Preparation method of double physical cross-linked polyacrylic acid hydrogel with high strength and high toughness

A technology of physical cross-linking and polyacrylic acid, applied in the field of polymer materials, can solve the problems of difficult to stabilize hydrogel properties and difficult mass production, and achieve the effects of excellent self-healing performance, short production cycle, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

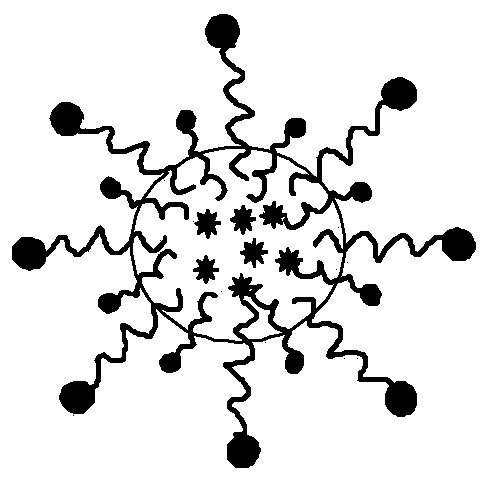

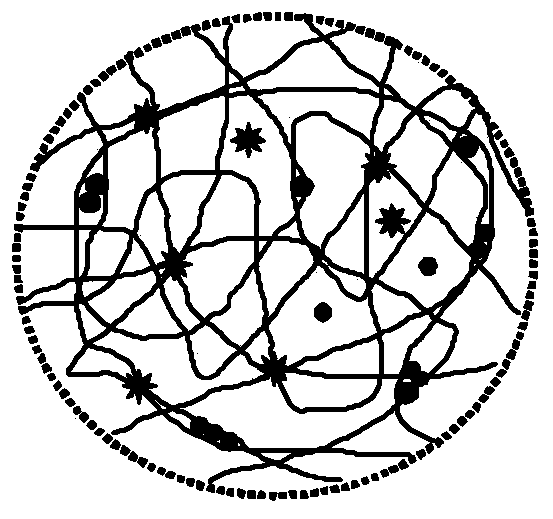

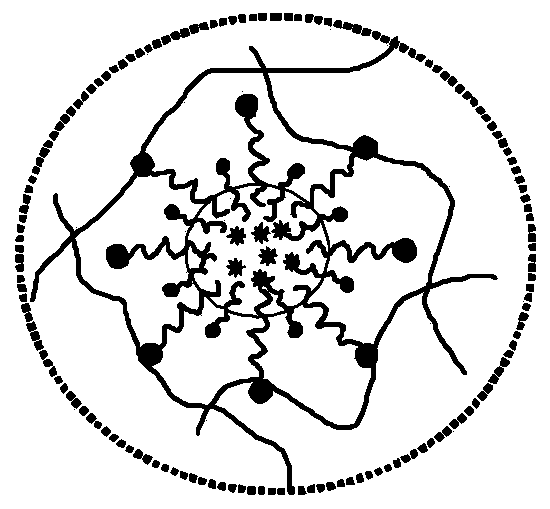

Method used

Image

Examples

Embodiment 1

[0027] Step 1): Weigh 1.095g STA (0.067mol / L), 3.5g SDS (0.243mol / L), and 3mL n-amyl alcohol (0.567mol / L) respectively in a three-necked flask, then add 27mL deionized water, and Stir at high speed in a water bath at 45°C for 1 hour to obtain a uniform and transparent emulsion.

[0028] Step 2): Weigh 15.426mL AAc (4.5mol / L), 0.135g Fe(NO 3 ) 3 9H 2 O (0.006mol / L), 0.033g KA (0.0045mol / L) in the emulsion of step 1), continue stirring at the same temperature and speed for 1 hour under a dark environment, and prepare AAc with 4.5mol / L, Fe 3+ 0.006mol / L, STA 0.067mol / L mixed solution.

[0029] Step 3): Inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, place the glass mold under a UV lamp at 20 cm for 10 to 12 hours, and obtain high-strength, high-toughness fully physical double crosslinking PAAc hydrogel.

[0030] Experiments show that the tensile strength of the double physically cross-linked PAAc hydrogel material obtained in...

Embodiment 2

[0033] Step 1): Weigh 1.095g STA (0.067mol / L), 3.5g SDS (0.243mol / L), and 3mL n-amyl alcohol (0.567mol / L) respectively in a three-necked flask, then add 27mL deionized water, and Stir at high speed in a water bath at 40°C for 0.5 hour to obtain a uniform and transparent emulsion.

[0034] Step 2): Weigh 15.426mL AAc (4.5mol / L), 0.398g Fe(NO 3 ) 3 9H 2 O (0.0197mol / L), 0.033g KA (0.0045mol / L) in the emulsion of step 1), continue stirring at the same temperature and speed for 0.5 hours under a dark environment, and prepare AAc with 4.5mol / L, Fe 3+ 0.0197mol / L, STA 0.067mol / L mixed solution.

[0035] Step 3): inject the mixed solution obtained in step 2) into a glass mold under the condition of shading, and place the glass mold under a UV lamp at 30 cm for 10 to 12 hours to obtain high-strength, high-toughness fully physical double cross-linking PAAc hydrogel.

[0036] Experiments show that the tensile strength of the double physically cross-linked PAAc hydrogel material obt...

Embodiment 3

[0039] Step 1): Weigh 1.785g STA (0.11mol / L), 3.5g SDS (0.243mol / L), and 3mL n-amyl alcohol (0.567mol / L) respectively in a three-necked flask, then add 23mL deionized water, and Stir at high speed in a water bath at 50°C for 1.5 hours to obtain a uniform and transparent emulsion.

[0040] Step 2): Weigh 18.855mL AAc (5.5mol / L), 0.324g Fe(NO 3 ) 3 9H 2 O (0.016mol / L), 0.040g KA (0.0045mol / L) in the emulsion of step 1), continue stirring at the same temperature and speed for 1.5 hours in a dark environment, and prepare AAc with 5.5mol / L, Fe 3+ 0.016mol / L, STA 0.11mol / L mixed solution.

[0041] Step 3): Inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, place the glass mold under a UV lamp at 10 cm for 10 to 12 hours, and obtain high-strength, high-toughness fully physical double crosslinking PAAc hydrogel.

[0042] Experiments show that the tensile strength of the double physically cross-linked PAAc hydrogel material obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com