Pressure-adjustable high-pressure limiting valve for common rail

An adjustable and restrictive valve technology, applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of large adjustable range of restricted pressure, inability to flexibly adjust opening pressure, inconvenience, etc., and achieve the effect of ensuring high-pressure sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

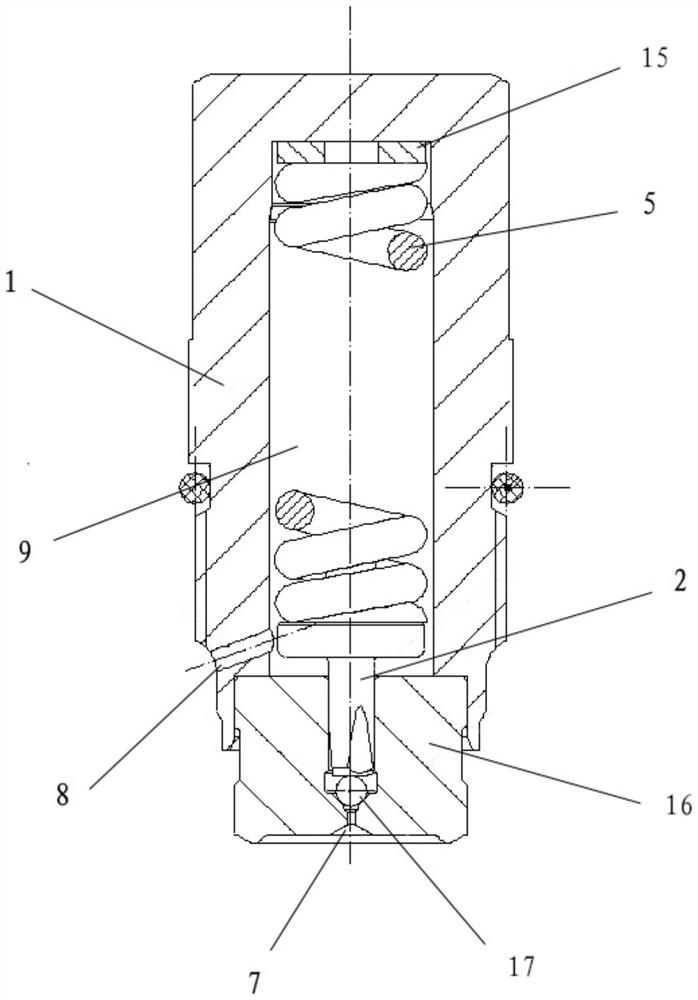

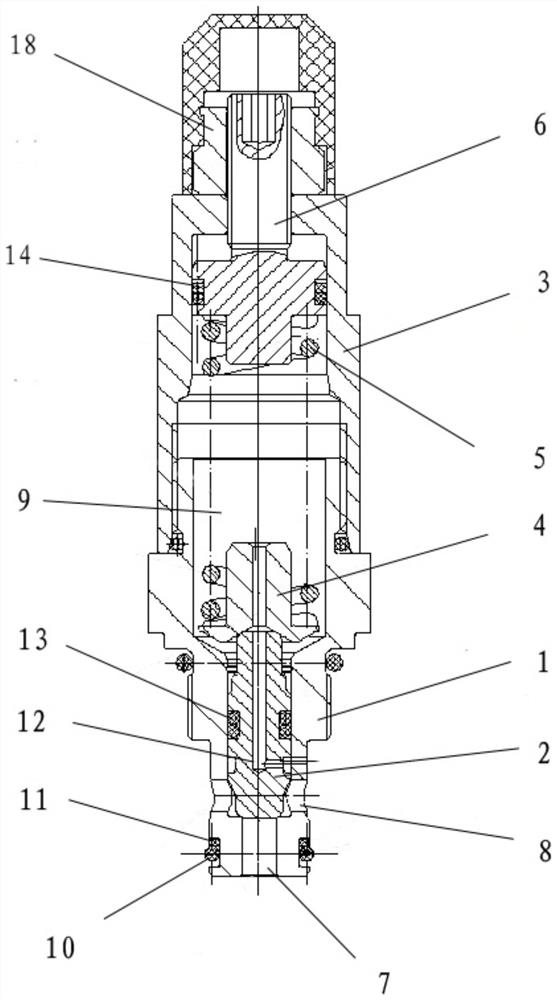

[0023] see figure 2 , the present invention provides a high-pressure limiting valve for adjustable pressure common rail, including a valve body 1, a valve core 2, a nut 3, a spring seat 4, a spring 5 and an adjusting bolt 6, and the valve body 1 and the nut 3 are With accommodating space, the nut 3 is detachably set on the valve body 1 , so that the nut 3 and the valve body 1 form a closed valve cavity 9 . The lower surface of the valve body 1 has an A hole 7 vertically, and the side wall of the valve body 1 has a B hole 8 horizontally, and the A hole 7 and the B hole 8 vertically meet and communicate with each other. The spool 2 is placed at the intersection of the A hole 7 and the B hole 8 and the A hole 7 is blocked, the spool 2 contacts and seals with the valve body 1 at the A hole 7, and the sealing surface is a tapered surface. A spring seat 4 is connected to the upper end of the valve core 2 for installing a spring 5 . The threaded cooperation between the adjusting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com