Material crushing mixer

A technology for mixers and materials, applied to mixers with rotating agitation devices, mixers, grain processing, etc., can solve the problems of affecting the pulverization and mixing effect, easy to cause clogging, complex structure, etc., achieve good pulverization and mixing effect, and avoid clogging , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

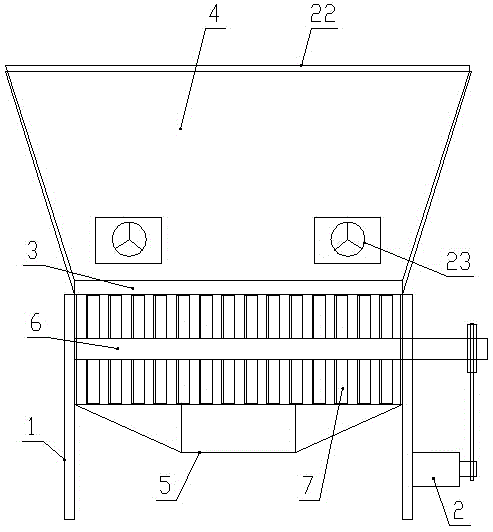

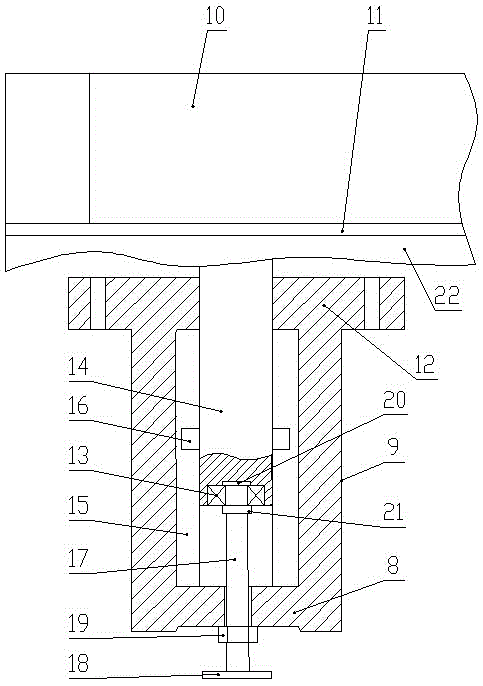

[0017] Such as figure 1 and figure 2 As shown, the material pulverizing mixer of the present invention comprises a frame 1, the left or right side of the frame 1 is provided with a motor 2, the frame 1 is provided with a crushing and mixing box 3 with an open top, and the top of the pulverizing and mixing box 3 A feed hopper 4 is provided, and the feed hopper 4 is a conical structure with a large top and a small bottom. The bottom of the pulverizing and mixing box 3 is provided with a discharge chute 5, and the horizontal rotation of the pulverizing and mixing box 3 is provided with a stirring shaft 6. A plurality of stirring rods 7 are evenly and vertically arranged on the shaft 6 along the axial direction and the circumferential direction, and the motor 2 is connected with the transmission at one end of the stirring shaft 6. The stirring rod 7 is made of angle iron, and the two sides of the angle iron are respectively connected with The axial direction of the stirring shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com