Crusher with joint filling function for traffic road and bridge construction

A traffic road bridge and crusher technology, applied in roads, roads, road repair and other directions, can solve the problems of poor use effect, poor crushing and mixing effect, etc., and achieve the effects of convenient construction and use, good crushing effect and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

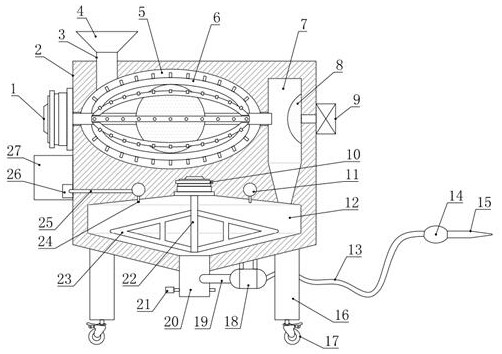

[0030] see figure 1 , in an embodiment of the present invention, a crusher for traffic road and bridge construction with a caulking function, comprising a body 2, a crushing cavity 5 is opened on the inner upper part of the body 2, the crushing cavity 5 is an ellipsoidal structure, and the crushing cavity 5 is installed with a crushing mechanism 6, and the crushing mechanism 6 is driven to rotate by the first motor 1 installed on the left side wall of the body 2, and the right side of the crushing chamber 5 is provided with a settling chamber 7, and the lower part of the settling chamber 7 is Conical, the crushing chamber 5 communicates with the settling chamber 7 through the crushing mechanism 6, the negative pressure fan 9 corresponding to the level of the crushing mechanism 6 is installed on the right side wall of the body 2, and the connecting port between the negative pressure fan 9 and the settling chamber 7 There is also a material blocking screen 8 protruding from the ...

Embodiment 2

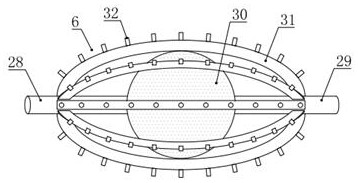

[0036] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

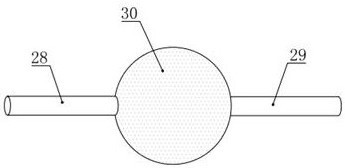

[0037] In this example, if figure 2 with 3 As shown, the crushing mechanism 6 includes a support shaft 28, a support pipe 29, a spherical filter screen 30, an arc crushing rod 31 and a crushing tooth 32. The support shaft 28 and the support pipe 29 are coaxially arranged, and the support shaft 28 and the support The tubes 29 are all rotatably connected with the body 2, and a spherical filter screen 30 is installed and fixed between the support shaft 28 and the support tube 29, and the inner wall of the spherical filter screen 30 is also provided with a convex edge (not shown) that allows the material to move to the support tube 29. out), and the support tube 29 communicates with the inner cavity of the spherical filter 30, the other end of the support tube 29 extends into the settling chamber 7, and the inner cavity of the spherical filter 30 communicates with the settling cavity 7 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com