Film recovery device

A recycling device and film technology, applied in thin material processing, transportation and packaging, winding strips, etc., can solve problems such as hidden dangers in production safety, occupation of factory space, etc., and achieve the effect of avoiding local accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

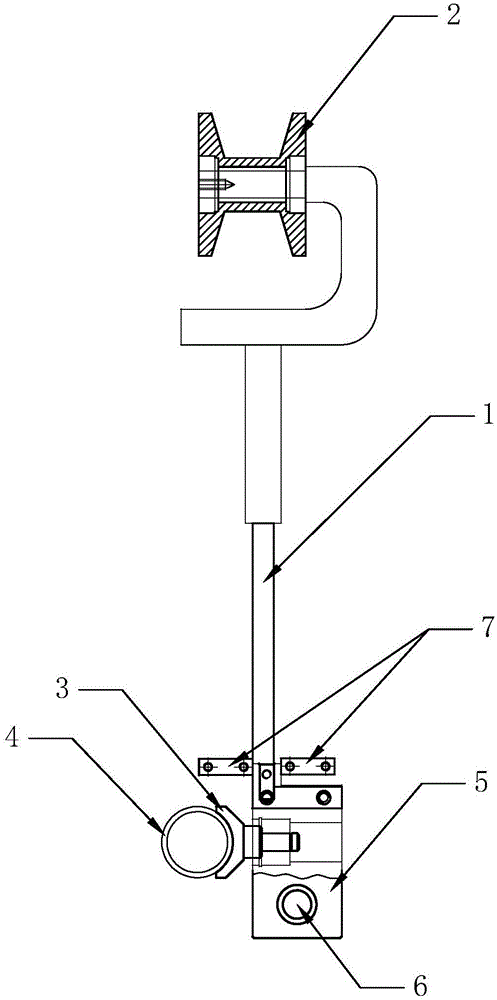

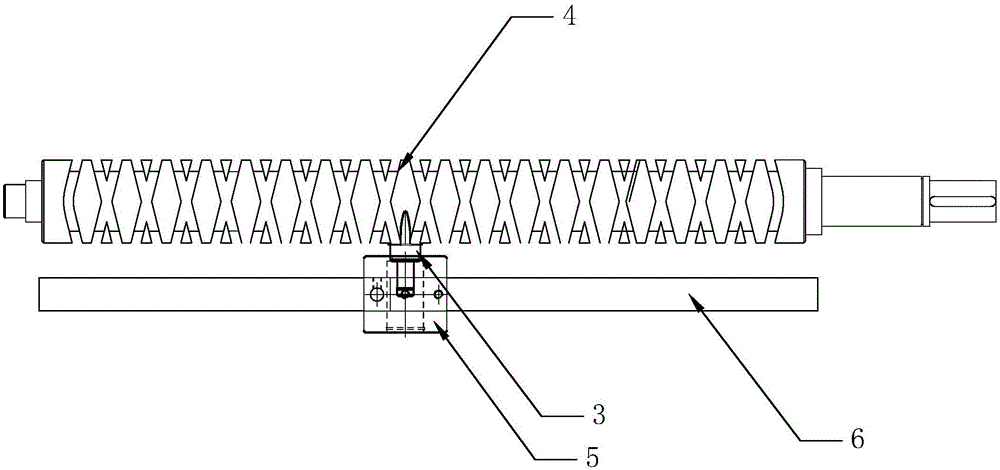

[0014] refer to Figure 1 to Figure 2 , a kind of film recycling device of the present invention comprises a slitting machine and a film recycling mechanism installed on the slitting machine, the film recycling mechanism includes a bracket 1, a roller 2 installed on the bracket 1 for recycling side materials and A sliding mechanism for laterally moving the bracket 1, the bracket 1 is fixed on the upper part of the sliding mechanism, and the roller 2 is connected with a first motor.

[0015] When working, wind the side material cut out by the slitting machine on the roller 2, and recycle the side material through the rotation of the first motor to drive the roller 2, so as to realize timely online recycling after the film is processed. In addition, through The sliding mechanism drives the bracket 1, so that the roller 2 moves laterally during recovery, so that the edge material evenly covers the entire roller 2, avoiding the problem of partial accumulation of the edge material....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap