Easily cleaned vacuumizing container for food processing

A food cooking and easy-to-clean technology, applied in applications, home appliances, kitchen appliances, etc., can solve the problems of insufficient sealing of the inner cavity of the container, long time for pressure relief, water intake of the vacuum pump, etc., to reduce leakage and other safety hazards, Increased service life and fast pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

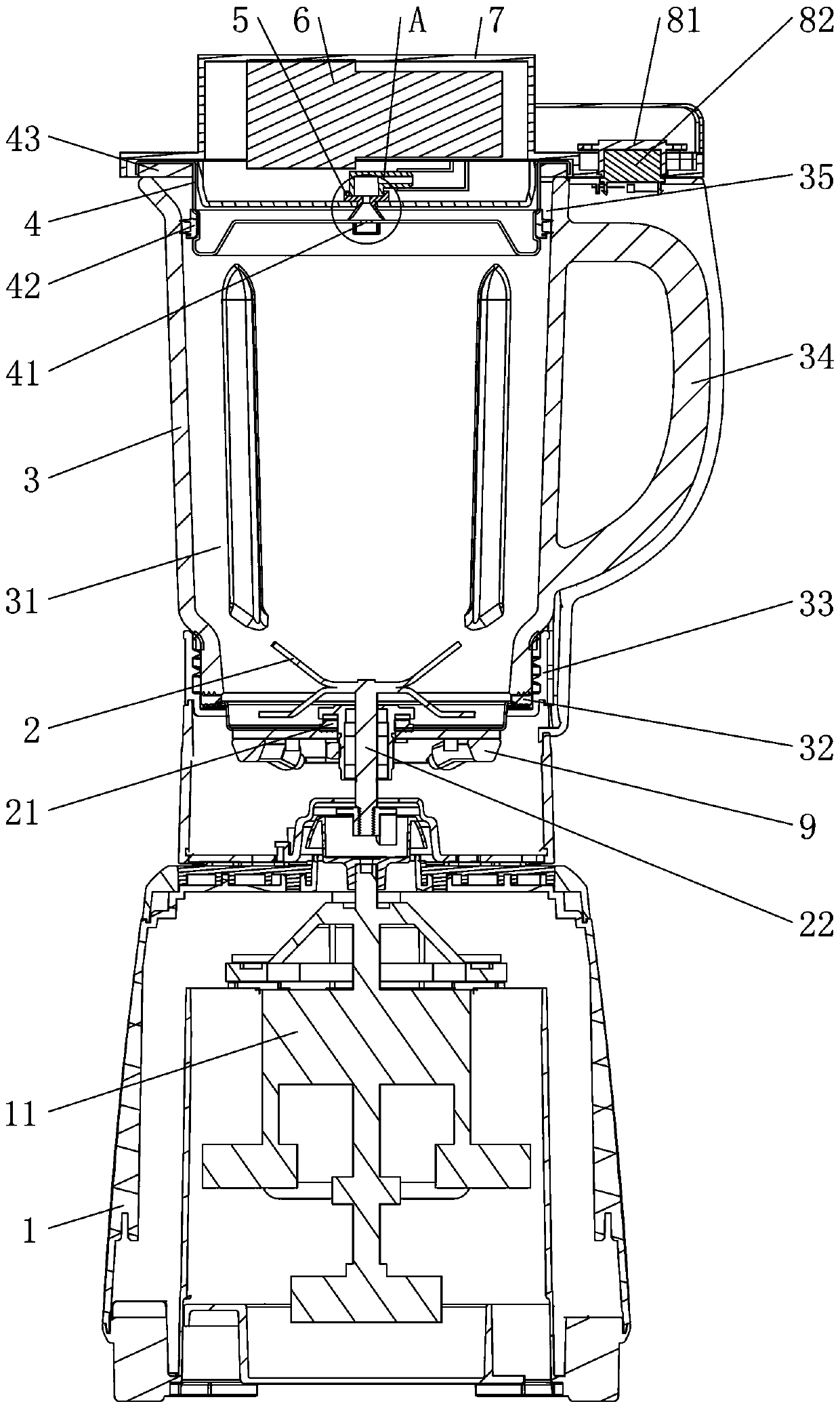

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

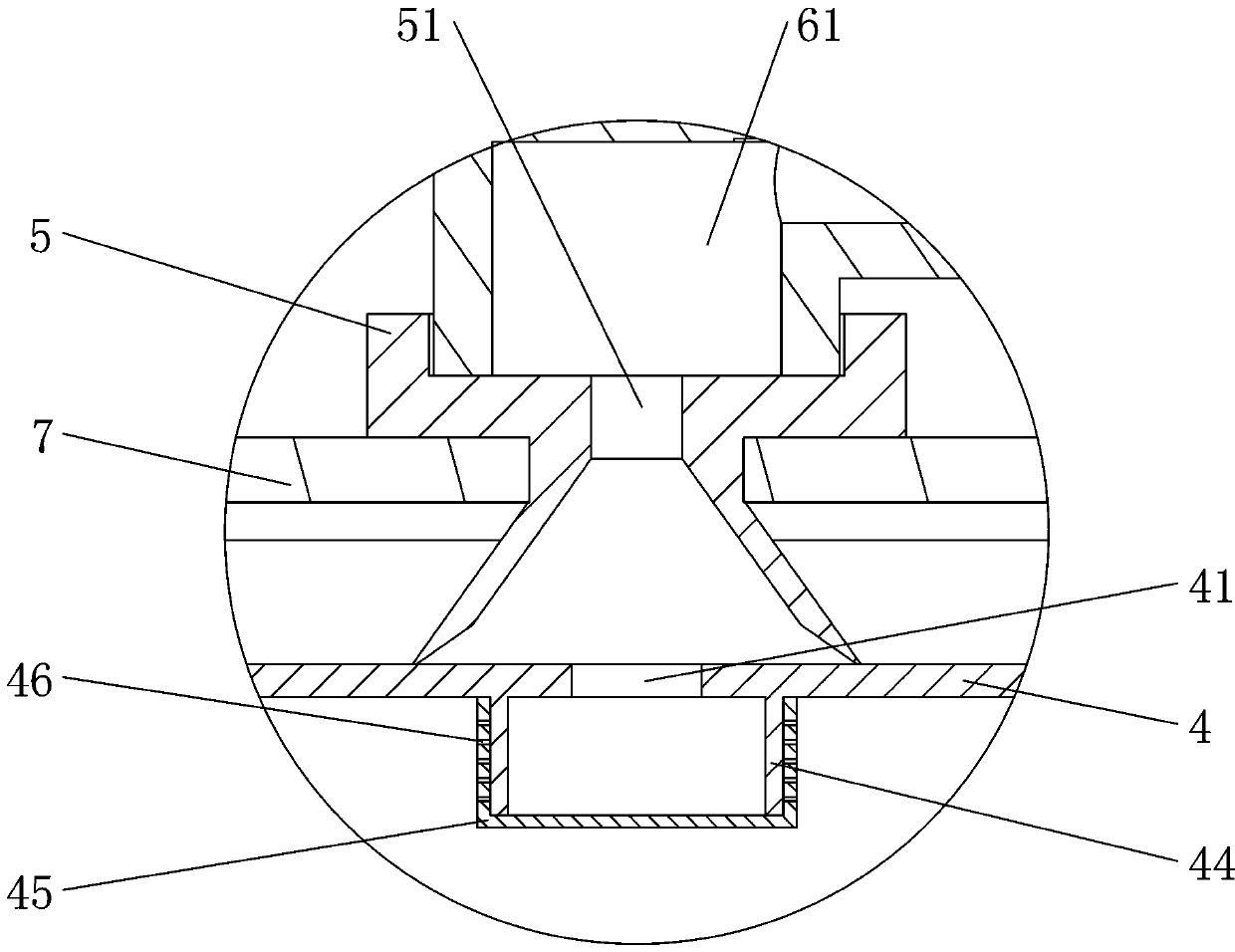

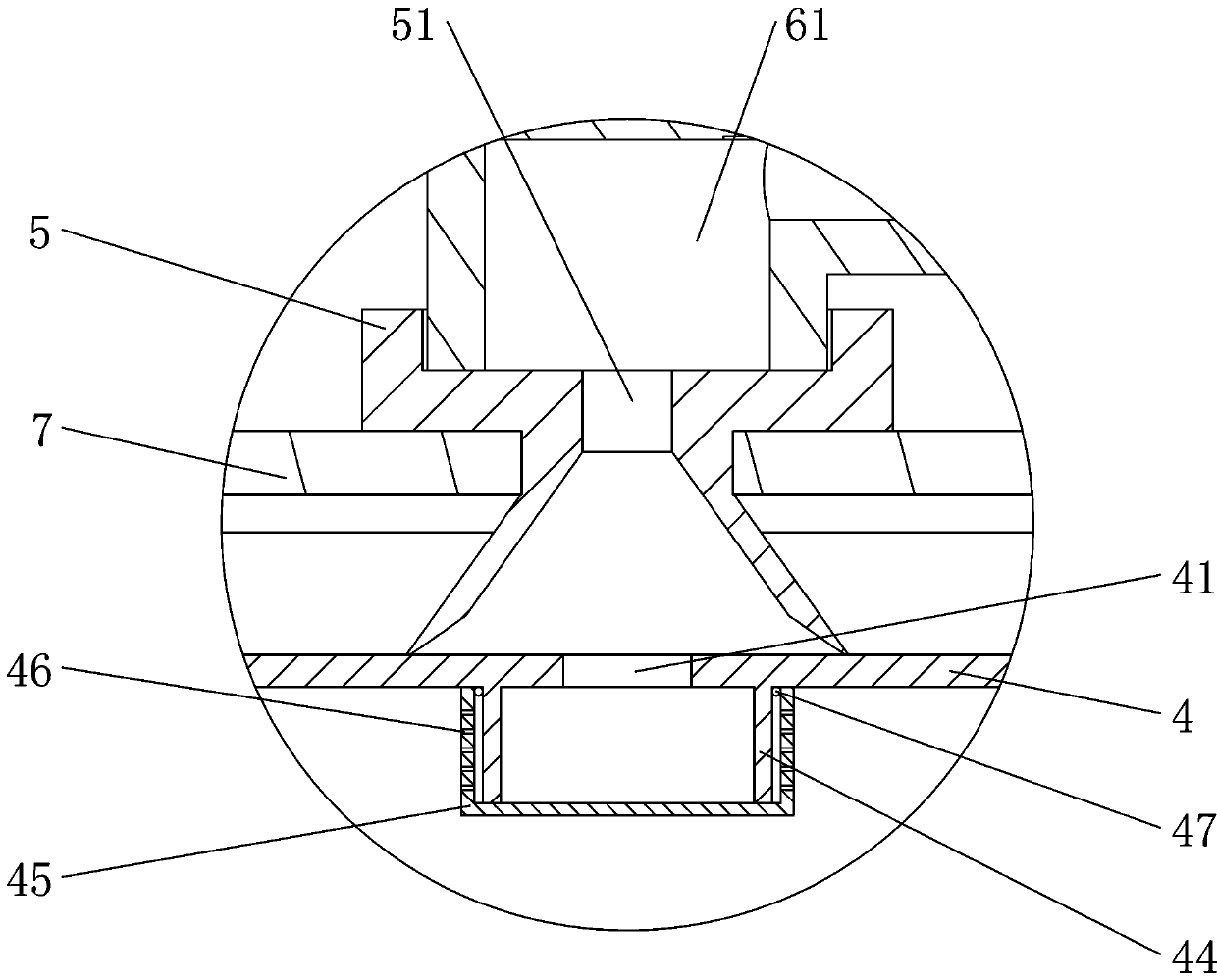

[0028] see figure 1 , figure 2 , Figure 4 and Figure 5 As shown, an easy-to-clean vacuumized container for food preparation includes a container 3, a cover body and a vacuum pump 6, the cover body includes an upper cover 7 and a lower cover 4, and the lower cover 4 is sealed with the opening 35 of the container 3 , the upper cover 7 is separately arranged on the lower cover 4, the vacuum pump 6 is arranged on the upper cover 7, and the suction port 61 of the vacuum pump 6 communicates with the inner chamber 31 of the container 3 through the lower cover 4.

[0029] The lower cover 4 is provided with an air inlet passage 41, and the air inlet passage 41 is provided with an outer port and an inner port, the outer port leads to the inner cavity 31 of the container 3, and the inner port communicates with the suction port 61 of the vacuum pump 6 and is sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com