Fully-automatic container wharf shipment scheduling method and scheduling system

A fully automated, scheduling method of technology, applied in data processing applications, resources, logistics, etc., can solve problems such as changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] First define some terms involved in the present invention:

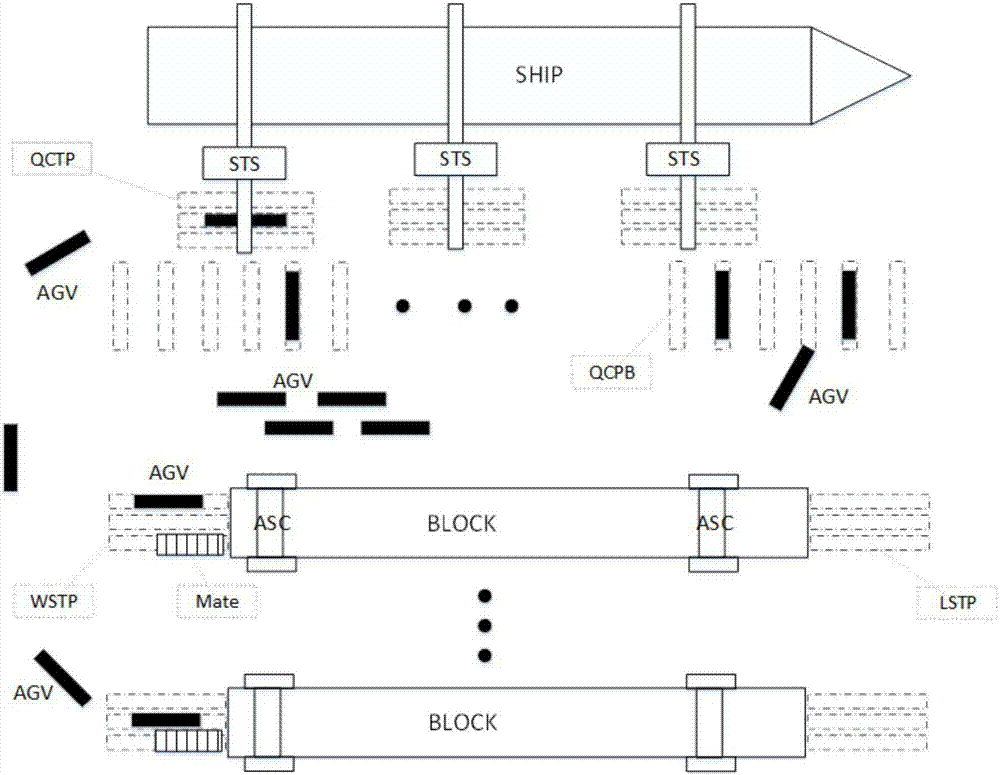

[0033] Operation path: the operation path for moving the container from the yard to the ship, including related equipment and resources such as shore crane STS, automatic transport vehicle AGV, automatic rail crane ASC, seaside exchange area companion, and driveway. The core equipment of the working road is STS, and the goal is to make the STS operate at full capacity during terminal operations. Task box information WI (WorkInstruction): a task box information, including the location of the ship's box, the physical and logical pre-boxes during shipment, etc.

[0034] Work Queue WQ (WorkQueue): Generally, a Bay on a ship is divided into one or more WQs. WQ contains a WI queue, and has information and content such as ship number, shipping space, planned operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com