Oil wiping unit for aluminum wire drawing and forming device

A technology for wire drawing and aluminum wire, which is applied in the field of oiling unit, can solve the problems of scratching aluminum wire or wire drawing die, affecting product quality, affecting deep processing production, etc., and achieves the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

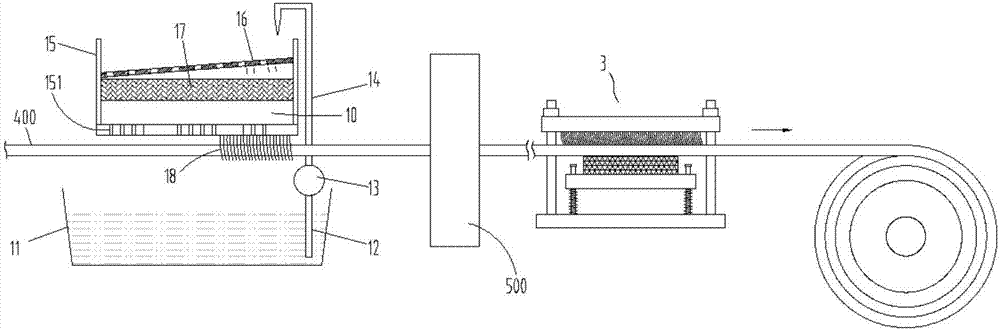

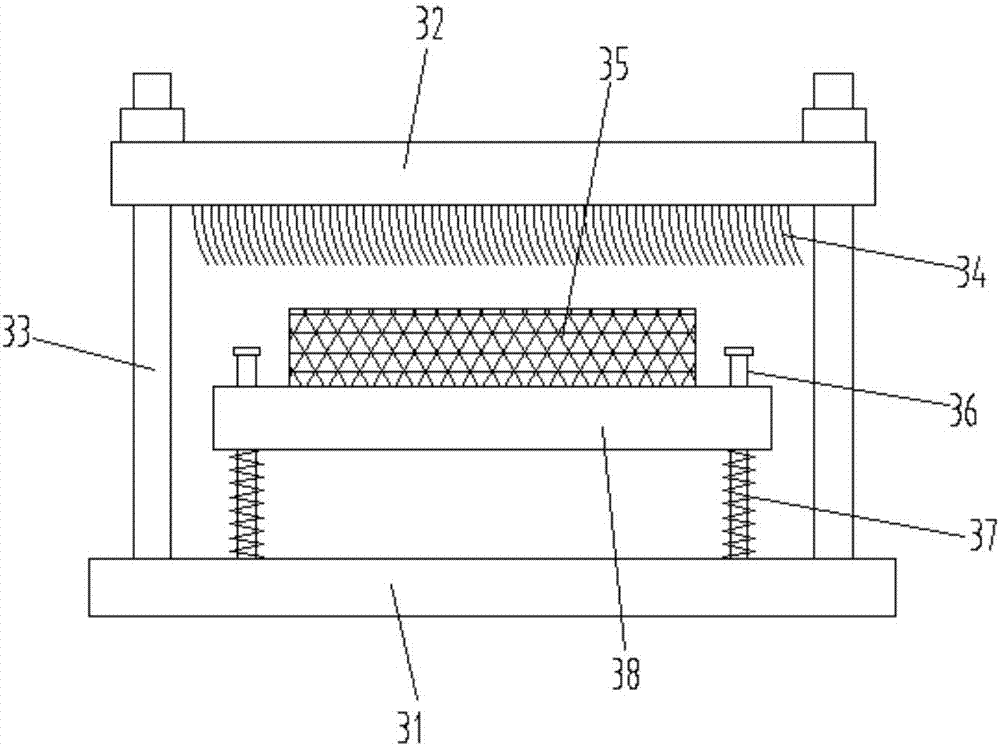

[0016] like figure 1 and figure 2 As shown, the present invention discloses an oiling unit used in an aluminum wire drawing forming device, including an oil tank 11, an oil pipe 12, a pump 13, an oil injection pipe 14, an oil collection tank 15, a filter plate 16, a sponge 17, and a brush 18 and the oil wiping unit 3, the bottom end of the oil pipe 12 stretches in the oil tank 11, the top links to each other with the liquid inlet end of the pump 13, and the liquid outlet end of the pump 13 links to each other with the oil injection pipe 14, and the liquid injection port of the oil injection pipe 14 is set Above the oil collecting tank 15 , the filter plate 16 and the sponge 17 are both arranged in the oil collecting tank 15 , and the filter plate 16 is obliquely placed above the sponge 17 , and an oil collecting cavity 10 is formed between the sponge 17 and the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com