Breaking and recovery device of plastic housing of electronic product

An electronic product and recycling device technology, applied in the field of electronic product plastic casing crushing and recycling device, can solve the problems of inaccurate crushing and long-time crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

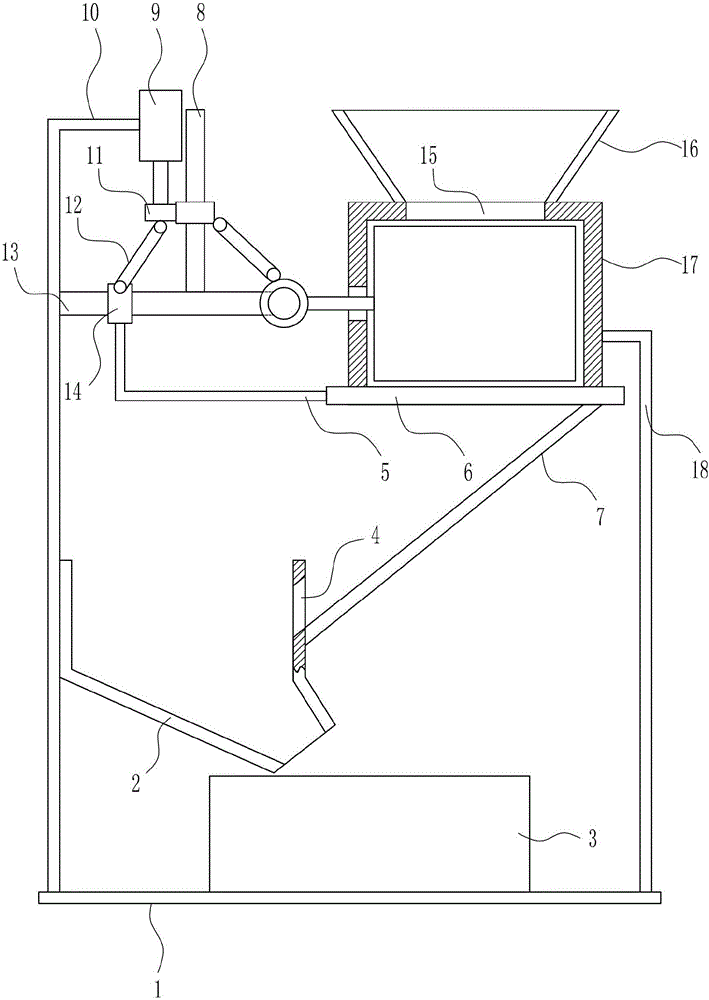

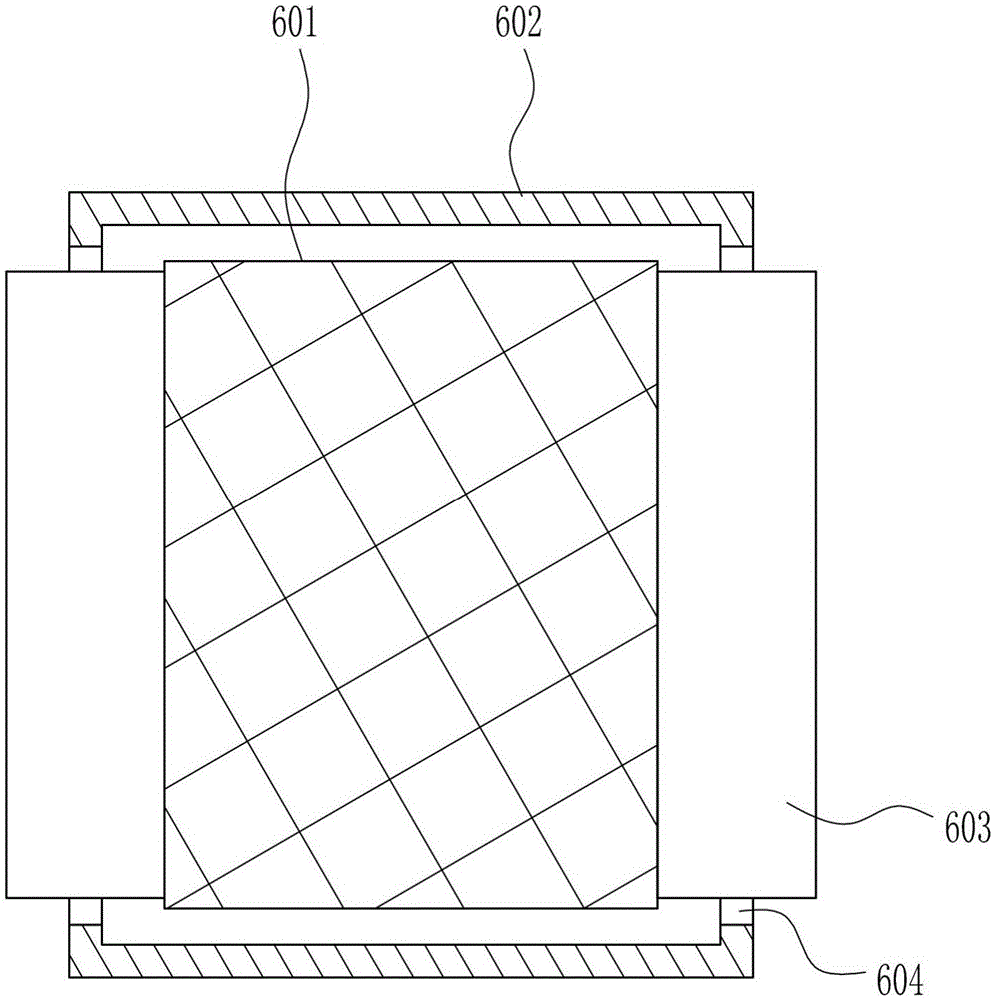

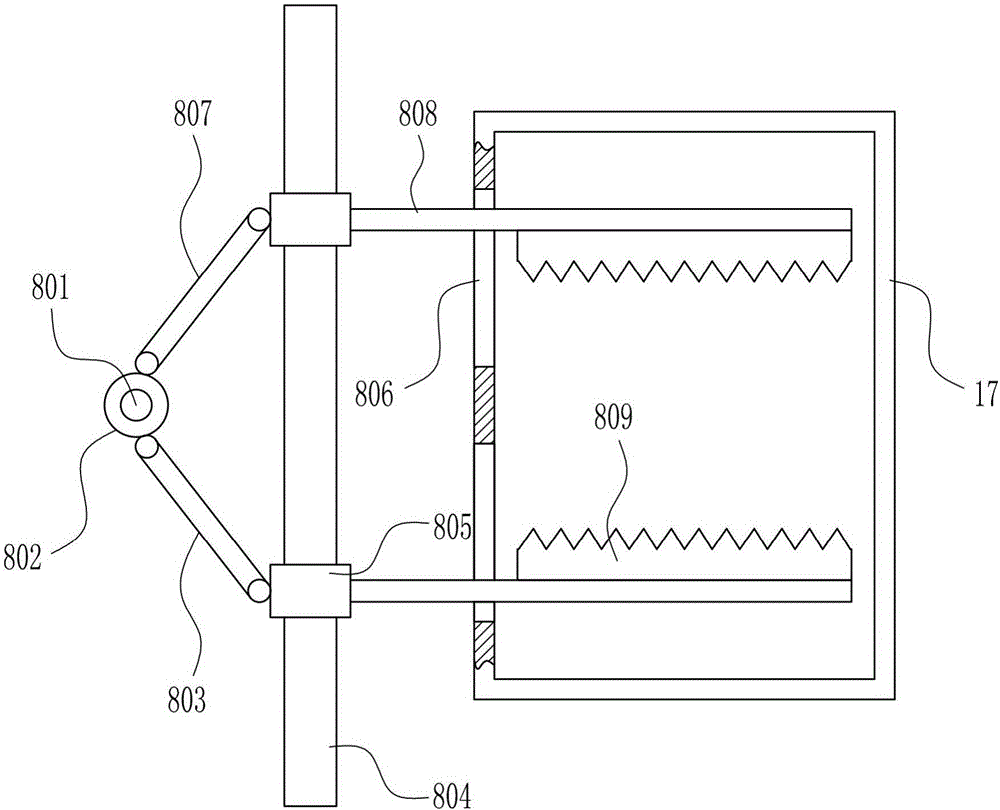

[0042] A crushing and recycling device for plastic shells of electronic products, such as Figure 1-8 As shown, it includes a bottom plate 1, a lower funnel 2, a collection tank 3, a moving frame 5, a feeding device 6, a guide groove 7, an extrusion device 8, a cylinder 9, a left bracket 10, a moving block 11, a swing rod 12, a second Three guide rods 13, a third sliding sleeve 14, a feed hopper 16, a crushing trough 17 and a right bracket 18, a collection tank 3 is placed in the middle of the top of the bottom plate 1, a left bracket 10 is arranged at the left end of the top of the bottom plate 1, and the left bracket 10 is arranged at an end There is a cylinder 9, the bottom end of the cylinder 9 is connected with a moving block 11, a third guide rod 13 and a lower funnel 2 are arranged on the left side of the left bracket 10, the lower funnel 2 is located below the third guide rod 13, and the upper right wall of the lower funnel 2 is arranged There is a through hole 4, the ...

Embodiment 2

[0044] A crushing and recycling device for plastic shells of electronic products, such as Figure 1-8 As shown, it includes a bottom plate 1, a lower funnel 2, a collection tank 3, a moving frame 5, a feeding device 6, a guide groove 7, an extrusion device 8, a cylinder 9, a left bracket 10, a moving block 11, a swing rod 12, a second Three guide rods 13, a third sliding sleeve 14, a feed hopper 16, a crushing trough 17 and a right bracket 18, a collection tank 3 is placed in the middle of the top of the bottom plate 1, a left bracket 10 is arranged at the left end of the top of the bottom plate 1, and the left bracket 10 is arranged at an end There is a cylinder 9, the bottom end of the cylinder 9 is connected with a moving block 11, a third guide rod 13 and a lower funnel 2 are arranged on the left side of the left bracket 10, the lower funnel 2 is located below the third guide rod 13, and the upper right wall of the lower funnel 2 is arranged There is a through hole 4, the ...

Embodiment 3

[0047] A crushing and recycling device for plastic shells of electronic products, such as Figure 1-8 As shown, it includes a bottom plate 1, a lower funnel 2, a collection tank 3, a moving frame 5, a feeding device 6, a guide groove 7, an extrusion device 8, a cylinder 9, a left bracket 10, a moving block 11, a swing rod 12, a second Three guide rods 13, a third sliding sleeve 14, a feed hopper 16, a crushing trough 17 and a right bracket 18, a collection tank 3 is placed in the middle of the top of the bottom plate 1, a left bracket 10 is arranged at the left end of the top of the bottom plate 1, and the left bracket 10 is arranged at an end There is a cylinder 9, the bottom end of the cylinder 9 is connected with a moving block 11, a third guide rod 13 and a lower funnel 2 are arranged on the left side of the left bracket 10, the lower funnel 2 is located below the third guide rod 13, and the upper right wall of the lower funnel 2 is arranged There is a through hole 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com