Chemical raw material stirring device

A stirring device and technology for chemical raw materials, applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of poor stirring effect, inability to stir the top layer of material and the bottom layer of material, etc., to achieve convenient operation and good supporting effect , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

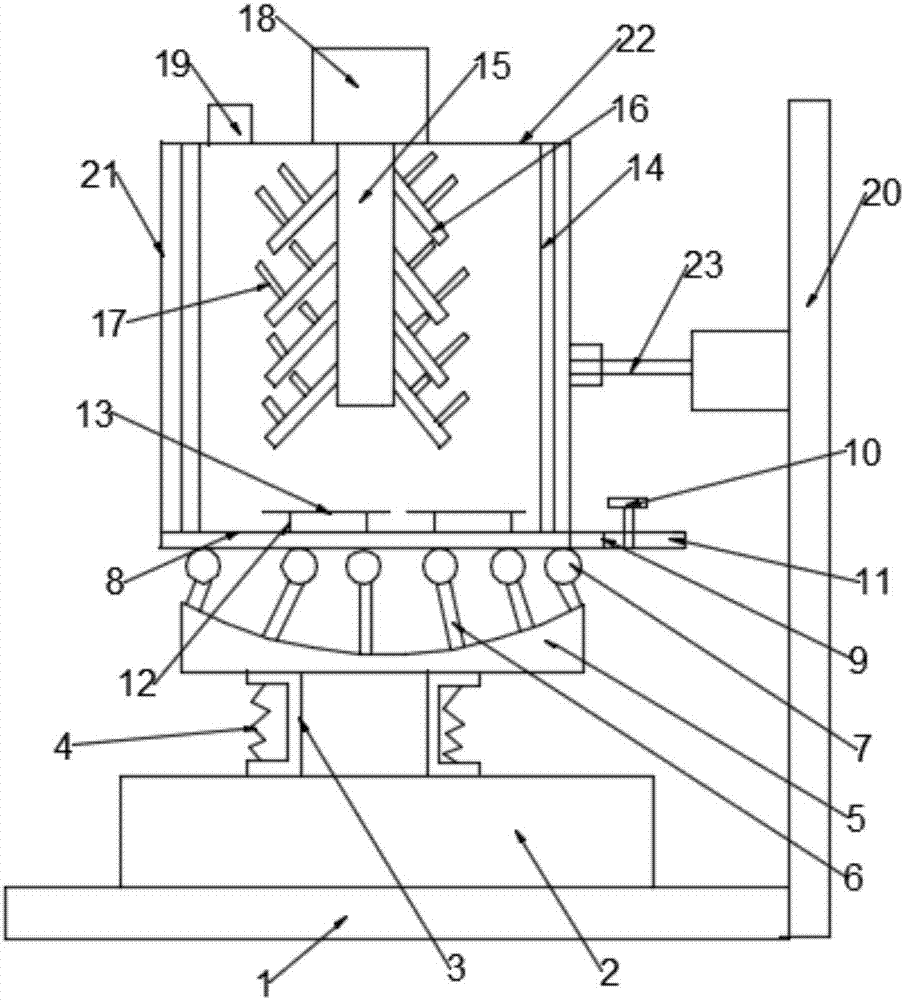

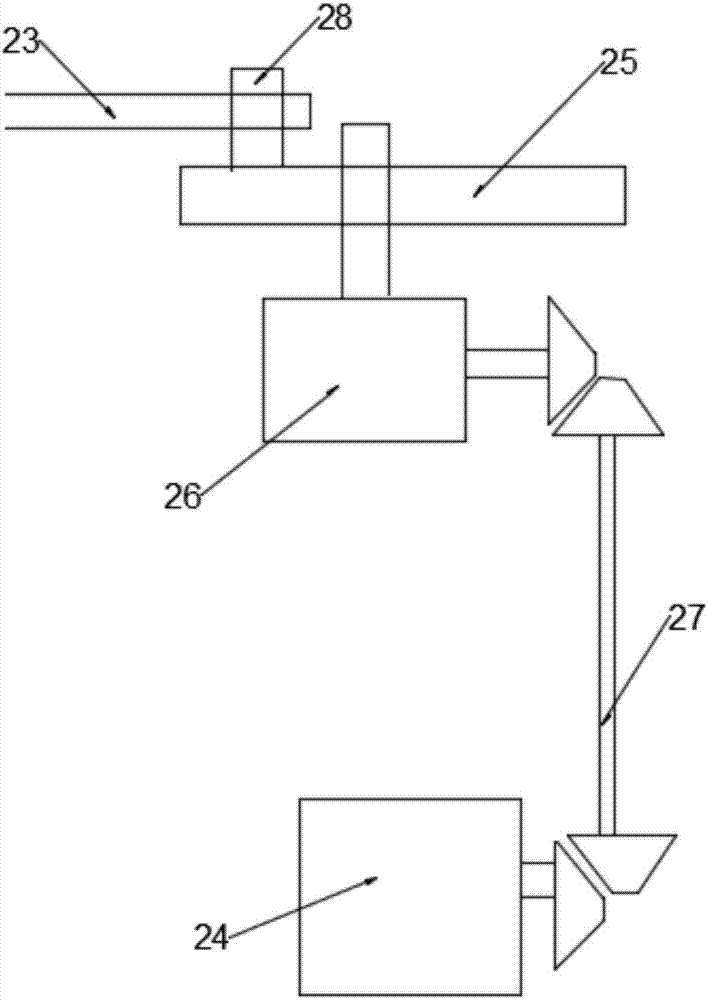

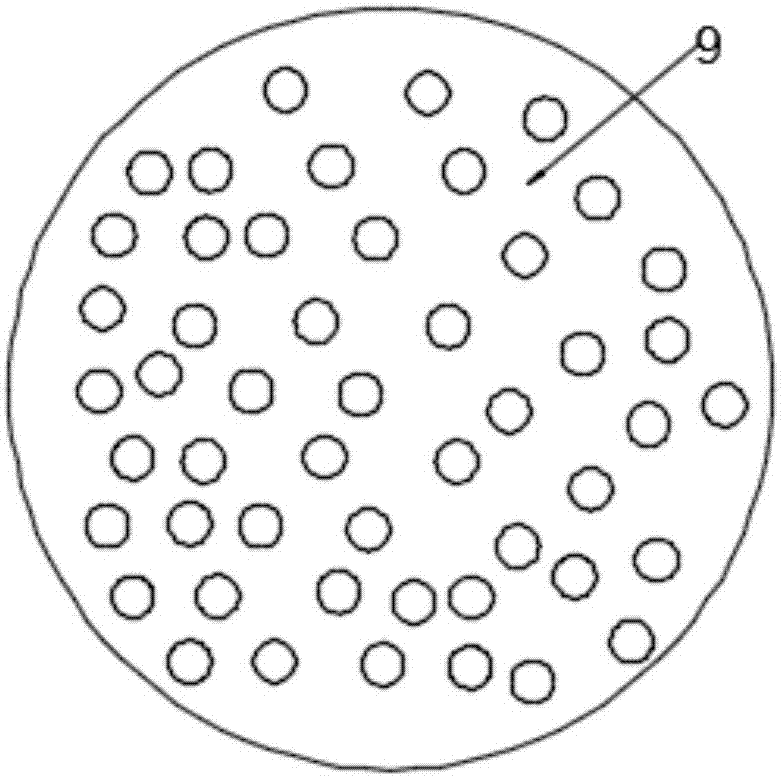

Embodiment 1

[0020] A stirring device for chemical raw materials, comprising a base 1, a stirring body 21 and a stirring device, the upper end of the base 1 is provided with a first fixed block 2, and buffer plates 3 are installed on both sides of the upper end of the first fixed block 2, and the buffer plate 3 The shape is inverted U-shaped and each buffer plate 3 is provided with a buffer spring 4, a second fixed block 5 is installed on the upper end of the buffer plate 3, a roller 7 is installed on the second fixed block 5, and the bottom of the stirring body 21 is in contact with the roller 7. contact, the upper end of the stirring body 21 is provided with a feed inlet 19 and a stirring motor 18, one side of the stirring body 21 bottom is provided with a discharge pipe 11, and a stirring device is arranged in the stirring body 21, and the stirring device includes a stirring shaft 15, a stirring wheel 16 and stirring member 17, stirring shaft 15 is connected with the output end of stirri...

Embodiment 2

[0022] A stirring device for chemical raw materials, comprising a base 1, a stirring body 21 and a stirring device, the upper end of the base 1 is provided with a first fixed block 2, and buffer plates 3 are installed on both sides of the upper end of the first fixed block 2, and the buffer plate 3 The shape is inverted U-shaped and each buffer plate 3 is provided with a buffer spring 4, the upper end of the buffer plate 3 is equipped with a second fixed block 5, the second fixed block 5 is equipped with a roller 7 through a fixed column 6, and the bottom of the stirring body 21 In contact with the roller 7, the upper end of the stirring body 21 is provided with a feed inlet 19 and a stirring motor 18, one side of the bottom of the stirring body 21 is provided with a discharge pipe 11, and a stirring device is arranged in the stirring body 21, and the stirring device includes a stirring shaft 15. The stirring wheel 16 and the stirring member 17, the stirring shaft 15 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com