Directional drilling signal transmission drill pipe

A signal transmission and directional drilling technology, applied in directional drilling, drill pipe, drill pipe, etc., can solve the problems of the ability of the drill pipe to withstand torque, the strength cannot be effectively guaranteed, and the assembly and maintenance of the drill pipe are unfavorable. Achieve the effects of reducing loss along the process, preventing damage to the thread profile, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

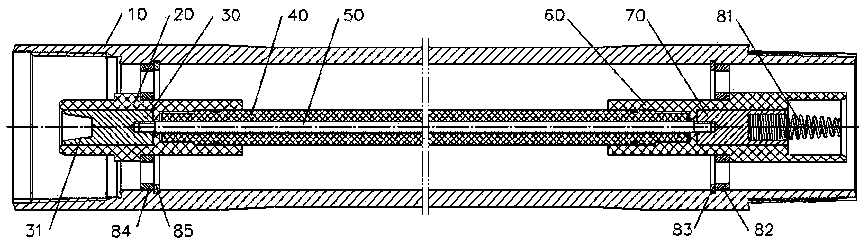

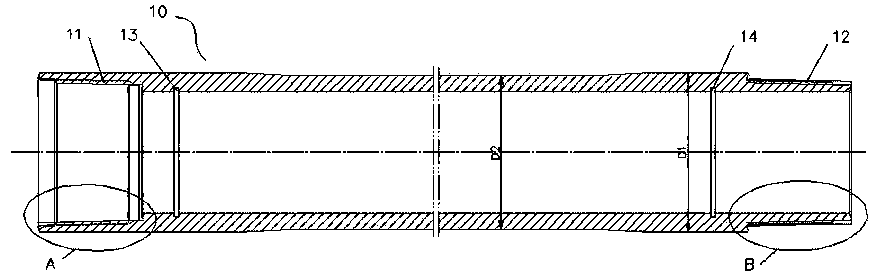

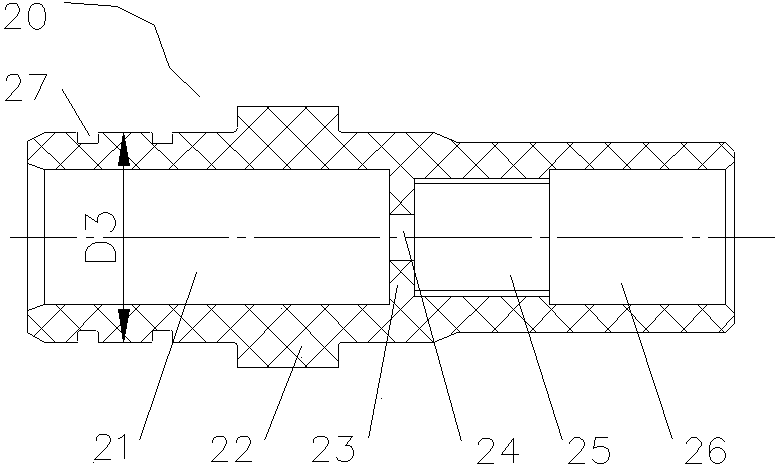

[0029] Such as figure 1 As shown, it is a schematic structural diagram of an embodiment of the directional drilling signal transmission drill pipe of the present invention. As shown in the figure, the directional drilling signal transmission drill pipe of this embodiment includes an outer pipe 10 and a locating frame erected in the outer pipe 10. In the cable assembly, the two ends of the outer tube 10 are respectively provided with mutually matching threaded connection structures, and the cable assembly includes a cable connector 20 and a cable connector 60 respectively arranged at the two ports of the outer tube 10, and respectively connected with the cable connector 20 and the cable connector 60. The core-protecting tube 40 fixedly connected to the tail of the inner side of the outer tube 10, the central cable 50 placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com