Flexible-manufacturing-based intelligent cosmetics production line

A technology for cosmetics and production lines, applied in the field of intelligent cosmetic production lines, can solve problems such as reducing production efficiency, failing to obtain products, increasing manufacturing costs, etc., and achieving the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

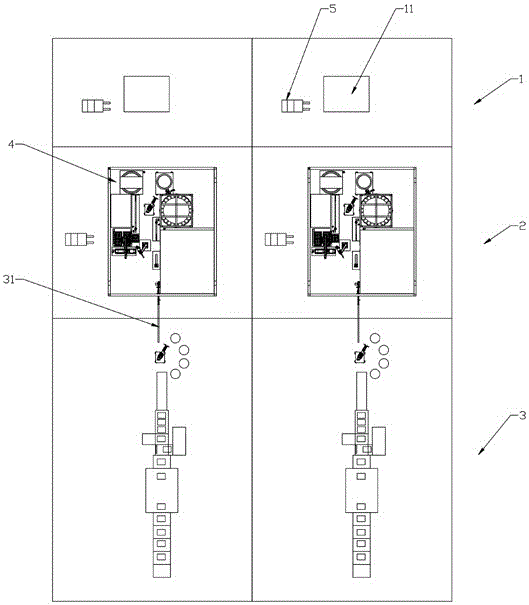

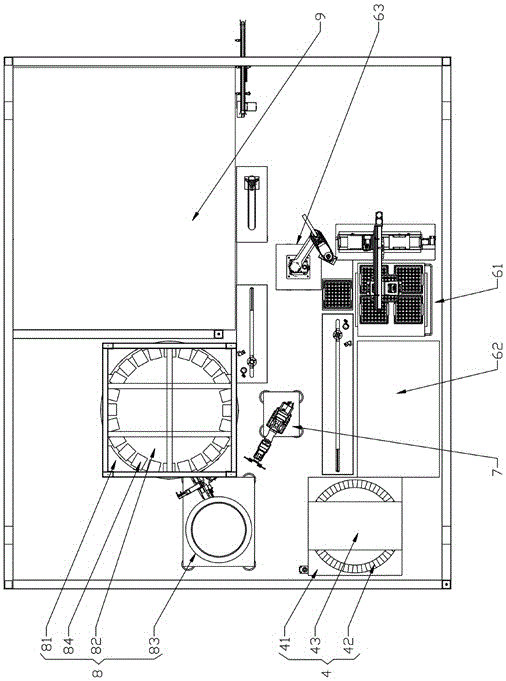

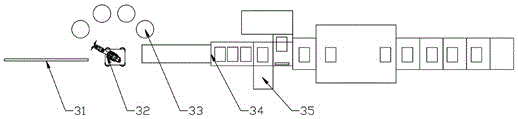

[0021] Such as Figure 1 to Figure 4 As shown, the specific embodiment of the present invention is: the present invention comprises database and base material emulsification area 1, personalized filling area 2 and packaging area 3 that are arranged successively according to production order; And store the personalized needs of each customizer; the base material emulsification area 1 includes the existing emulsification machine, and the base material emulsification area 1 carries out the emulsification process of the cosmetic base material through the emulsification machine 11; the personalized The filling area 2 is mainly used for pouring the emulsified base material into the cosmetic bottle body; the packaging area 3 is mainly used for the packaging and packaging of the final cosmetics. The present invention uses computers and the Internet to collect the individual needs of each customizer and upload them to the database, through detection and analysis of cosmetic formulas, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com