Construction method for nonlinear type lintels

A construction method and non-linear technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of structural construction difficulties, and the shelving length cannot meet the minimum requirements, etc., and achieve good results, low cost, and fast speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

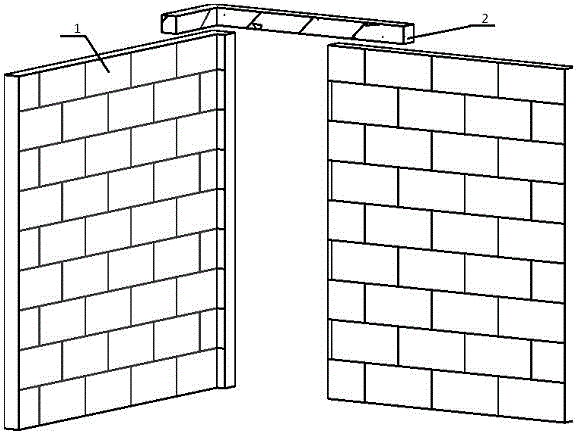

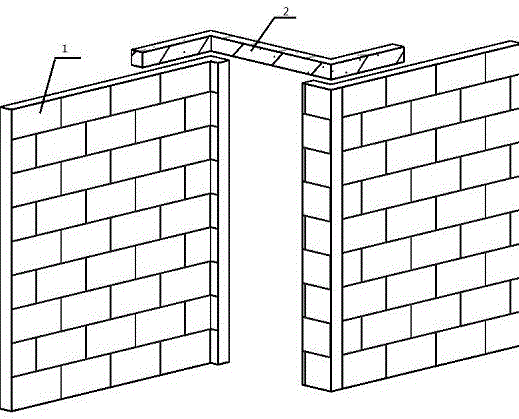

[0026] Such as Figure 1~2 As shown, a non-linear lintel construction method is composed of a cast-in-place concrete lintel construction method or a prefabricated concrete lintel construction method; wherein

[0027] The cast-in-place concrete lintel construction method includes the following steps:

[0028] ⑴Reinforcement binding: When meeting door openings and window openings, according to the design requirements of section, size, shape, etc., pre-reinforce the required reinforcement in L-shaped, U-shaped, Z-shaped and other irregularly shaped non-linear lintels 2 in the steel bar processing area Processing and forming.

[0029] Since the steel longitudinal bars used in non-linear lintels have one or more bending points, the bending angle must be strictly controlled during steel bar processing, and the installation position must be strictly controlled during installation to ensure that the thickness of the steel bar protective layer can meet the acceptance criteria. Avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com