A kind of felodipine sustained-release tablet and preparation process thereof

A technology of felodipine and felodipine, which is applied in the field of sustained-release tablets containing felodipine, can solve the problems of good stability, high fluidity requirements, simple preparation process, etc., achieve easy industrialized large-scale production, and solve stable release The effect of high stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

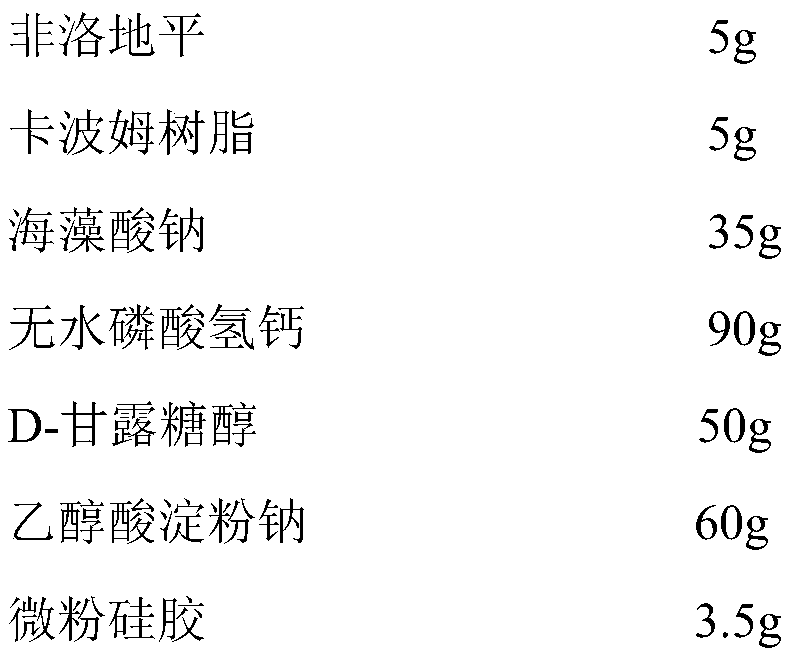

[0033]

[0034] Preparation process: get felodipine 5g, carbomer resin 5g and sodium alginate 25g to mix, suspend in absolute ethanol, dry and remove ethanol to obtain felodipine solid dispersion; Gained felodipine solid dispersion and Anhydrous calcium hydrogen phosphate 90g, D-mannitol 50g, sodium starch glycolate 60g, and sodium alginate 10g were mixed uniformly, 60% ethanol was used as a binder, granulated, and dried at 45°C to obtain drug-containing granules; The drug granules are passed through a 18-mesh sieve, then mixed evenly with 3.5g of finely powdered silica gel, and compressed into tablets.

Embodiment 2

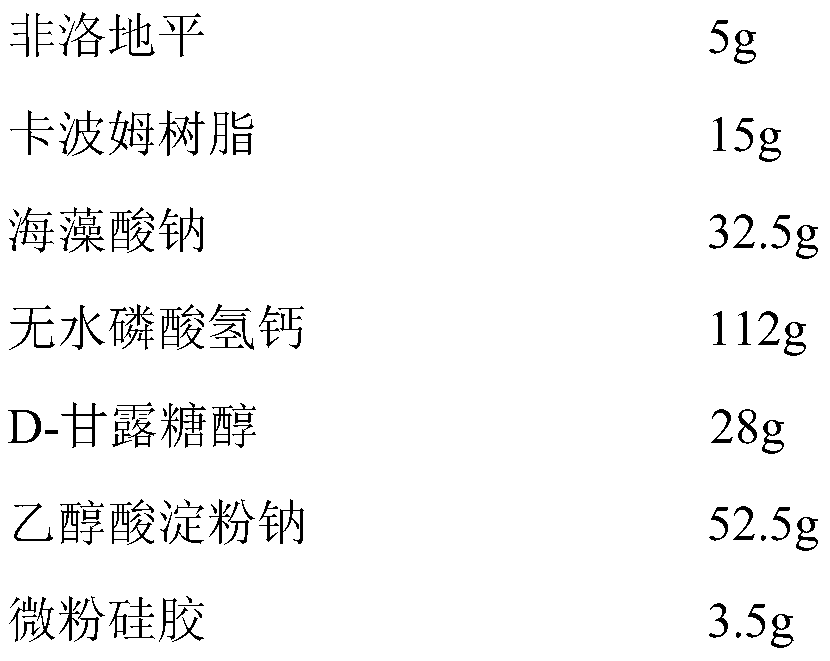

[0036]

[0037] Preparation process: get felodipine 5g, carbomer resin 15g and sodium alginate 15g to mix, suspend in absolute ethanol, dry and remove ethanol to obtain felodipine solid dispersion; Gained felodipine solid dispersion and 112g of anhydrous calcium hydrogen phosphate, 28g of D-mannitol, 52.5g of sodium starch glycolate, and 17.5g of sodium alginate were mixed evenly, and 60% ethanol was used as a binder, granulated, and dried at 45°C to obtain drug-containing granules; The drug-containing granules are passed through an 18-mesh sieve, then mixed evenly with 3.5 g of finely powdered silica gel, and compressed into tablets.

Embodiment 3

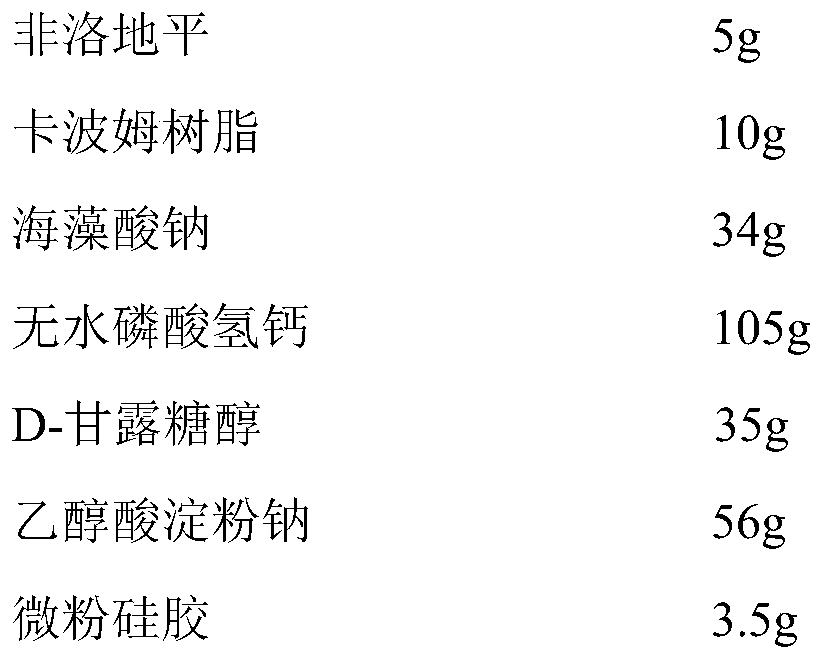

[0039]

[0040] Preparation process: get felodipine 5g, carbomer resin 10g and sodium alginate 20g to mix, suspend in absolute ethanol, dry and remove ethanol to obtain felodipine solid dispersion; Gained felodipine solid dispersion and 105g of anhydrous calcium hydrogen phosphate, 35g of D-mannitol, 56g of sodium starch glycolate, and 14g of sodium alginate were mixed uniformly, 60% ethanol was used as a binder, granulated, and dried at 45°C to obtain drug-containing granules; The drug granules are passed through a 18-mesh sieve, then mixed evenly with 3.5g of finely powdered silica gel, and compressed into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com