-adjusting mechanism; a receiving box corresponding to the No. 1 mixing box, the coating liquid mixing box and the No. 2 mixing box is arranged at the bottom end of the bottom plate; the mounting frame is arranged on the top of the base; a screening box is arranged on the base; a smashing box is arranged on the top of the screening box; and a smashing mechanism is arranged on the smashing box. The vitamin tablet raw material smashing-stirring production equipment is convenient to use, low in cost, good in smashing-stirring effect and high in working efficiency.

Owner:杨丽娟

A screening device for soil restoration

ActiveCN111001470BEffective stirringHigh shear forceSievingDispersed particle filtrationSoil remediationElectric machine

The invention discloses a screening device for soil remediation, which comprises a screening box, the upper end of the screening box starts to have a feeding trough, the inner wall of the feeding trough is offset by an upper cover, and the inner wall of the screening box A partition is fixed, and the upper end of the partition is provided with a plurality of division grooves, the inner wall of each division groove runs through and connects the partition tube, and the circumferential side wall of each partition tube is fixed with a plurality of Scraper, the outer wall of the screening box is fixed with a bearing plate, the upper end of the bearing plate is provided with a power mechanism, and the side wall of the screening box is provided with an air outlet slot. The advantage is that the rotating tube is driven by the motor to rotate, so that the rotating tube drives the stirring plate on it to rotate, so that the stirring plate can effectively stir the soil on the top of the partition, so that the soil is stirred and pulverized, which is convenient for subsequent screening. The rotation of the pipes is opposite, and the soil between the two rotating pipes is subjected to greater shear force, so that the mixing and crushing effect of the soil is strengthened.

Owner:博思英诺科技(北京)有限公司

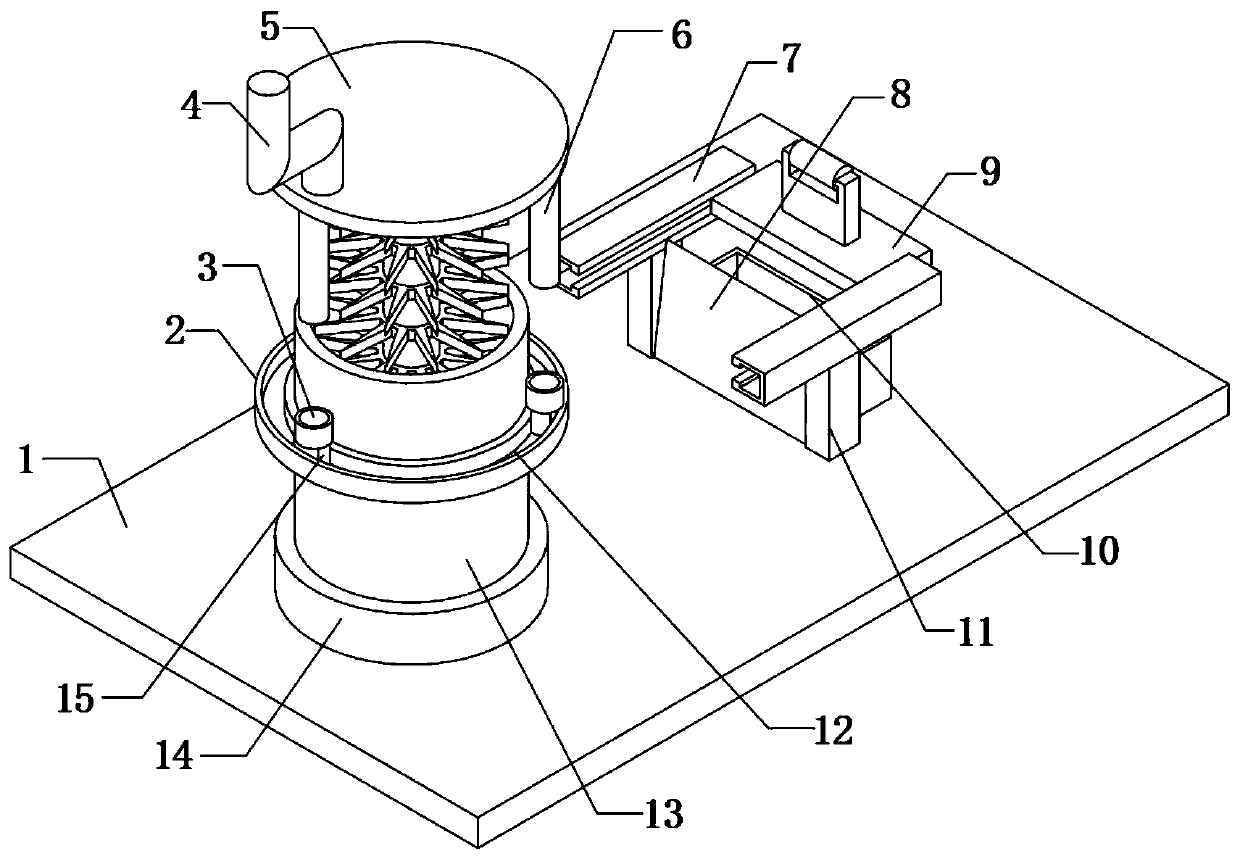

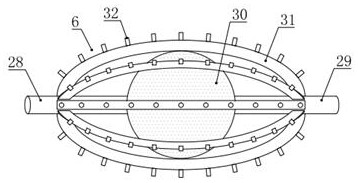

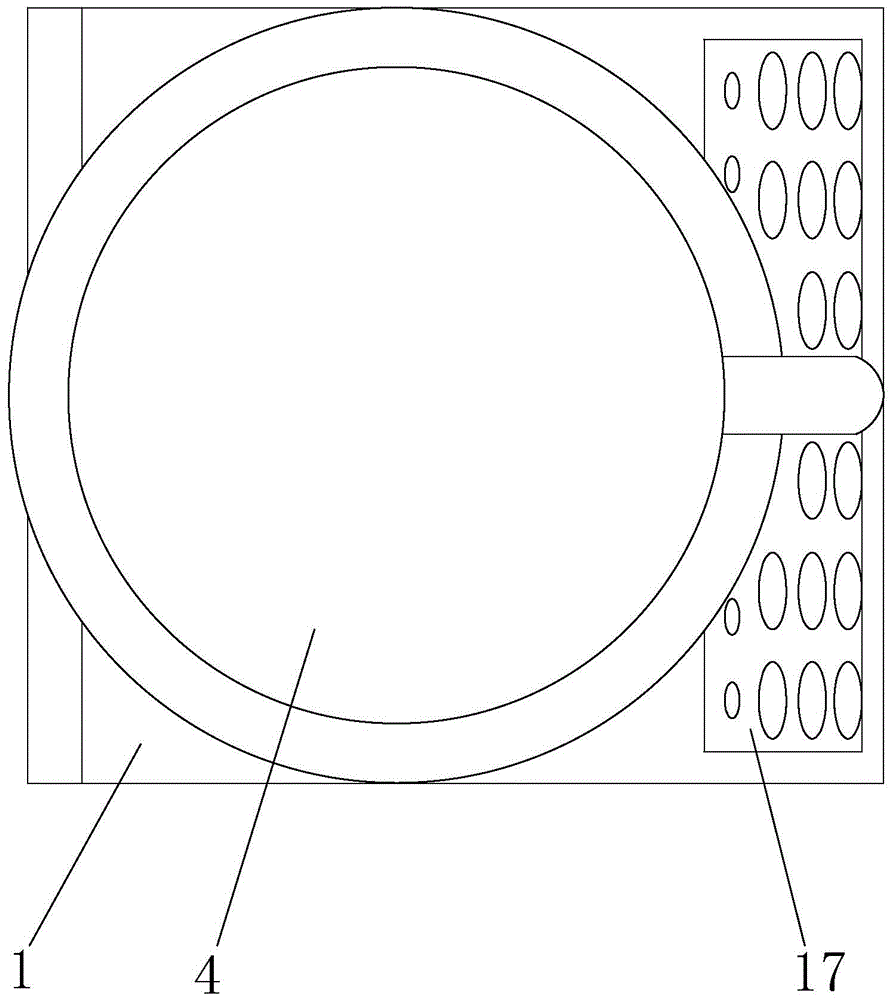

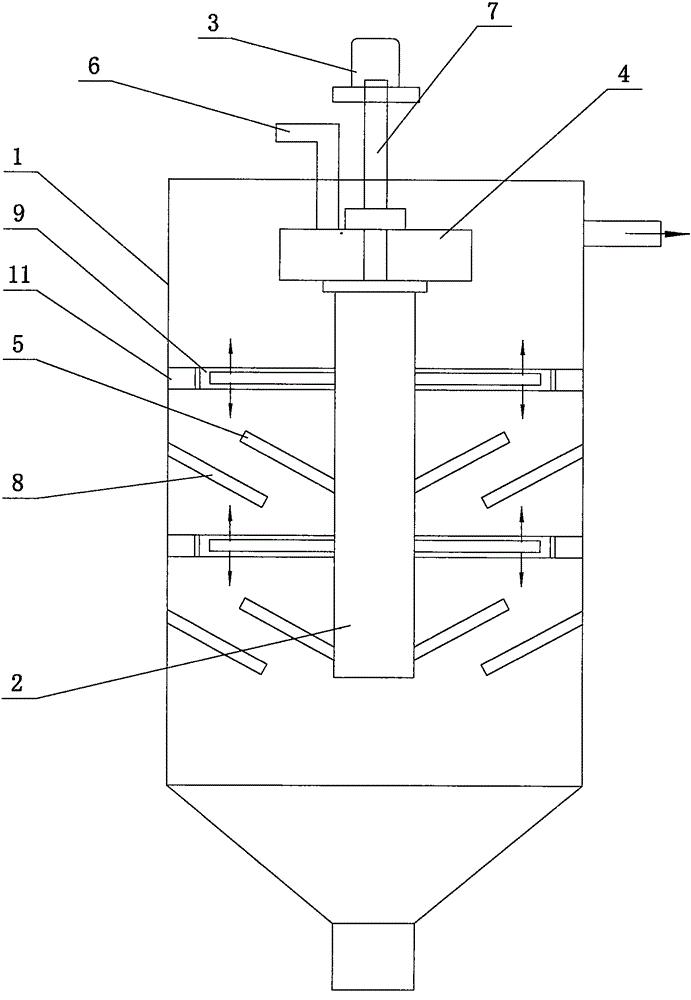

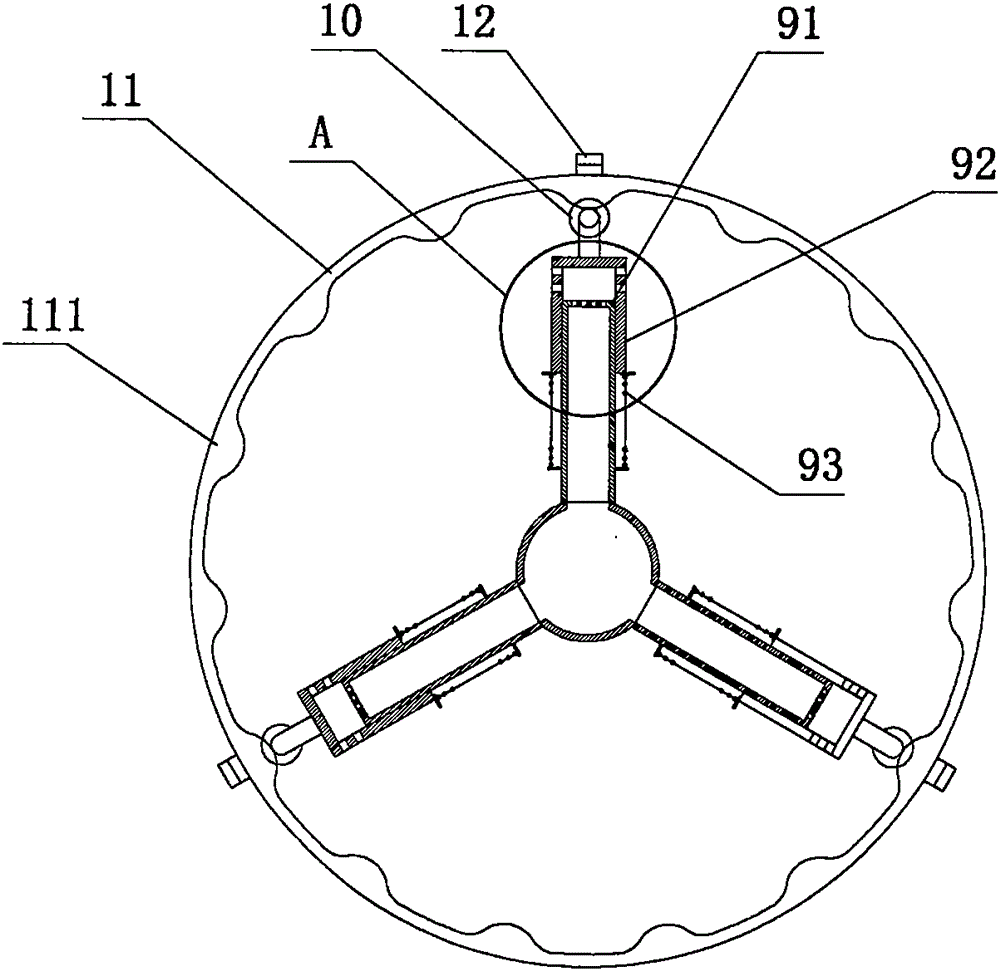

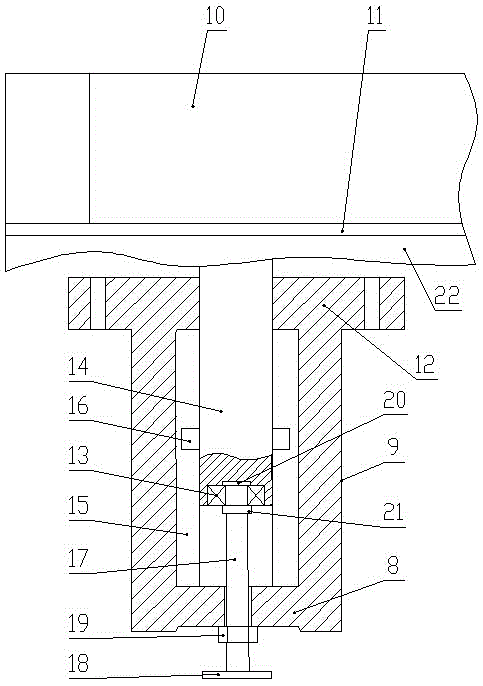

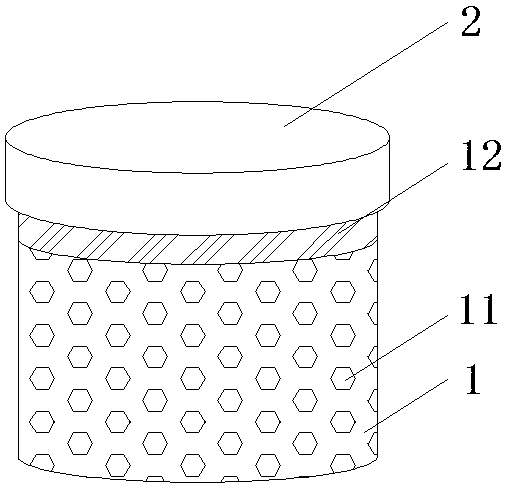

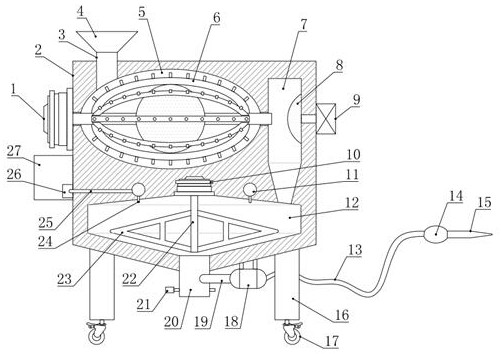

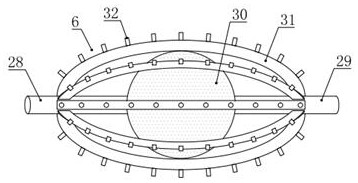

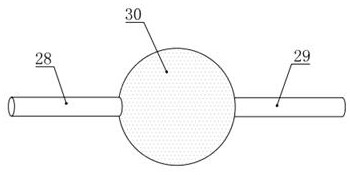

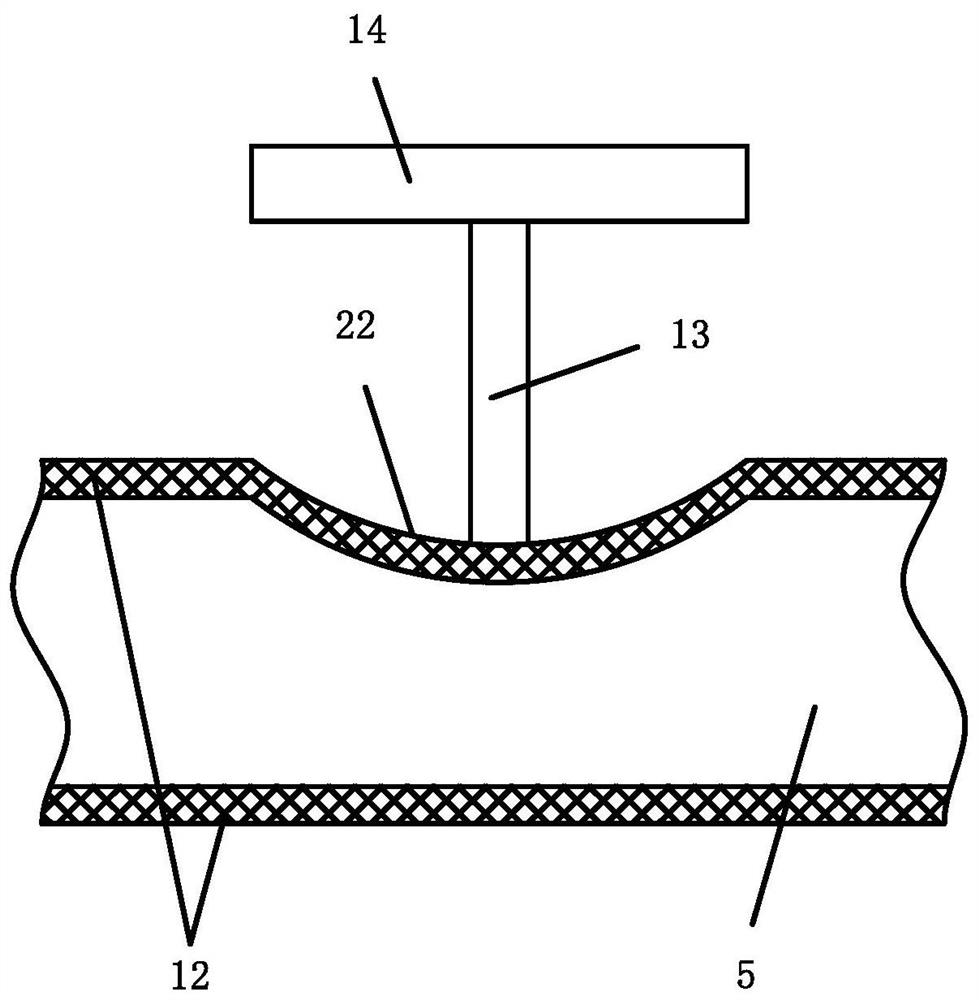

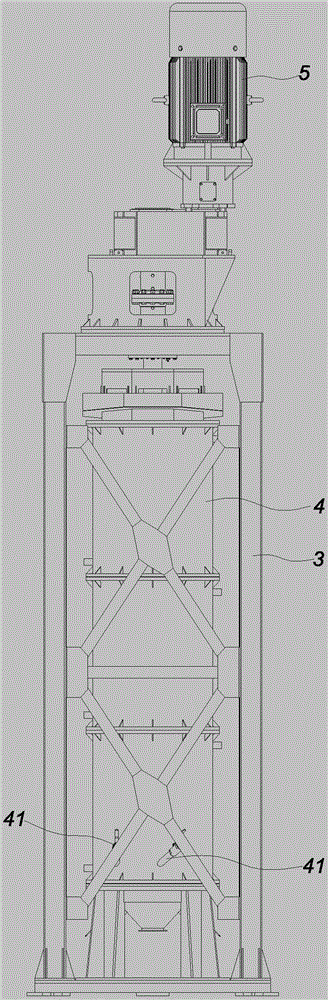

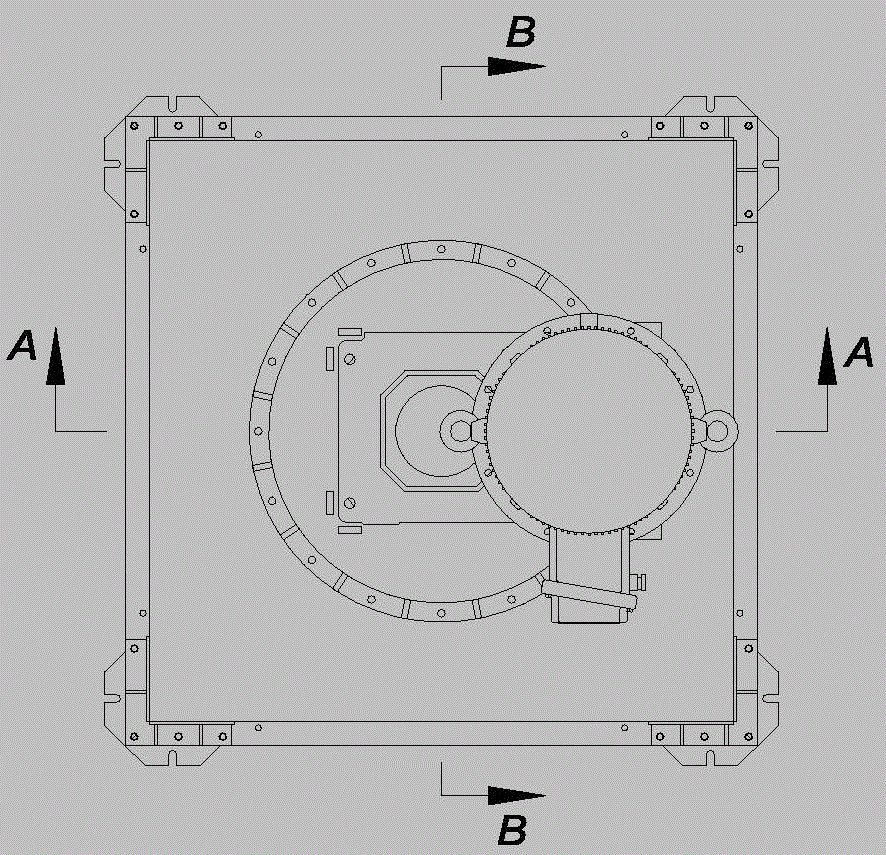

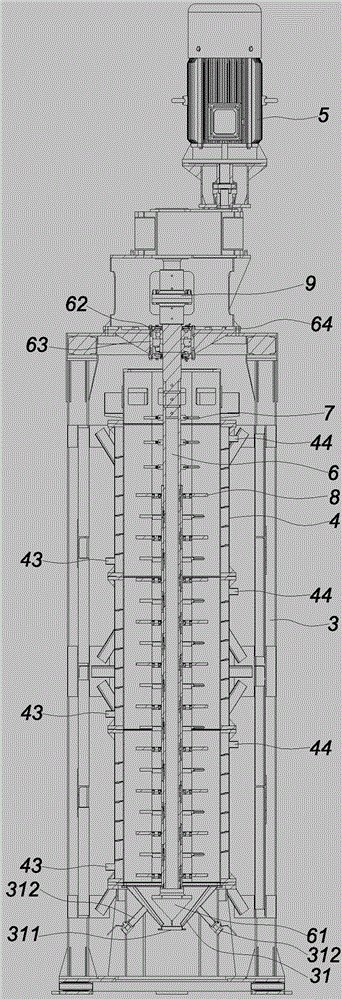

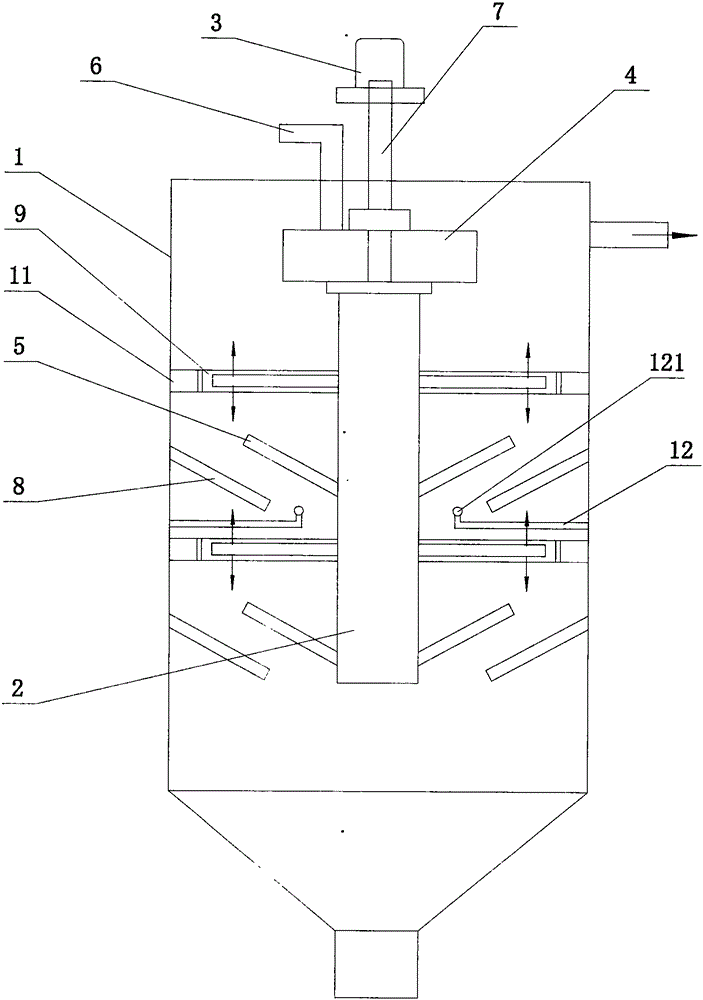

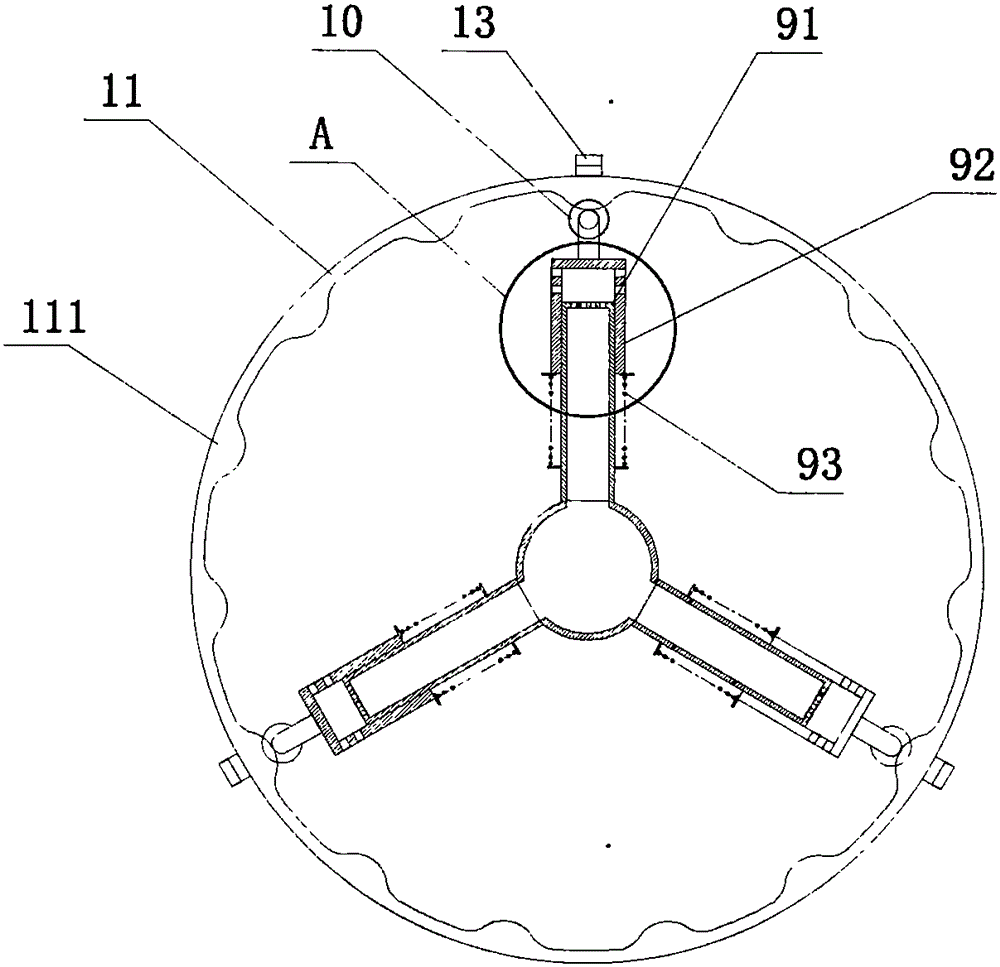

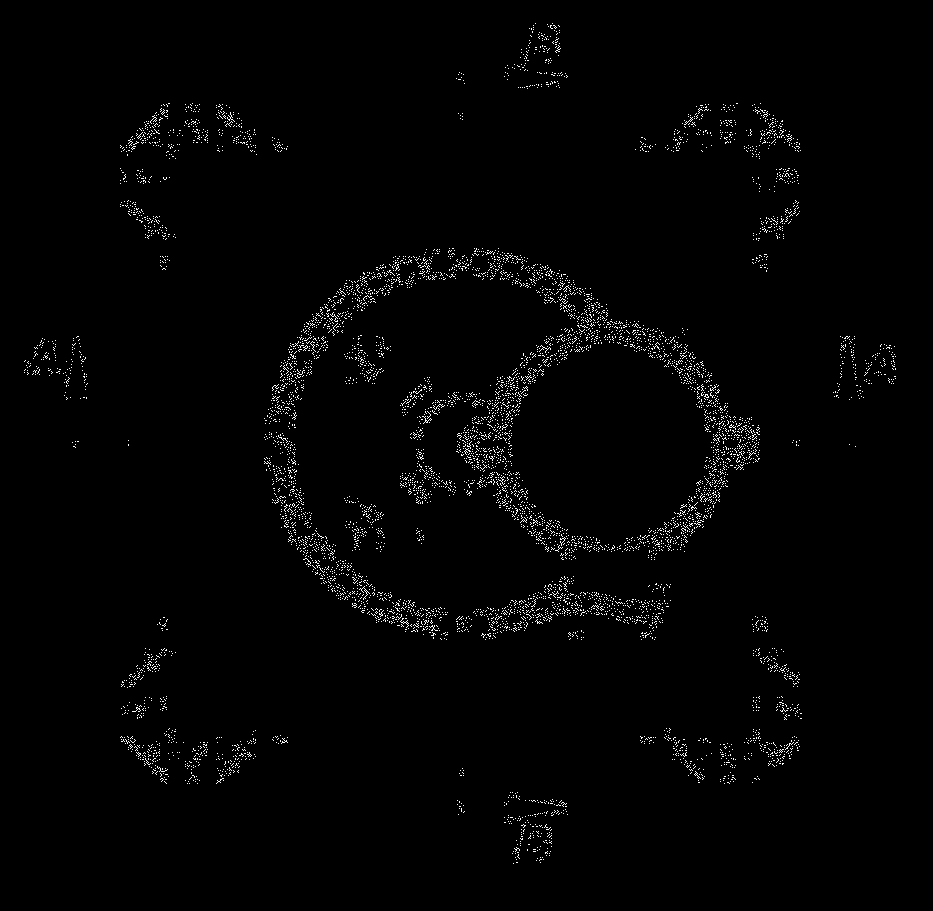

Water mill

ActiveCN107519998AStirring structure is simpleImprove mixing and crushing effectGrain treatmentsEngineering

The invention discloses a water mill. The water mill comprises a rack, a stirring cavity and a speed reducer, wherein the stirring cavity is vertically mounted relative to the rack, the bottom and the top of the stirring cavity are separately provided with a feeding opening and a discharging opening, the outer side wall of the stirring cavity is provided with a cooling water inlet and a cooling water outlet, cooling water is arranged between the inner and outer walls of the stirring cavity, a rotating shaft is arranged in the stirring cavity, the top end of the rotating shaft is in power connection with the output end of the speed reducer, a first stirring disc and a second stirring disc are sequentially arranged on the rotating shaft in a sleeving manner from the top end to the bottom end, the first stirring disc and the second stirring disc are arranged in parallel, and clearances are separately arranged between the outer edges of the first stirring disc and the second stirring disc and the inner wall of the stirring cavity. The water mill is simple in structure and convenient to assemble and effectively improves stirring and pulverizing effects.

Owner:龙岩亿丰机械科技有限公司

Ultrasonic separation stirring type sludge sedimentation tank

PendingCN106310732AImprove sedimentation efficiencyReduce stirring resistanceSettling tanks feed/dischargeSedimentation settling tanksSludgePulp and paper industry

The invention relates to an ultrasonic separation stirring type sludge sedimentation tank which comprises a sedimentation tank body, wherein a distribution pipe is arranged at the center of the sedimentation tank body; a motor is mounted at the upper end of the distribution pipe through a rotary shaft and placed on the outer-side top surface of the sedimentation tank body; an incoming water distribution disc is mounted at the upper end of the distribution pipe in the sedimentation tank body, and an up-down movable stirring blade is mounted on the side wall; the incoming water distribution pipe is connected with a water-in pipe; a fixed stirring blade is mounted up and down on the inner wall of the sedimentation tank body; the up-down fixed stirring blade and an up-down movable stirring blade are spaced, and a grinding space is reserved; elastic telescopic water guide pipes are mounted on the side wall of the distribution pipe; a roller is arranged at the end part of the elastic telescopic water guide pipe; the roller is in rolling contact with a guide ring on the inner wall of the sedimentation tank body; an ultrasonic generator is also arranged in the sedimentation tank body; and a transmission end of the ultrasonic generator is bent upward and arranged between the upper elastic telescopic water guide pipe and the lower elastic telescopic water guide pipe.

Owner:WUXI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY CO LTD

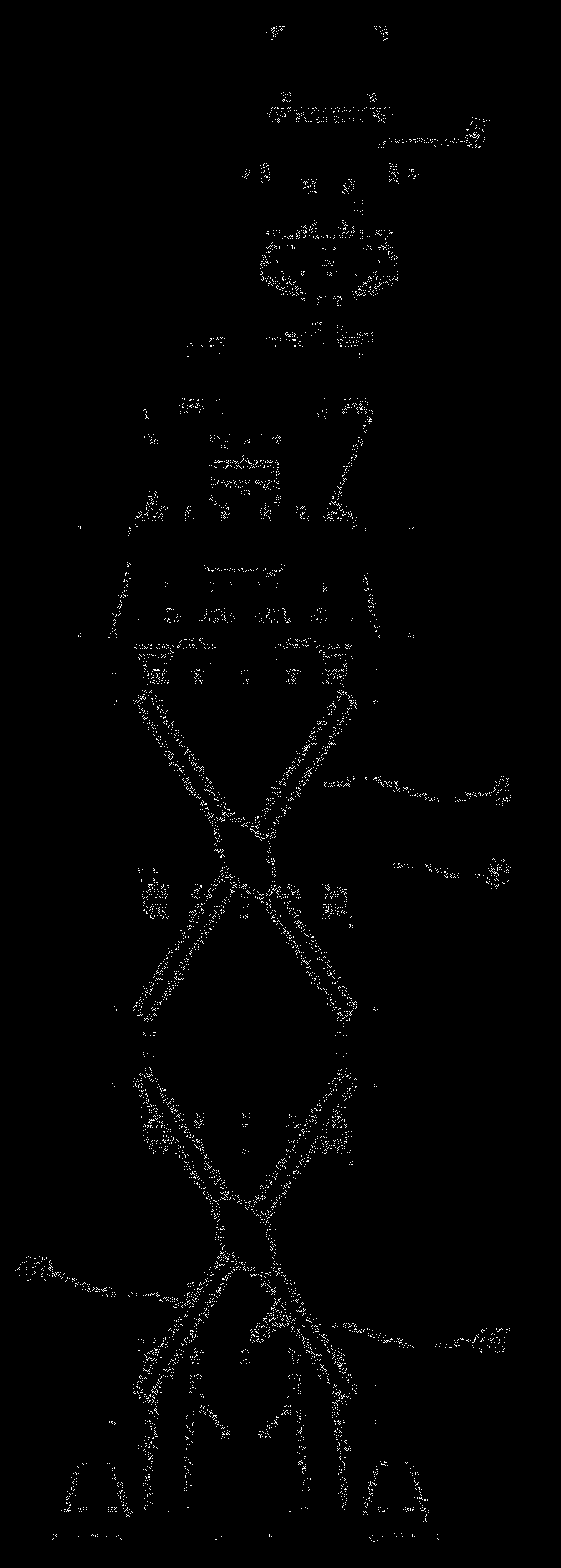

Friction stir welding tool for improving fluidity of plastic metal

PendingCN113996912AImprove liquidityImprove material flowWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringFriction stir welding

The invention belongs to the technical field of friction stir welding, and provides a friction stir welding tool for improving fluidity of plastic metal, comprising a cylindrical stirring head main body and a stirring needle, wherein the stirring head main body is provided with a shaft shoulder, and the front end of the shaft shoulder is provided with a storage hole; the stirring needle is detachably arranged on the storage hole, the front end head of the stirring needle is provided with three independent cutting edges, and the outer surface of each cutting edge is provided with a thread of an anticlockwise structure. Compared with the prior art, the stirring needle has the advantages that the stirring needle is provided with the three independent stirring needle cutting edges, each cutting edge is provided with the threads of the anticlockwise structure so that the material fluidity in the welding process can be improved, the stirring needle and the stirring head main body are designed in a separated mode, and follow-up operators can conveniently overhaul and replace the stirring needle.

Owner:MINTH AUTOMOTIVE TECH RES & DEV CO LTD

water mill

The invention discloses a water mill. The water mill comprises a rack, a stirring cavity and a speed reducer, wherein the stirring cavity is vertically mounted relative to the rack, the bottom and the top of the stirring cavity are separately provided with a feeding opening and a discharging opening, the outer side wall of the stirring cavity is provided with a cooling water inlet and a cooling water outlet, cooling water is arranged between the inner and outer walls of the stirring cavity, a rotating shaft is arranged in the stirring cavity, the top end of the rotating shaft is in power connection with the output end of the speed reducer, a first stirring disc and a second stirring disc are sequentially arranged on the rotating shaft in a sleeving manner from the top end to the bottom end, the first stirring disc and the second stirring disc are arranged in parallel, and clearances are separately arranged between the outer edges of the first stirring disc and the second stirring disc and the inner wall of the stirring cavity. The water mill is simple in structure and convenient to assemble and effectively improves stirring and pulverizing effects.

Owner:龙岩亿丰机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com