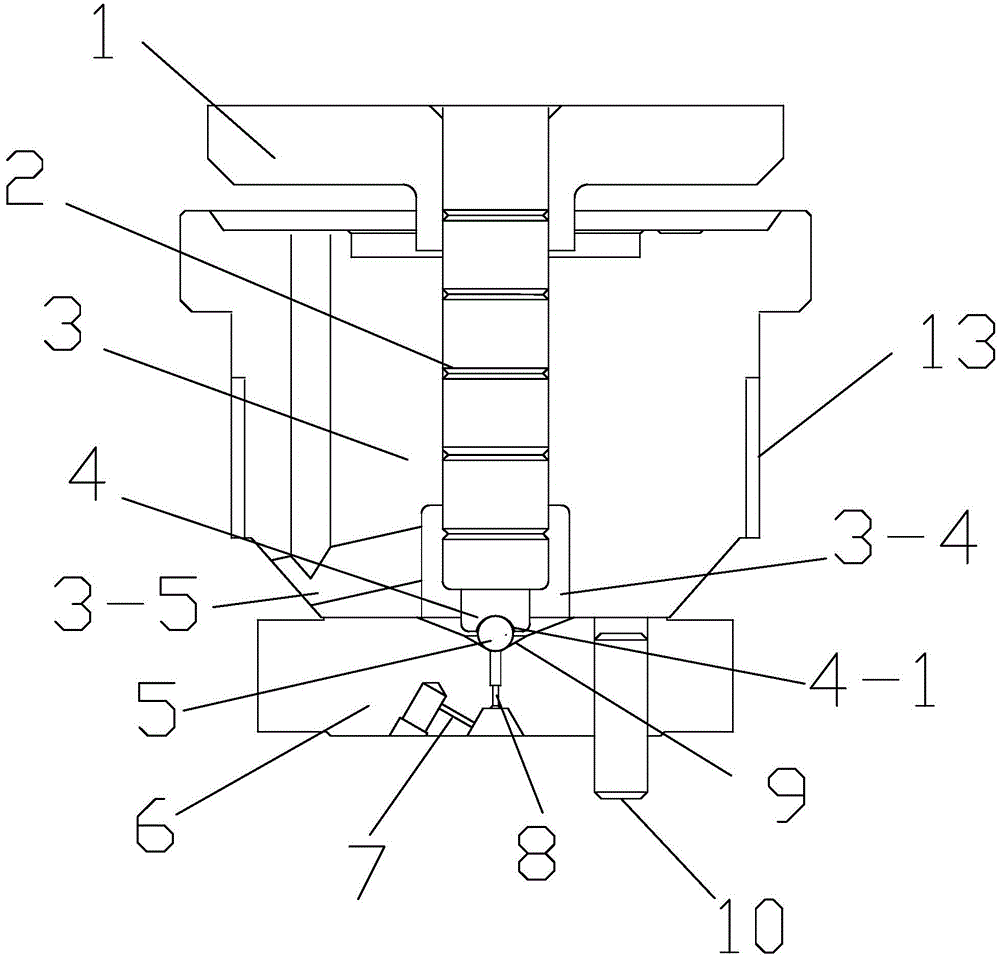

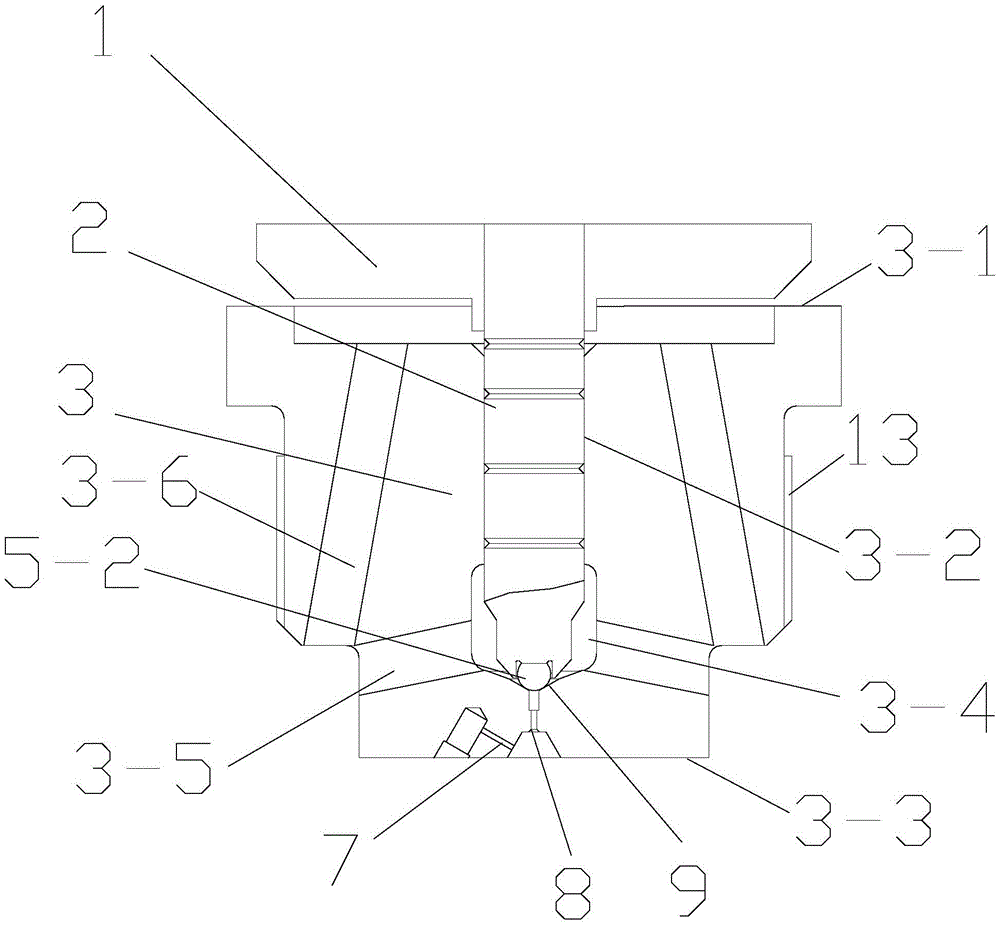

Integral control ball valve for common rail injector

A common rail fuel injector and ball valve control technology, which can be applied to machines/engines, fuel injection devices, engine components, etc., can solve the problems of high cost, high processing requirements, low qualification rate, etc., so as to improve reliability and reduce processing difficulty. , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

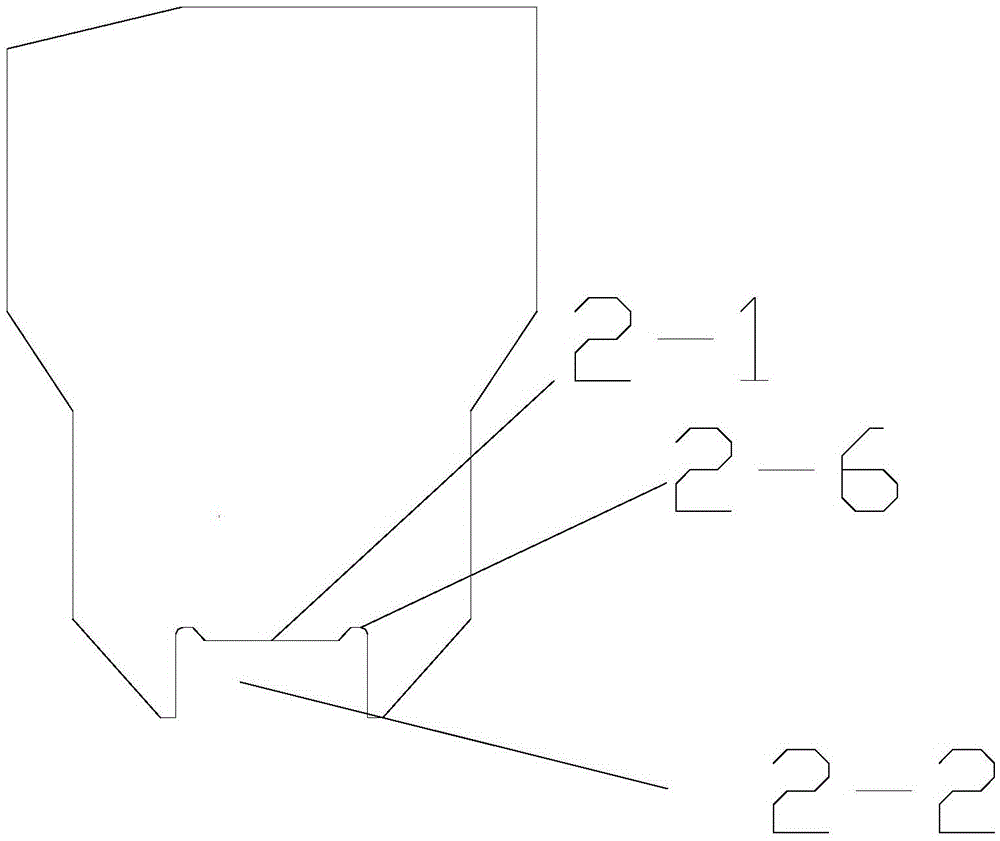

[0031] Such as Figure 5 , Image 6 Shown: the groove structure is the groove 2-2 provided on the lower end surface of the control rod 2. The integral control ball valve of the common rail fuel injector also includes a cylindrical boss 2-3 and a collar 11 whose height is higher than the boss 2-3. The boss 2-3 is located on the lower end surface of the control rod 2, and the boss 2 The central axis of -3 coincides with the central axis of the control rod 2, the diameter of the inner hole of the ring sleeve 11 is equal to the diameter of the boss 2-3 and the ring sleeve 11 is sleeved on the periphery of the boss 2-3, and the groove structure is a ring The inner hole of the sleeve 11 beyond the part of the boss 2-3 and the groove 2-2 formed by the boss plane 2-4.

Embodiment 2

[0033] Such as Figure 7 , Figure 8 Shown: the groove structure is the groove 2-2 provided on the lower end surface of the control rod 2. The integral control ball valve of the common rail fuel injector also includes an inner hole 2-5 and a pin 12 whose length is shorter than the depth of the inner hole 2-5. The inner contour of the part where the inner hole 2-5 is filled by the pin 12 matches, and the groove structure is the groove 2-2 formed by the space of the inner hole 2-5 not filled by the pin 12 and the pin end plane 12-1.

Embodiment 3

[0035] The groove structure is a groove 2-2 provided on the lower end surface of the control rod 2. This is also the easiest processing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com