Modular container type distributing station

A container-type, container-based technology, applied in the field of batching stations, can solve the problems of low probability of design and production reuse, complex on-site construction, long installation period, etc., and achieve the effect of reducing design and production costs, reducing construction costs, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

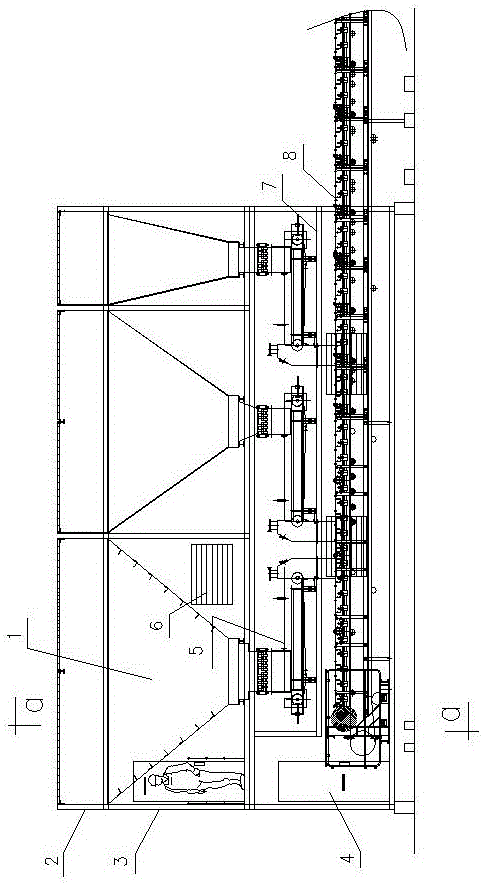

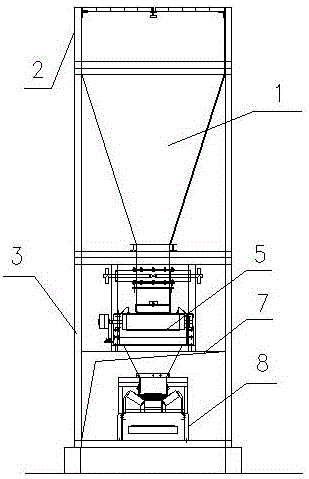

[0014] see figure 1 , figure 2 , a modular container-type batching station, the batching bin 1 is a three-hopper structure, including clinker bins, mixed material bins and gypsum bins, the bins are 20, 17, and 8 cubic meters respectively, and the bin body is directly integrated with the container The design of the clinker warehouse, the mixed material warehouse and the gypsum warehouse is integrated in a 40GP container 3. The specifications of the 40GP container 3 are: length 12.192m, width 2.438m, height 2.896m; the upper straight section of the third warehouse is The detachable baffle 2 structure is used for on-site assembly; the quantitative feeder 5 and its support platform 7 at the lower part of the three-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com