High-pressure quick-opening ball valve

A ball valve, high pressure technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problem of ball valve switching torque and switching time increase, the ball valve is difficult to meet the fast switching, the scope of application is small, etc., to reduce the torque, meet the Quick opening requirements and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below through specific examples.

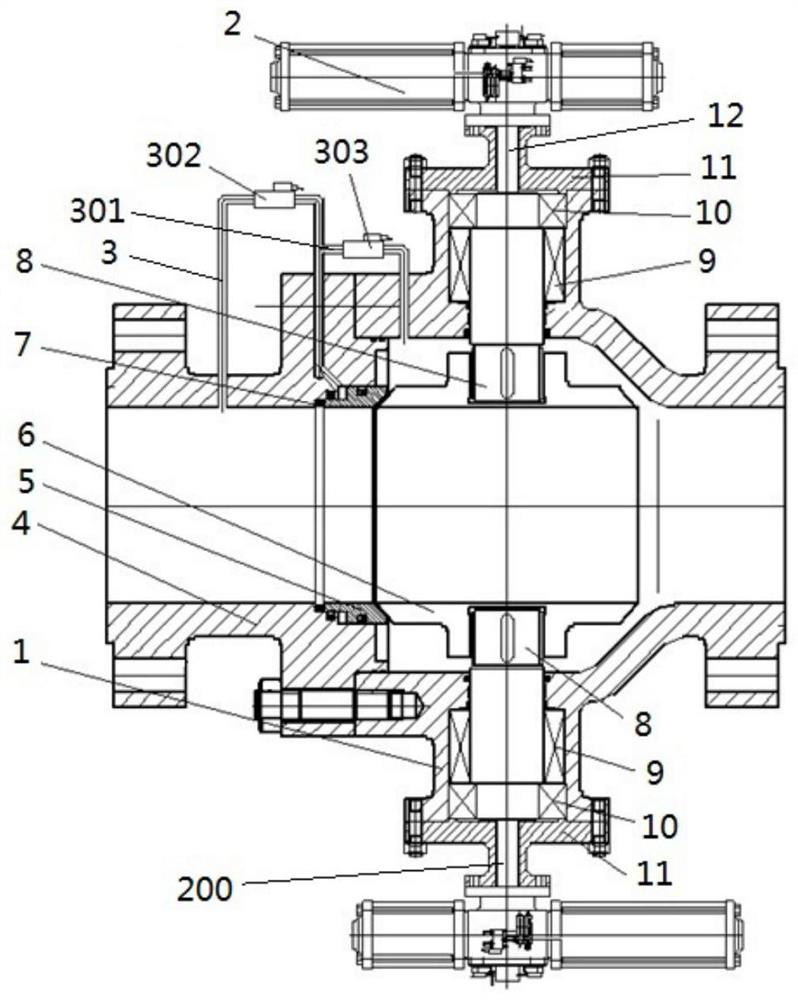

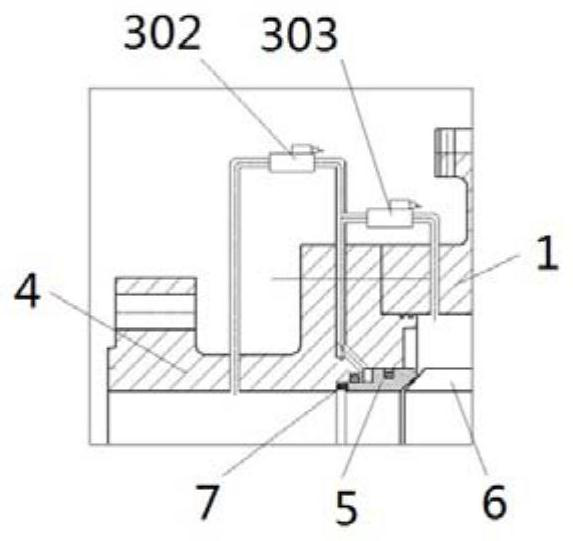

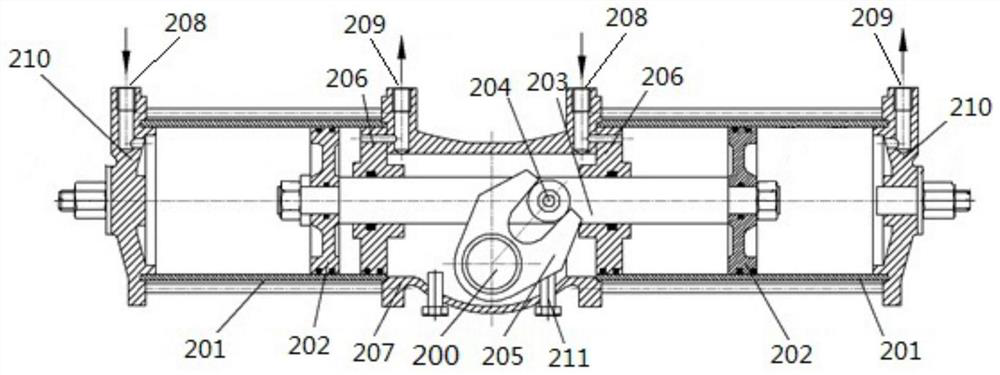

[0018] Such as Figure 1 to Figure 4 As shown, the high-pressure quick-opening ball valve includes a valve body 1, a valve cover 4 and an actuator 2. The valve body 1 includes a valve cavity and a ball 6 located in the valve cavity. The valve cover 4 is connected to the left side of the valve body 1 by bolts and nuts. The left side of the ball 6 is provided with a valve seat 5, and the valve cover 4 is provided with a medium inflow hole, and the outer peripheral surface of the valve seat 5 is tightly matched with the medium inflow hole of the valve cover 4. There is a medium outflow hole on the right side. The actuator 2 includes a rotating shaft 200. The ball 6 and the rotating shaft 200 are connected and rotated synchronously through the valve stem 8. An elastic member 7 is pressed between the valve seat 5 and the valve cover 4. The valve cover 4 A connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com