Vitamin tablet raw material smashing-stirring production equipment

A raw material crushing and production equipment technology, which is applied in the direction of dissolution, grain processing, mixer, etc., can solve the problems of cumbersome drug ratio classification, crushing and mixing, poor drug mixing effect, and easy fatigue of workers, so as to improve the mixing effect and effect Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

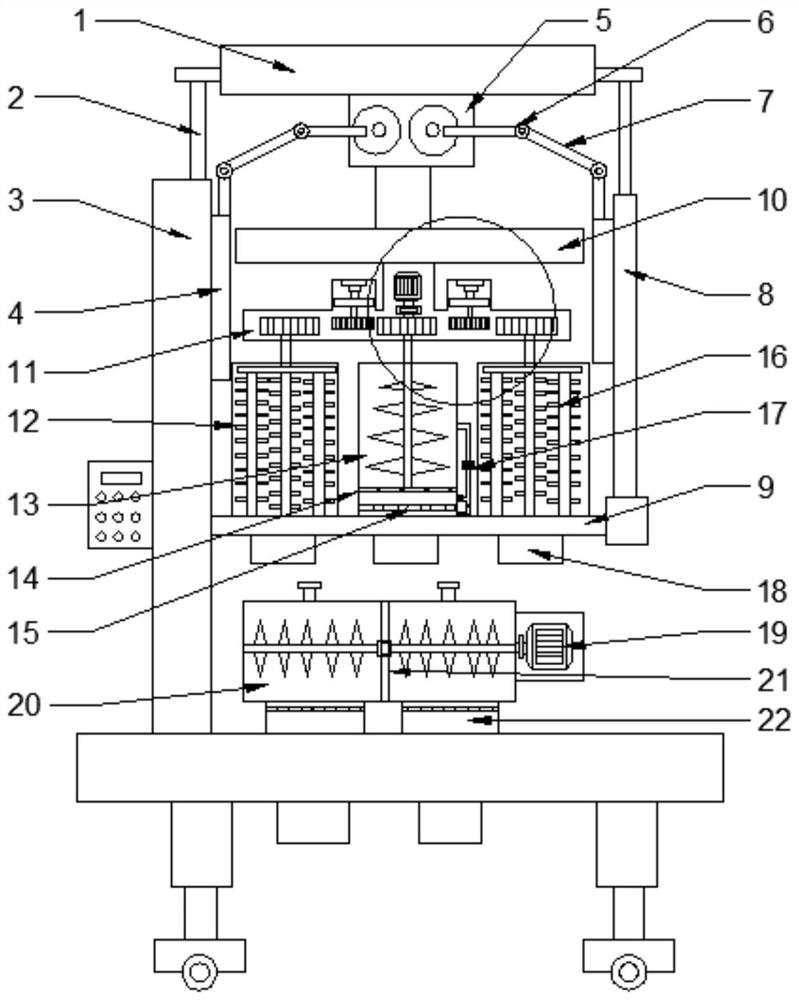

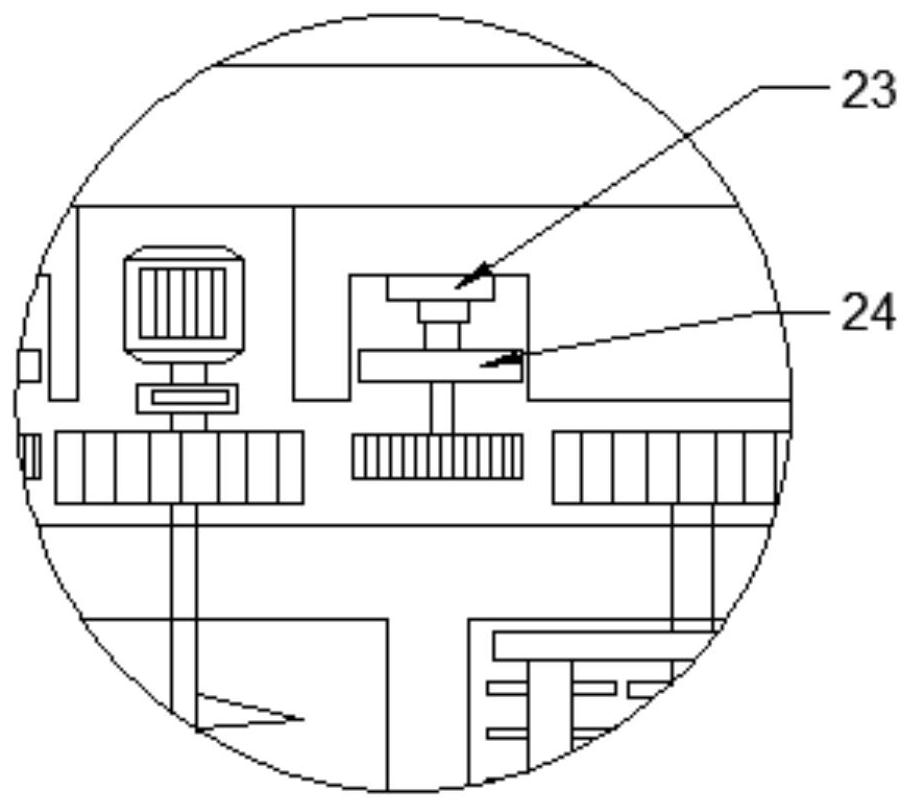

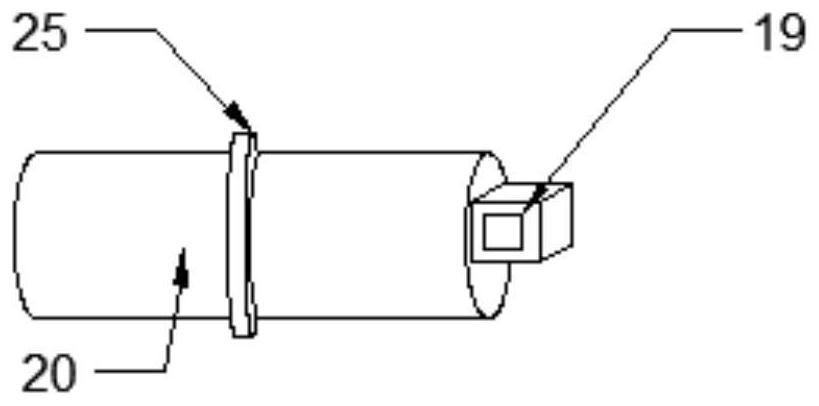

[0022] see Figures 1 to 3 , In the embodiment of the present invention, a vitamin tablet raw material crushing and stirring production equipment includes an installation frame 3; a bottom plate 9 is installed on one side of the installation frame 3; one end of the base plate 9 away from the installation frame 3 is fixedly installed with a side plate 8; The top of the bottom plate 9 is sequentially provided with a No. 1 mixing box 12, a coating liquid mixing box 13 and a No. 2 mixing box 16 according to the distance from the mounting frame 3 from near to far; the mounting frame 3 and the side A stirring adjustment mechanism is installed on the plate 8; a stirring mechanism is installed at the bottom end of the stirring adjustment mechanism; the bottom end of the bottom plate 9 corresponds to the No. 1 mixing box 12, the coating liquid mixing box 13 and the No. 2 mixing box 16 A receiving box 18 is provided; the mounting frame 3 is mounted on the top of the base; a screen box 2...

Embodiment 2

[0030] see figure 1 , the bottom of the base is equipped with a moving mechanism; the moving mechanism includes a hydraulic lifting rod; the hydraulic lifting rod is provided with at least four; the bottom of the hydraulic lifting rod is equipped with a lifting box; There is a lifting mechanism; the bottom end of the lifting mechanism is correspondingly connected with a moving wheel; the lifting mechanism can be any type of lifting mechanism in the prior art; through the setting of the lifting mechanism, the moving wheel can be received inside the lifting box; Through the setting of the hydraulic lifting rod, the height of the device can be adjusted to reduce the fatigue of the workers, and it is suitable for workers of different heights.

[0031] The working principle of the present invention is: through the setting of the partition plate 21, the screen box 22, the screen and the crushing mechanism, it is convenient to crush multiple raw materials at the same time, and it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com