Feeding device for production of grinding tool

A technology of feeding device and abrasive tool, applied in mixers with rotary stirring device, transportation and packaging, dissolving and other directions, can solve problems such as affecting the production progress of abrasive tools, jamming, etc. Controllable, good crushing and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

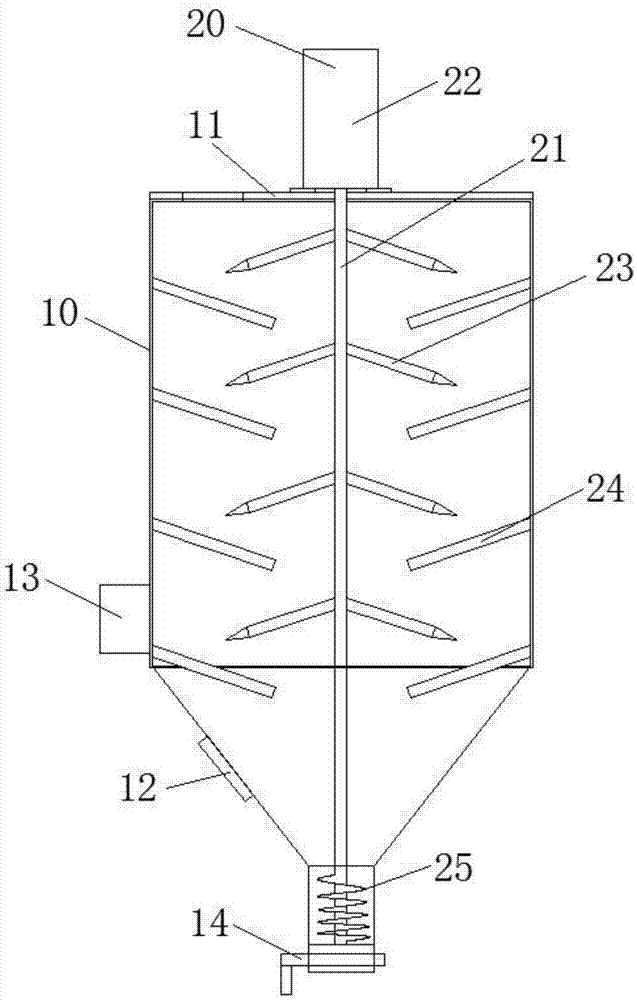

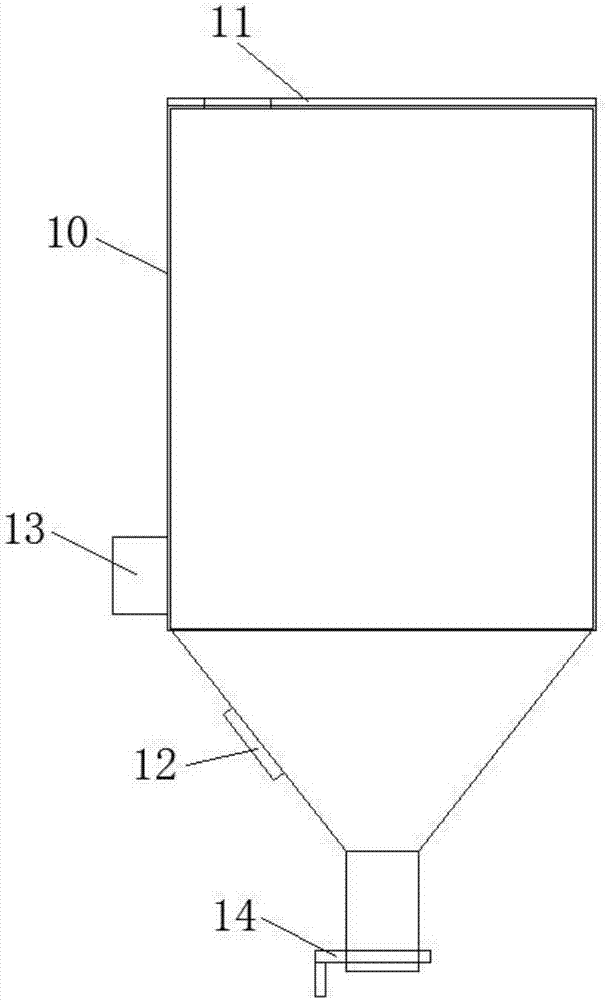

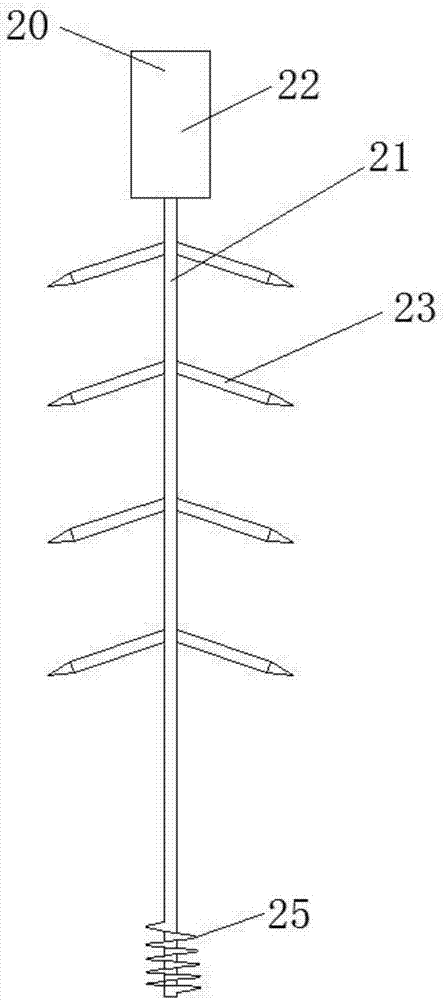

[0022] see figure 1 , the feeding device for abrasive tool production of the present invention includes a feeding tank 10 and a stirring assembly 20, the upper and lower parts of the feeding tank 10 are respectively provided with a feeding port and a discharge port, and the stirring assembly 20 is arranged on the feeding tank within 10.

[0023] see figure 2 , The top of the feeding tank 10 in this embodiment is preferably provided with a cover plate 11 , and the feeding port is opened on the cover plate 11 . In order to facilitate the material to slide downward, the lower part of the feeding tank 10 in this embodiment is preferably set in a funnel shape.

[0024] In order to clean out the materials remaining in the feeding tank 10 , in this embodiment, a material cleaning port is preferably provided at the lower part of the feeding tank 10 , and a material cleaning plate 12 is provided on the upper cover of the material cleaning port. When the feeding tank 10 is not used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com