Patents

Literature

31results about How to "Free form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

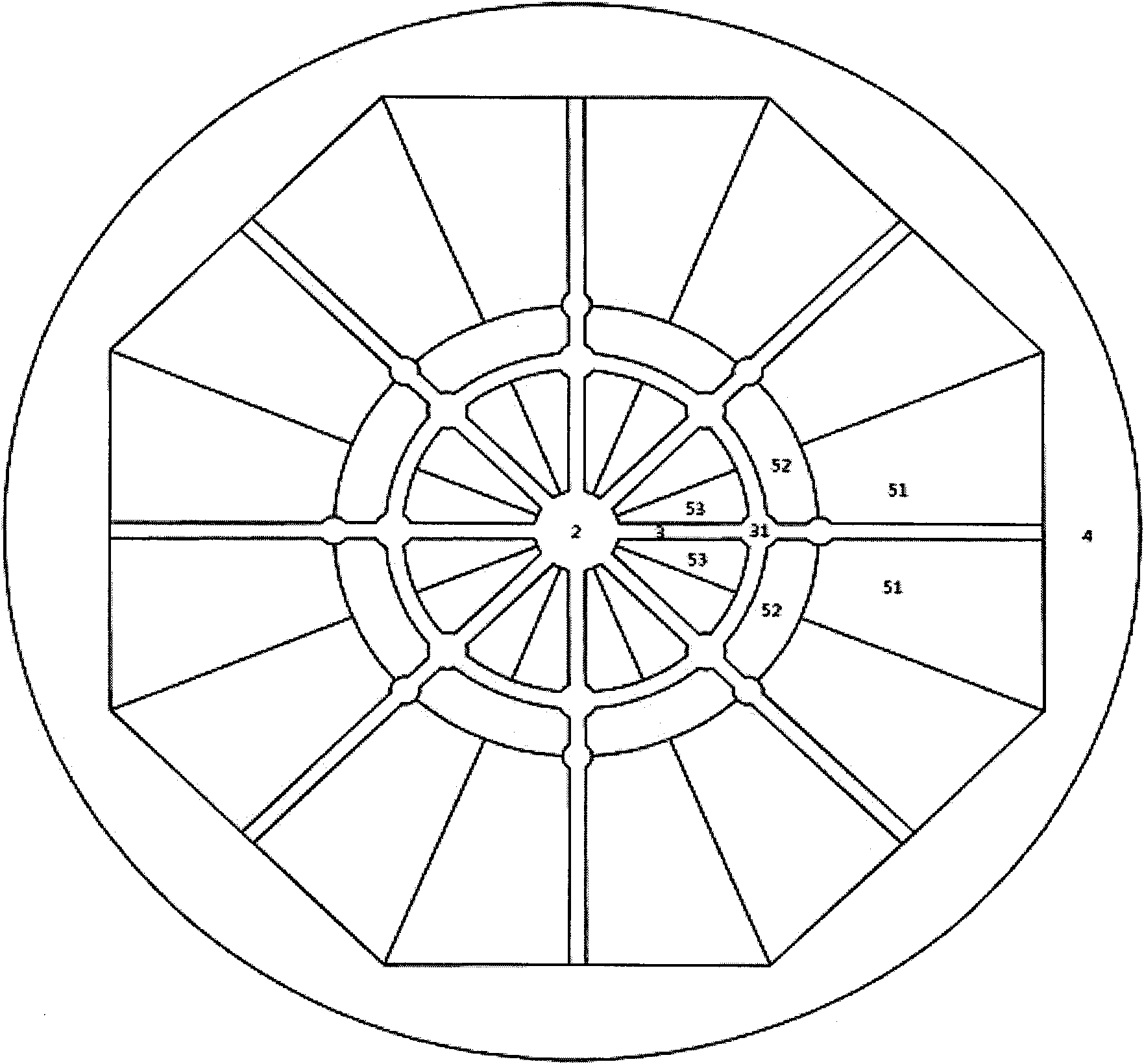

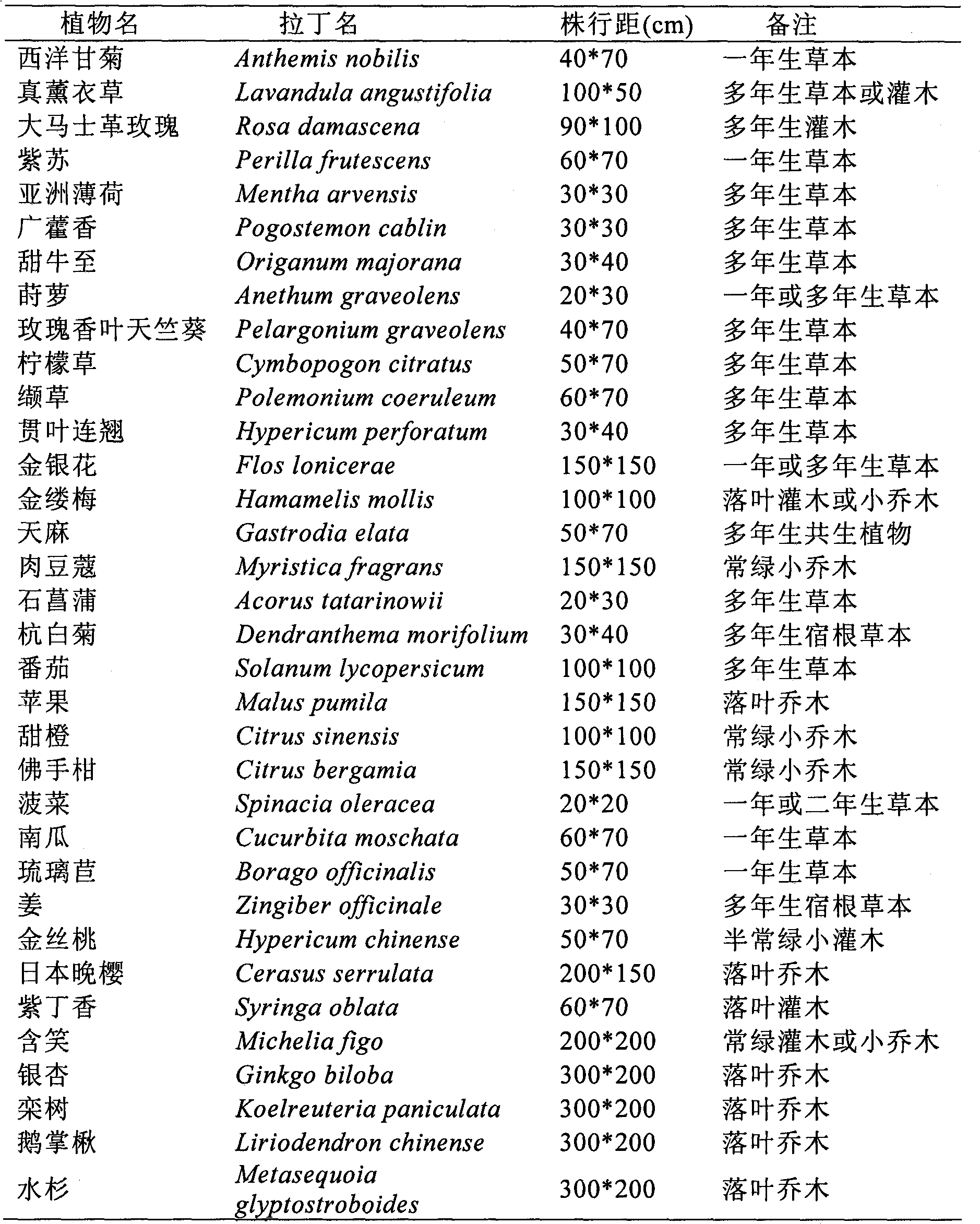

Aromatic plant health-care green land setting method with function of anxiety symptom resistance

InactiveCN102106223AEasy to resolveFree formPublic buildingsHorticultureHypericum perforatumHamamelis virginiana

The invention provides an aromatic plant health-care green land setting method with the function of anxiety symptom resistance, which can comprehensively improve the anxiety symptom with various sensory functions such as the smell sense mainly, the visual sense, etc. A park with a certain area is internally provided with the aromatic plant, the medicinal plant, the vegetable, the fruit and the flower in proportion, and the park is divided into a plurality of plant blocks by a plurality of footpaths, wherein the selected aromatic plant is the anthemis, the true lavender, the damask rose, the purple perilla, the Asian mint, the pogostemon cablin, the sweet oregano and the dill, the medical plant is the valerian, the hypericum perforatum, the honeysuckle, the witch hazel, the gastrodia elata, the myristica fragrans and the rhizoma acori graminei, and the fruit and the vegetable are the tomato, the apple, the sweet orange, the bergamot, the spinach, the pumpkin,the borago officinalis and the ginger. The selected aromatic plant, the medical plant, the fruit and the vegetable are configured according to a certain proportion and quantity to form a proper color, and the periphery of the park is isolated by the varieties of trees. On the premise that the number of people is not larger than the maximum bearing capacity, the user can enjoy or directly contact the plant by smelling the fragrance within a certain time in the region, so that the anxiety symptom is obviously improved.

Owner:APPLE FLAVOR & FRAGRANCE GRP +1

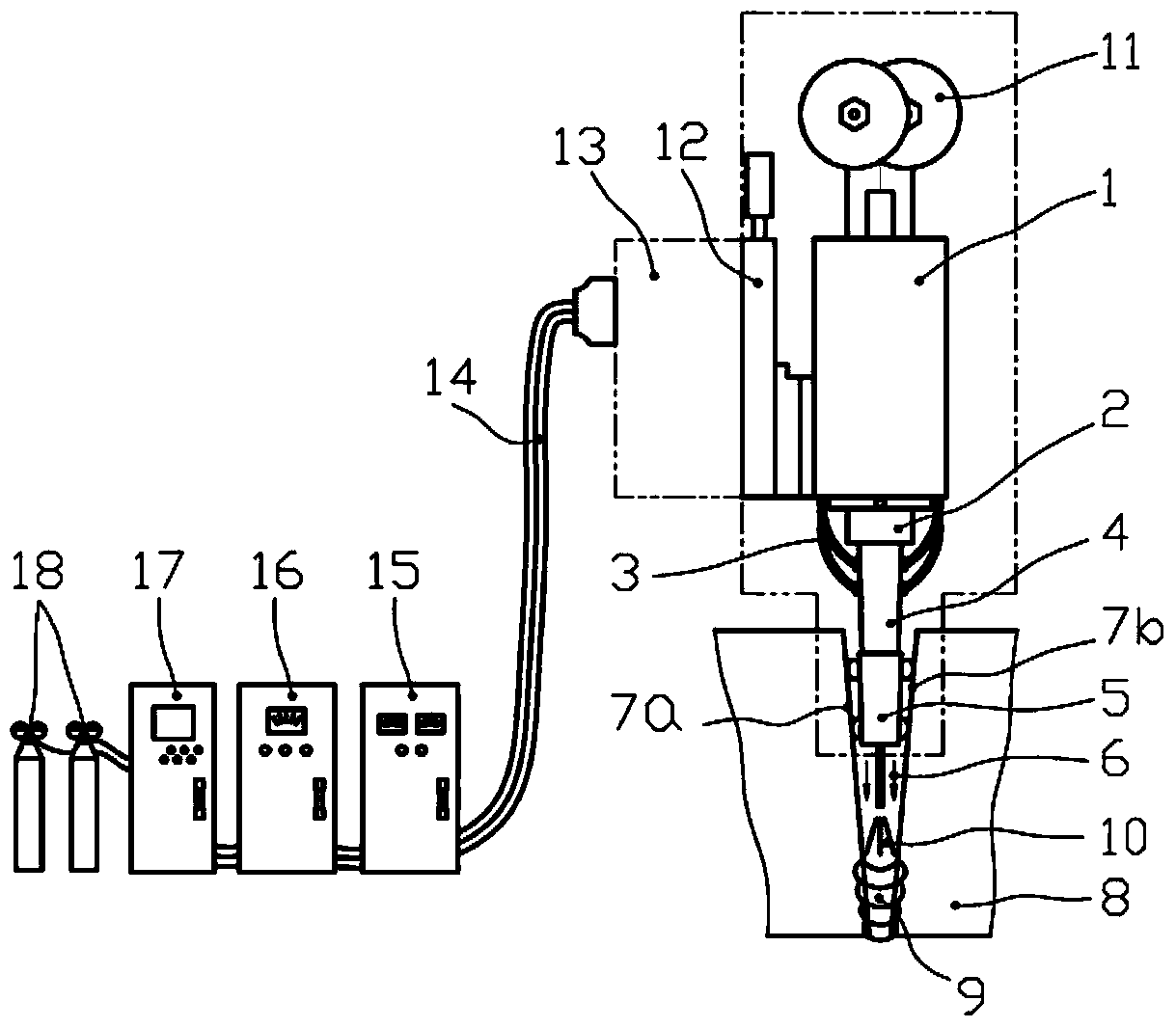

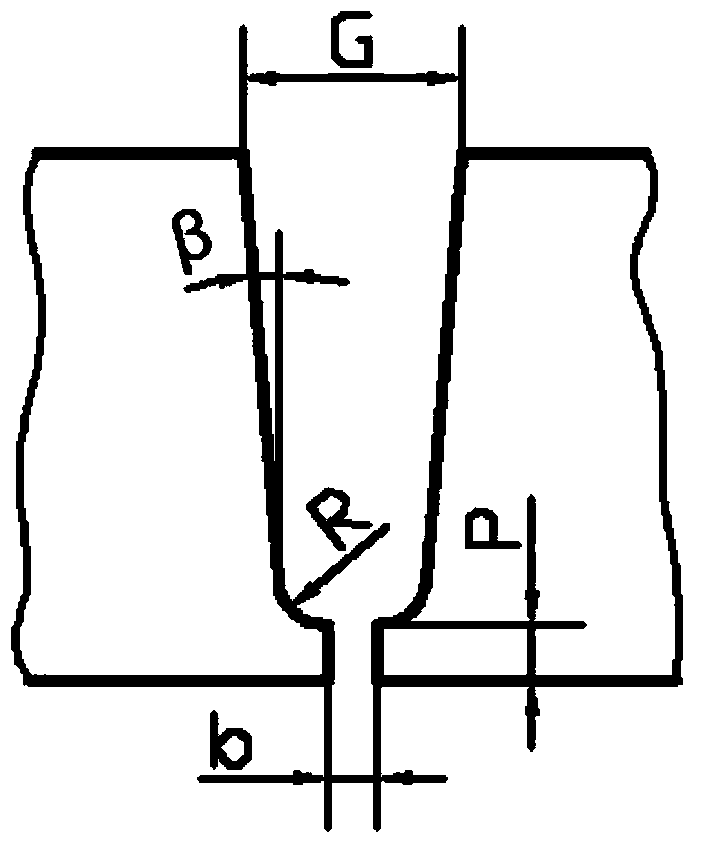

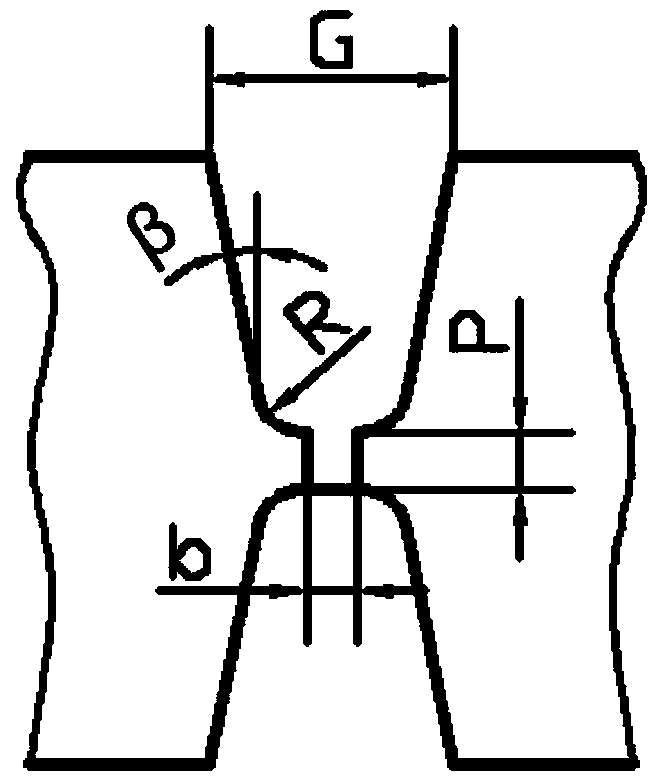

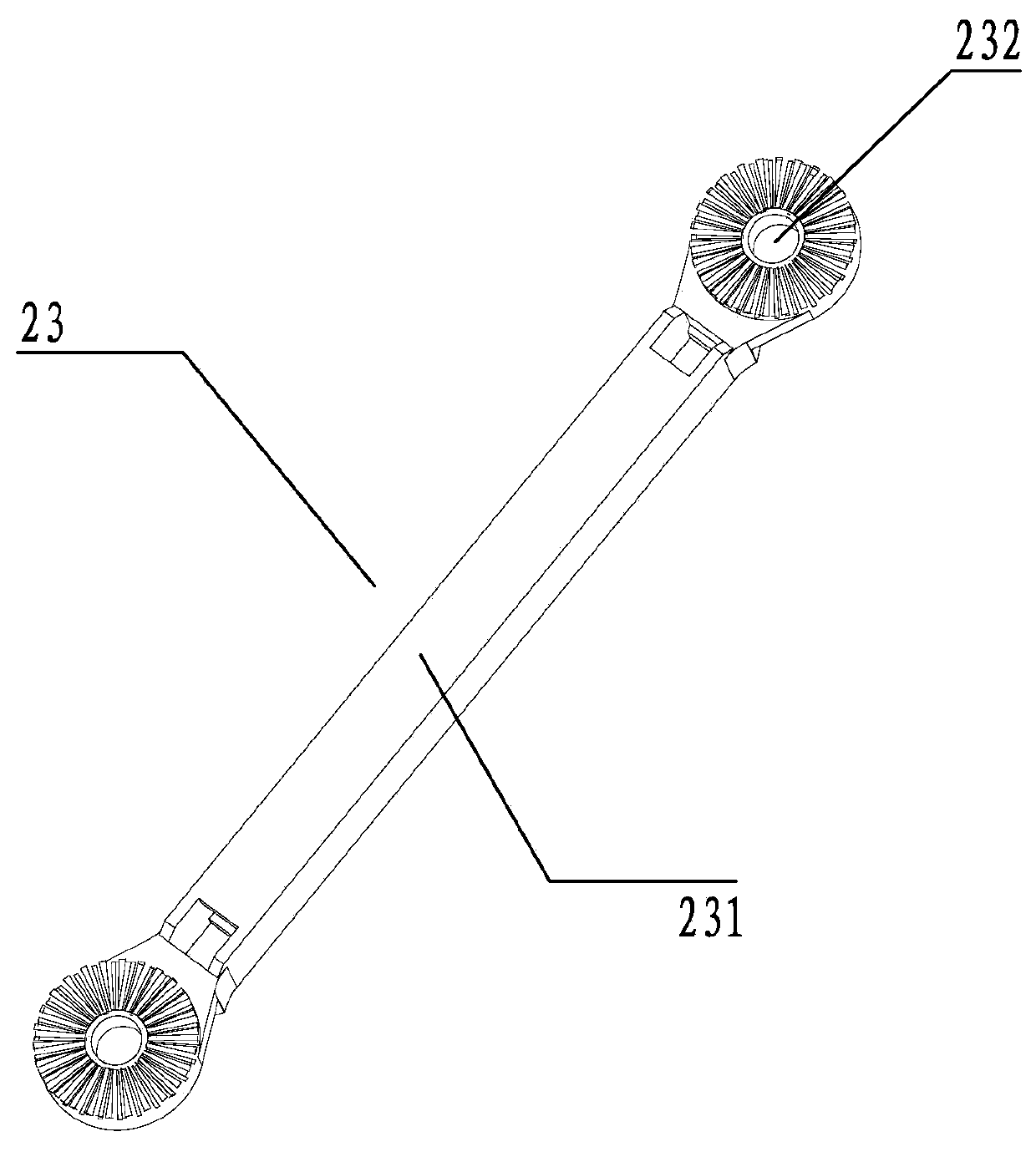

MAG/MIG automatic welding device and method

InactiveCN104289795AImprove reliabilityImprove protectionElectrode supporting devicesWelding coupling meansEngineeringWeld seam

The invention relates to an MAG / MIG automatic welding device and method. The device comprises a wire feeding mechanism, a wire plate is installed at the upper portion of the wire feeding mechanism, and a three-dimensional self-adaptation centering device is installed at the lower portion of the wire feeding mechanism. A plate type welding gun is fixed to the lower portion of the centering device, and a self-adaptation centering sensor is installed at the lower portion of the plate type welding gun. A gas splitting device is arranged in the middle of the lower portion of the welding gun, and the lower portion of the splitting device is connected with a protection nozzle. A welding gun height adjusting mechanism is further included. The welding method includes the steps that welding groove types and sizes, welding wire slip angles and deposition manners are determined, and root gaps, the input power of all welding layers and welding parameters are determined. The MAG / MIG automatic welding device and method have the advantages that self-adaptation intelligent tracking of welding seam tracks under various MAG / MIG welding groove conditions can be achieved, the ultra low welding spattering rate is achieved, welding high-temperature areas under various welding technology conditions can be effectively and reliably protected, the device is durable, high in welding quality, stable, reliable and high in working efficiency, and the welding production cost is greatly lowered.

Owner:武汉纳瑞格智能设备有限公司

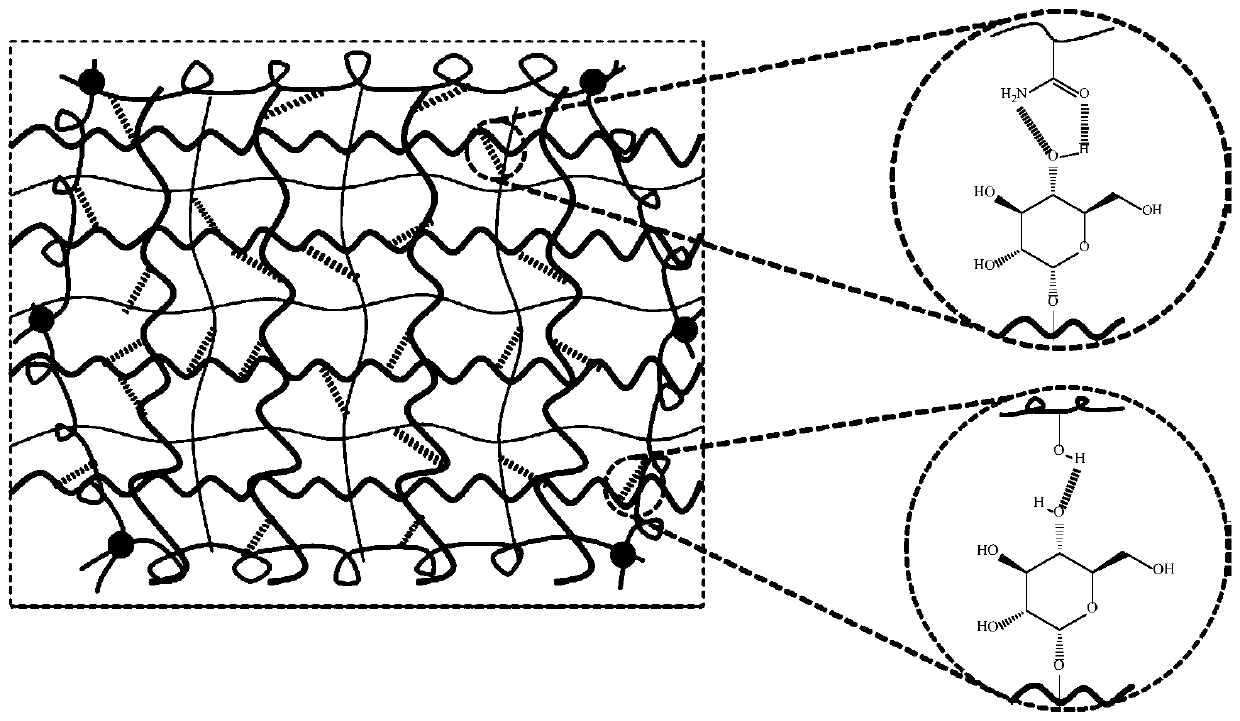

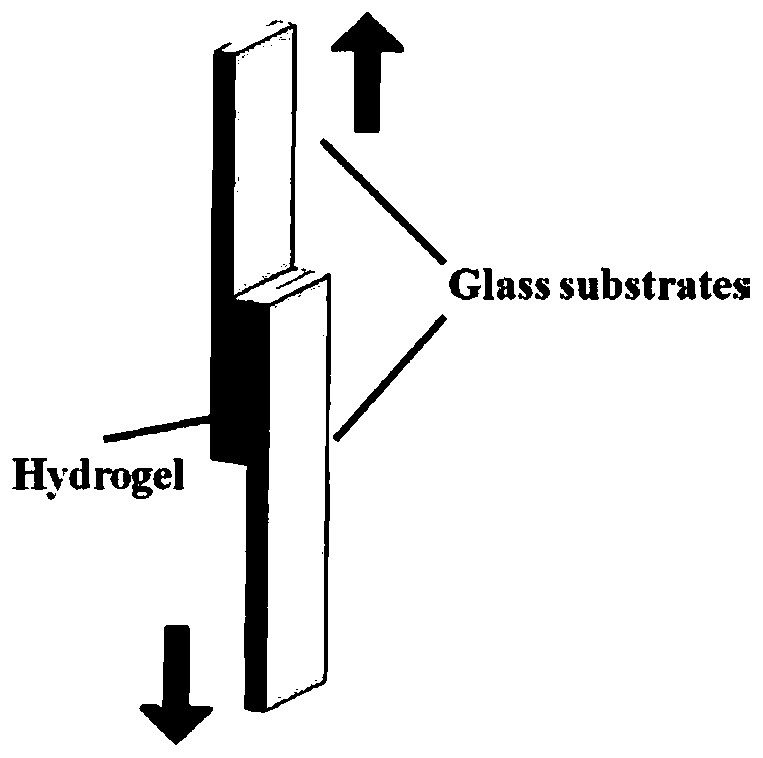

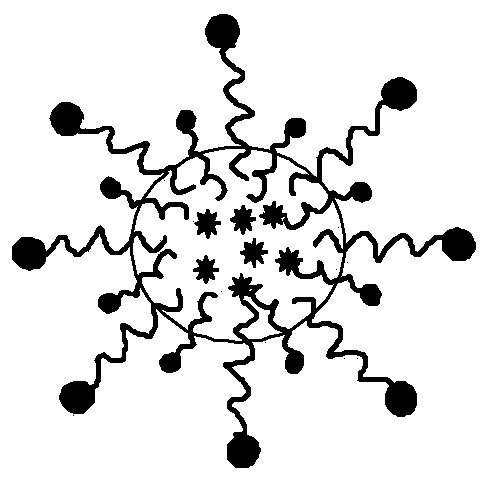

Preparation method of high-strength and high-adhesion branched starch composite hydrogel with strong hydrogen bonding effect

The invention discloses a preparation method of a high-strength and high-adhesion branched starch composite polyacrylamide / polyvinyl alcohol hydrogel with a strong hydrogen bonding effect, the methodcomprises the following steps: branched starch, polyvinyl alcohol, polymer monomer acrylamide and a photoinitiator are dissolved to obtain a uniform mixed solution, firstly, the uniform mixed solution is initiated under the condition of ultraviolet light, so that the acrylamide is polymerized, micro-crystals are formed in a polyvinyl alcohol network in the freezing and unfreezing process, a multi-hydrogen bond interaction can be formed between molecular chains of the branched starch and molecular chains of the polyacrylamide and molecular chains of the polyvinyl alcohol, and under the doubleactions of multiple hydrogen bonds and the micro-crystals, multi-physical-bond cooperative cross-linking is realized. The preparation process is simple and convenient to operate, and the prepared hydrogel has relatively high mechanical strength and excellent adhesion property on the surface of glass, and can be used as a preferred material of a soft robot.

Owner:HUBEI UNIV OF TECH

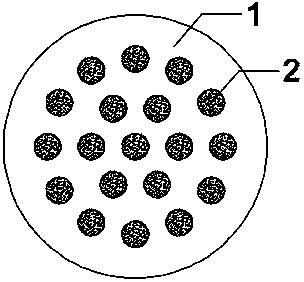

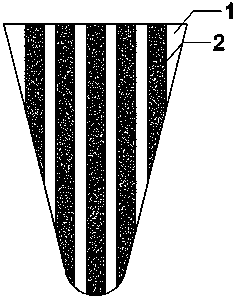

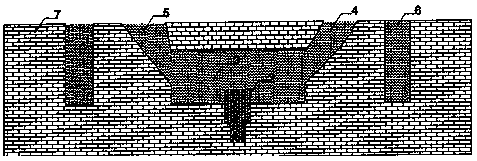

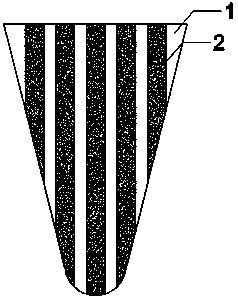

Ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and manufacturing method thereof

ActiveCN108380850AFacilitate compounding processEfficient feedingBallastwayTransportation and packagingManufacturing technologyWear resistant

The invention discloses a ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and a manufacturing method of the ceramic particle multi-scale reinforced metalbase composite wear-resistant raking tooth head, and belongs to the field of part manufacturing. According to the manufacturing method, ceramic particles and alloy powder are compacted and sintered tomanufacture rod-shaped composite materials, the rod-shaped composite materials are embedded into a metal base through the combination of the powder metallurgy technology and the embedment casting technology, and the purpose that the metal base covers the uniformly-distributed rod-shaped composite materials is achieved. The ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head solves the problems that an ordinary raking tooth is prone to being worn, and a homogeneous composite wear-resistant part is poor in toughness, brittle and low in impact resistance. Compared with overall metallurgical sintering, the manufacturing method has the advantages that by means of the technology of combination of powder metallurgy and embedment casting, the dimensionalaccuracy of parts is guaranteed, the requirements of specific parts for using performance are met, the assembling working procedure is omitted, the manufacturing technology is simplified to a certainextent, the part manufacturing cost is greatly reduced, the organization is compact, the metallurgical bonding is good, and the ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head can be applied to cleaning and screening vehicles for railway maintenance and parts of raking teeth of scraper loaders.

Owner:KUNMING UNIV OF SCI & TECH

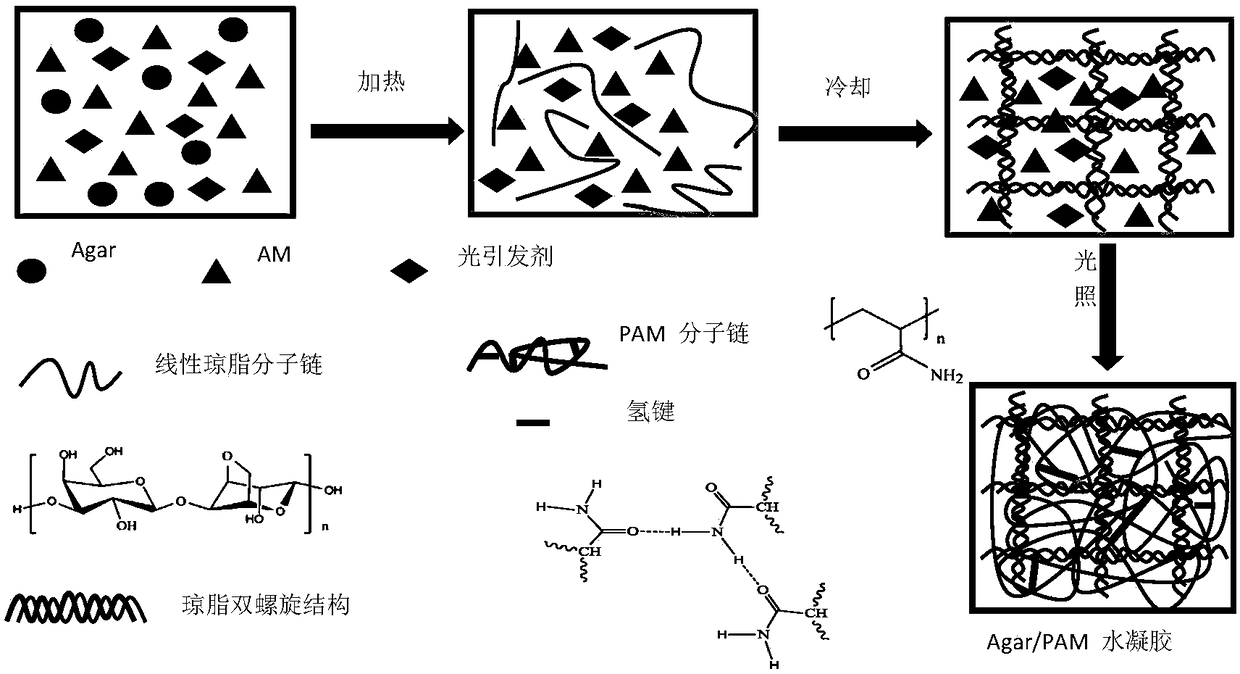

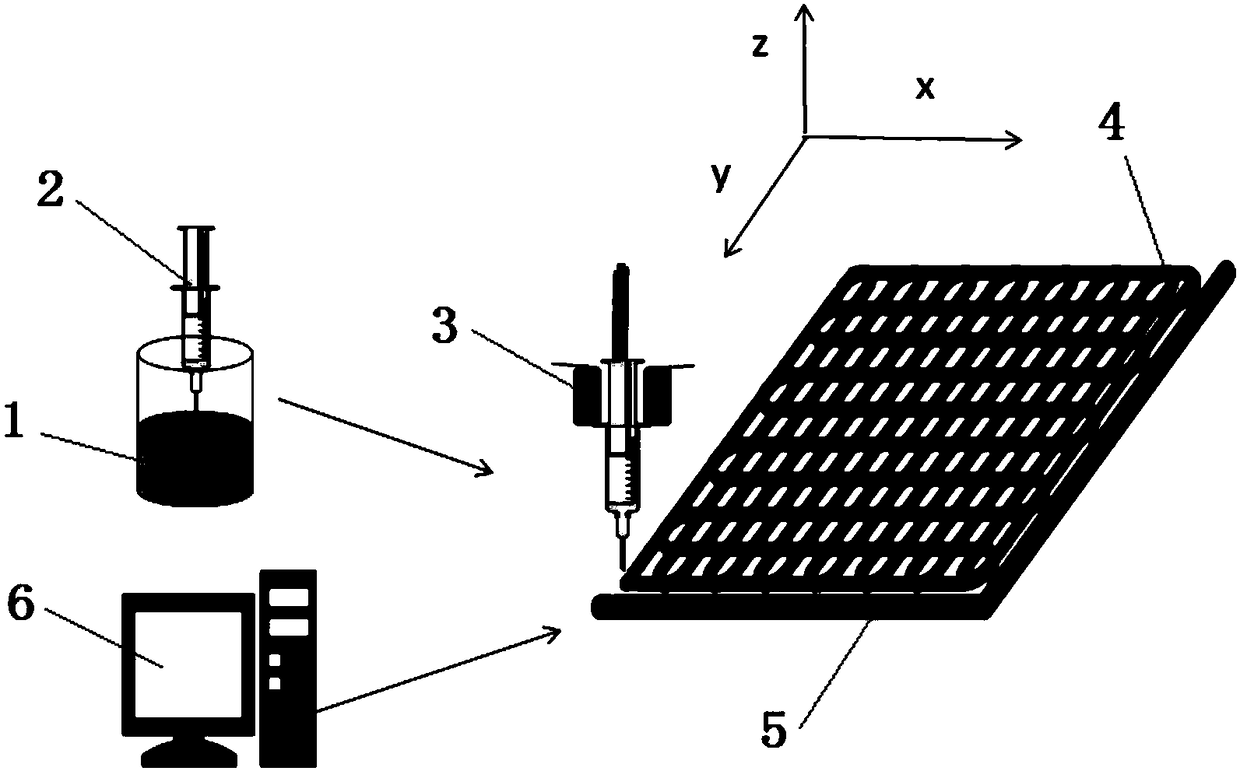

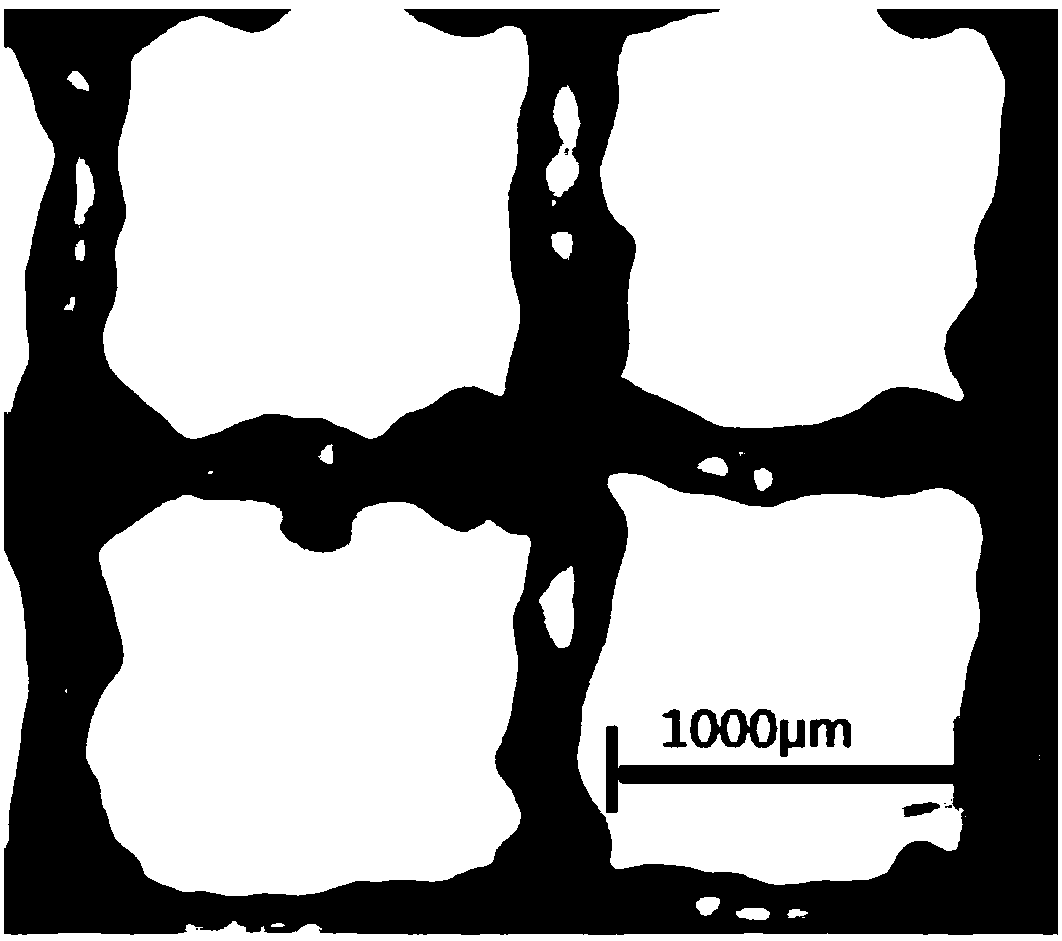

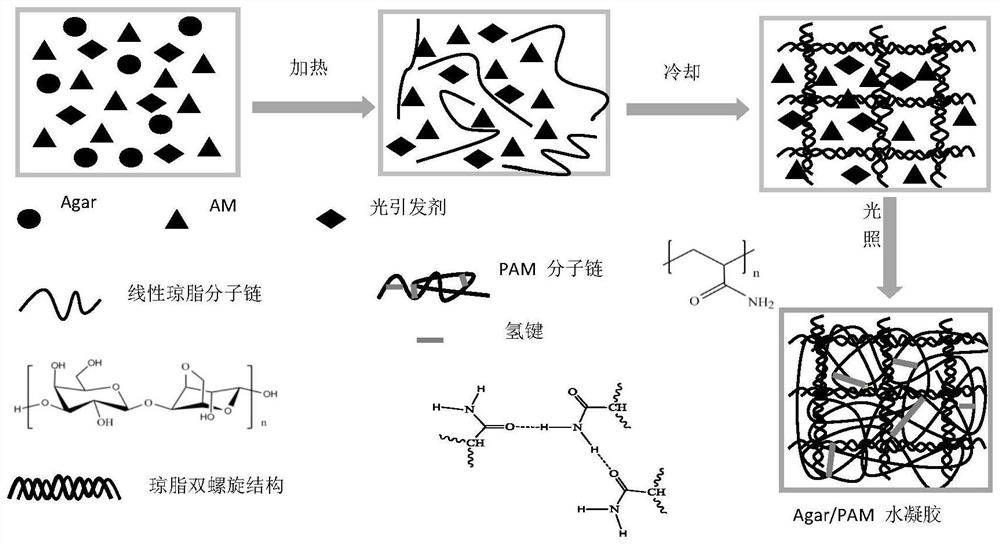

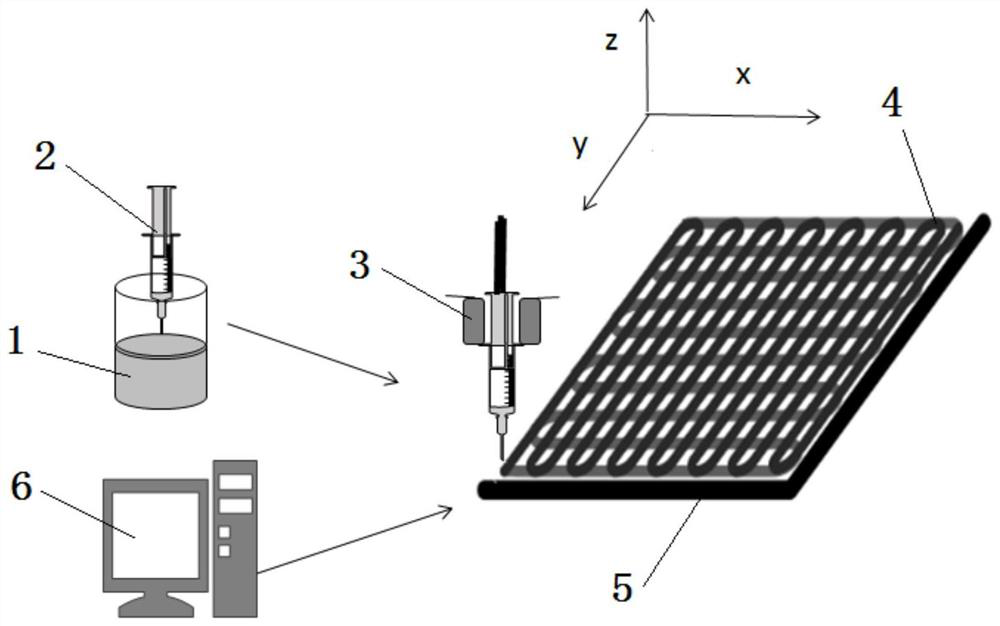

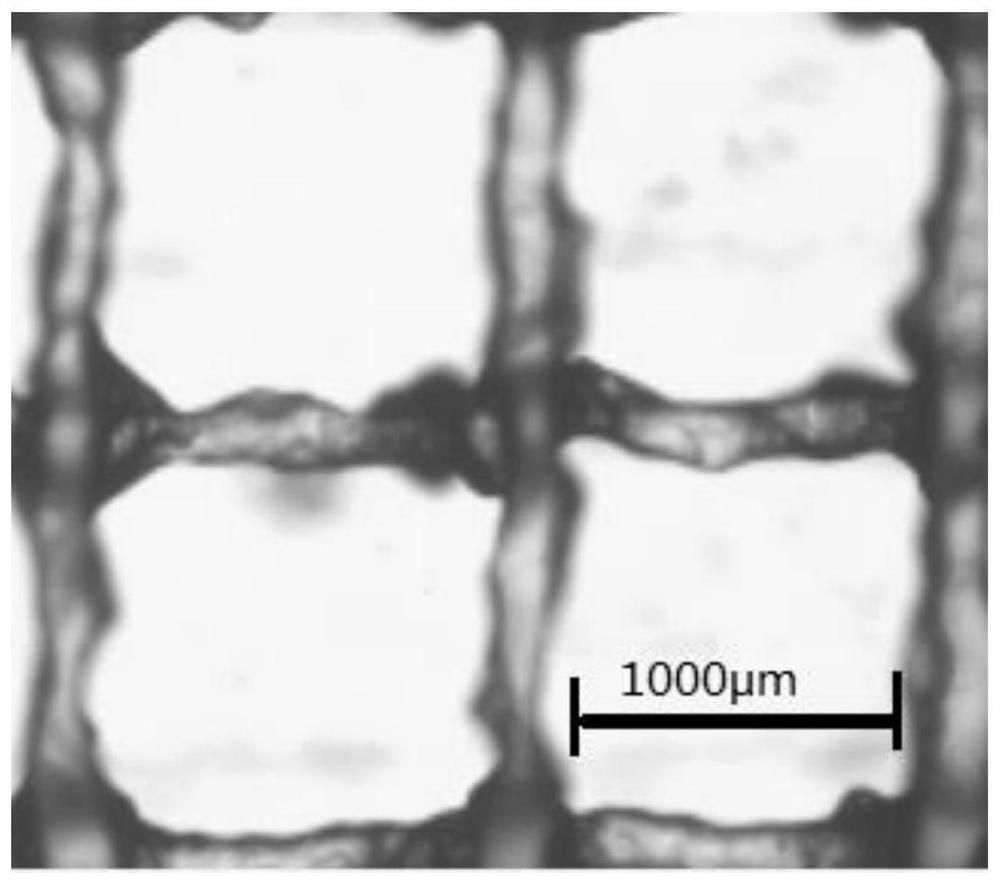

Preparation method of agar/polyacrylamide dihydrogen bond cooperative crosslinking high-tenacity hydrogel capable of 3D printing

ActiveCN108276590ASimple preparation processShort preparation cycleAdditive manufacturing apparatusCross-linkGas phase

The invention discloses a preparation method of an agar / polyacrylamide dihydrogen bond cooperative crosslinking high-tenacity hydrogel capable of 3D printing. The preparation method comprises the following steps: firstly dissolving agar into deionized water under heating and stirring conditions to obtain a uniform water solution, then adding a mixed solution of acrylamide and a light initiator dissolved into deionized water into a water solution of agar for uniform mixing, pre-forming the final mixed solution in a mold or 3D printing manner, firstly cross-linking agar at a low temperature, then putting the cross-linked agar under an ultraviolet lamp so that acrylamide is polymerized and hydrogen bonds are cross-linked, and the dihydrogen bond cooperative crosslinking high-tenacity hydrogelis formed; due to the fact that the hydrogel contains natural high molecular agar, and the viscosity is regulated and controlled by adding a small amount of fumed silica under the state of sol, the hydrogel has good sagging resistance and rapid gelatinization characteristics, and 3D printing can be realized.

Owner:HUBEI UNIV OF TECH

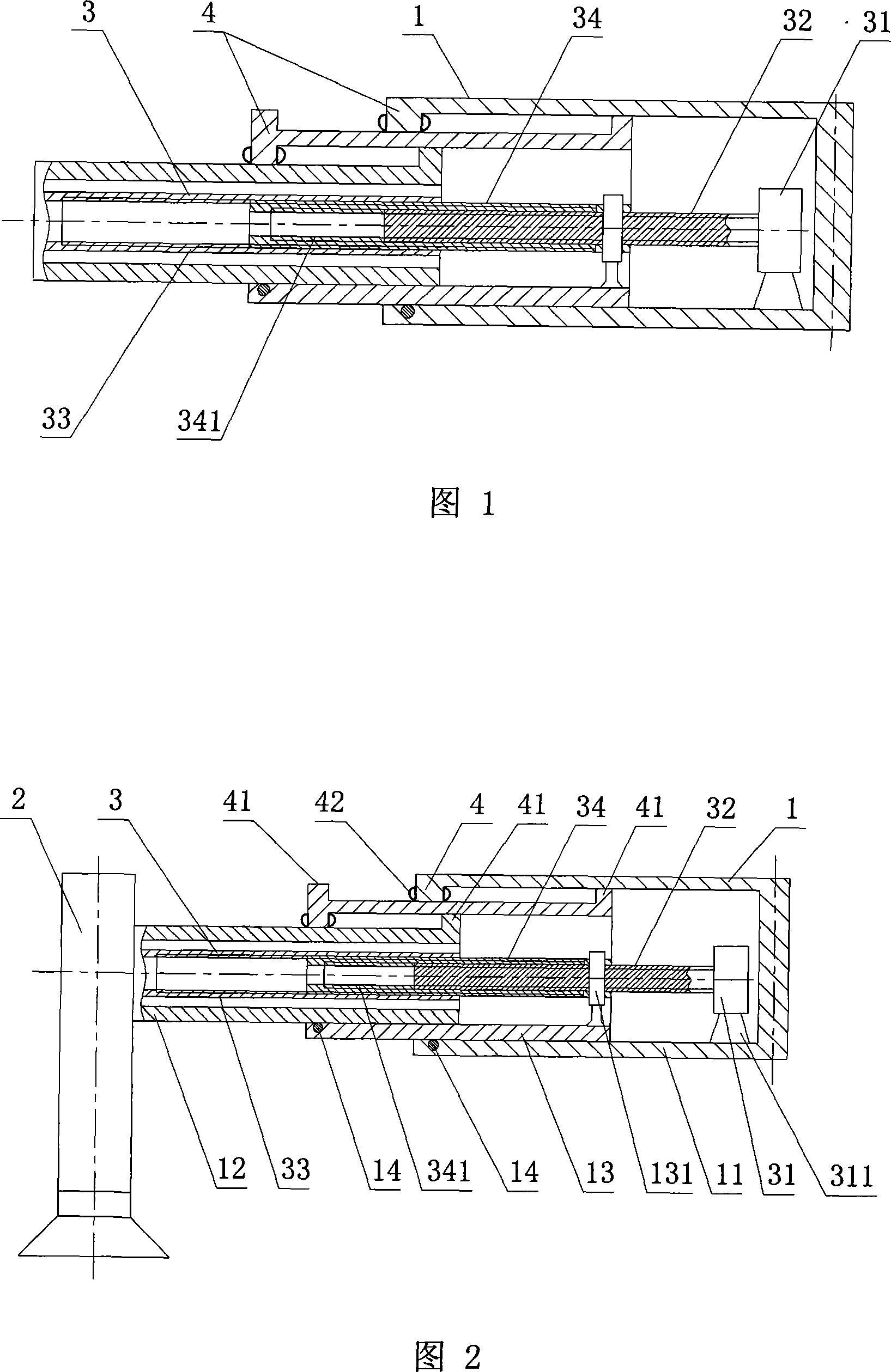

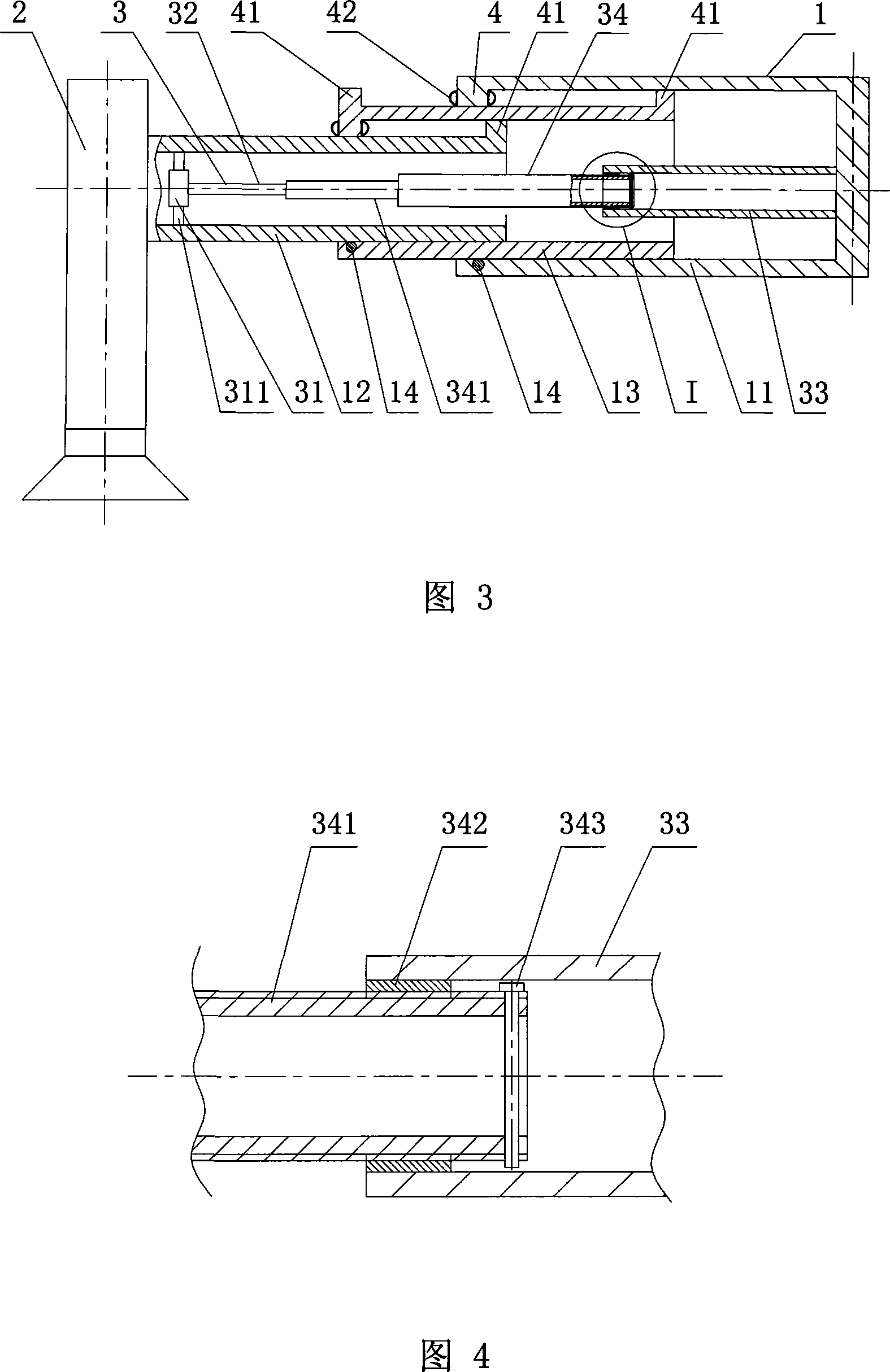

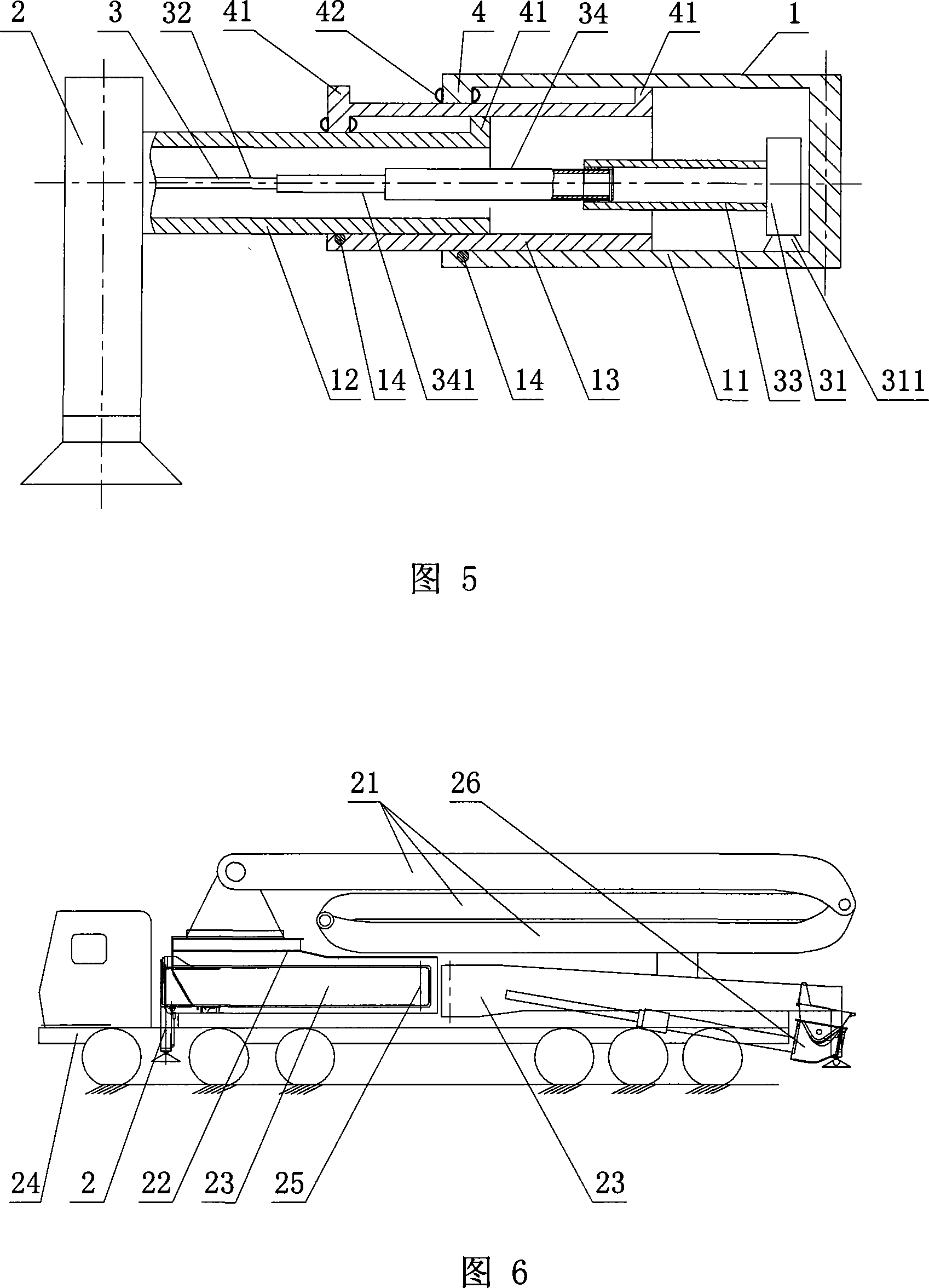

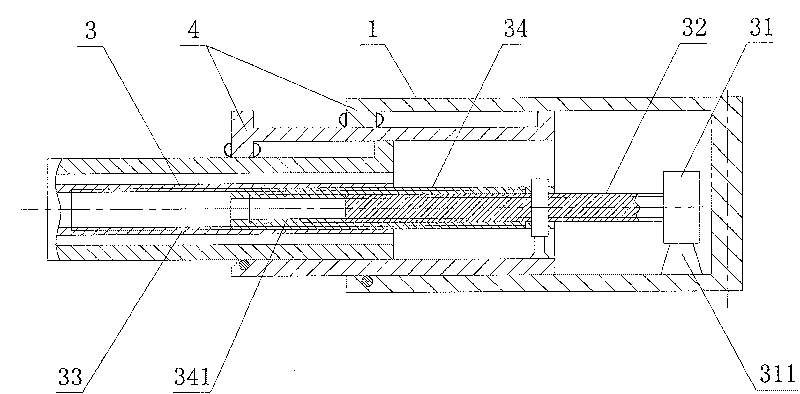

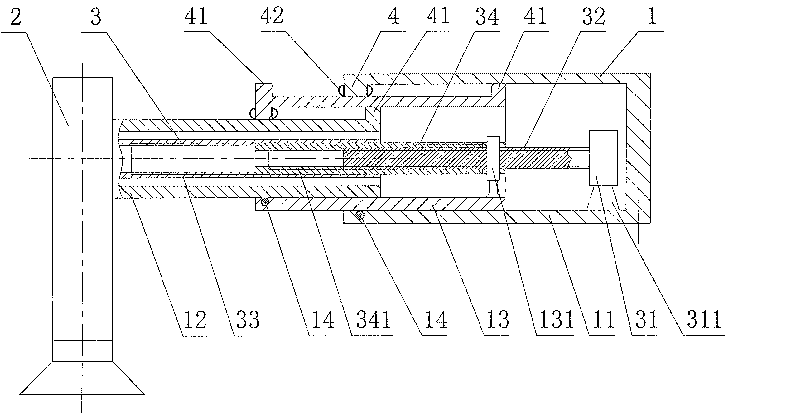

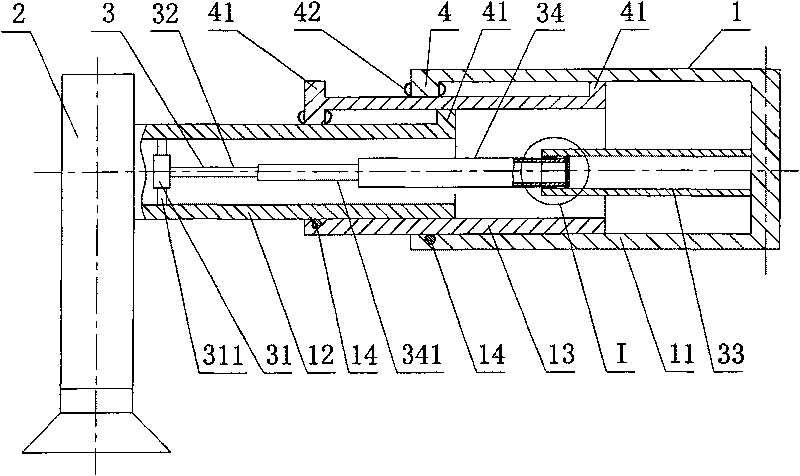

Telescopic component and support for engineering machinery and concrete pump vehicle with the support

InactiveCN101121399ASimple structureEasy to processVehicle fittings for liftingEngineeringScrew thread

A telescopic component used for construction machinery, a telescopic support leg and a concrete pump truck composed of the component. The telescopic assembly includes a telescopic sleeve assembly, and the sleeve assembly is equipped with a screw mechanism and a stop device. The screw mechanism includes a prime mover, a circular shaft and a hollow cylinder, and the circular shaft and the hollow cylinder are threaded, or between the circular shaft and the hollow cylinder Set the middle hollow shaft group, the middle hollow shaft group is composed of the middle hollow shaft with internal and external threads, the two ends of the middle hollow shaft group are respectively screwed with the round shaft and the hollow tube, the prime mover is connected with the end of the round shaft or the hollow tube connection, the prime mover is fixed at one end of the sleeve assembly, and the other end of the sleeve assembly is fixedly connected with the end of the screw mechanism where the prime mover is not installed. The telescopic part of the telescopic outrigger is composed of the telescopic assembly, and one end of the telescopic outrigger is provided with a supporting foot assembly, and the other end is connected with the bracket on the chassis of the construction machine. The telescopic outrigger is installed in the supporting part of the concrete pump truck. The invention has the advantages of simple structure, convenient manufacture and low cost.

Owner:SANY AUTOMOBILE MFG CO LTD

Method for removing halogen series gas and agent for removing halogen series gas

InactiveUS20070253879A1Improve abilitiesSuppress feverGas treatmentOther chemical processesHydrogen halideSorbent

To provide a method for removing a halogen series gas, which has high capability of treating a halogen series gas, can prevent ignition of an adsorbing agent, is free from formation of carbon dioxide and can reduce generation of wastes, and a removing agent to be used for the method. The method for removing a halogen series gas comprises bringing a gas comprising at least one halogen series gas selected from the group consisting of F2, Cl2, Br2, I2 and a compound which undergoes hydrolysis to form a hydrogen halide or hypohalogenous acid into contact with a granulated product comprising from 80 to 99.9 mass % of an alkali metal base and from 0.1 to 20 mass % of a thiosulfate based on the total mass of the granulated product, in the presence of water, to remove the halogen series gas.

Owner:ASAHI GLASS CO LTD

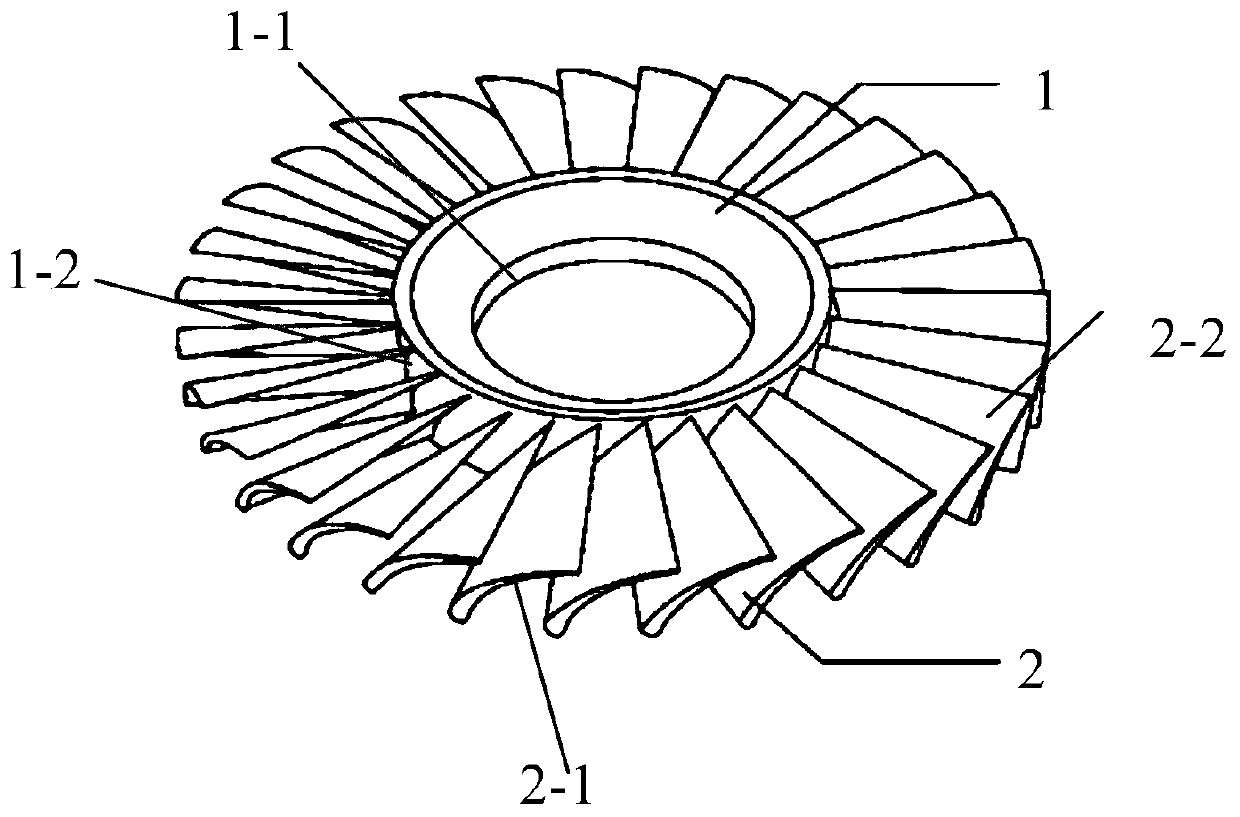

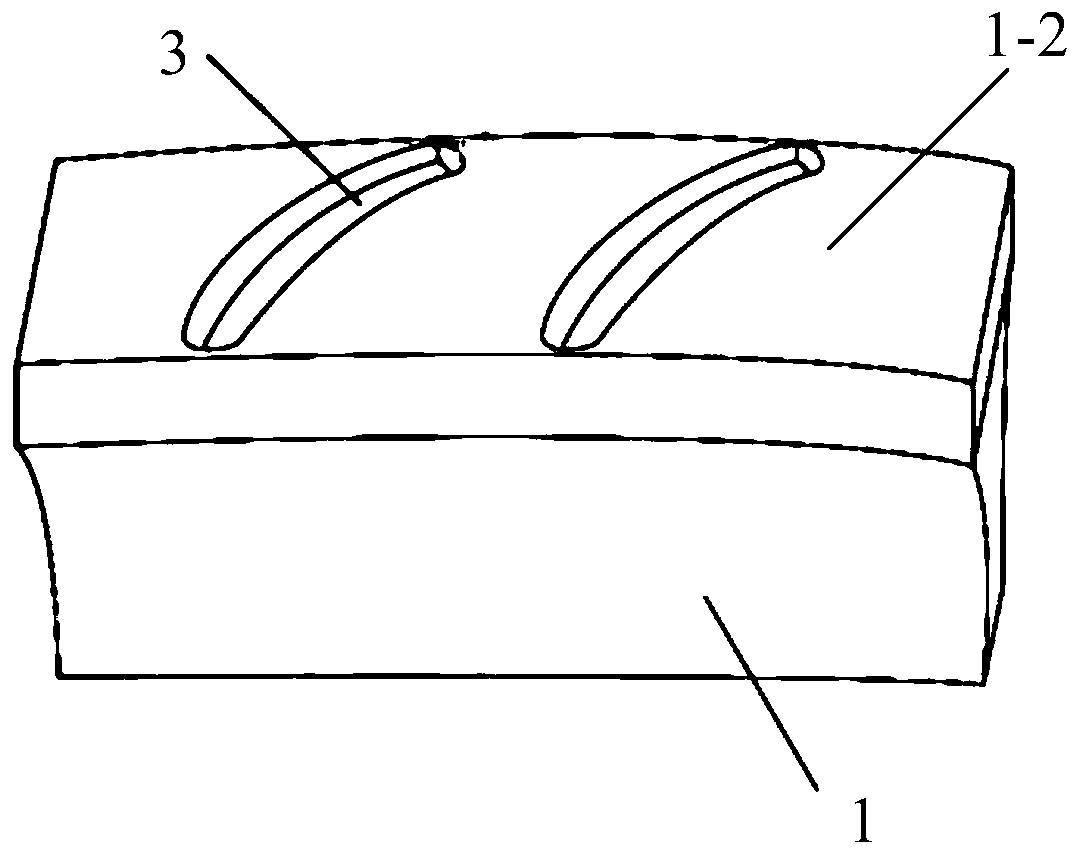

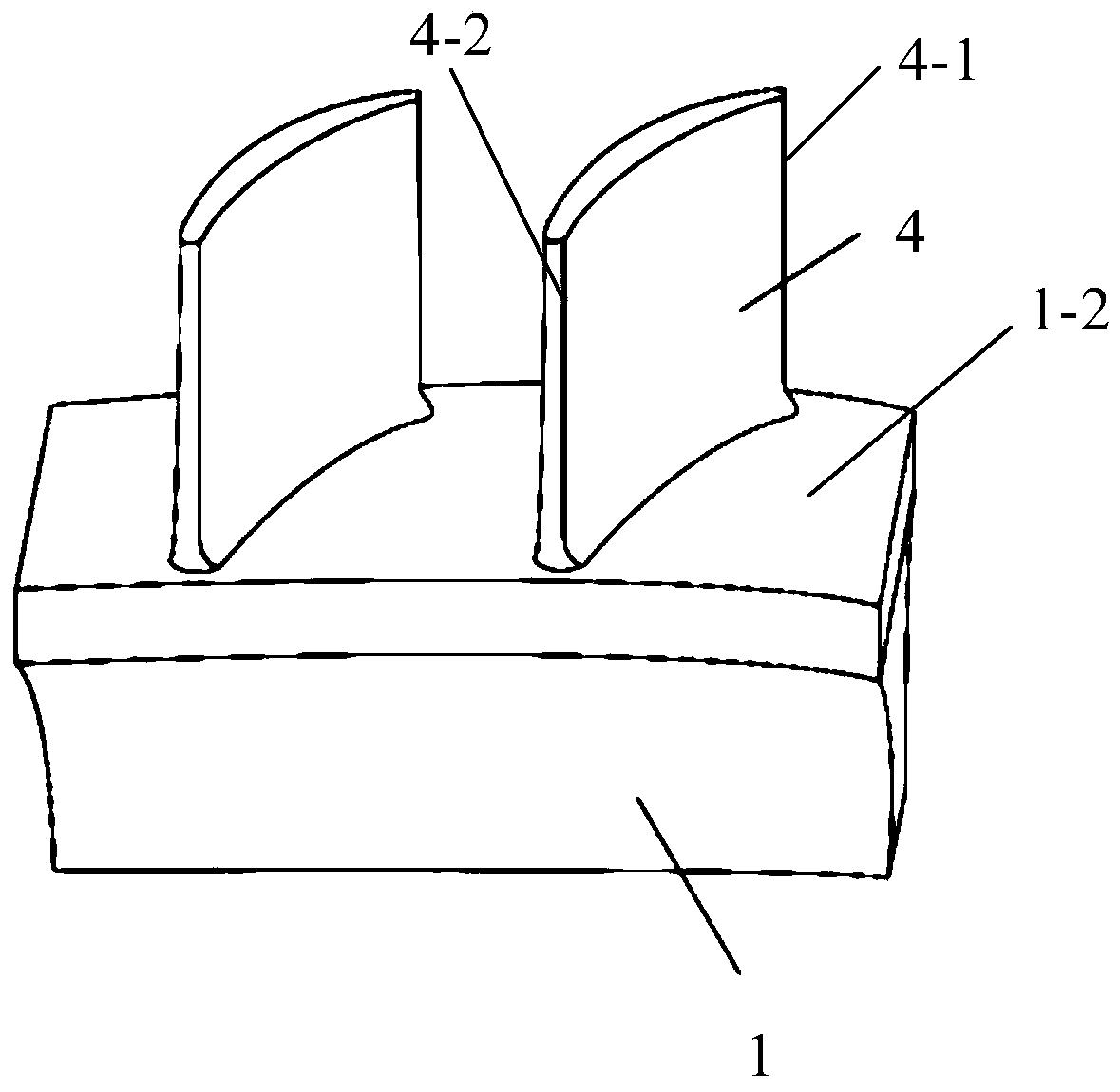

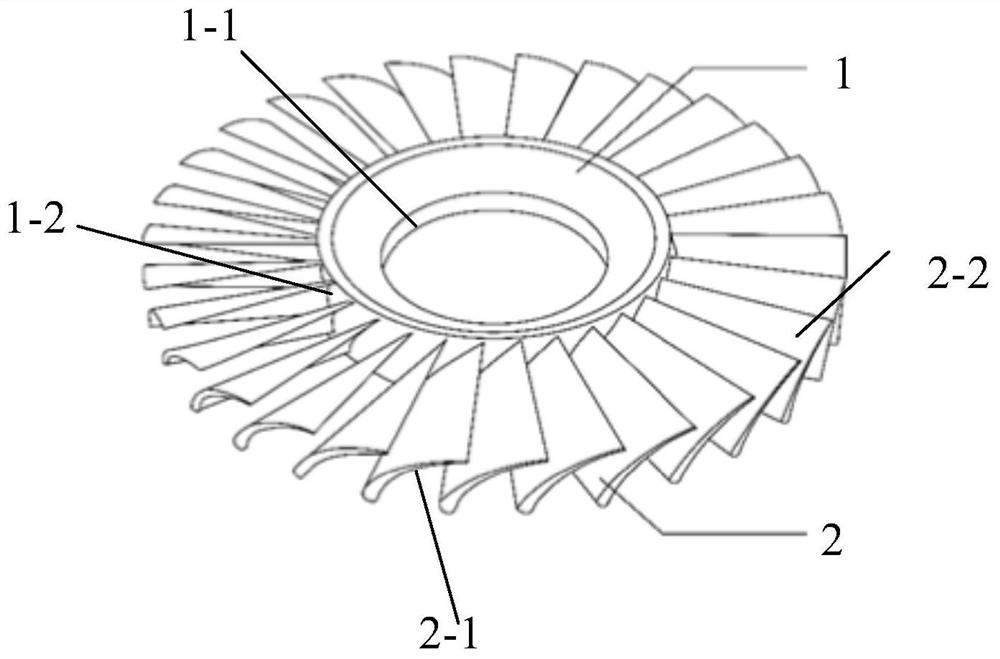

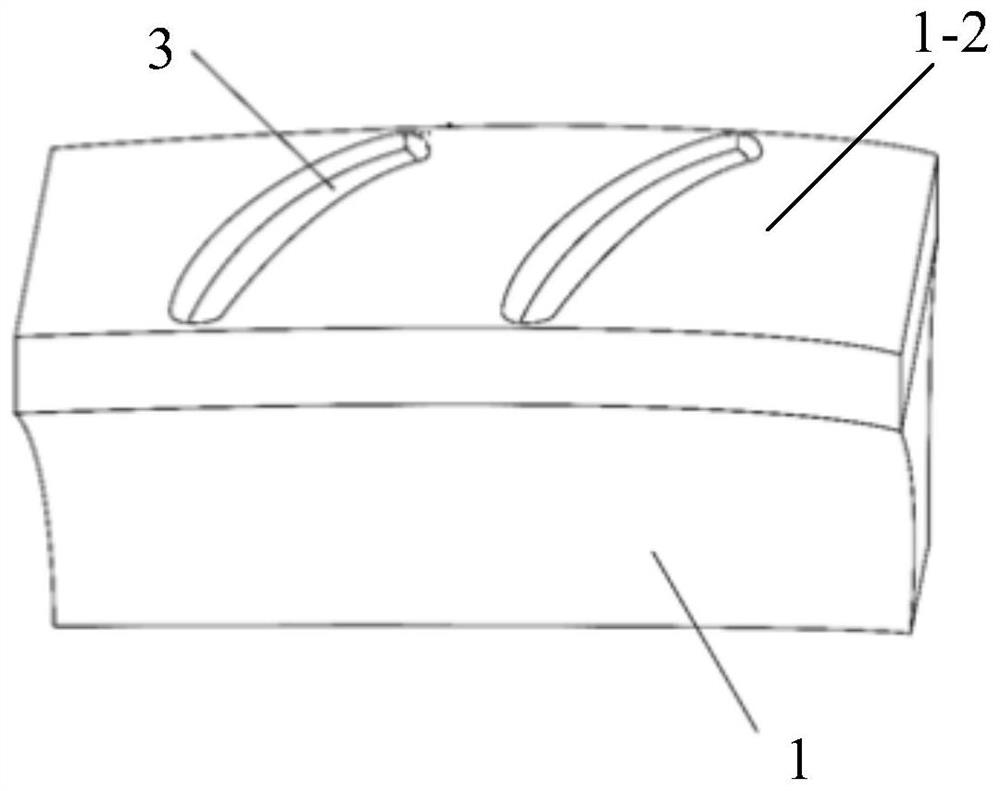

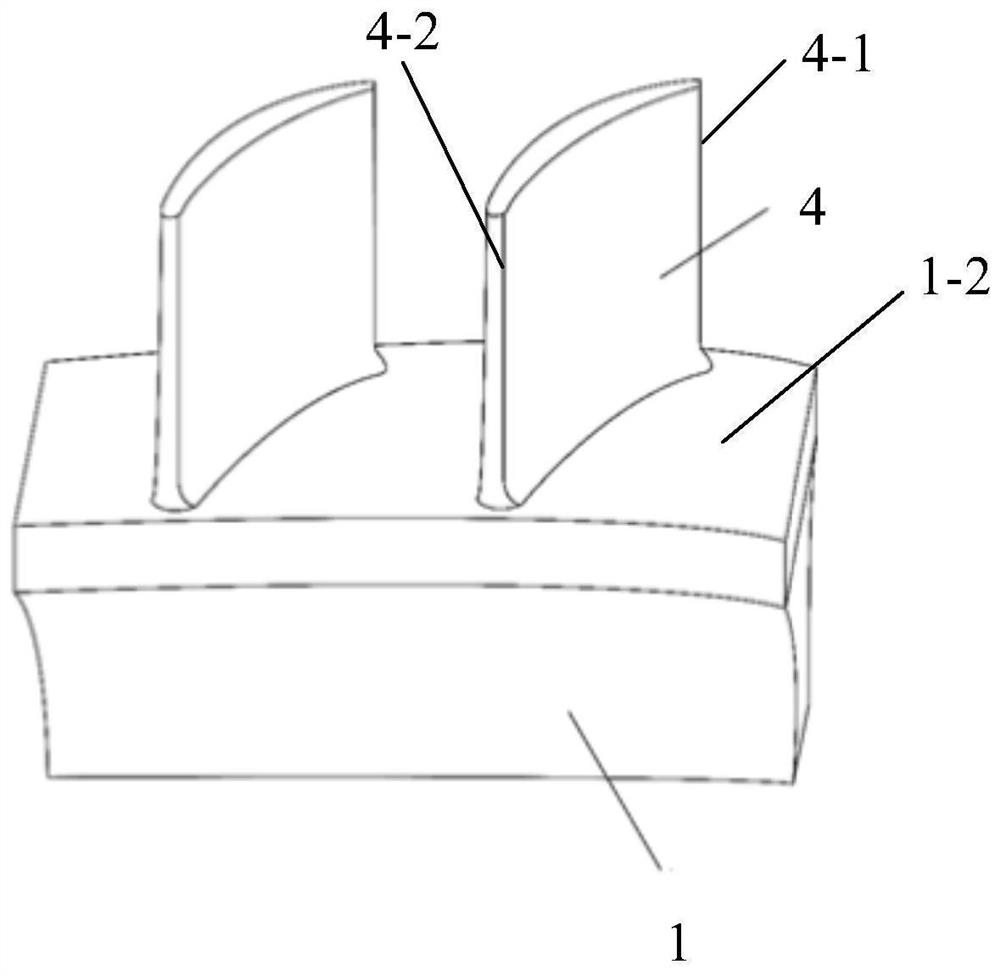

Method for preparing overall semal accurately formed by additive manufacturing and electrolytic machining

ActiveCN110539132AEasy to useExtended service lifeAdditive manufacturing apparatusLife lengthHigh standard

The invention discloses a method for preparing an overall semal accurately formed by additive manufacturing and electrolytic machining. The method combines an electrolytic machining method with a laser additive manufacturing method, at first, grooves are formed in a hub through electrolytic machining, then blade blanks are fabricated on the hub with the grooves by the laser additive manufacturingmethod, the blade blanks are finally machined by the electrolytic machining method, and thus the overall semal can reach design accuracy; and blade additive deposition begins at the grooves, stress concentration at the joint of the hub and blades can be effectively avoided, the overall use performance of components is improved, and the service life of the components is prolonged. The method not only can give full play to the advantages of high utilization rate and free forming of additive manufacturing materials, but also overcome the contradiction between the deposition efficiency and workpiece accuracy of the additive manufacturing materials, enables the dimensional accuracy and surface quality of workpieces to reach high standards, finally reduces manufacturing procedures, greatly shortens the processing cycle of the overall components and reduces the production cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

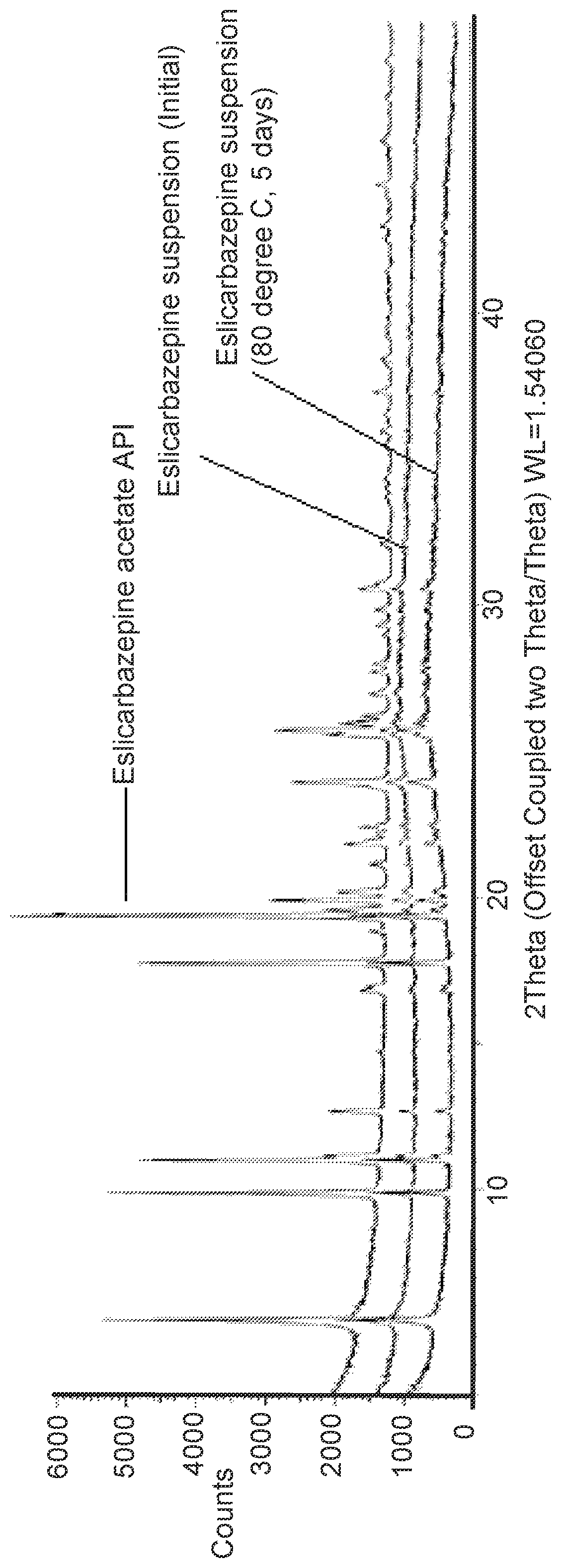

Eslicarbazepine suspension

Owner:JUBILANT GENERICS

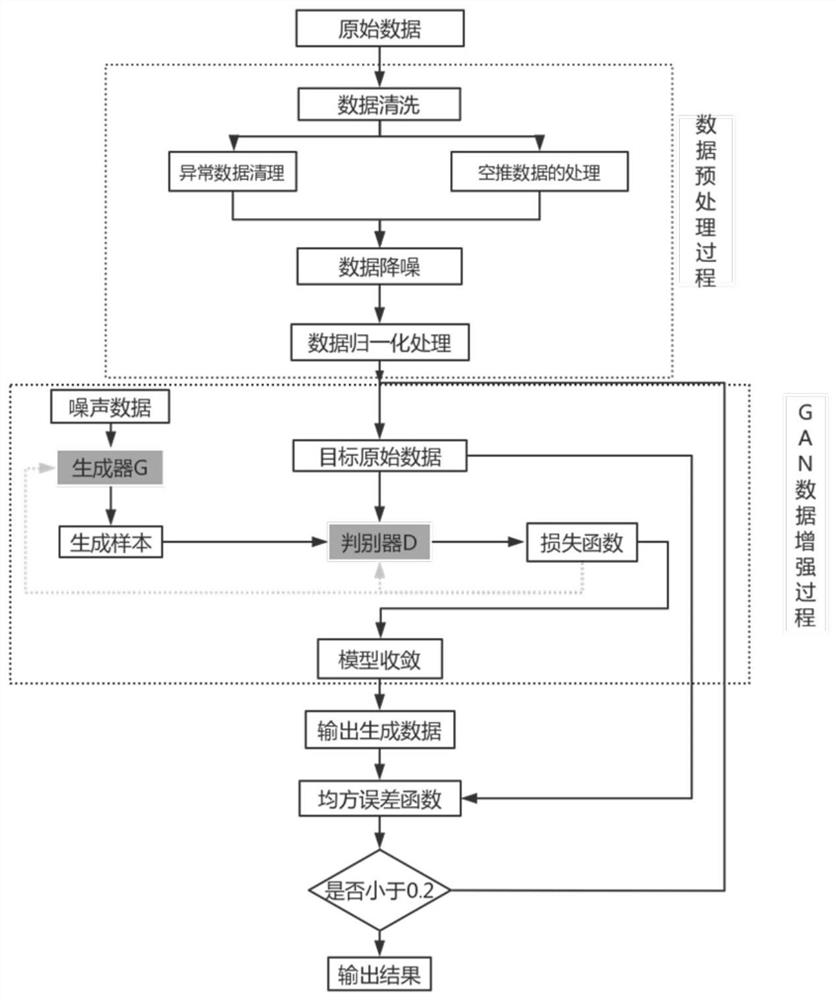

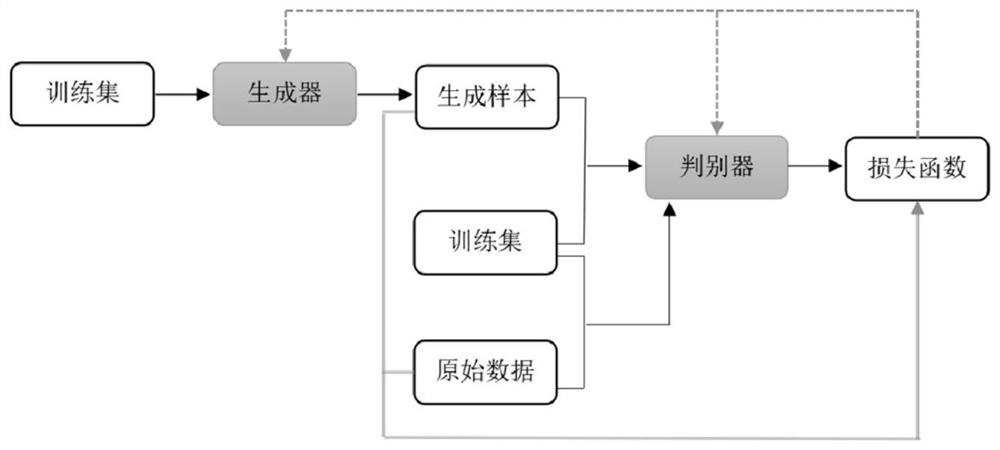

Engineering data enhancement algorithm based on generative adversarial network

InactiveCN113360485AEasy to generate dataGenerating data is simpleDigital data information retrievalNeural architecturesDiscriminatorAlgorithm

The invention discloses an engineering data enhancement algorithm based on a generative adversarial network, and aims to provide enough data information for researchers so as to carry out more accurate research work, and the method comprises the steps: obtaining original data, carrying out data preprocessing such as shutdown data processing, noise reduction processing, normalization processing and the like on the original data, and obtaining a group of smooth and stable construction data; substituting the processed data into a GAN generative adversarial network data enhancement algorithm, and performing data enhancement by using a mutual adversarial principle of a generator and a discriminator; and outputting engineering data similar to the original data in distribution. According to the method, the combination of data preprocessing and data enhancement is realized, multiple groups of useless data including noise are removed, the confrontation principle of a generator and a discriminator in the generative adversarial network is utilized, the enhancement of construction airborne data is realized, and the problem of data shortage in research is solved.

Owner:TIANJIN UNIV

Telescopic component and support for engineering machinery and concrete pump vehicle with the support

InactiveCN101121399BSimple structureEasy to processVehicle fittings for liftingPrime moverScrew thread

An extension component for the engineering plant, an extension landing leg formed by the component and a concrete-pump car are provided. The extension component includes a telescopic bushing component on which a helix mechanism and an arresting device are arranged. The helix mechanism contains a prime mover, a circular shaft and a hollow barrel. The circular shaft is connected with the hollow barrel via a thread or a middle hollow shaft group is arranged between the circular shaft and the hollow barrel, the middle hollow shaft group comprising a middle hollow shaft which has an internal thread and an outside thread. The both sides of the middle hollow shaft group are connected respectively with the circular shaft and the hollow barrel via the thread and the prime mover is connected withthe end of the circular shaft or the hollow barrel, the prime mover fixed on one end of the bushing component and the other end of the bushing component fixed and connected with the end of no prime mover in the helix mechanism. The extension part of the extension landing leg comprises the extension component and one end of the extension landing leg is provided with a supporting component while theother end is connected with a bracket on an underpan of the engineering plant. A supporting part of the concrete-pump car is provided with the extension landing leg. The invention has the advantagesof simple structure, convenient manufacture and low cost.

Owner:SANY AUTOMOBILE MFG CO LTD

Making method of jasmine tea back cushion

InactiveCN107467995AFree formWith floral fragrance sustained releasePillowsDeodrantsCooking & bakingDiuresis

A method for preparing a jasmine tea pillow, the process steps are as follows: (1) processing tea base; (2) processing jasmine flowers: alternately performing heat dissipation and stacking and heating to make the buds open; (3) smelling flowers: jasmine flowers Stir evenly with the tea dregs at a weight ratio of 1:0.5‑0.8, and scent the flowers for 10 to 12 hours; (4) Gangpine treatment; (5) Baking: control its moisture content within 10%; (6) Breaking: made Granular; (7) Mixing: Mix jasmine tea granules and Gangsongye granules in a weight ratio of 3-4:1, add corn modified starch and water, and stir evenly; (8) Coating: Prepare the coating agent Mix evenly into a viscous material, immerse the mixed granules in the coating agent, soak for 2-5min, take out and dry; (9) make pillowcase; (10) shape. The jasmine tea pillow of the present invention has a unique fragrance that makes people feel comfortable, and has certain effects of clearing away heat and detoxifying, diuresis and treating stranguria, killing insects and relieving itching, inhibiting fungus, expelling wind and cold, clearing the lung and clearing the nose.

Owner:广西巧恩茶业有限公司

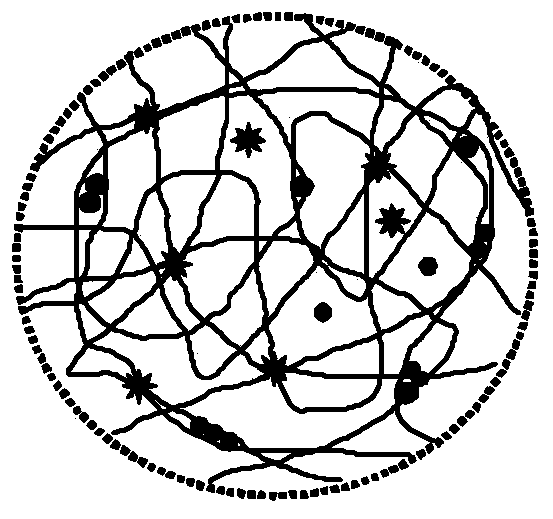

Method for immobilizing enzyme on polymer film

InactiveCN1181200CImproved performance of immobilized enzymesImprove stabilityOn/in organic carrierPolymerReagent

In present ivnention,l soaking method is used to make a hydrophilic polymer containing cation or amine group be adsorbed on the polymer membrane containing anion-active centre, then enzyme preparation or other reagent containing separation or catalytic activity are used to make treatment so as to form immobilized enzyme membrane. Said invention utilizes proper crosslinking reaction to raise stability of immobilized membrane. Said invention can adopt similar method to fix the substance with separation and catalytic activity on the polymer membrane to prepare active membrane with separation and synthesis functions.

Owner:FUDAN UNIV

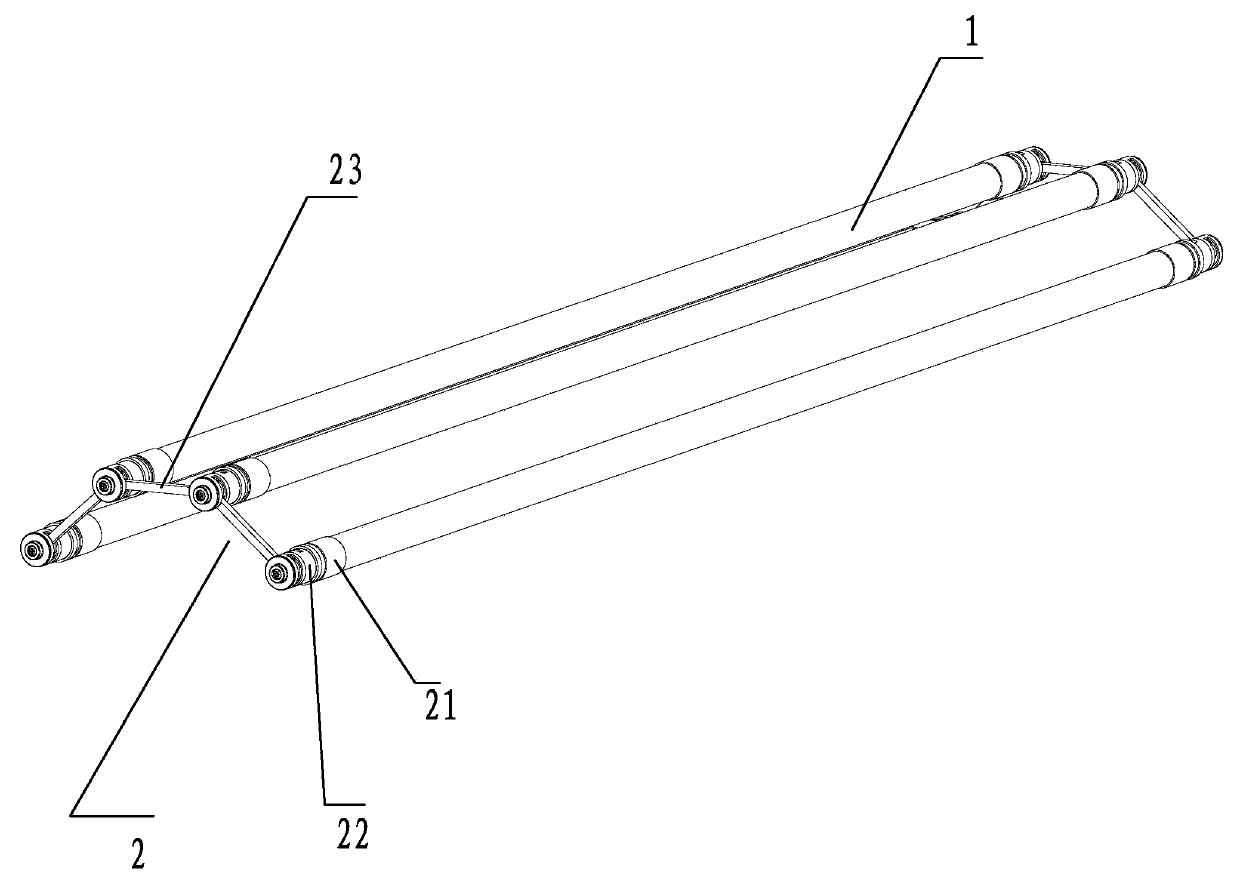

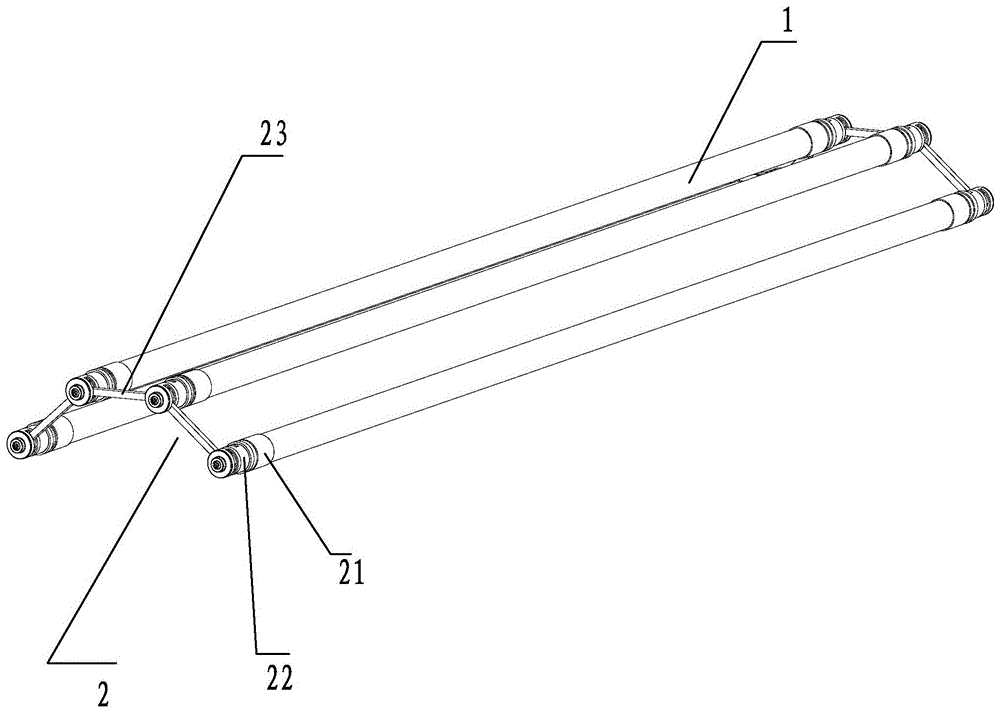

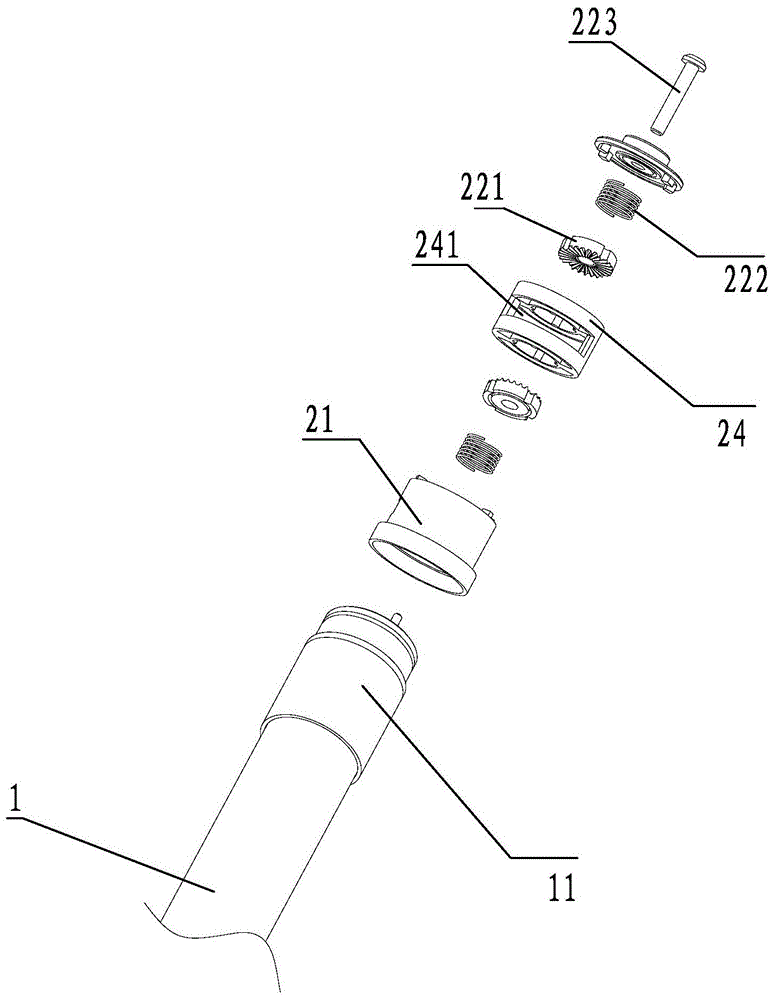

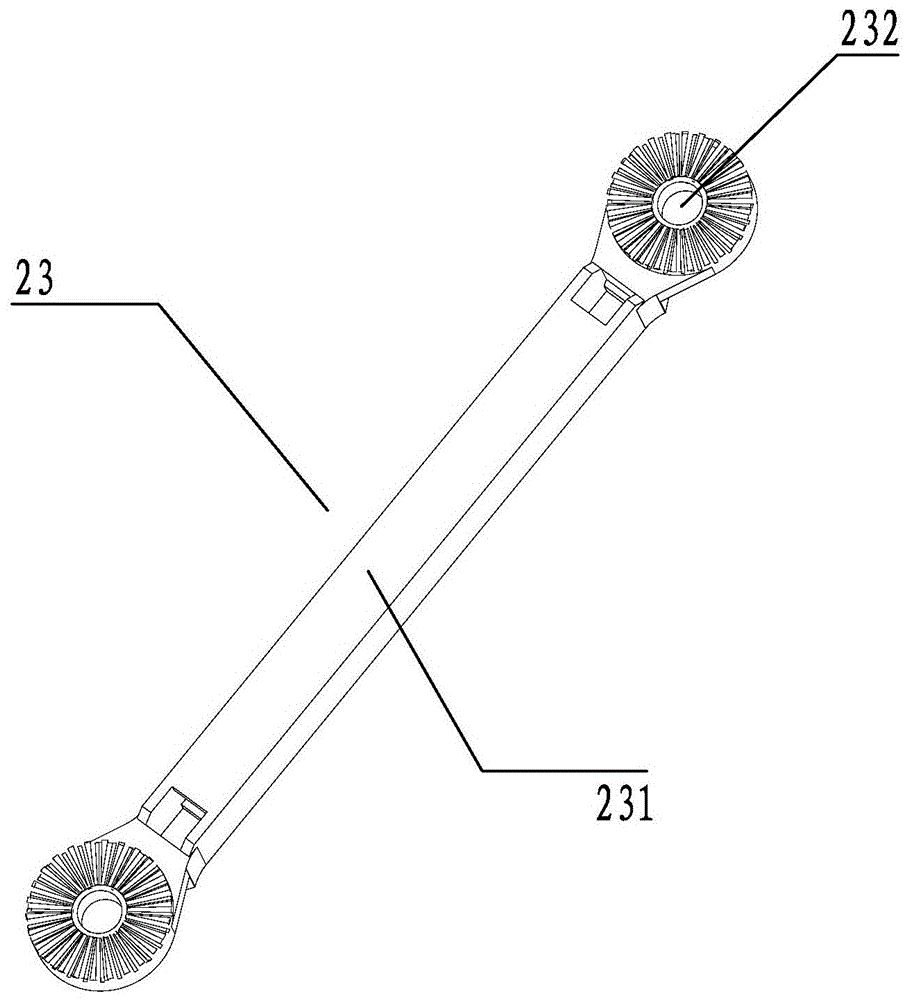

LED fluorescent lamp

InactiveCN104180262AQuantity adjustmentAdjust relative positionPoint-like light sourceLighting support devicesEngineeringDaylight

The invention provides an LED fluorescent lamp which comprises at least two LED fluorescent lamp tubes and lamp brackets. The lamp brackets comprise bases, rotating mechanisms and connecting mechanisms; pin holes are formed in the bases, and the bases are electrically connected with lamp holders of the lamp tubes; the rotating mechanisms are connected with the bases; each connecting mechanism is connected between the corresponding rotating mechanisms; the connecting mechanisms can rotate around the rotating mechanisms. The LED fluorescent lamp has the advantages that the multiple LED fluorescent lamp tubes can be connected with one another by the rotating mechanisms and the connecting mechanisms, the quantity of the connecting mechanisms can be increased and decreased, accordingly, the quantity of the LED fluorescent lamp tubes can be adjusted, and the LED fluorescent lamp is simple and practical; the connecting mechanisms of the LED fluorescent lamp can rotate around the rotating mechanisms, accordingly, the fluorescent lamp tubes can be repositioned relatively to form different shapes, illuminating angles can be adjusted, and light rays can be scattered or gathered according to actual requirements.

Owner:DAHOM FUJIAN ILLUMINATION TECH

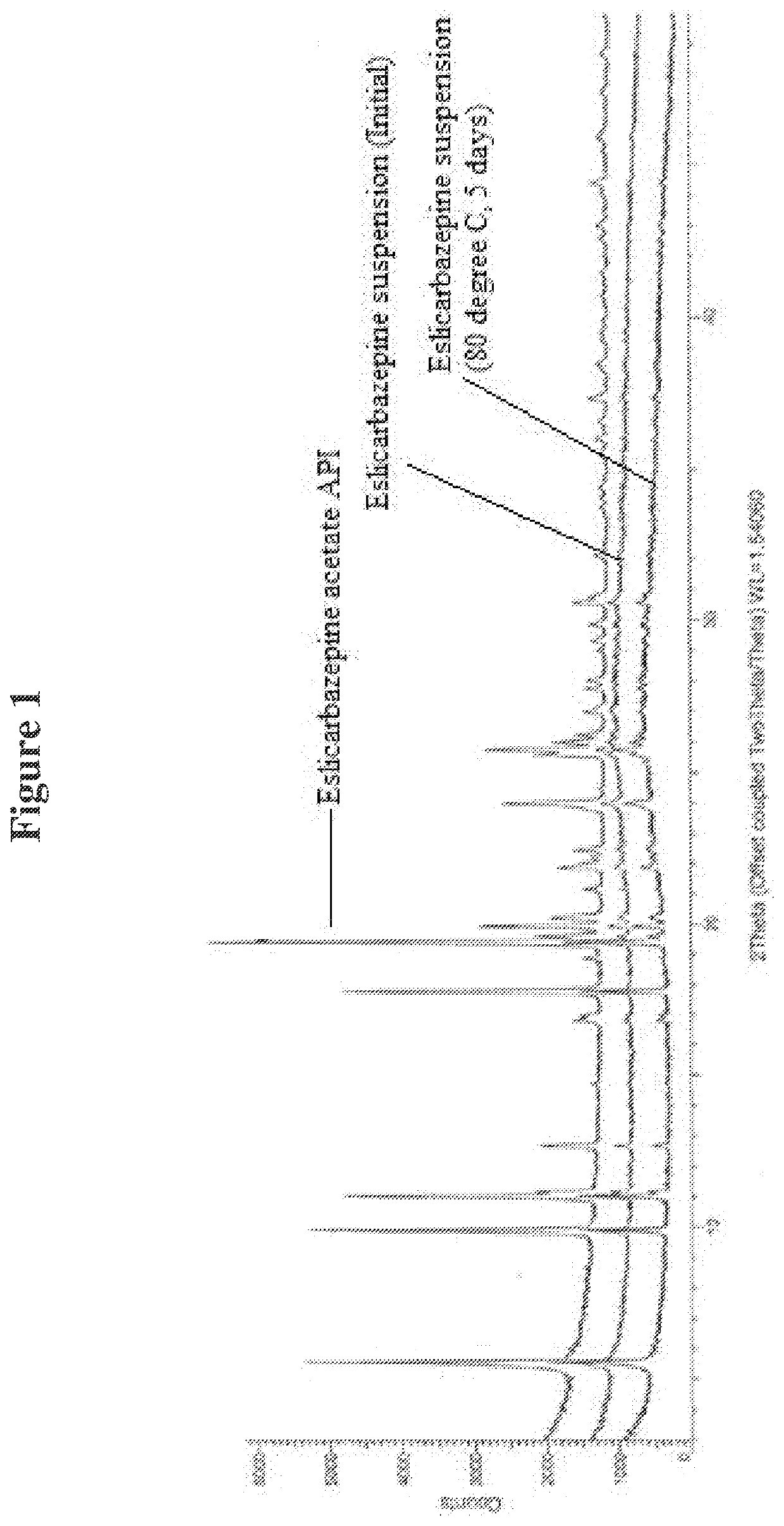

Modified release suspension of eslicarbazepine

ActiveUS20200222421A1Patient compliance is goodIncrease dosing flexibilityPowder deliveryDispersion deliveryLicarbazepineImmediate release

The present invention discloses an extended release oral liquid pharmaceutical composition comprising eslicarbazepine or its pharmaceutically acceptable esters, salts, solvates, polymorphs, enantiomers or mixtures thereof in a pharmaceutically acceptable carrier. The extended release liquid compositions are in the form of ready-to-use liquid compositions or reconstituted liquid compositions. It also relates to processes for the preparation of said extended release liquid compositions. The prior art discloses immediate release oral liquid dosage form. The prepared novel test formulations exhibited desired pharmaceutical technical attributes.

Owner:JUBILANT GENERICS

Modified release suspension of eslicarbazepine

ActiveUS11331324B2Patient compliance and dosing flexibilityComposition is stablePowder deliveryDispersion deliveryLicarbazepineImmediate release

The present invention discloses an extended release oral liquid pharmaceutical composition comprising eslicarbazepine or its pharmaceutically acceptable esters, salts, solvates, polymorphs, enantiomers or mixtures thereof in a pharmaceutically acceptable carrier. The extended release liquid compositions are in the form of ready-to-use liquid compositions or reconstituted liquid compositions. It also relates to processes for the preparation of said extended release liquid compositions. The prior art discloses immediate release oral liquid dosage form. The prepared novel test formulations exhibited desired pharmaceutical technical attributes.

Owner:JUBILANT GENERICS

Eslicarbazepine suspension

The present invention relates to oral ready to use liquid pharmaceutical compositions of eslicarbazepine. It also relates to the processes for the preparation of said liquid compositions. The present invention provides liquid compositions of eslicarbazepine with desired technical attributes such as release profile, viscosity, pH, stability, and acceptable organoleptic properties. The prepared compositions are useful in patients having difficulties in swallowing tablets and provide the physician with providing a more convenient and less cumbersome posology.

Owner:JUBILANT GENERICS

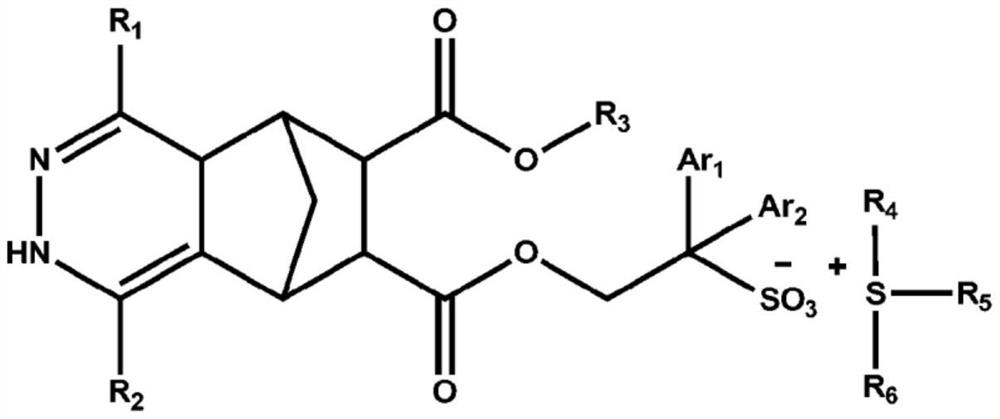

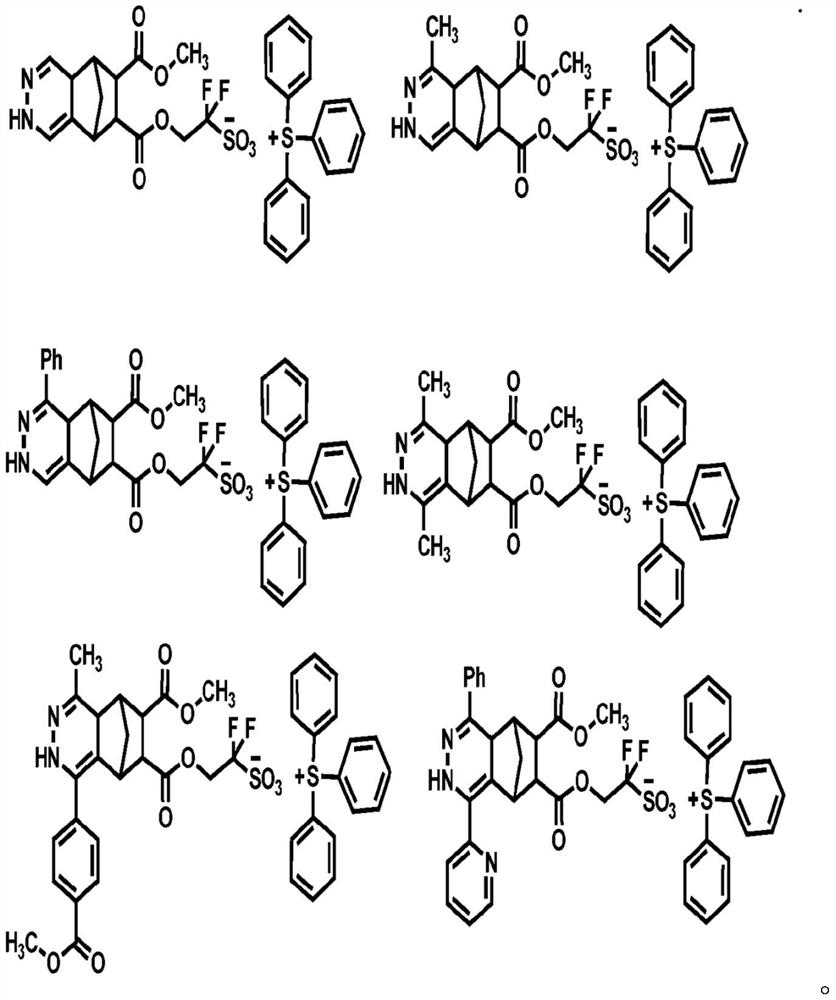

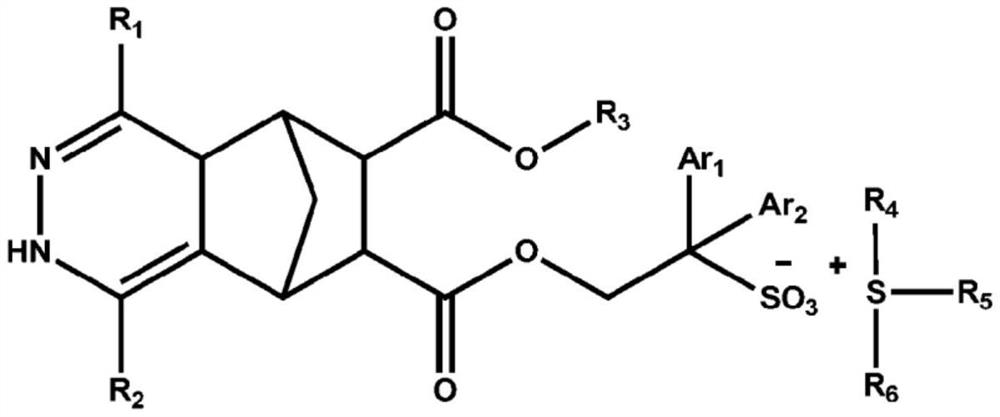

Compound, photoresist composition comprising same, photoresist pattern comprising same, and method for manufacturing photoresist pattern

PendingCN111868038AIncrease contrastImprove line width roughnessOrganic chemistrySemiconductor/solid-state device manufacturingPolymer scienceOrganic chemistry

The present invention relates to a compound, a photoresist composition comprising same, a photoresist pattern comprising same, and a method for manufacturing a photoresist pattern.

Owner:LG CHEM LTD

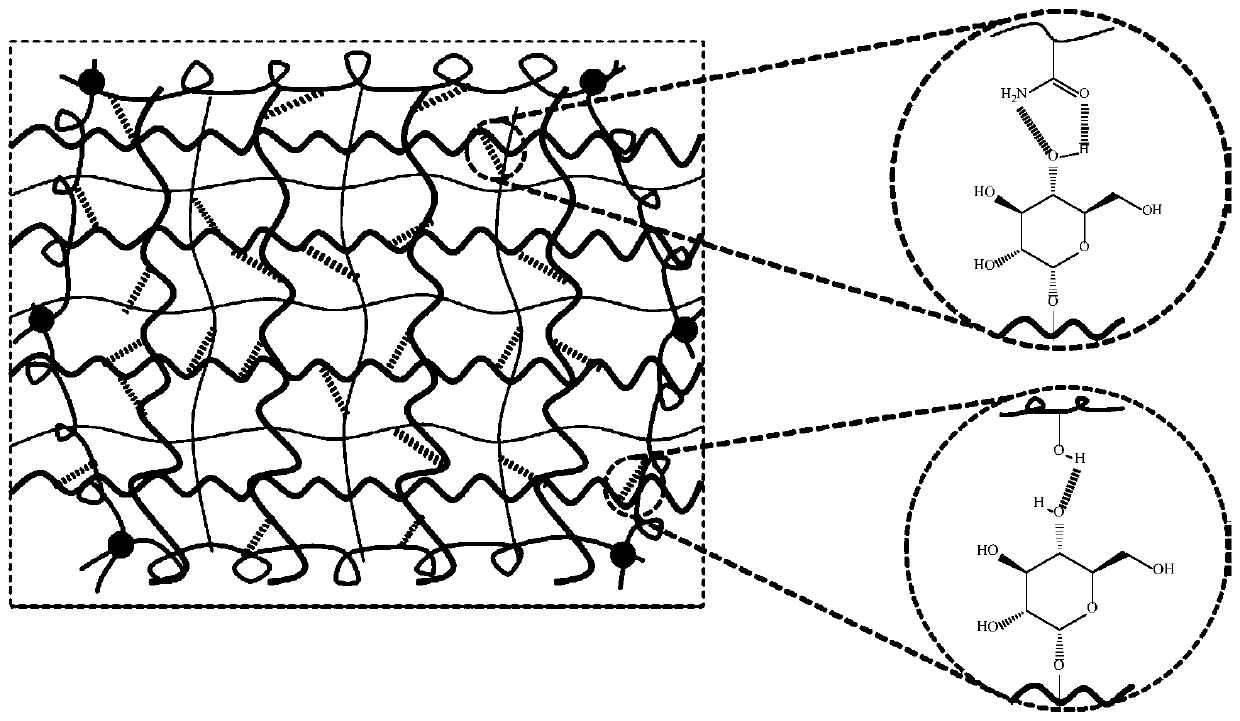

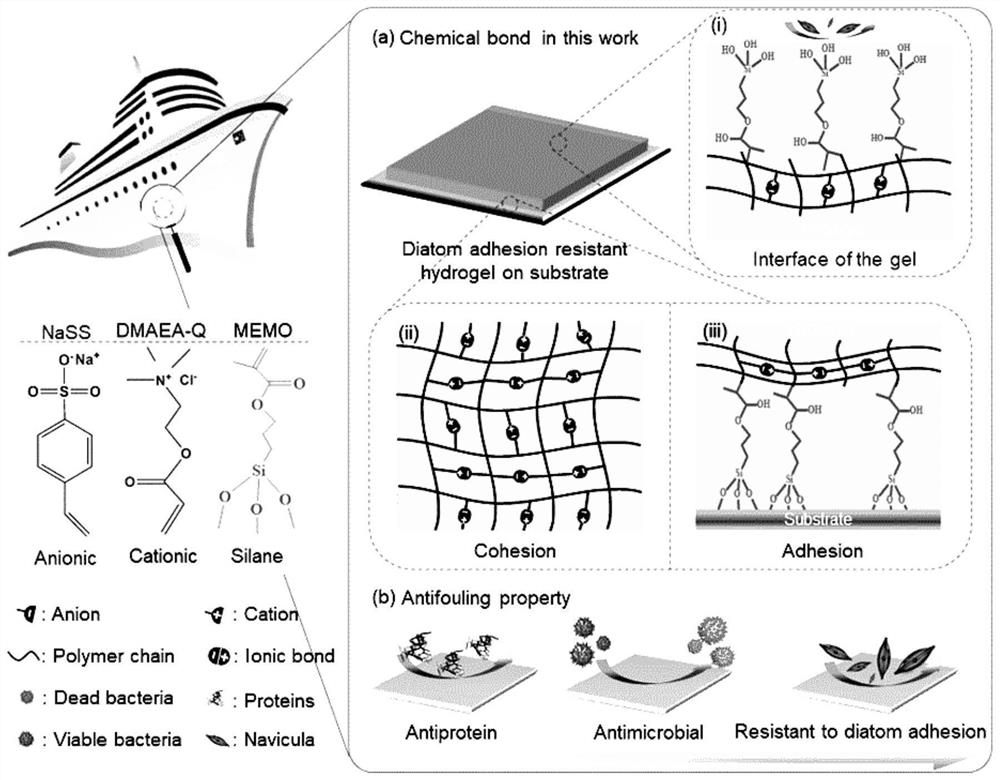

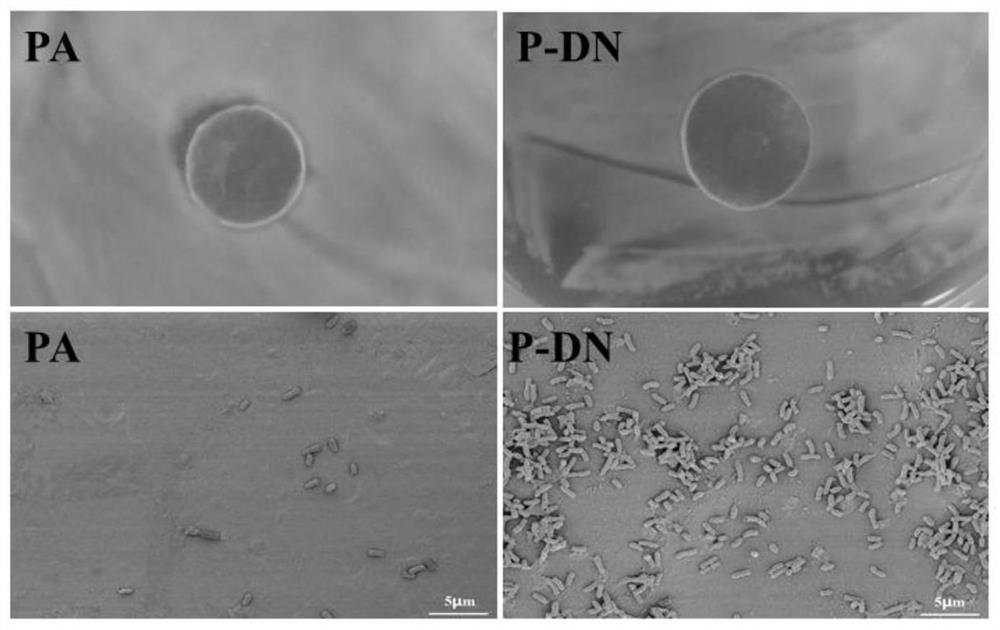

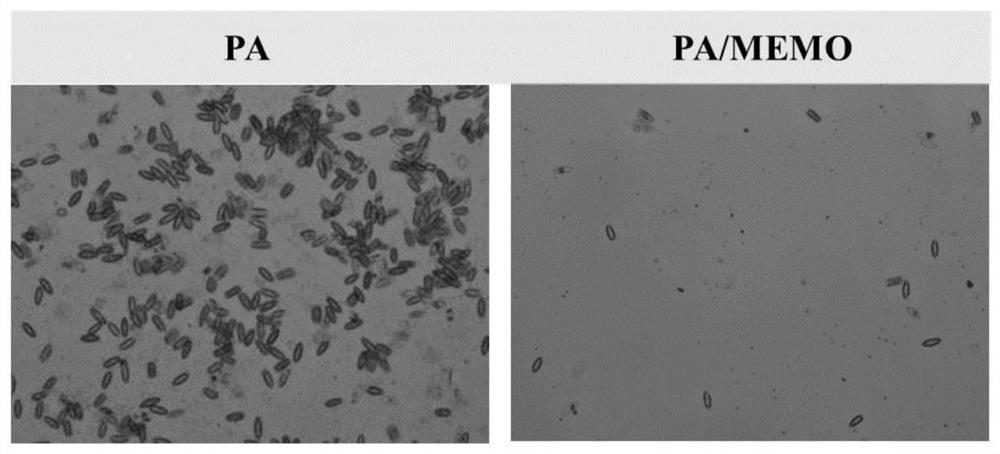

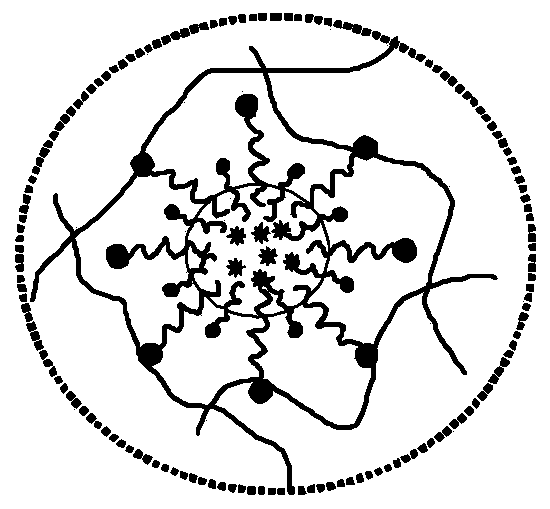

Bacteriostatic and seaweed adhesion-resistant silane modified polyampholyte hydrogel high-adhesion coating and preparation method thereof

ActiveCN114456669AGood mechanical propertiesImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesPrepolymerEnvironmental geology

The invention relates to a preparation method of a silane modified poly-ampholyte hydrogel high-adhesion coating with bacteriostasis and algae adhesion resistance, which comprises the following steps: mixing DAC, NaSS, a cross-linking agent, an initiator, deionized water and MEMO to obtain a prepolymer solution, covering the prepolymer solution on the surface of a base material subjected to hydroxylation treatment and silane treatment, and forming to obtain a hydrogel coating, the antibacterial and seaweed adhesion resistant silane modified polyampholyte hydrogel high-adhesion coating is obtained. The silane modified polyampholyte hydrogel is adopted, through the coupling effect of silane and the synergistic effect of DAC molecular chains and ionic bonds of the substrate, the hydrogel coating has the excellent bonding performance, meanwhile, the hydrogel coating has the good antibacterial performance and diatom adhesion resistance, and the hydrogel coating can serve as a preferred material of a marine antifouling coating. Wide application prospects are realized.

Owner:HUBEI UNIV OF TECH

Preparation method of 3D-printable agar/polyacrylamide double hydrogen bond synergistic cross-linked high-toughness hydrogel

ActiveCN108276590BSimple preparation processShort preparation cycleAdditive manufacturing apparatusUltraviolet lightsFumed silica

The invention discloses a preparation method of agar / polyacrylamide double hydrogen bond synergistically cross-linked high-toughness hydrogel which can be used for 3D printing. First, the agar is dissolved in deionized water under heating and stirring conditions to obtain a uniform aqueous solution, and then the mixed solution of acrylamide and photoinitiator dissolved in deionized water is added to the aqueous solution of agar and mixed evenly, and the final mixed solution is used in a mold or The method of 3D printing is preformed. First, the agar is crosslinked at low temperature, and then the acrylamide is polymerized and hydrogen bonded and crosslinked under ultraviolet light, forming a high-toughness hydrogel with double hydrogen bonds and synergistic crosslinking; due to the hydrogel The gel contains natural polymer agar, and in the sol state, the viscosity is regulated by adding a small amount of fumed silica. It has good anti-collapse and rapid gelation characteristics, and can realize 3D printing.

Owner:HUBEI UNIV OF TECH

Eslicarbazepine suspension

The present invention relates to oral ready to use liquid pharmaceutical compositions of eslicarbazepine. It also relates to the processes for the preparation of said liquid compositions. The present invention provides liquid compositions of eslicarbazepine with desired technical attributes such as release profile, viscosity, pH, stability, and acceptable organoleptic properties. The prepared compositions are useful in patients having difficulties in swallowing tablets and provide the physician with providing a more convenient and less cumbersome posology.

Owner:JUBILANT GENERICS

Preparation method of double physical cross-linked polyacrylic acid hydrogel with high strength and high toughness

The invention discloses a preparation method of full-physical bi-crosslinked polyacrylic acid high-strength and high-toughness hydrogel. According to the technical scheme, the preparation method comprises the following steps: firstly dissolving stearyl acrylate (STA), sodium dodecyl sulfate (SDS) and n-pentyl alcohol to obtain transparent emulsion, then adding acrylic monomers, iron nitrate nonahydrate and a photoinitiator, fully stirring to obtain a uniform mixed solution, initiating under a ultraviolet irradiation condition to enable the acrylic monomers to be polymerized, taking hydrophobicassociation formed by virtue of hydrophobic micelles and polyacrylic acid as a first physical crosslinking point (soft crosslinking point), and taking coordination complexation formed by ferric ionsand polyacrylic acid as a second physical crosslinking point (hard crosslinking point), so that full-physical bi-crosslinked hydrogel formed under the dual function, realizes that crosslinking with 'soft' and 'hard' bi-physical forces exists on a molecular chain. The preparation method disclosed by the invention is not only easy in operation, and a product is excellent in performance and can be used as a biological soft tissue substitute.

Owner:HUBEI UNIV OF TECH

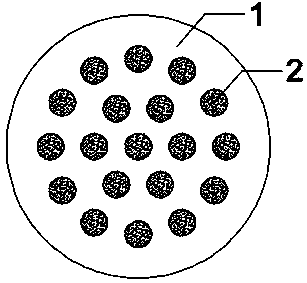

Ceramic particle multi-scale reinforced metal matrix composite wear-resistant rake tooth head and preparation method thereof

ActiveCN108380850BLow priceGood application effectBallastwayTransportation and packagingMetal matrix compositeTooth part

The invention discloses a ceramic particle multi-scale reinforced metal-based composite wear-resistant rake tooth head and a preparation method thereof, belonging to the field of parts preparation. The invention prepares rod-shaped composite materials by pressing and sintering ceramic particles and alloy powders, and inlays multiple rod-shaped composite materials in a metal matrix in combination with an inlay casting process, so as to realize wrapping of evenly distributed multiple rod-shaped composite materials by the metal matrix. The rake tooth head of the present invention avoids the problems of common rake teeth being easy to wear, homogeneous composite wear-resistant parts having poor toughness, brittleness and impact resistance, and adopting the combination process of powder metallurgy and inlay casting, compared with the overall metallurgical sintering, the parts are guaranteed Precise size, meeting the performance requirements of specific components, omitting the assembly process, simplifying the manufacturing process to a certain extent, greatly reducing the cost of parts preparation compared with the overall metallurgical sintering, dense structure and good metallurgical bonding, can be applied to cleaning vehicles and railway maintenance vehicles Rake bucket rock loading machine rake tooth parts, etc.

Owner:KUNMING UNIV OF SCI & TECH

A led daylight lamp

InactiveCN104180262BQuantity adjustmentAdjust relative positionLighting support devicesSemiconductor devices for light sourcesDaylightEngineering

The invention provides an LED fluorescent lamp which comprises at least two LED fluorescent lamp tubes and lamp brackets. The lamp brackets comprise bases, rotating mechanisms and connecting mechanisms; pin holes are formed in the bases, and the bases are electrically connected with lamp holders of the lamp tubes; the rotating mechanisms are connected with the bases; each connecting mechanism is connected between the corresponding rotating mechanisms; the connecting mechanisms can rotate around the rotating mechanisms. The LED fluorescent lamp has the advantages that the multiple LED fluorescent lamp tubes can be connected with one another by the rotating mechanisms and the connecting mechanisms, the quantity of the connecting mechanisms can be increased and decreased, accordingly, the quantity of the LED fluorescent lamp tubes can be adjusted, and the LED fluorescent lamp is simple and practical; the connecting mechanisms of the LED fluorescent lamp can rotate around the rotating mechanisms, accordingly, the fluorescent lamp tubes can be repositioned relatively to form different shapes, illuminating angles can be adjusted, and light rays can be scattered or gathered according to actual requirements.

Owner:DAHOM FUJIAN ILLUMINATION TECH

A preparation method of integral blisks precisely formed by additive manufacturing and electrolytic machining

ActiveCN110539132BEasy to useExtended service lifeAdditive manufacturing apparatusElectrolysisProcess engineering

The invention discloses a method for preparing an overall semal accurately formed by additive manufacturing and electrolytic machining. The method combines an electrolytic machining method with a laser additive manufacturing method, at first, grooves are formed in a hub through electrolytic machining, then blade blanks are fabricated on the hub with the grooves by the laser additive manufacturingmethod, the blade blanks are finally machined by the electrolytic machining method, and thus the overall semal can reach design accuracy; and blade additive deposition begins at the grooves, stress concentration at the joint of the hub and blades can be effectively avoided, the overall use performance of components is improved, and the service life of the components is prolonged. The method not only can give full play to the advantages of high utilization rate and free forming of additive manufacturing materials, but also overcome the contradiction between the deposition efficiency and workpiece accuracy of the additive manufacturing materials, enables the dimensional accuracy and surface quality of workpieces to reach high standards, finally reduces manufacturing procedures, greatly shortens the processing cycle of the overall components and reduces the production cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

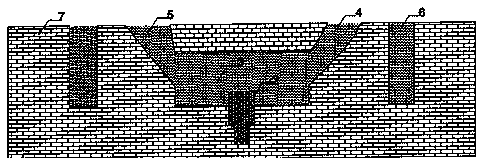

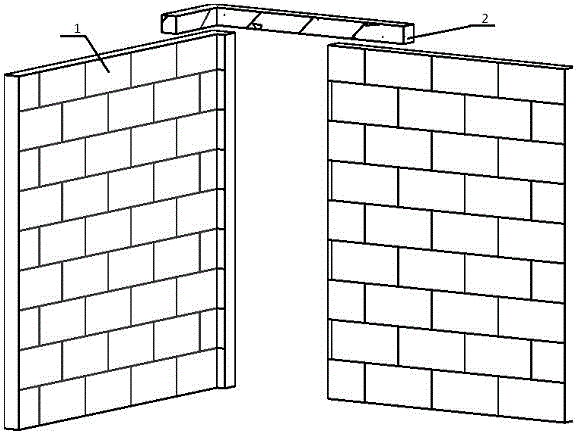

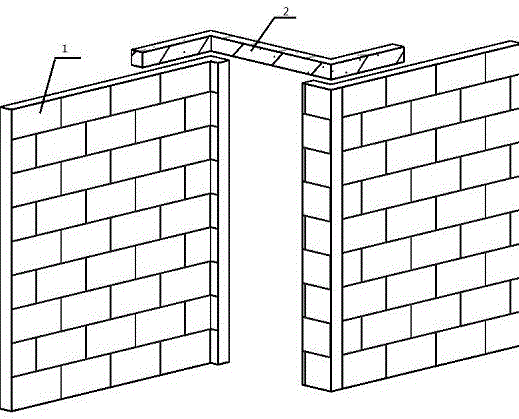

Construction method for nonlinear type lintels

The invention relates to a construction method for nonlinear type lintels. The construction method constituted by a construction method for the cast-in-place concrete lintels or a construction method for the prefabricated concrete lintels. The construction method for the cast-in-place concrete lintels comprises the following steps that (1) steel bars are bound, specifically, at a door opening and a window opening, the distribution bars needed in the L-shaped nonlinear type lintel, the U-shaped nonlinear type lintel, the Z-shaped nonlinear type lintel and the other nonlinear type lintels with the irregular shapes are machined to be formed in a steel bar machining area in advance according to the design requirements; (2) formworks are erected; (3) concrete is cast; (4) curing is conducted; and (5) the formworks are dismantled. The construction method for the prefabricated concrete lintels comprises the following steps that (1) sites are prepared, specifically, the prefabrication sites for the L-shaped nonlinear type lintel, the U-shaped nonlinear type lintel, the Z-shaped nonlinear type lintel and the other nonlinear type lintels with the irregular shapes are specially arranged on site; (2) the detailed design is conducted, specifically, the number of the nonlinear type lintels is counted in a classified mode in advance, and the machining sizes and the shapes of the nonlinear type lintels and the distribution bars in the lintels are designed; (3) the steel bars and the formworks are mounted; (4) the concrete is cast; (5) the formworks are dismantled; (6) stacking and curing are conducted; and (7) mounting is conducted. The process is simple, and the speed is high.

Owner:甘肃第七建设集团股份有限公司

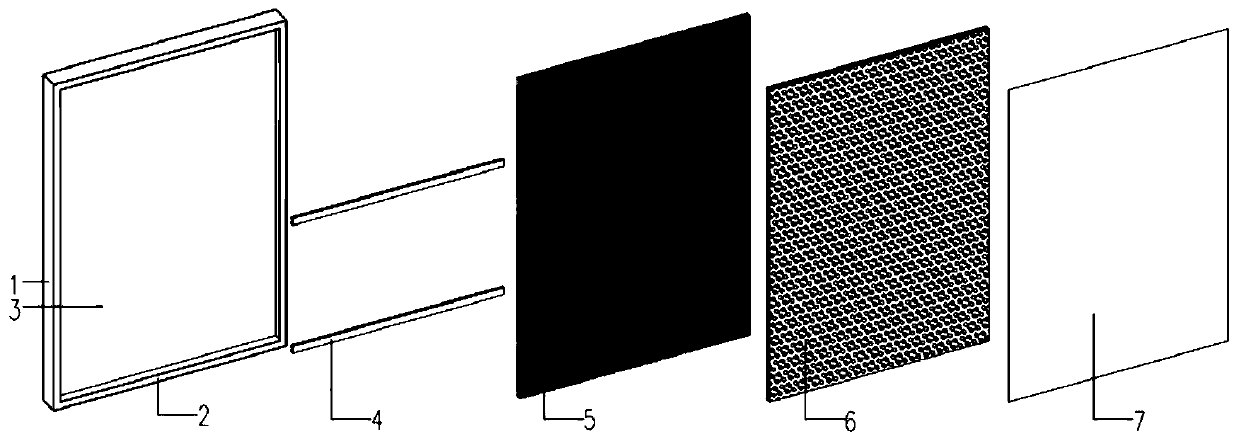

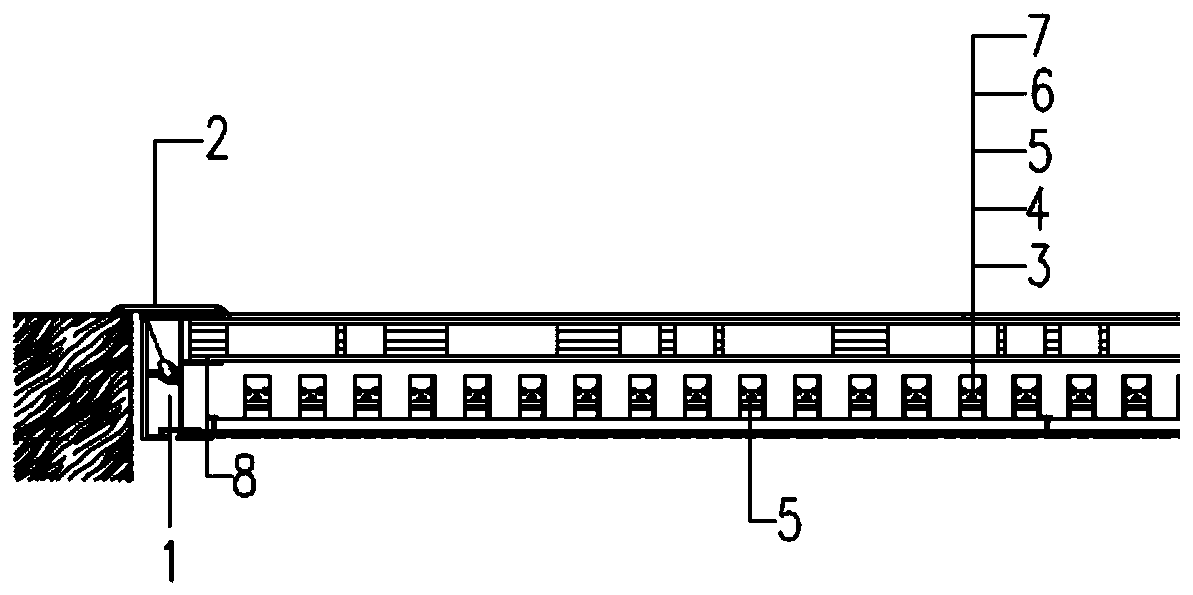

Pseudoisochromatic plate optical media display interface

ActiveCN111223415AReduce energy consumptionLow costEye treatmentIlluminated signsDisplay deviceEngineering

The invention discloses a pseudoisochromatic plate optical media display interface, belonging to the technical field of display devices. The pseudoisochromatic plate optical media display interface mainly comprises a light source and a pattern plate. Compared with an existing LED indoor screen, the pseudoisochromatic plate optical media display interface is low in energy consumption, low in manufacturing cost, easy to construct, attractive in effect and easy to maintain; a low-pixel LED screen with the LED dot spacing of 33 mm is adopted, and in consideration of the situation that indoor sightdistance is mostly between 1 m and 3 m, an abstract pattern in a pseudoisochromatic plate pattern style is suitable for being used, so visual load generated by media information can be reduced, visual fatigue is relieved, eye muscles of high-intensity workers can be relaxed, and the low-vision people can relax the mind and body easily; a soft light plate with an acrylic frosted effect is adoptedon the surface of media, so LED light emitting points cannot be directly seen, the media are soft and free of glare, and the effect of displaying abstract pseudoisochromatic images is better achieved; and patterns of a laser-engraved fireproof PVC dielectric layer can be customized and are free in form, so patterns of different styles can be created in subsequent use, and various effects are achieved through combined usage of the light-emitting characteristics of the LED.

Owner:TONGJI UNIV

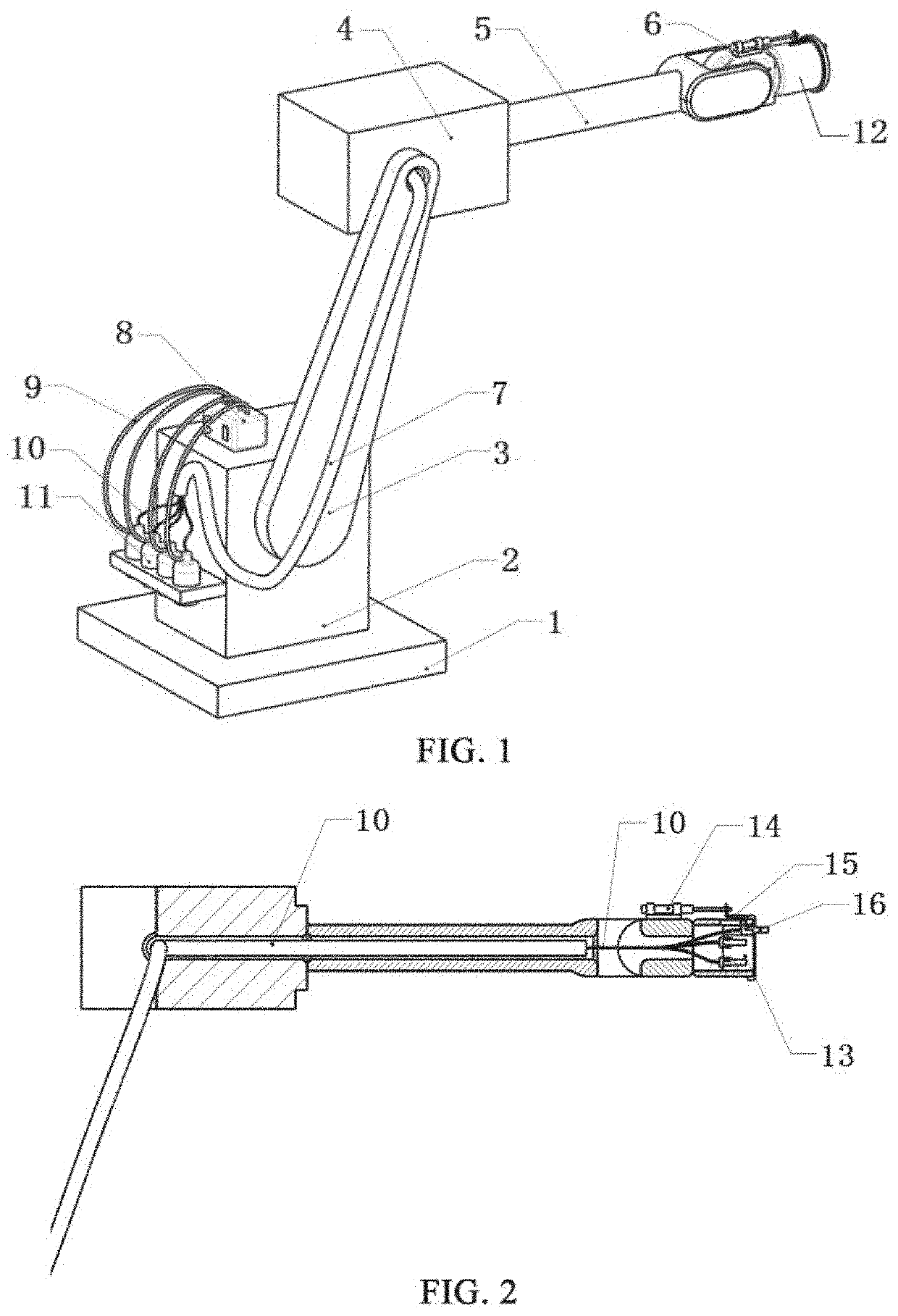

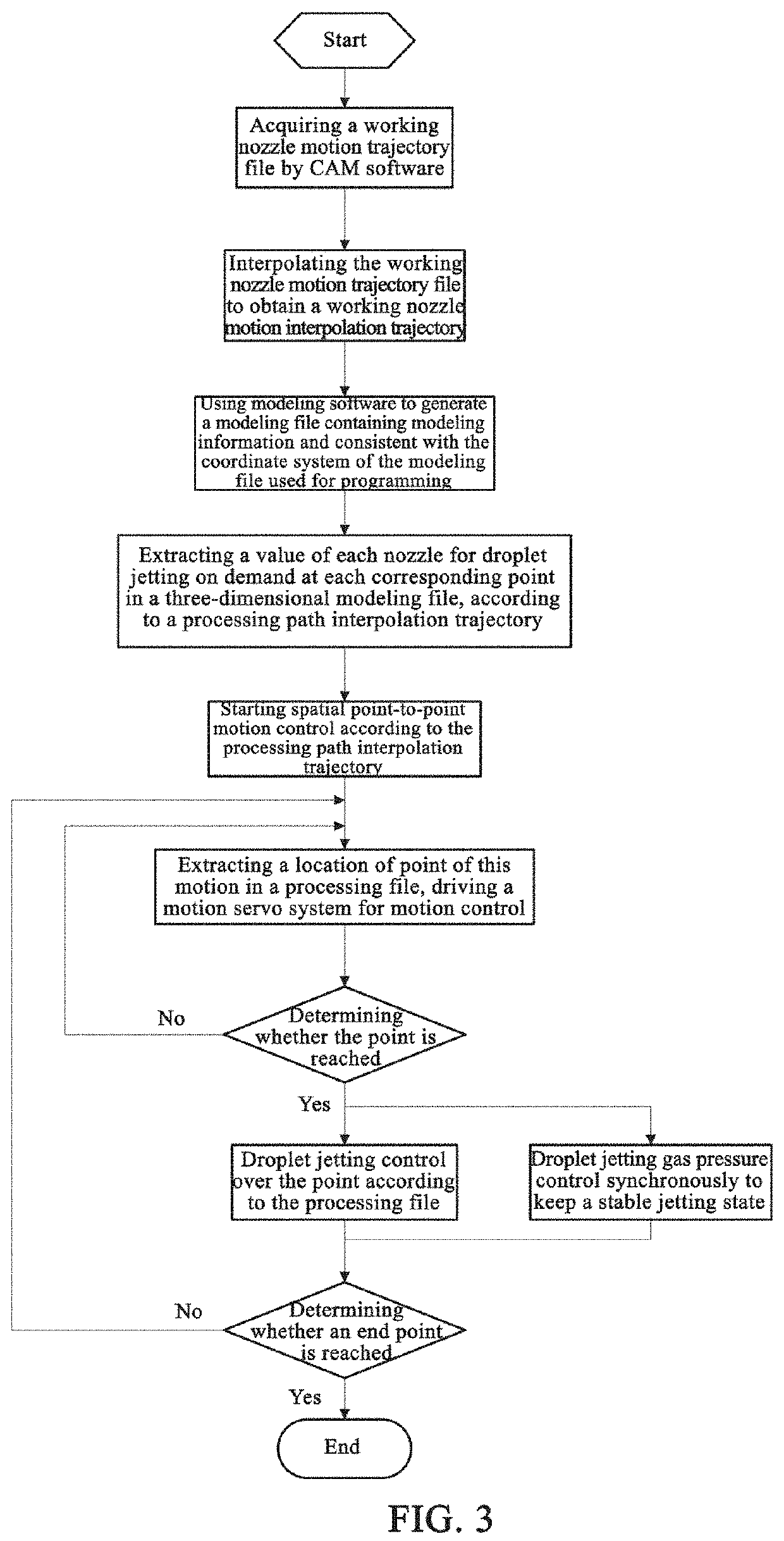

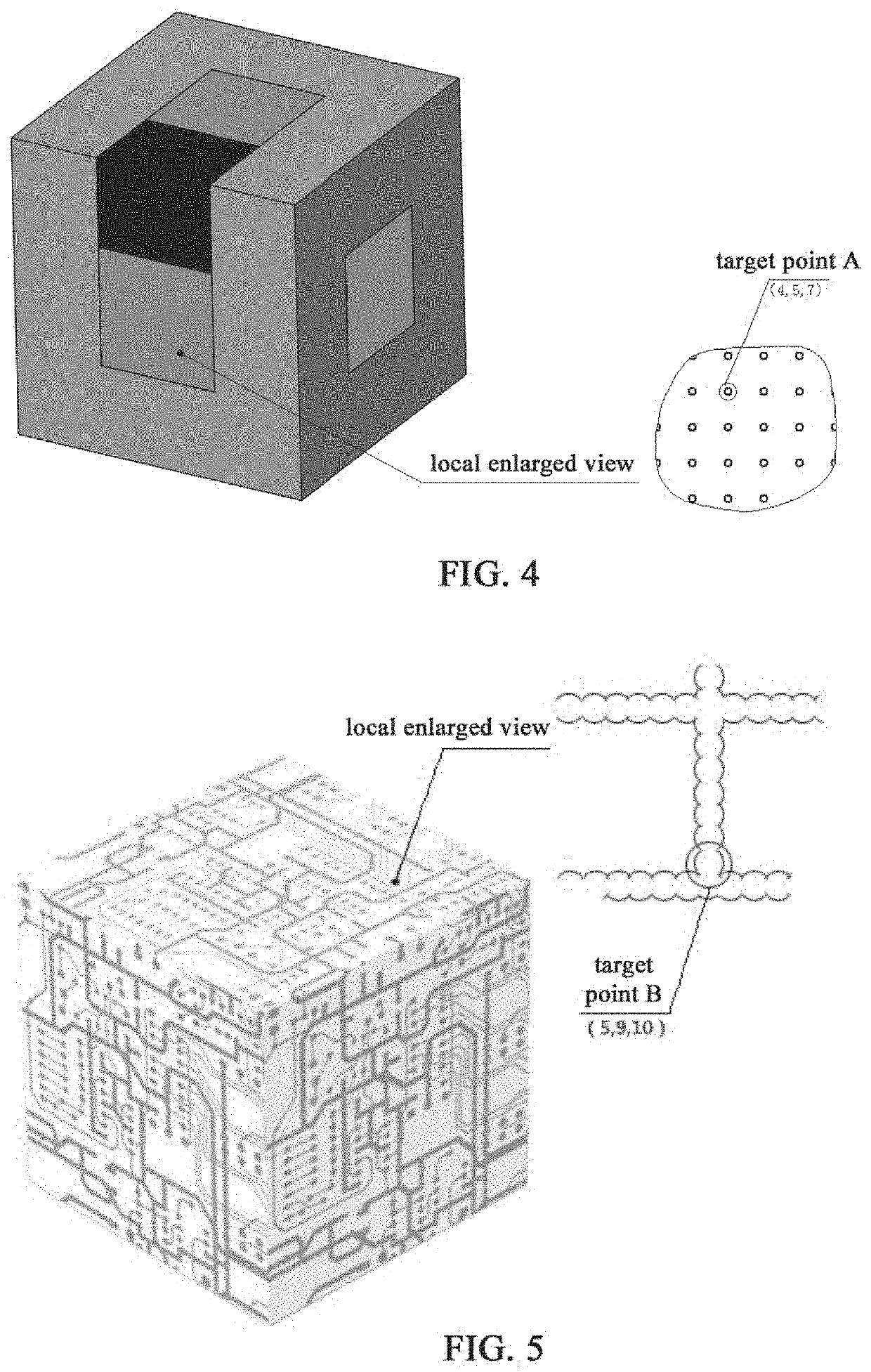

Robot for performing droplet jetting and droplet jetting control method for robot

InactiveUS20200078812A1Flexible operationComplicated spraying effectProgramme-controlled manipulatorLiquid surface applicatorsControl systemClassical mechanics

Provided are a robot for performing droplet jetting, and a droplet jetting control method for a robot. The robot for performing droplet jetting comprises a control system, a mechanical motion structure, a droplet jetting system, and an aerodynamic balance system. The control system implements motion control and droplet jetting control. The mechanical motion structure is a multi-degree-of-freedom mechanical structure and is used to implement a multi-degree-of-freedom motion function. The droplet jetting system is installed at the mechanical motion structure. The aerodynamic balance control system controls, according to a change in an air pressure of a nozzle, air pressures inside and outside of the nozzle to attain a balance so as to ensure a stable jetting, thereby preventing jetting of an excessive amount or an insufficient amount of droplets. The robot for performing droplet jetting can realize freer fabrication of products having planar and curved surfaces without any dead angles by performing omni-directional micro-droplet jetting.

Owner:SHAANXI HWATEC TECH CO LTD

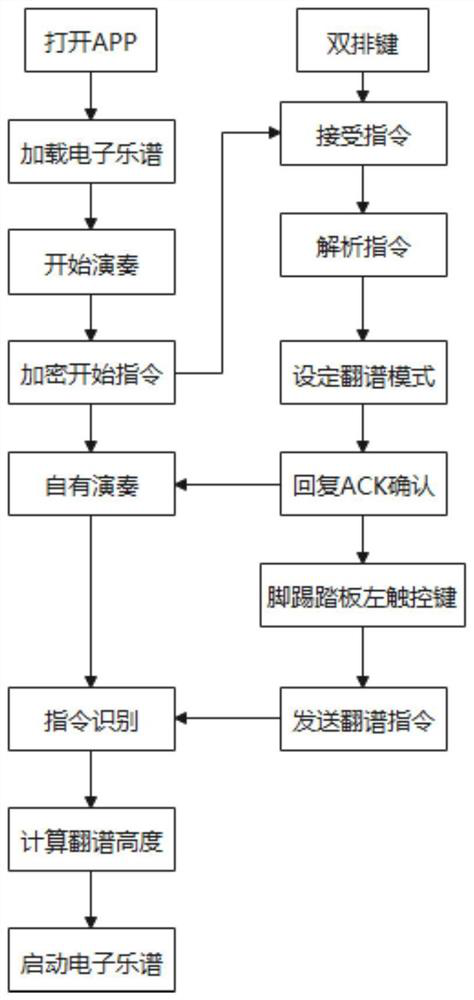

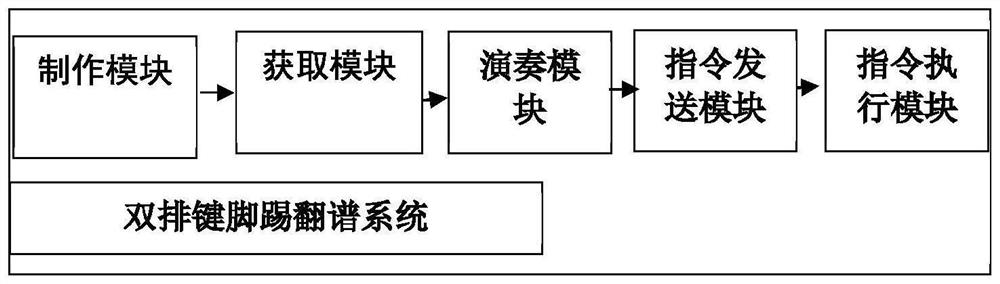

Double-row key foot music score kicking method and system

The invention provides a double-row key foot music score kicking method and system. The method comprises the following steps: arranging two touch switches on a pedal of double-row keys, wherein when a tiptoe kicks the left touch switch, an MIDI instruction is triggered, and the instruction can be set as a music score turning instruction; forwarding the MIDI instruction to an App through the double-row keys; and after the App recognizes the instruction, turning a music score page. According to the music score turning method provided by the invention, music score turning control can be carried out by feet, playing conflicts with hands are avoided, convenience and high efficiency are achieved, the playing form is free, repeated playing and pause can be carried out at any time, and the method has the same advantages as paper music score playing.

Owner:玖月音乐科技(北京)有限公司

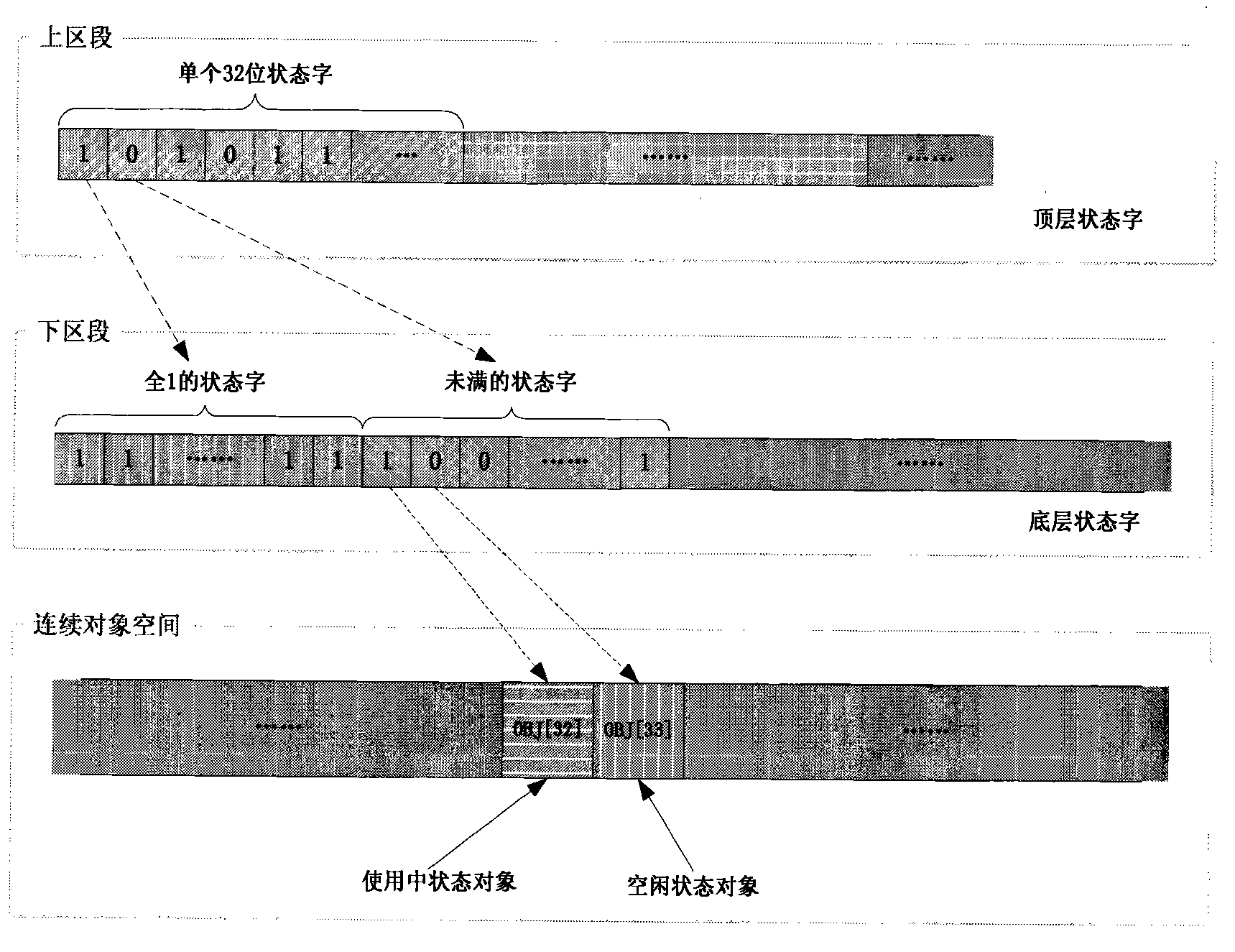

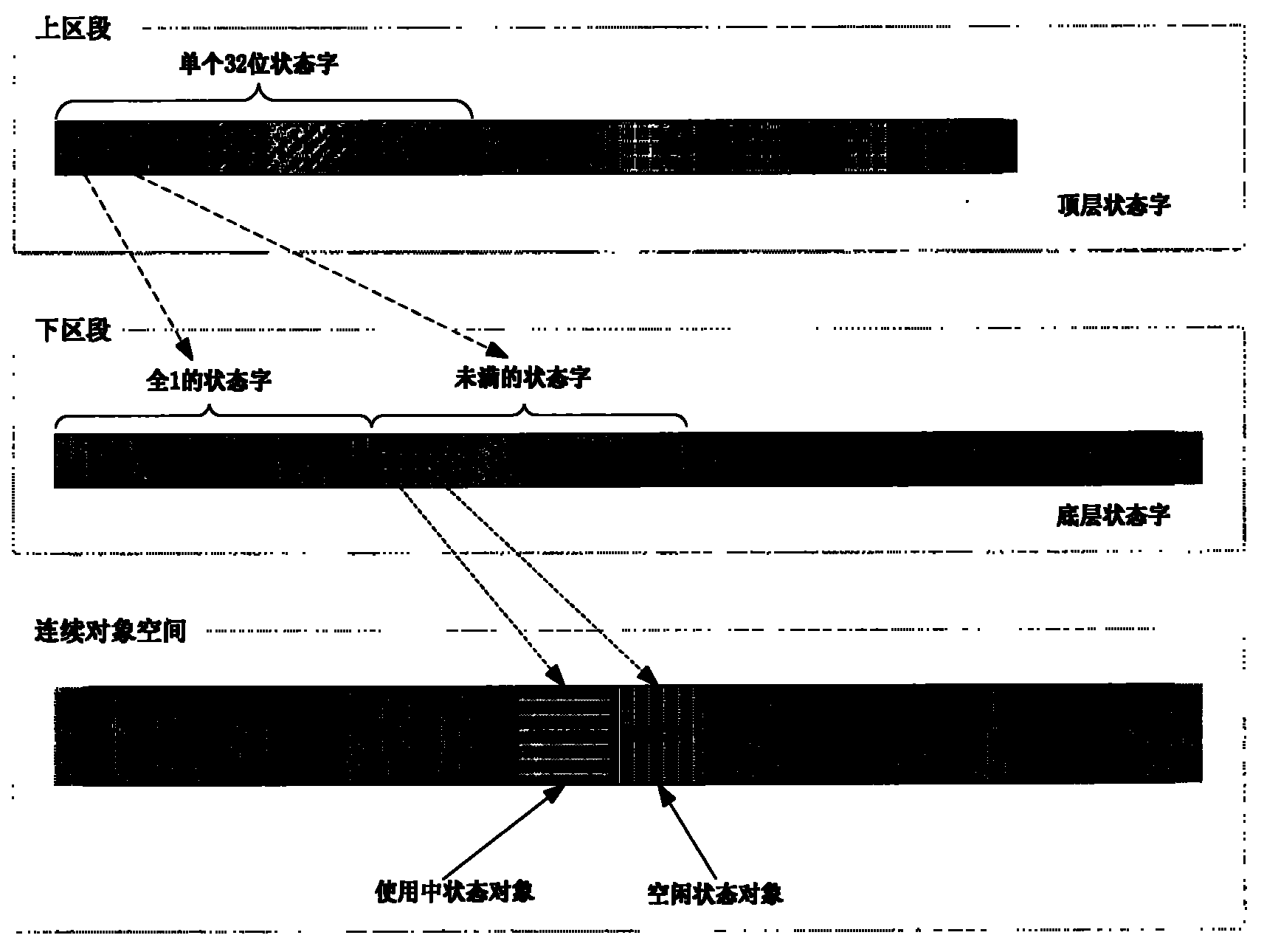

Object management method for dynamic binary translation

InactiveCN101408848BHighlight Substantial ProgressImprove robustnessProgram controlMemory systemsAlgorithmBinary translation

The invention relates to an object management method for dynamic binary translation. With a multilevel status word mode, the values of continuous binary bits are used for marking the object state of the same category, wherein, each binary bit is used for marking two states of an object. A plurality of status word layers are used for marking the state of a huge number of objects of the same category, that is, the status word layer is divided into an upper section and a lower section which contains a status word set for marking the state of objects and is realized by arraying a plurality of status words continuously and transversely; the upper section can be realized by a plurality of status word layers and is the status word set for marking the status of status words, each status word layer is formed by arraying a plurality of status words continuously and transversely and then longitudinally. In the invention, the memory space of the object is completely under control of a dynamic binary translator and continuous space is applied to storing objects of the same category, thus effectively improving the control of the translator over space utilization and object operation and degrading performance loss.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com