One-step forming method for high-low pressure bidirectional high-strength oil seal

A molding method and high-strength technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of high cost, many problems, limitations of applicability and practicability, etc., to reduce processing costs, and the method is reasonable and practical. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

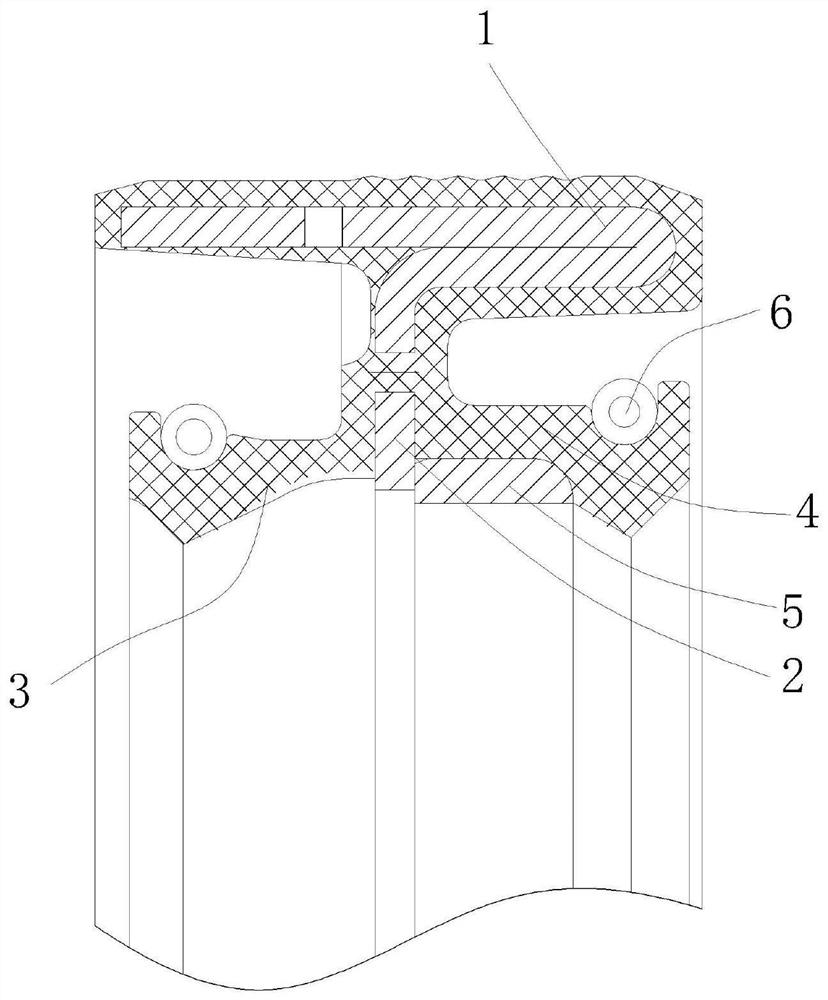

[0016]figure 1A specific embodiment of the present invention is shown in whichfigure 1A schematic structural diagram of the finished product of the present invention.

[0017]seefigure 1A high-pressure bidirectional high strength oil seal primary molding method, including a T-shaped outer skeleton and a vertical inner skeleton, including the following steps: Step A. Position the T-shaped outer skeleton 1 and the vertical inner skeleton 2 to make vertical The frame of the skeleton and the T-shaped skeleton is in the same straight line and there is a gap between the two;

[0018]Step B, inject rubber and bone gum to vulcanize, and wrap the T-shaped outer skeleton and vertical inner skeleton, forming the low pressure end 3 and the high voltage end 4, and the low pressure end and the high voltage end are in the vertical inner skeleton, respectively. side;

[0019]Step C, engage the support ring 5 in the inner side of the high voltage end;

[0020]Step D, the annular spring body 6 is attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com