A kind of pottery plant automatic water supply tray and preparation method thereof

An automatic water supply and plant technology, applied in the field of ceramics, can solve the problems of high cost, time-consuming and laborious installation of irrigation equipment, and inability to automatically realize water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

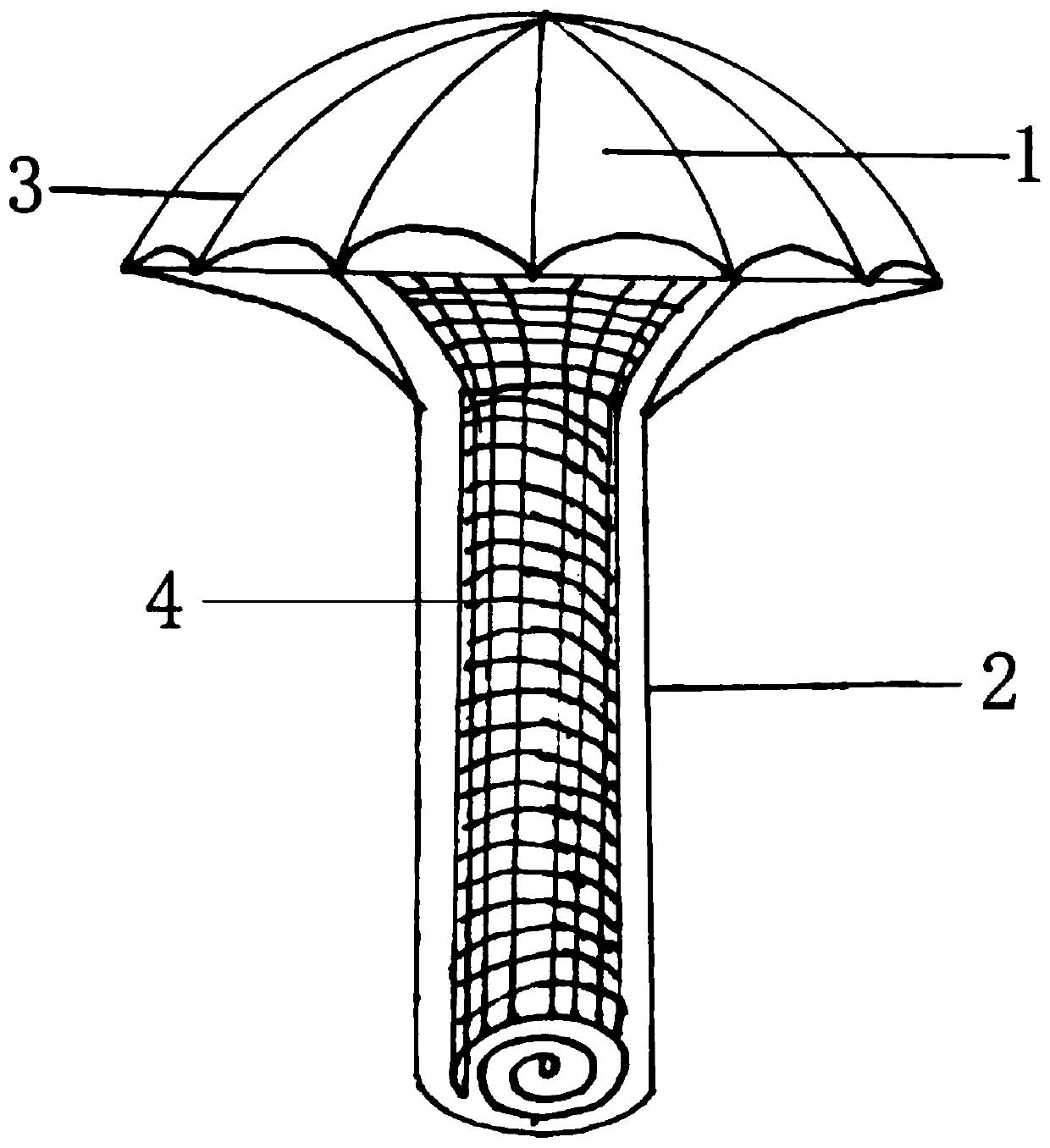

Image

Examples

Embodiment 1

[0034] A pottery plant automatic water supply tray is made by the following method:

[0035] (1), batching: prepare following raw material according to percentage by weight: 10 order red clay 73, 10 order mud brick powder 10, 20 order river sand 2, waste cotton 1.5, waste gauze 0.5, 40 order poplar wood chips 4, water twenty three;

[0036] (2), soak waste cotton with 10 times the water of weight for 2 hours for subsequent use;

[0037] (3), stir the waste cotton in the water evenly at a speed of 300 revolutions per minute, add red clay, mud brick powder, sawdust, river sand, and add water to stir into thick mud while stirring;

[0038] (4) Kneading the mud to make a billet: first knead the thick mud into a ball, then extrude it into a rectangular clay plate according to the specified size of the automatic water supply tray, with a thickness of 1 cm, and spread the waste gauze under the strip-shaped clay plate, Roll up the mud plate from one end, put it in the mold and extru...

Embodiment 2

[0044] A pottery plant automatic water supply tray is made by the following method:

[0045] (1), batching: prepare following raw material according to percentage by weight: 25 order red clay 75, 25 order mud brick tile powder 15, 30 order river sand 4, waste cotton 1.6, waste gauze 0.8, 50 order wood chips 4, water 25;

[0046] (2), take the raw material red clay below 50 centimeters from the ground, pour water thoroughly before freezing, and sieve 10-40 meshes after freezing the powder the next year to make, soak waste cotton with 10 times the water of weight for 2 hours for later use;

[0047] (3), stir the waste cotton in the water evenly at a speed of 300 revolutions per minute, add red clay, mud brick powder, sawdust, river sand, and add water to stir into thick mud while stirring;

[0048] (4) Kneading the mud to make a billet: first knead the thick mud into a ball, and then squeeze it into a rectangular mud plate according to the specified size of the automatic water ...

Embodiment 3

[0054] A pottery plant automatic water supply tray is made by the following method:

[0055](1), batching: prepare following raw material according to percentage by weight: 40 order red clay 74, 40 order mud brick tile powder 19, 40 order river sand 5, waste cotton 1.8, waste gauze 1.2, 60 order pine wood chips 7, water 27;

[0056] (2), take the raw material red clay below 50 centimeters from the ground, pour water thoroughly before freezing, sieve 10-40 mesh after freezing the powder and make it in the next year, soak the waste cotton with 10 times the water of the weight for 2 hours for later use;

[0057] (3), stir the waste cotton in the water evenly at a speed of 300 revolutions per minute, add red clay, mud brick powder, sawdust, river sand, and add water to stir into thick mud while stirring;

[0058] (4) Kneading the mud to make a billet: first fully knead the thick mud into a ball, and then extrude it into a rectangular mud board according to the specified size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com