Nanostructure lithium battery electrolyte additive, its preparation method and electrolyte

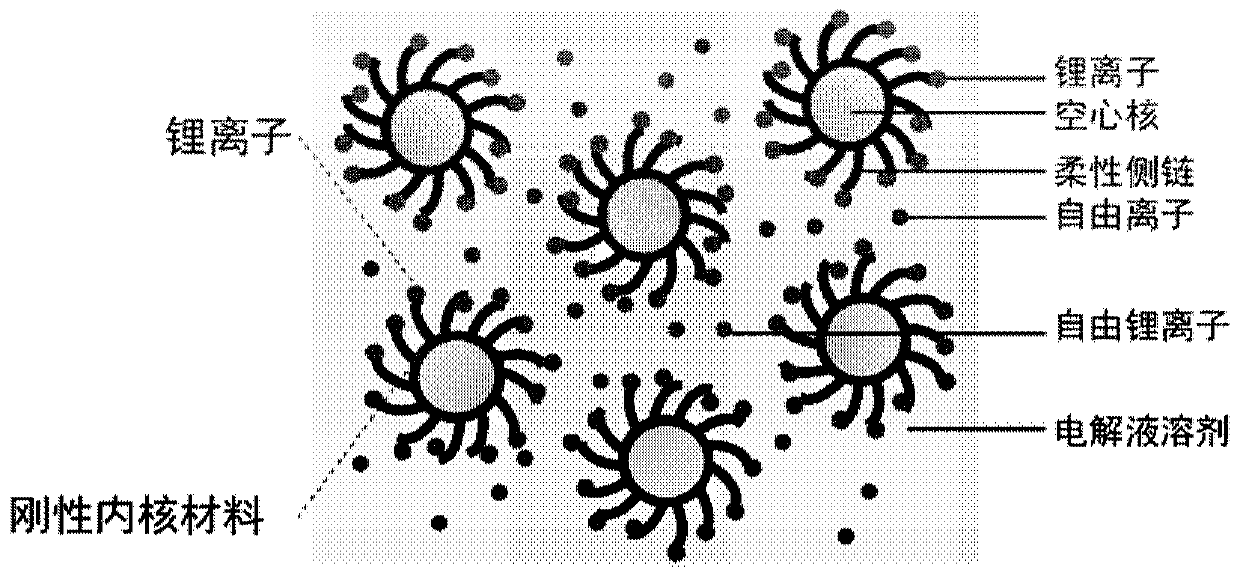

An electrolyte additive and nanostructure technology, which can be used in the manufacture of electrolyte batteries, nanotechnology, secondary batteries, etc., can solve problems such as the inability to meet the needs of the full life cycle of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of additives

[0027] The preparation method of the additive of the present embodiment comprises the steps:

[0028] (1) 0.6g (about 1mM) nanostructured SiO 2 (about 7nm in diameter) was added to 10mL of water, and ultrasonically dispersed for 30min to make SiO 2 Disperse uniformly in water, then add 1.23g of 1-bromopropane to disperse uniformly, then slowly add saturated LiOH solution until the pH value is 14, and then continue ultrasonic dispersion for 20min to obtain a mixture;

[0029] (2) Transfer the mixture prepared in step (1) to the liner of a polytetrafluoroethylene-made hydrothermal kettle, then cover it, put it into the hydrothermal kettle, conduct a hydrothermal reaction at 150°C for 6 hours, centrifuge or filter to obtain a solid substance, Wash with ultrapure water until the washing water is neutral, and dry in vacuum at 75°C for 24 hours to obtain the obtained product.

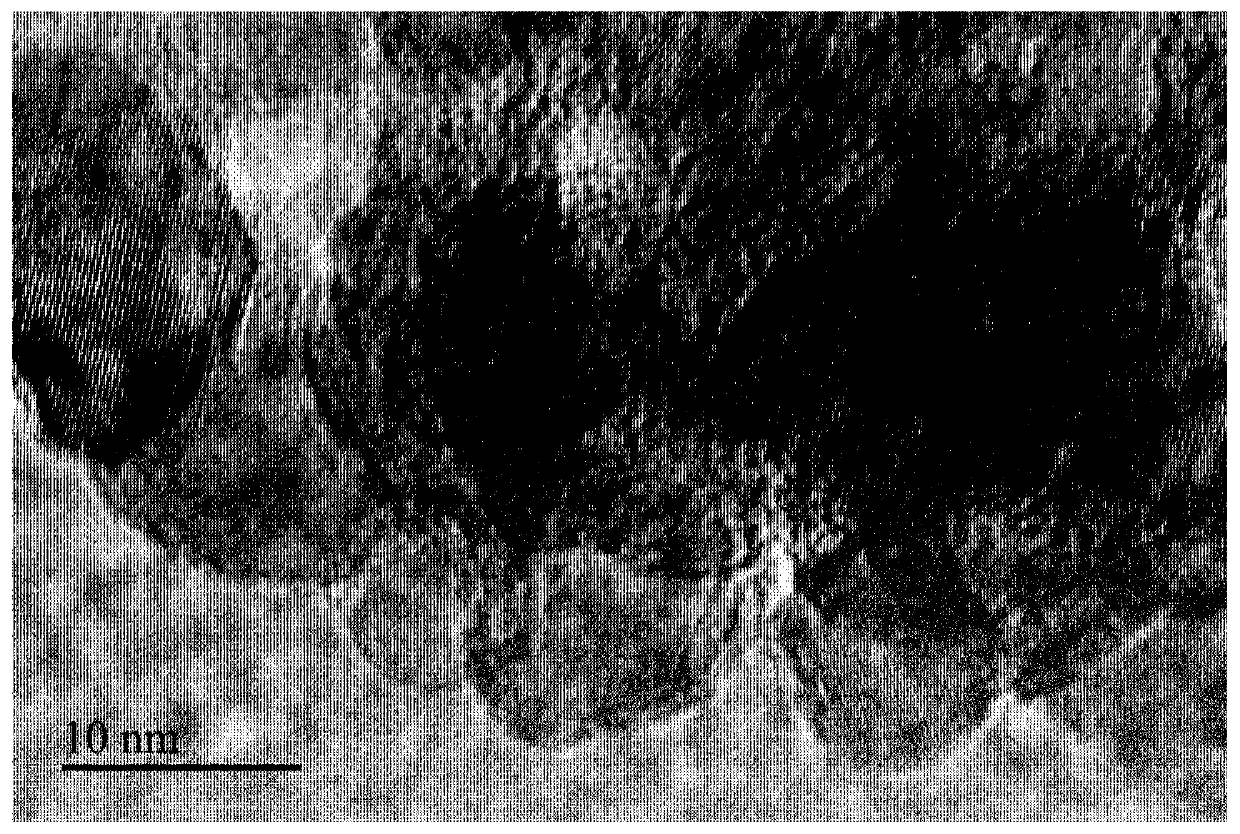

[0030] The additive in this embodiment is a white solid powder, wh...

Embodiment 2

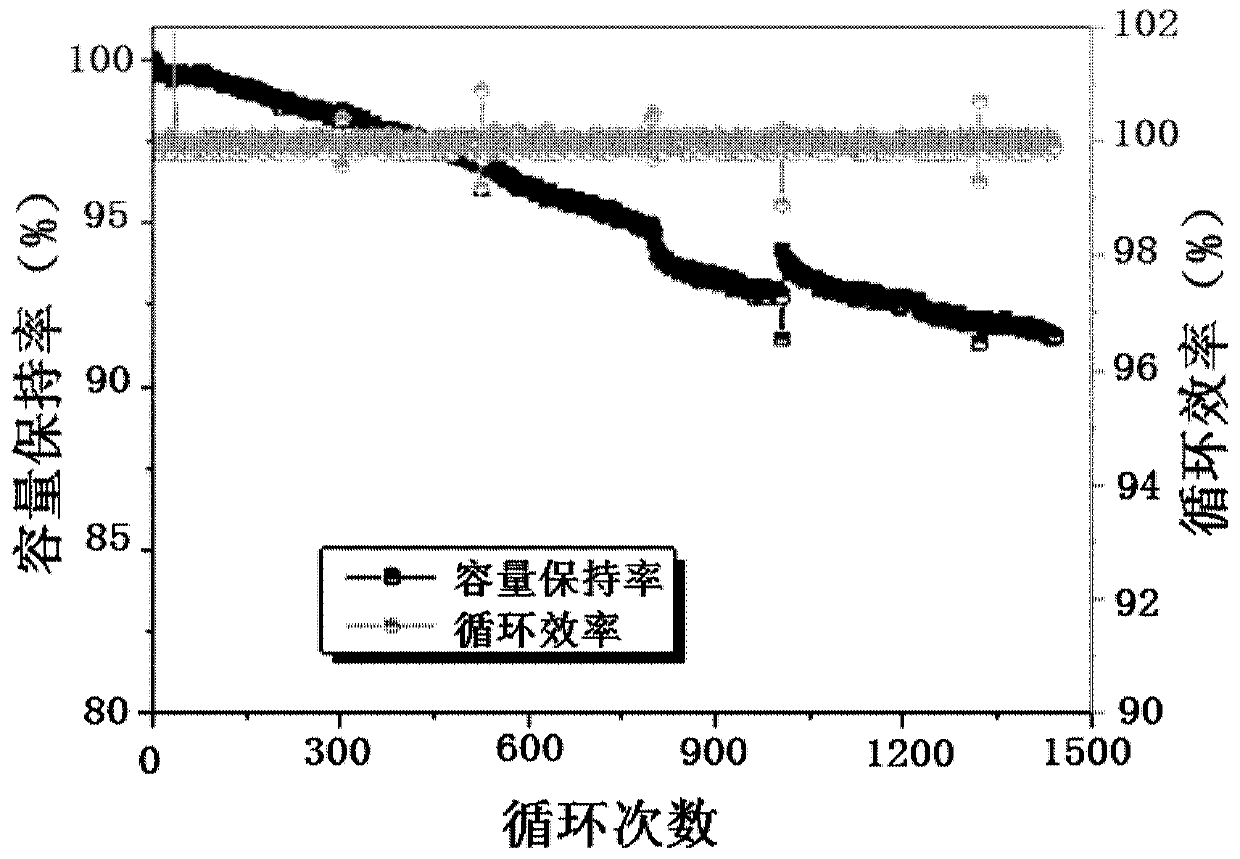

[0035] The preparation method of the additive is basically the same as in Example 1, but the reaction temperature is lowered to 120°C, and the reaction time is 8 hours. In addition, the electrolyte uses EC instead of PC, that is, the composition of the electrolyte is 1M LiPF 6 / EC+EMC+DMC(4:3:3, wt), also used for ternary materials||lithium titanate soft pack battery, the amount of electrolyte remains unchanged. Test its cycle performance at 60°C.

Embodiment 3

[0037] 1. Preparation of additives

[0038] (1) 0.6g (about 1mM) nanostructured SiO 2 (about 7nm in diameter) was added to 10mL of water, and ultrasonically dispersed for 30min to make SiO 2 Disperse uniformly in water, then add 3g of 1-chlorotetraethylene glycol dimethyl ether to disperse uniformly, then slowly add saturated LiOH solution until the pH value is 13, and then continue ultrasonic dispersion for 30min to obtain a mixture;

[0039] (2) Transfer the mixture prepared in step (1) to the liner of the polytetrafluoroethylene material hydrothermal kettle, then cover it, put it into the hydrothermal kettle, react with water at 180°C for 8h, centrifuge or filter to obtain solid matter, and use Wash with ultrapure water until the washing water is neutral, and dry in vacuum at 75°C for 24 hours to obtain the final product.

[0040] 2. Electrolyte preparation

[0041] Use molecular sieves to remove water from PC, FEC, and DMC, and filter to obtain a dry solvent with a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com