A hexagonal plug-in outer groove high-pressure compact drill pipe

A hexagonal, plug-in technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve the problem of limited smooth and slagging ability of triangular drill pipe body, increased difficulty of troubleshooting, and easy drilling and clamping. In case of problems such as sliding, it can achieve the effects of efficient slag discharge, improved mixing and crushing ability, and improved stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

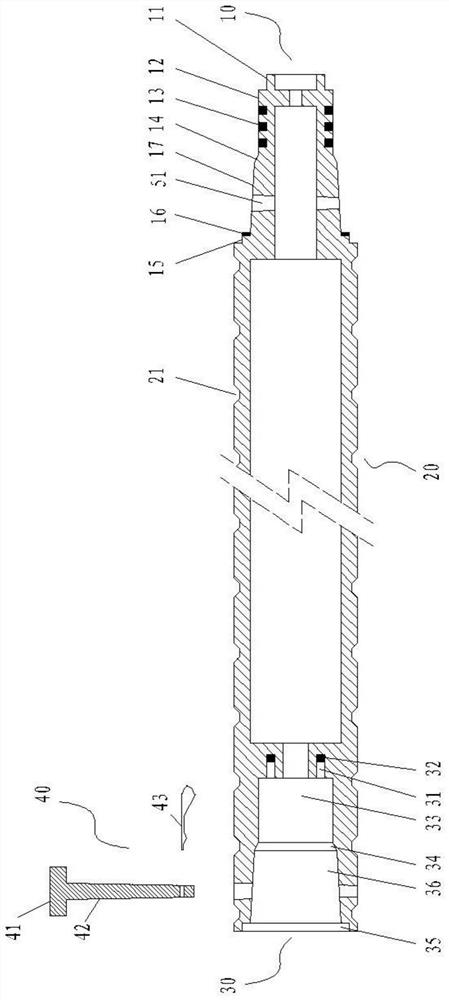

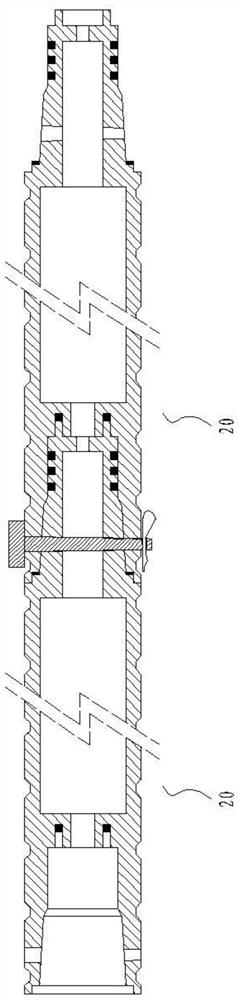

[0021] figure 1 A schematic diagram of the drill pipe structure; figure 2 It is a schematic diagram of the connection structure of adjacent drill pipes;

[0022] As shown in the figure: a hexagonal plug-in type external groove high-pressure dense drill pipe in this embodiment includes a male joint 10, a drill pipe body 20 and a female joint 30 connected in sequence, and is used to connect the male joint and the female joint. The connecting pin 40 of the drill pipe body 20 has a hexagonal structure, and the male joint 10 and the female joint 30 are radially provided with a connecting hole 51. When the male joint and the female joint are connected, the corresponding connecting hole of the male joint and the female joint The connecting holes corresponding to the joints are diametrically opposite to form the pin holes for the connecting pins to radially pass through to connect the male joint and the female joint. The inner side is the side close to the center of the drill pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com