Cooking utensil control method and device, and cooking utensil

A technology of cooking utensils and control methods, applied in the field of control of cooking utensils and control devices of cooking utensils, capable of solving problems such as exhaustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

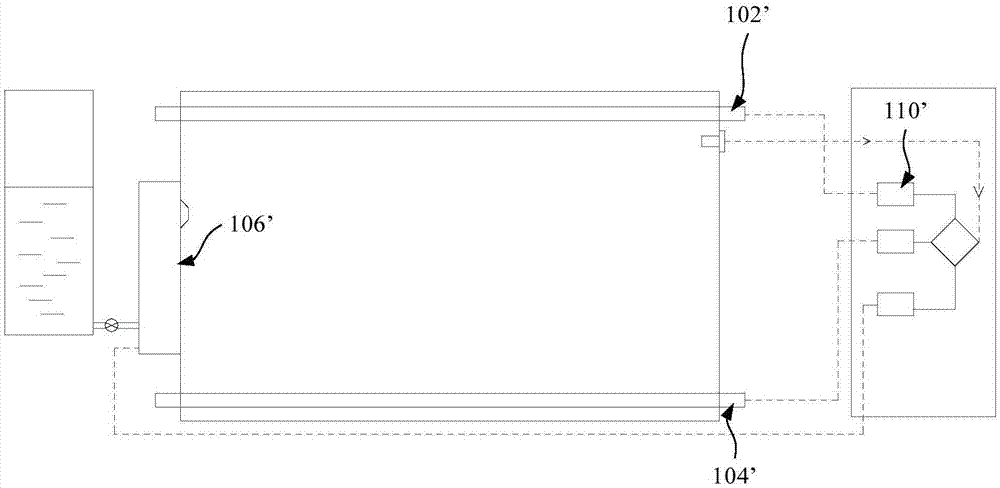

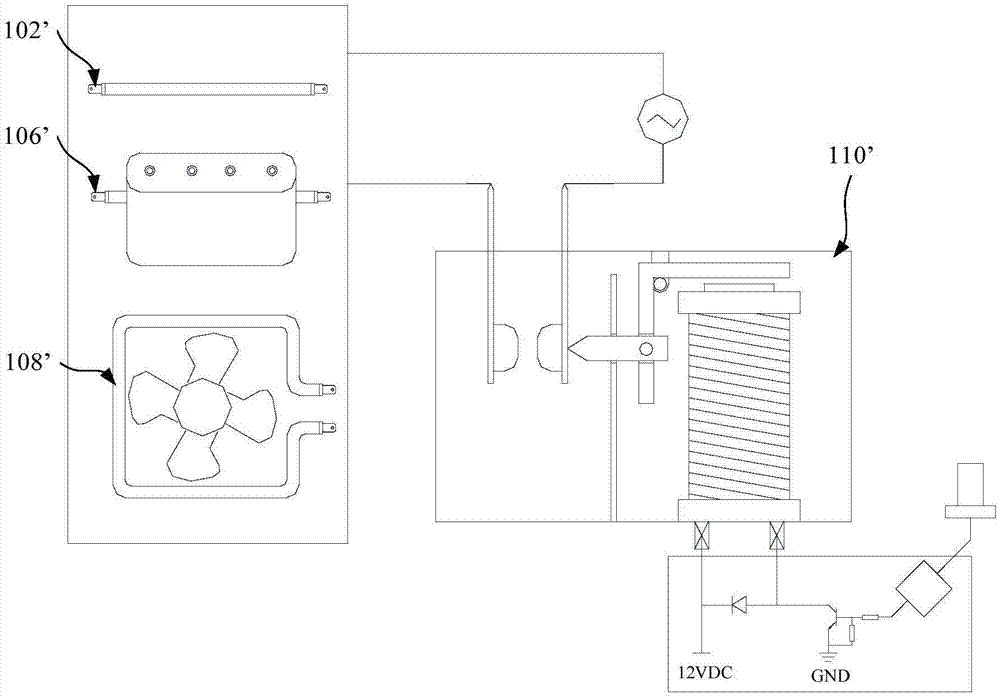

[0139] In specific embodiments, a smart oven includes an oven heating tube, a hot air component, an oven cooking cavity, a steam generator, water supply components (water pump, water valve, etc.), a water tank, a mechanical contact relay, and a cavity temperature sensor, It also includes a control device for a cooking appliance as in any of the above embodiments.

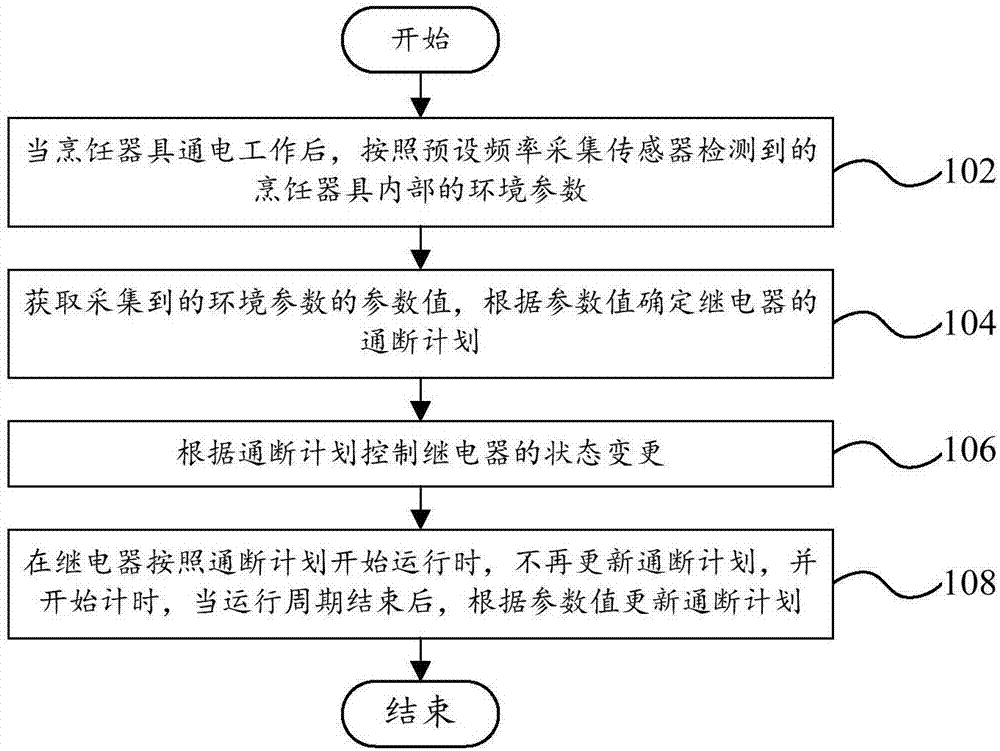

[0140] After the oven is powered on, the main chip program starts to sample the sensor. The sampling method can use the existing commonly used methods, such as reading the data from the corresponding port of the sensor circuit every 1 millisecond, and performing ADC conversion (analog-to-digital conversion). And calculate the parameter value measured at the sensor from the obtained ADC value (of course, the program can also directly provide the ADC value without relevant conversion). The main chip program calculates the corresponding revision value according to the obtained parameter value, for the relay control module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com