An energy-saving and environment-friendly automatic impregnation molding device

An impregnation molding, energy saving and environmental protection technology, applied in the direction of coating, etc., can solve the problems of difficult treatment of organic waste gas, environmental pollution, complicated impregnation process, etc., and achieve the effect of ensuring stability, improving utilization efficiency, and rapid heat transfer and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

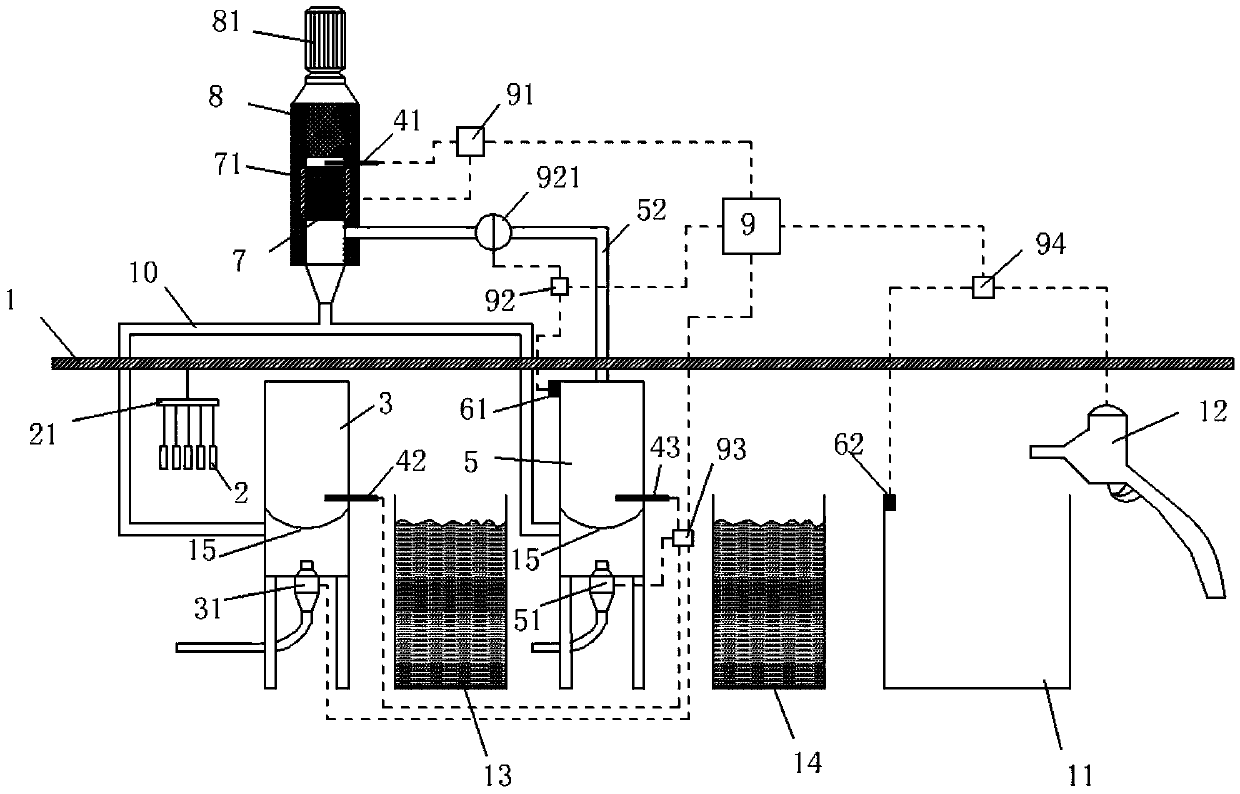

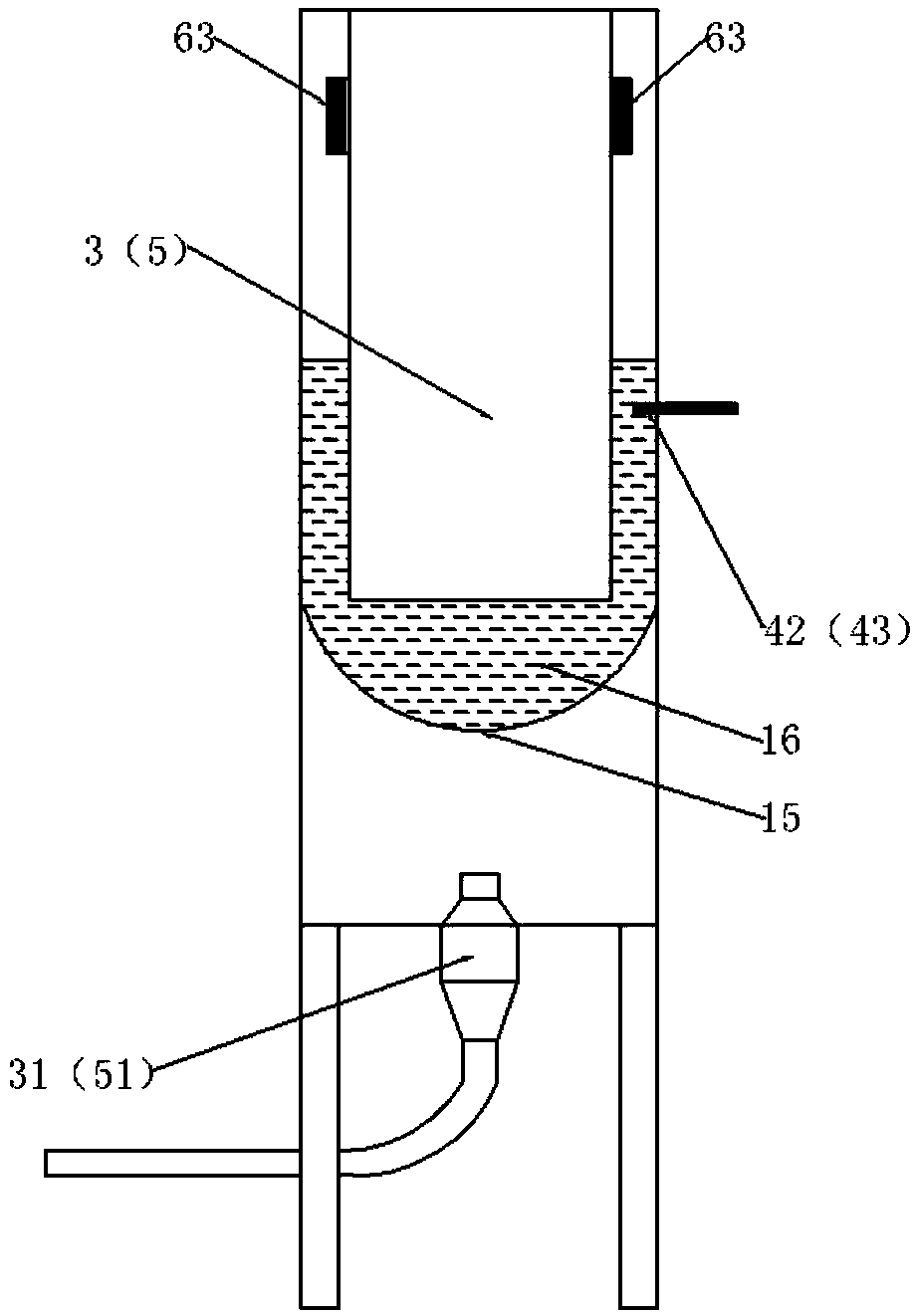

[0019] An energy-saving and environment-friendly automatic impregnation molding device, including a mold 2, a preheating furnace 3, a feed liquid tank 13, a plasticizing furnace 5, a cooling liquid tank 14, and a demoulding air gun 12, characterized in that the mold 2 is hoisted on the track 1 , the preheating furnace 3, the feed liquid tank 13, the plasticizing furnace 5, the cooling liquid tank 14 and the demoulding air gun 12 are arranged sequentially along the extending direction of the track 1, and the finished product collection box 11 is arranged below the demoulding air gun 12; the preheating furnace 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com