Modified spring cushion for film frame shipper

A technology of conveyors and membrane racks, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as damage to wafers, parts that can contact other wafers, racks 42 or conveyors, etc., to achieve enhanced jumping and jumping Effect of prevention and reduction of backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

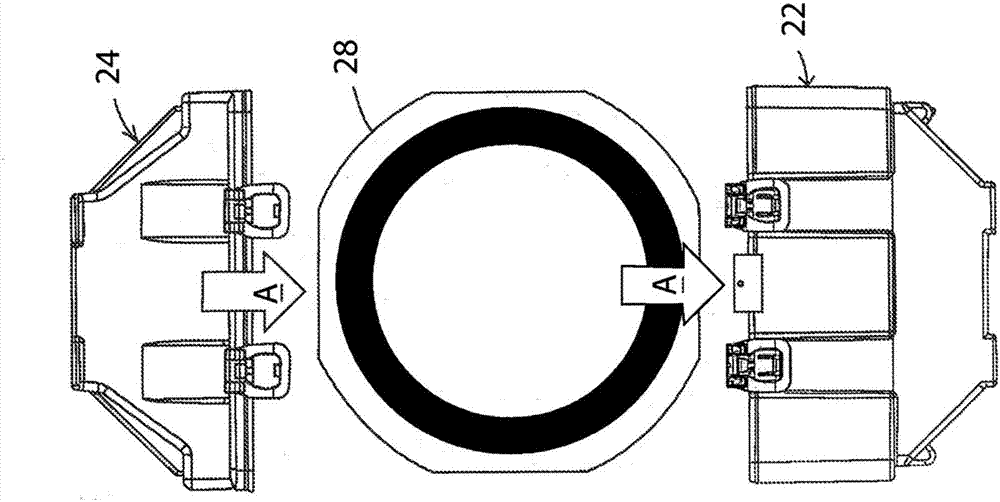

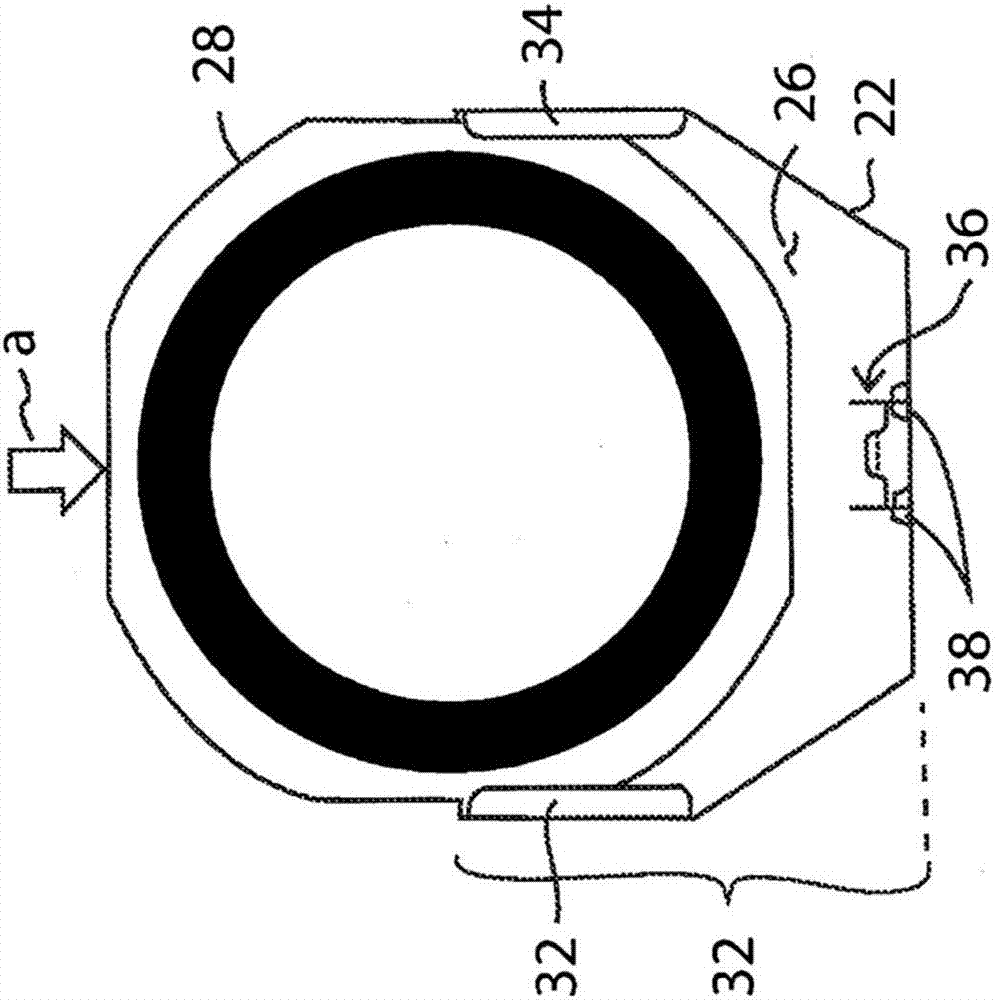

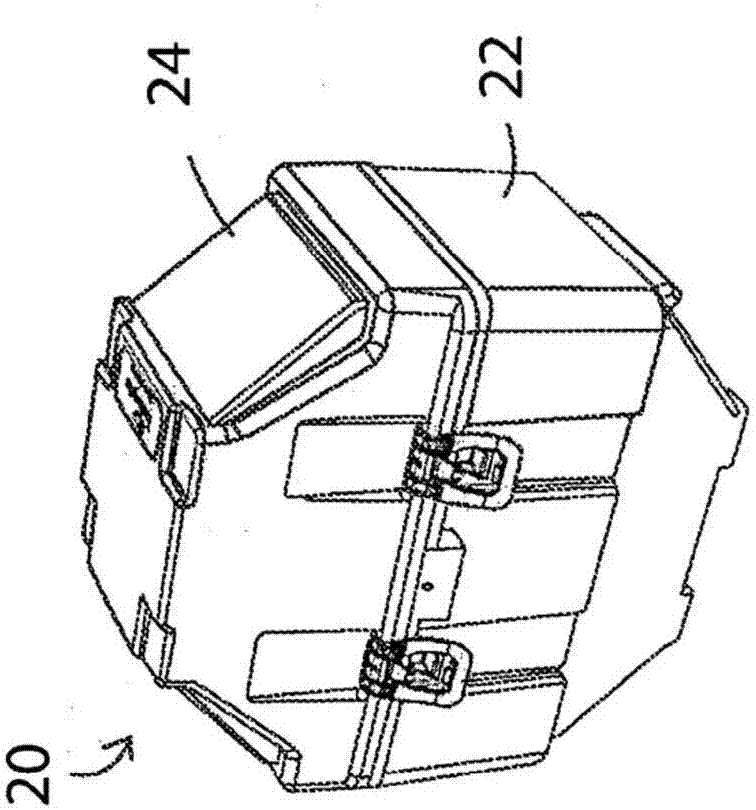

[0029] figure 1 Through 4 depict the frame conveyor 20 in an embodiment of the present invention. The film rack conveyor 20 includes a container 22 and a cover 24 forming a closure over the container portion to define an interior chamber 26 for storing a plurality of film racks 28 . The container 22 includes sides 32 that may include guides 34 ( FIG. 2 ) for guiding the membrane holder 28 into the container 22 . Spring rack pad 36 is coupled to at least one of container 22 and lid 24 . In one embodiment, the rack pad 36 is removably mounted to a grooved rail 38 on the container 22 or lid 24 . As shown, the film holder 28 is directed in a direction A into the interior chamber 26 of the container 22 and then the lid 24 is moved in the same direction A to couple with the container 22 .

[0030] refer to Figures 6 to 8 , depicts the form of the spring mount 36 in an embodiment of the invention. Spring mount 36 is specifically referred to as spring mount 36a ( Figure 6 ) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com