Rolling-element bearing unit for wheel bearing assembly

A technology for rolling bearings and wheel bearings, applied in the directions of bearing components, bearings, wheels, etc., can solve the problems of reducing bearing service life, increasing production time and manufacturing cost, and entering dirt, and achieving the effect of increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the following, identical or functionally identical operating elements are designated by the same reference numerals.

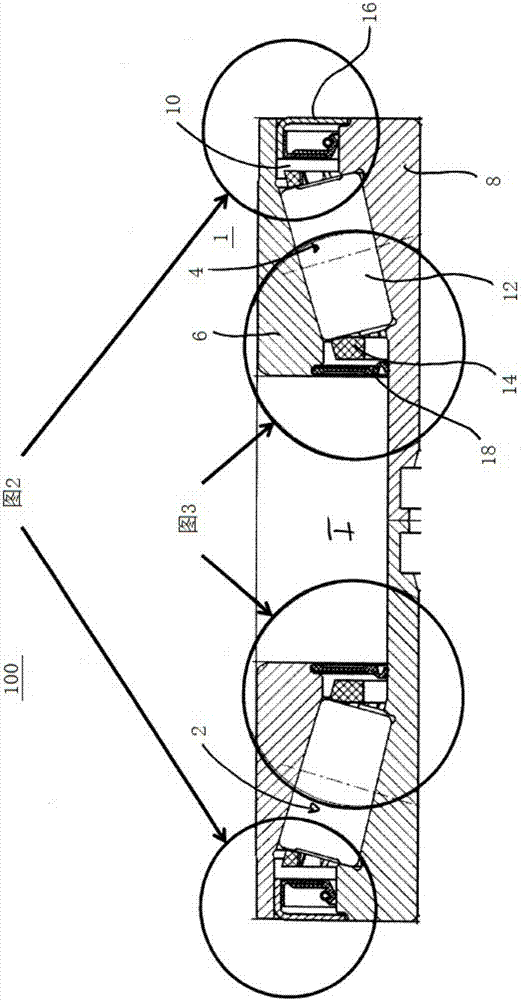

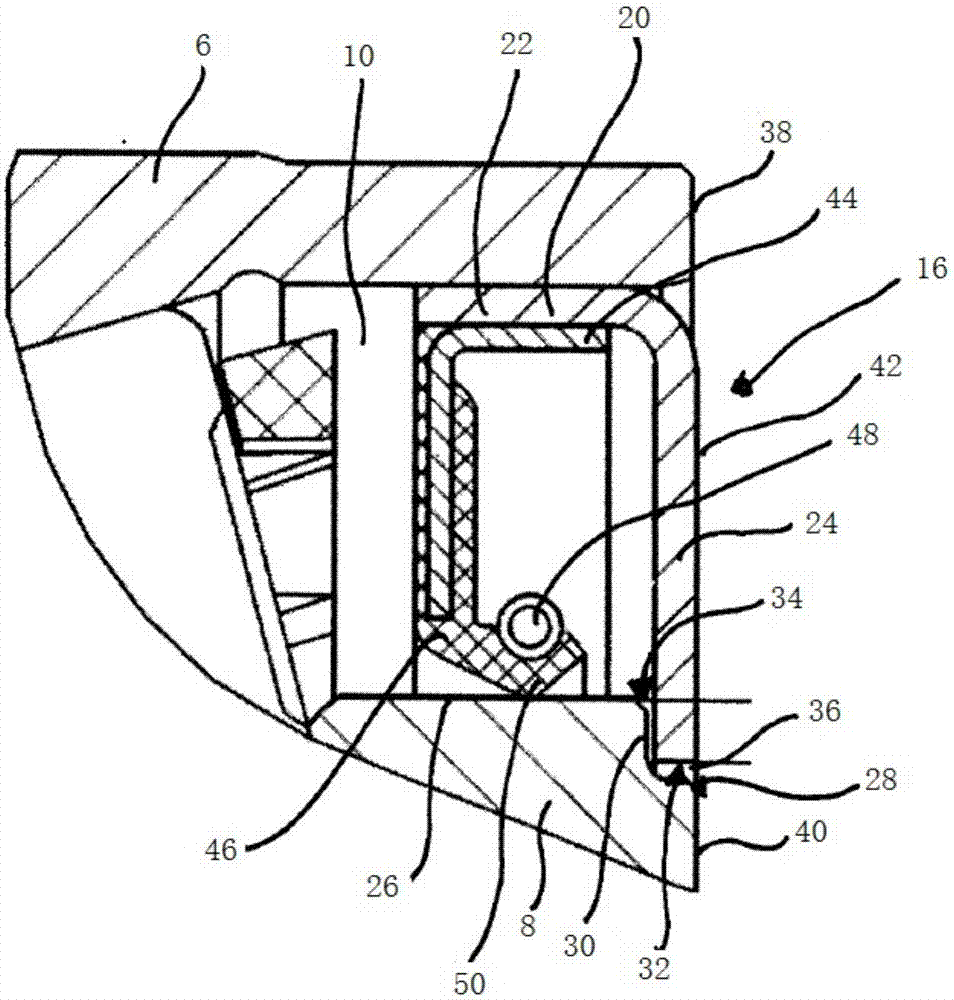

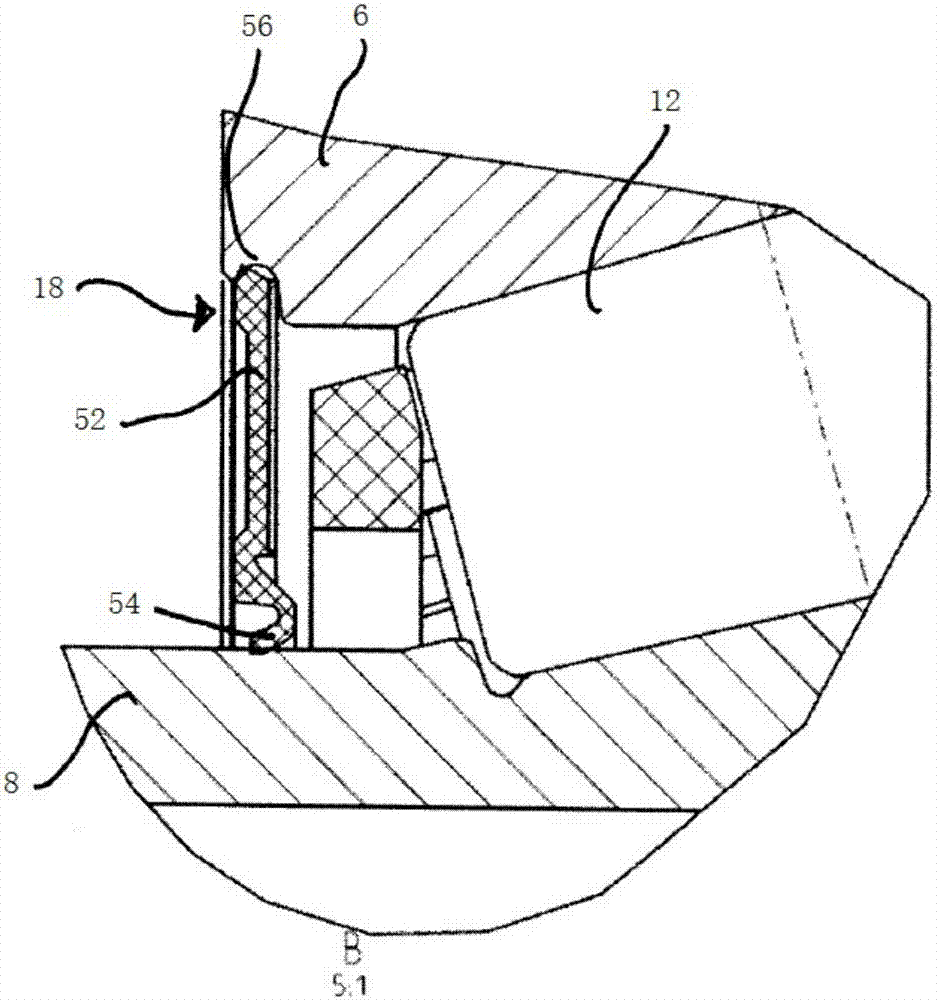

[0052] figure 1 A schematic cross-sectional view of a wheel bearing assembly 100 for a vehicle is shown in figure 2 and image 3 is shown in a sectionally enlarged manner in . here,figure 1 The wheel bearing assembly shown in is configured as a double row tapered roller bearing 2, 4, wherein the two tapered roller bearings are arranged in a back-to-back configuration, thereby enabling a high stiffness with respect to lateral forces.

[0053] For the sake of simplicity, in the following, a tapered roller bearing 4 carrying elements of the invention is discussed.

[0054] figure 1 The rolling bearing 4 shown in includes a bearing outer ring 6 and a bearing inner ring 8 capable of rotating relative to the bearing outer ring 6, and a bearing inner space in which rolling elements 12 are arranged is formed between the bearing outer ring 6 and the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com