Gel electrolyte based on porous matrix and resisting electrolyte leakage and preparation method thereof

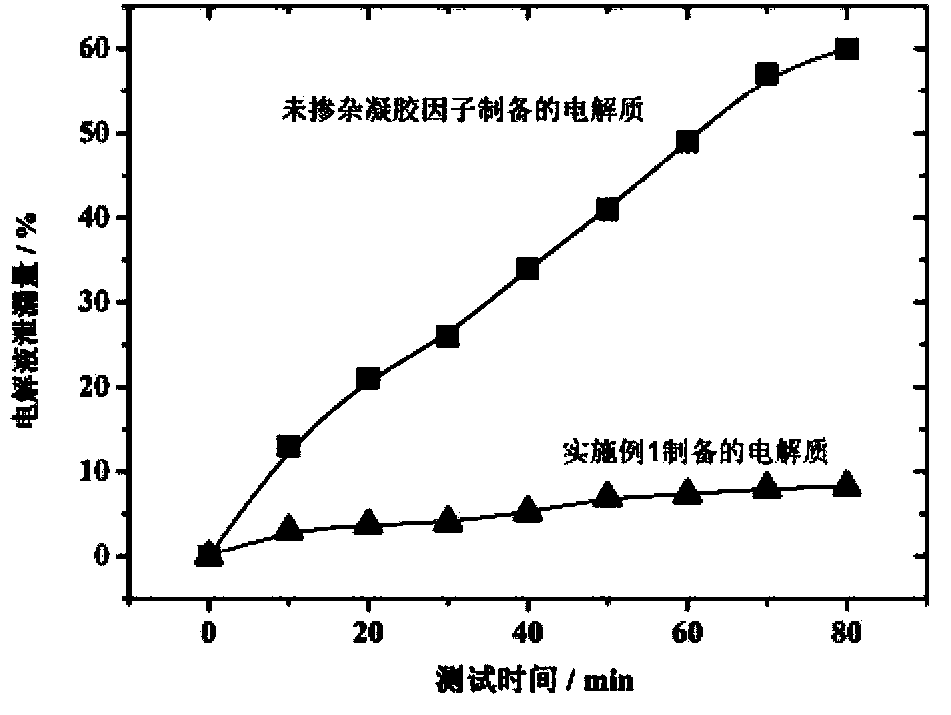

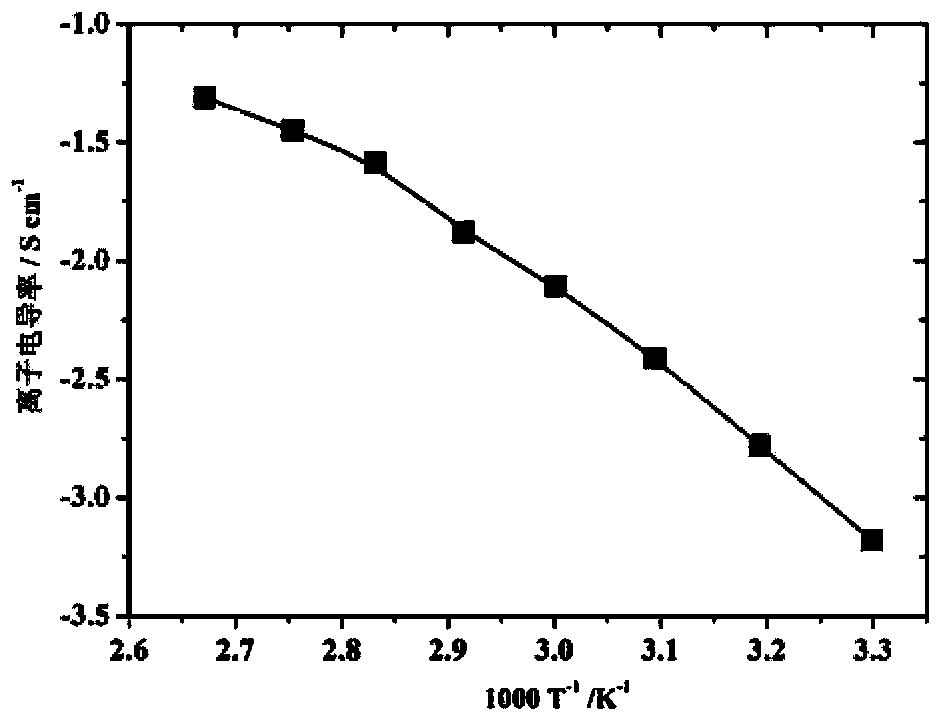

A gel electrolyte and porous matrix technology, applied in the field of chemistry, can solve the problem that the electrolyte retention effect is not very effective, and achieve the effects of increasing the number of lithium ion migration, high conductivity, and suppressing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 4g polyvinylidene fluoride-chlorotrifluoroethylene, 100mg CuCl, 300mg 2'2-bipyridine and 10g sodium styrene sulfonate in a flask in a vacuum glove box, take out from the glove box after sealing; Add 150ml of N-methylpyrrolidone distilled under reduced pressure to the above solid mixture and stir at 90°C for 12 hours. After the reaction is complete, dilute the resulting mixed solution with acetone and use Al2 o 3 The chromatographic column is separated, and finally the chromatographic product is precipitated by methanol, and vacuum-dried to obtain polyvinylidene fluoride-trifluorochloroethylene grafted with polystyrene sodium sulfonate.

[0026] The prepared polyvinylidene fluoride-trifluorochloroethylene grafted with sodium polystyrene sulfonate was dissolved in dimethylformamide to prepare a solution with a concentration of 5wt%, and added relative to the sodium polystyrene sulfonate grafted The mass of polyvinylidene fluoride-chlorotrifluoroethylene is 70% polye...

Embodiment 2

[0030] Weigh 2g of polyvinylidene fluoride, 100mg of CuBr, 200mg of 2'2-bipyridine and 20g of sodium styrene sulfonate in a vacuum glove box, seal it and take it out from the glove box, and distill the dimethylformamide in advance Add 100ml of sulfoxide to the above solid mixture and stir at 120°C for 24 hours. After the reaction is complete, dilute the resulting mixture with acetone and use Al 2 o 3 The chromatographic column is separated, and finally the chromatographic product is precipitated by methanol, and vacuum-dried to obtain polyvinylidene fluoride grafted with polystyrene sodium sulfonate.

[0031] Dissolve the prepared polyvinylidene fluoride grafted with sodium polystyrene sulfonate in dimethylacetamide to prepare a solution with a mass fraction of 25%, and add 60% glycerol relative to the mass fraction of the grafted polymer as a pore-forming agent, pour the mixed solution into a film, put it in a vacuum drying oven at 80°C for 24 hours to remove dimethylacetami...

Embodiment 3

[0035] Weigh 2.5g of PVC, 200mg of FeCl in a vacuum glove box 2 1.5g of pentamethyldiethylenetriamine and 20g of sodium styrene sulfonate were sealed in the flask and taken out from the glove box, then 150ml of dimethyl sulfoxide distilled under reduced pressure was added to the above solid mixture and stirred at 100°C 9 hours, after the completion of the reaction, the resulting mixed solution was diluted with acetone and used Al 2 o 3 Chromatographic separation, and finally using methanol to precipitate the chromatographic product and vacuum drying to obtain polyvinyl chloride grafted with sodium polystyrene sulfonate.

[0036] The prepared polyvinyl chloride grafted with sodium polystyrene sulfonate is dissolved in N-methylpyrrolidone to prepare a solution with a concentration of 5wt%, and the amount of polyvinyl chloride grafted with respect to sodium polystyrene sulfonate is 80% ethanol is used as a pore-forming agent, the mixed solution is poured into a film, placed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com