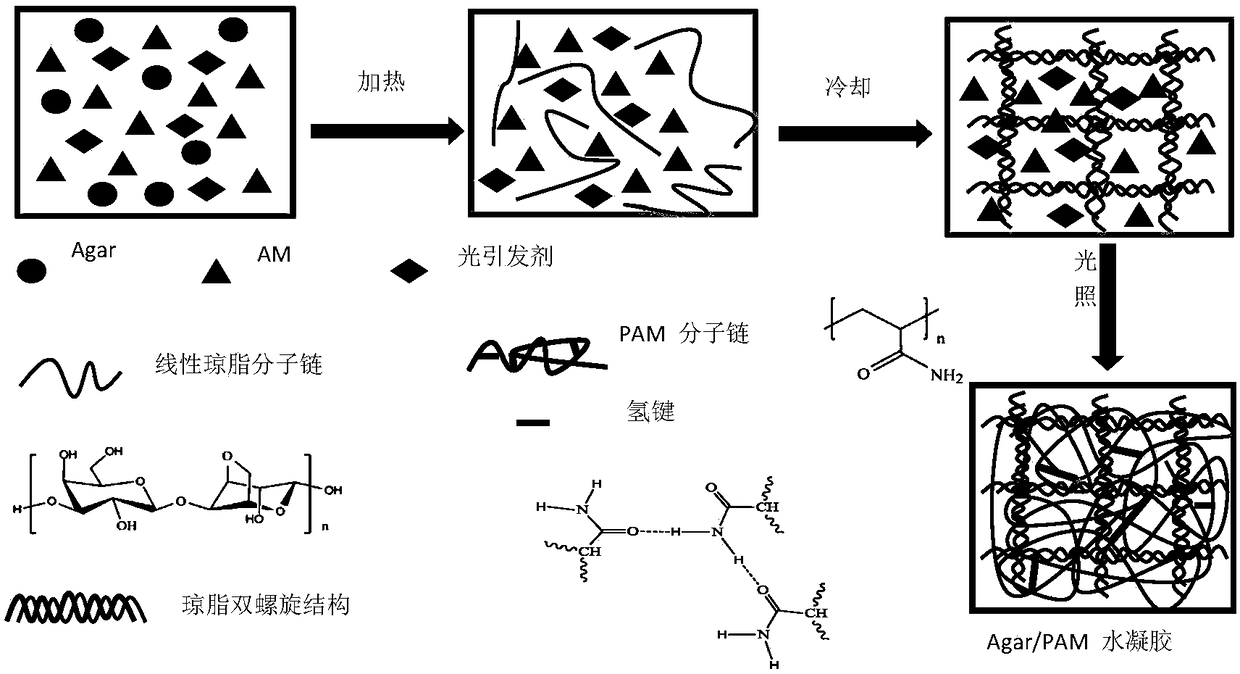

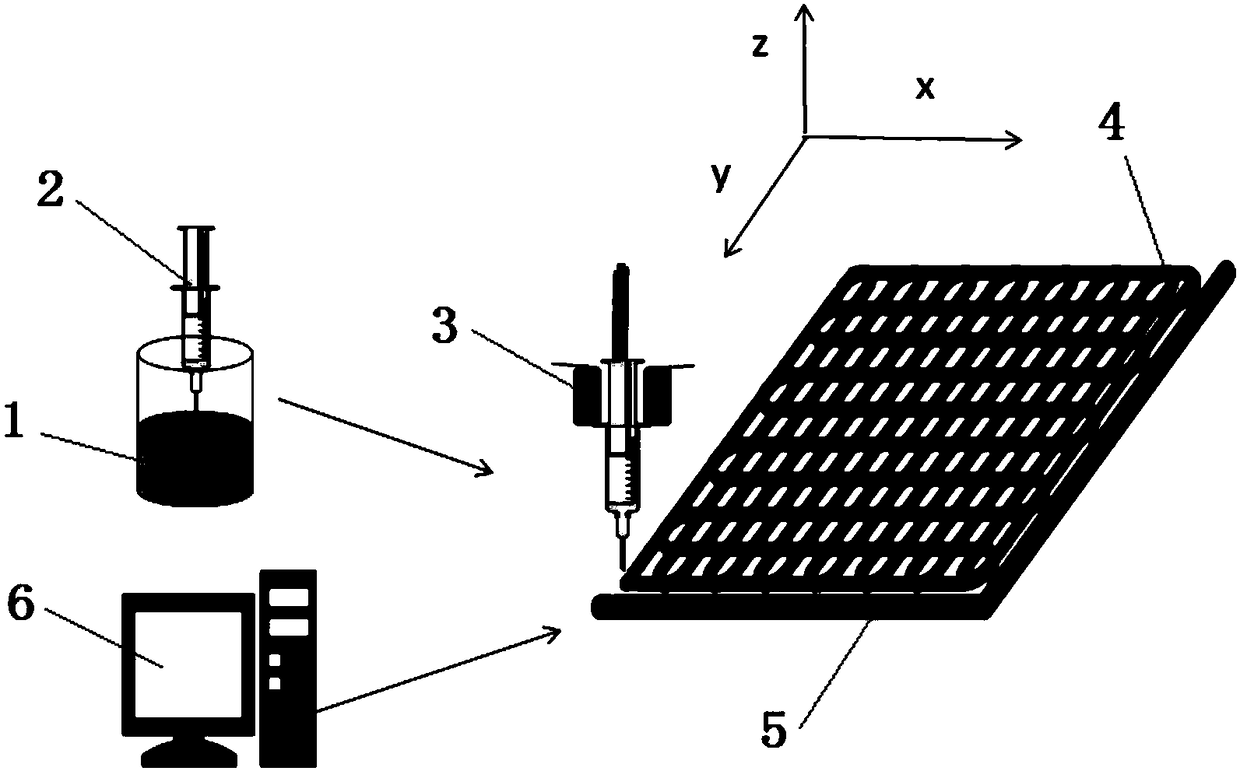

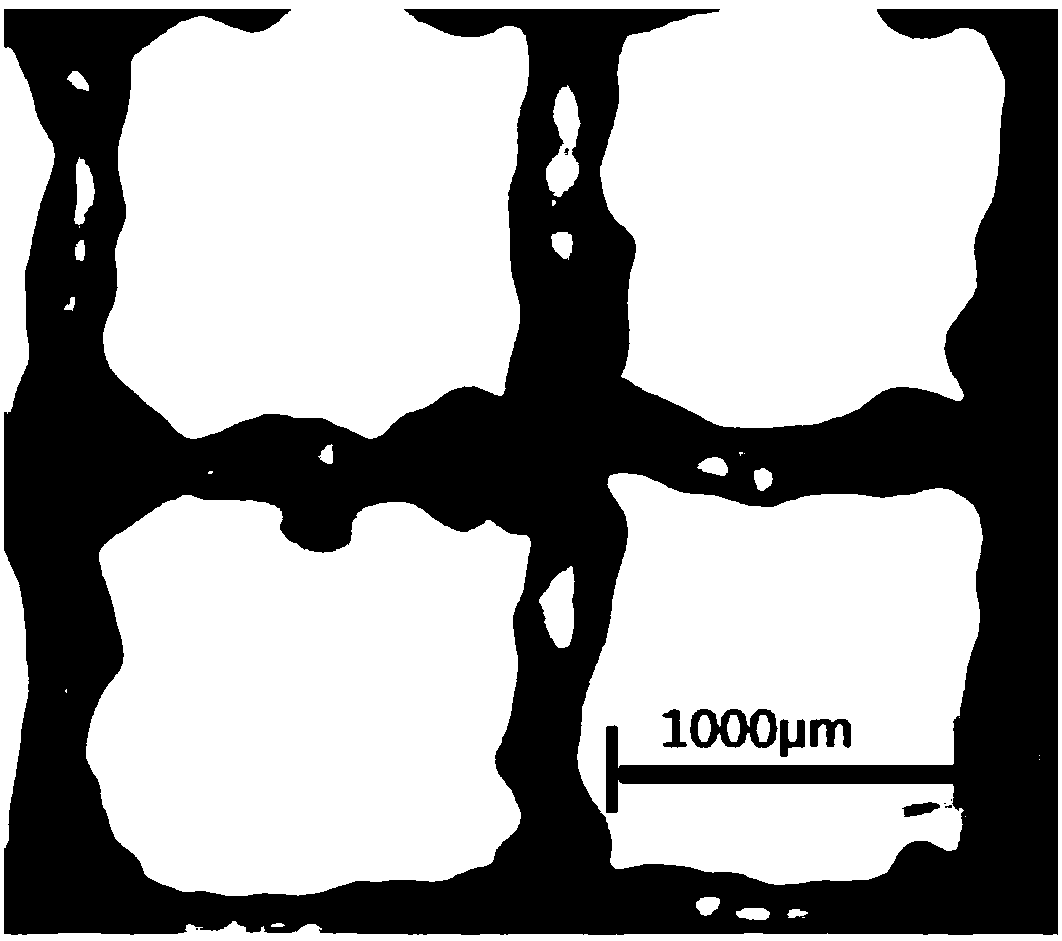

Preparation method of agar/polyacrylamide dihydrogen bond cooperative crosslinking high-tenacity hydrogel capable of 3D printing

A polyacrylamide, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of hydrogel preparation and molding process limitations, inability to apply hydrogels, difficult to control synthesis, etc., to achieve a short preparation cycle, ensure uniformity, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1): Weigh 0.2g of agar (Agar) into 8mL of deionized water, stir at 75°C and 500RPM at high speed for 20min to dissolve to obtain a transparent aqueous solution.

[0034]Step 2): Weigh 3.554g AM and 0.0074g KA respectively, add to 2mL and stir to dissolve to obtain a uniform transparent aqueous solution. Stir this solution in the solution of step 1) at 50°C and 500RPM for 5min in a dark environment to prepare a mixed solution with 0.06536mol / L Agar, 5mol / L AM and 0.005mol / L KA.

[0035] Step 3): Inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, and place the glass mold under ultraviolet light for 5-7 hours to obtain a strong double hydrogen bond synergistically cross-linked and high-toughness Agar / PAM Hydrogels.

[0036] Experiments show that the tensile strength of the double hydrogen bond synergistically cross-linked Agar / PAM hydrogel material obtained in this example is 0.449 MPa, and the elongation at break is 658...

Embodiment 2

[0038] Step 1): Weigh 0.2g of agar (Agar) into 8mL of deionized water, stir at 75°C and 500RPM at high speed for 20min to dissolve to obtain a transparent aqueous solution.

[0039] Step 2): Weigh 4.9756g AM and 0.0103g KA respectively, add to 2mL and stir to dissolve to obtain a uniform transparent aqueous solution. Stir this solution in the solution of step 1) at 50°C and 500RPM for 5min in a light-proof environment to prepare a mixed solution with 0.06536 mol / L Agar, 7 mol / L AM and 0.007 mol / L KA.

[0040] Step 3): Inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, and place the glass mold under ultraviolet light for 5-7 hours to obtain a strong double hydrogen bond synergistically cross-linked and high-toughness Agar / PAM Hydrogels.

[0041] Experiments show that the tensile strength of the double hydrogen bond synergistically cross-linked Agar / PAM hydrogel material obtained in this example is 0.490 MPa, and the elongation at ...

Embodiment 3

[0043] Step 1): Weigh 0.2g of agar (Agar) into 8mL of deionized water, stir at 75°C and 500RPM at high speed for 20min to dissolve to obtain a transparent aqueous solution.

[0044] Step 2): Weigh 6.3972g AM and 0.0132g KA respectively, add to 2mL and stir to dissolve to obtain a uniform transparent aqueous solution. Stir this solution in the solution of step 1) at 50°C and 500RPM for 5min in a dark environment to prepare a mixed solution with 0.06536mol / L Agar, 9mol / L AM and 0.009mol / L KA.

[0045] Step 3): Inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, and place the glass mold under ultraviolet light for 5-7 hours to obtain a strong double hydrogen bond synergistically cross-linked and high-toughness Agar / PAM Hydrogels.

[0046] Experiments show that the double hydrogen bond synergistically cross-linked Agar / PAM hydrogel material obtained in this example has a tensile strength of 0.500 MPa and an elongation at break of 4631...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com