Mixed flow stirring soybean milk machine

A soymilk machine and mixed-flow technology, which is used in household appliances, applications, kitchen utensils, etc., can solve the problems of affecting the effect of crushing and stirring, inconvenient processing, and insufficient heating, so as to improve the effect of nutrient intake and ensure the efficiency of material utilization. , to ensure the effect of crushing and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments.

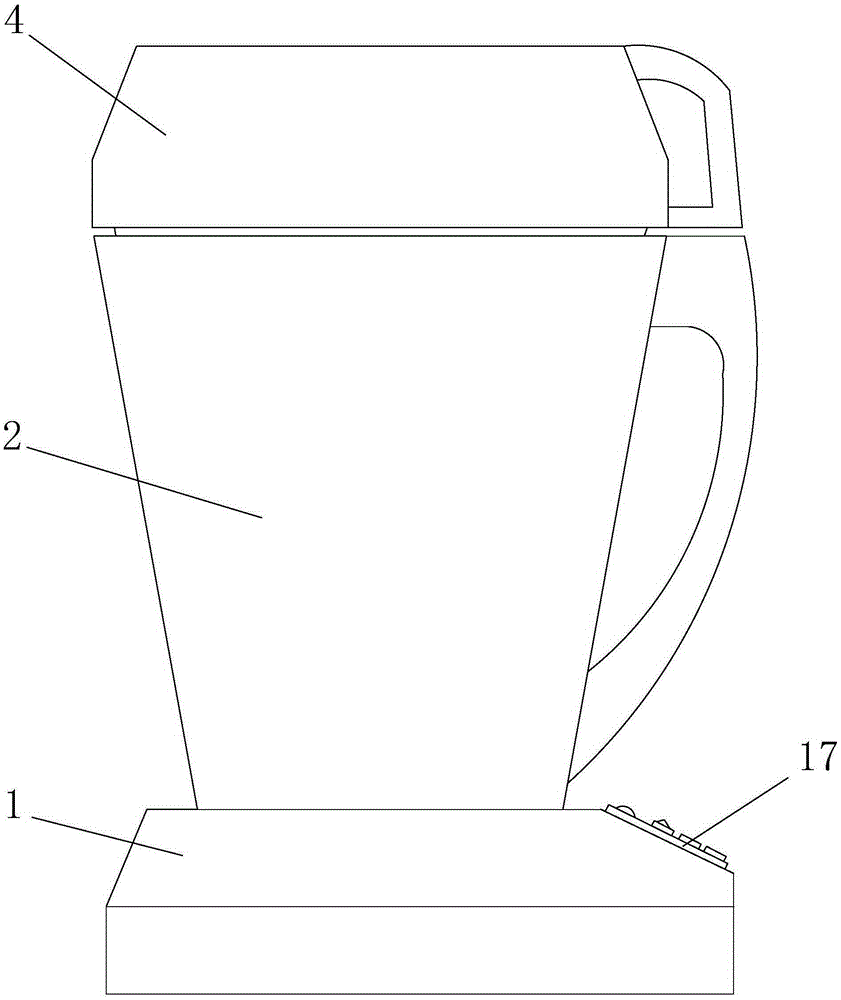

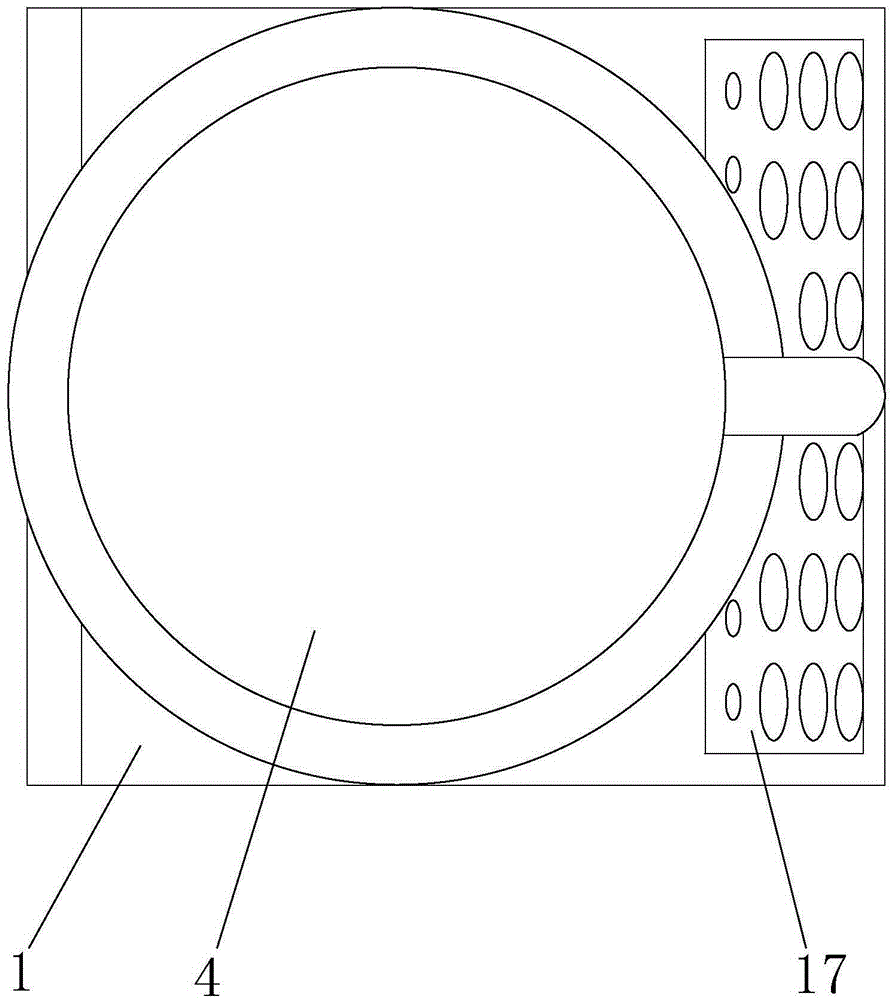

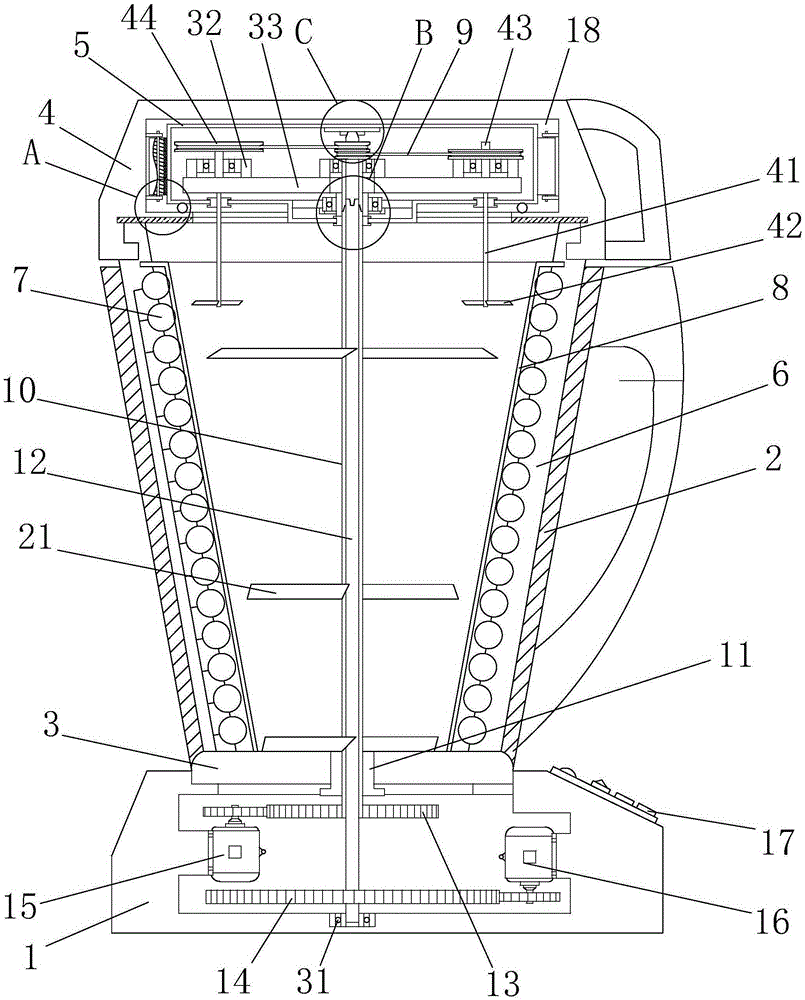

[0039] Such as Figure 1-8As shown, the mixed-flow stirring soybean milk machine includes a base 1, an outer barrel body 2, a barrel body fixing plate 3, a barrel cover 4, and a stirring rotating disk 5. The inner wall of the outer barrel body 2 is provided with a heat-insulating barrel 6, and a heat-insulating barrel 6 There are multiple heating tubes 7 arranged inside, and the inner side of the heating tube 7 is provided with a heating barrel 8 in close contact with it. The bottoms of the outer barrel body 2, the heat insulation barrel 6, and the heating barrel 8 are fixed on the base 1 through the barrel body fixing plate 3, The center of the barrel body fixing plate 3 runs through an outer rotation sleeve shaft 10, and the part where the outer rotation sleeve shaft 10 penetrates the barrel body fixing plate 3 is covered with a sealing ring 11, and the inner rotation sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com