Friction stir welding tool for improving fluidity of plastic metal

A friction stir welding and fluidity technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of reducing the shear strength and peel strength of joints, poor fluidity of plastic metal, etc., to facilitate maintenance and replacement. , The effect of increasing material fluidity and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

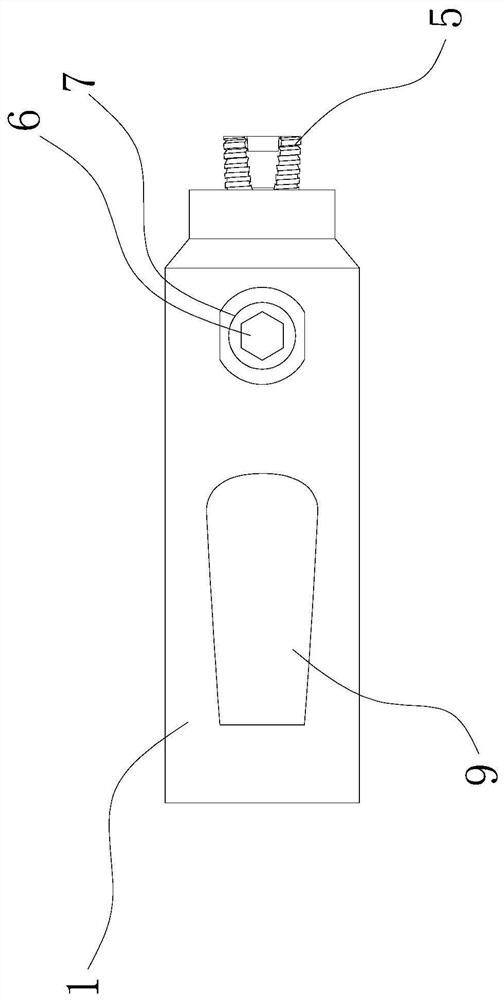

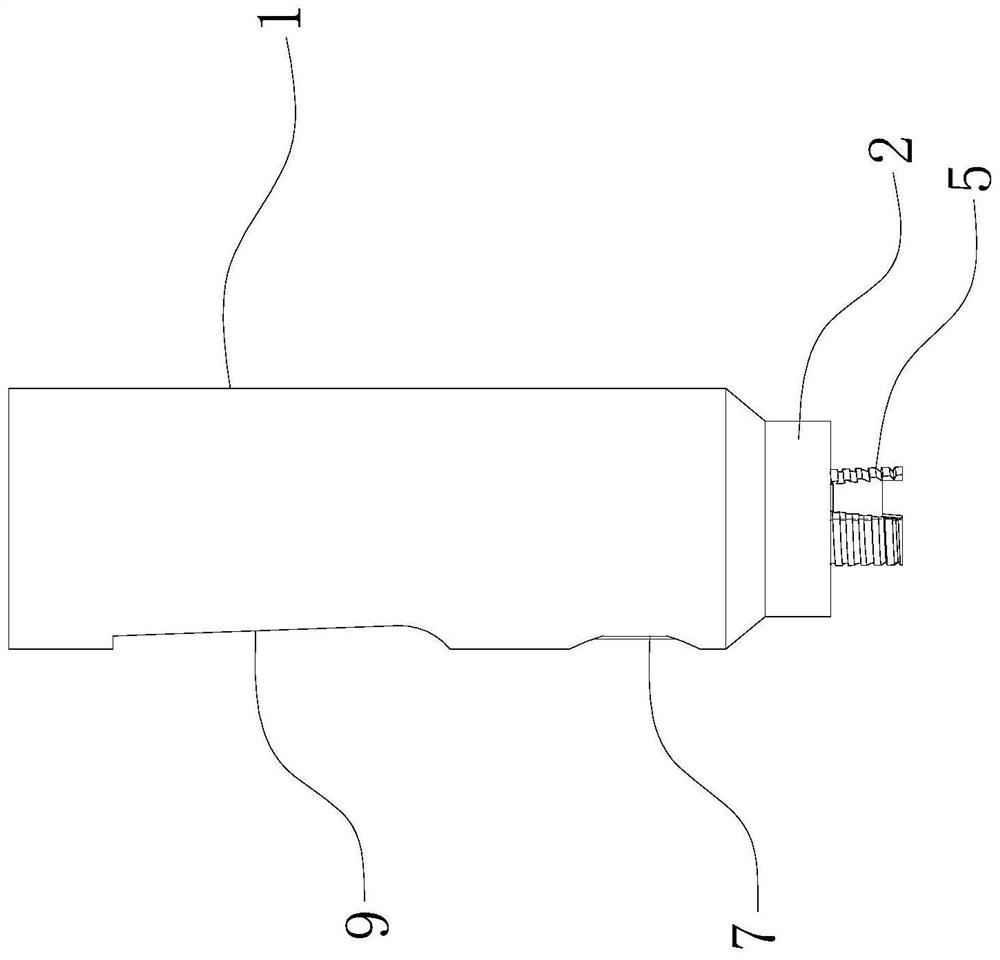

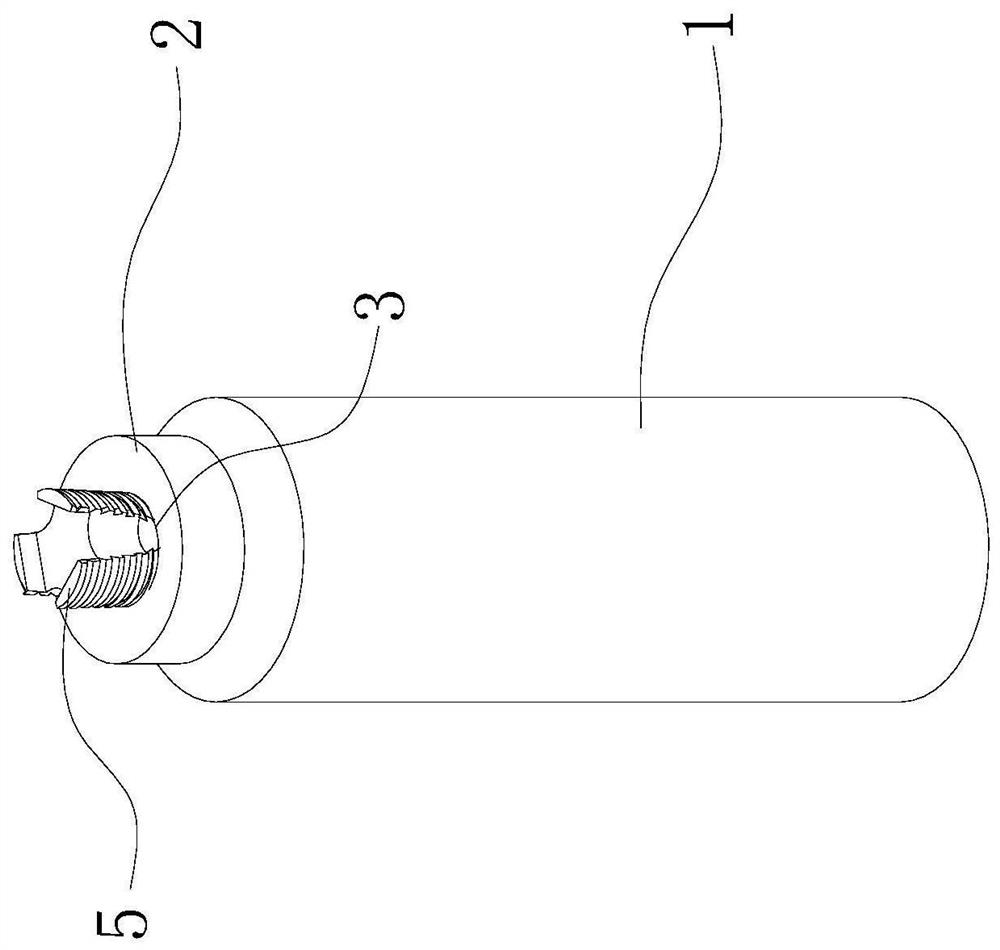

[0022] Such as Figure 1-Figure 4 As shown, the friction stir welding tool for improving the fluidity of plastic metals comprises: a stirring head main body 1, which is cylindrical in shape, the stirring head main body 1 has a shaft shoulder 2, and a storage hole 3 is provided at the front end of the shaft shoulder 2; The needle 4 is detachably installed on the object hole 3. The front end of the stirring needle 4 has three independent cutting edges 5, and each cutting edge 5 has a counterclockwise thread on the outer surface.

[0023] Stirring needle 4 and stirring head main body 1 are connected by screw 6, wherein stirring needle 4 and stirring head main body 1 have the same rotation speed and moving direction during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com