Angle jaw tongs applicable to automobile electromechanical maintenance

A curved-nose pliers, electromechanical technology, applied in the field of curved-nose pliers, can solve problems such as interference with sight, unfavorable maintenance, poor insulation ability of curved-nose pliers, etc., and achieve the effects of good insulation performance, smooth maintenance, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

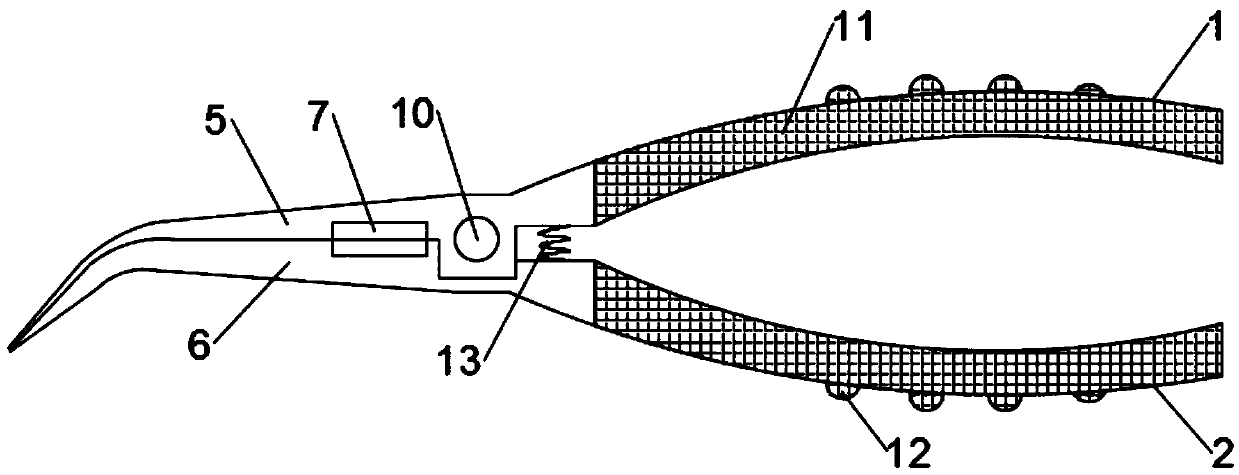

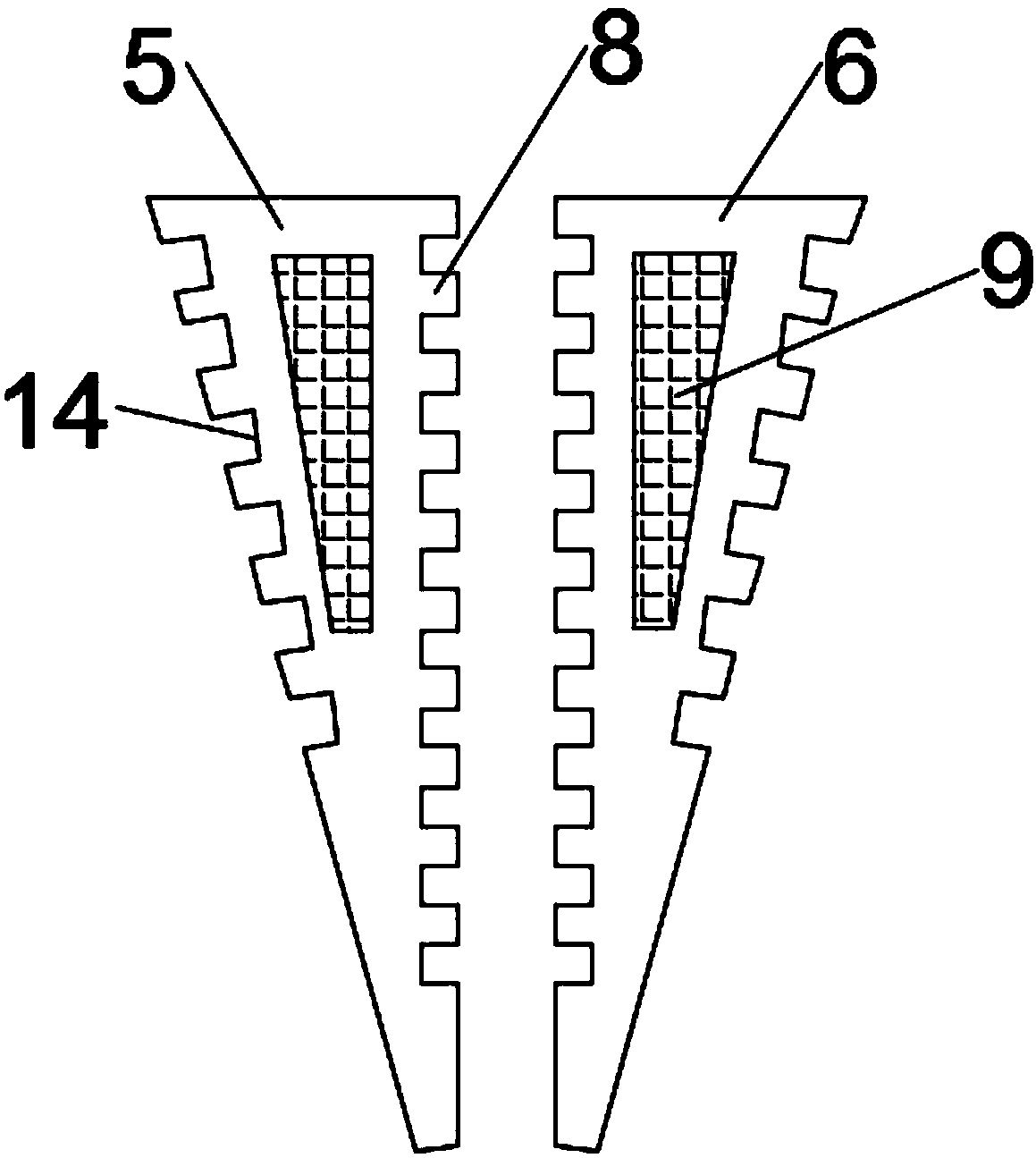

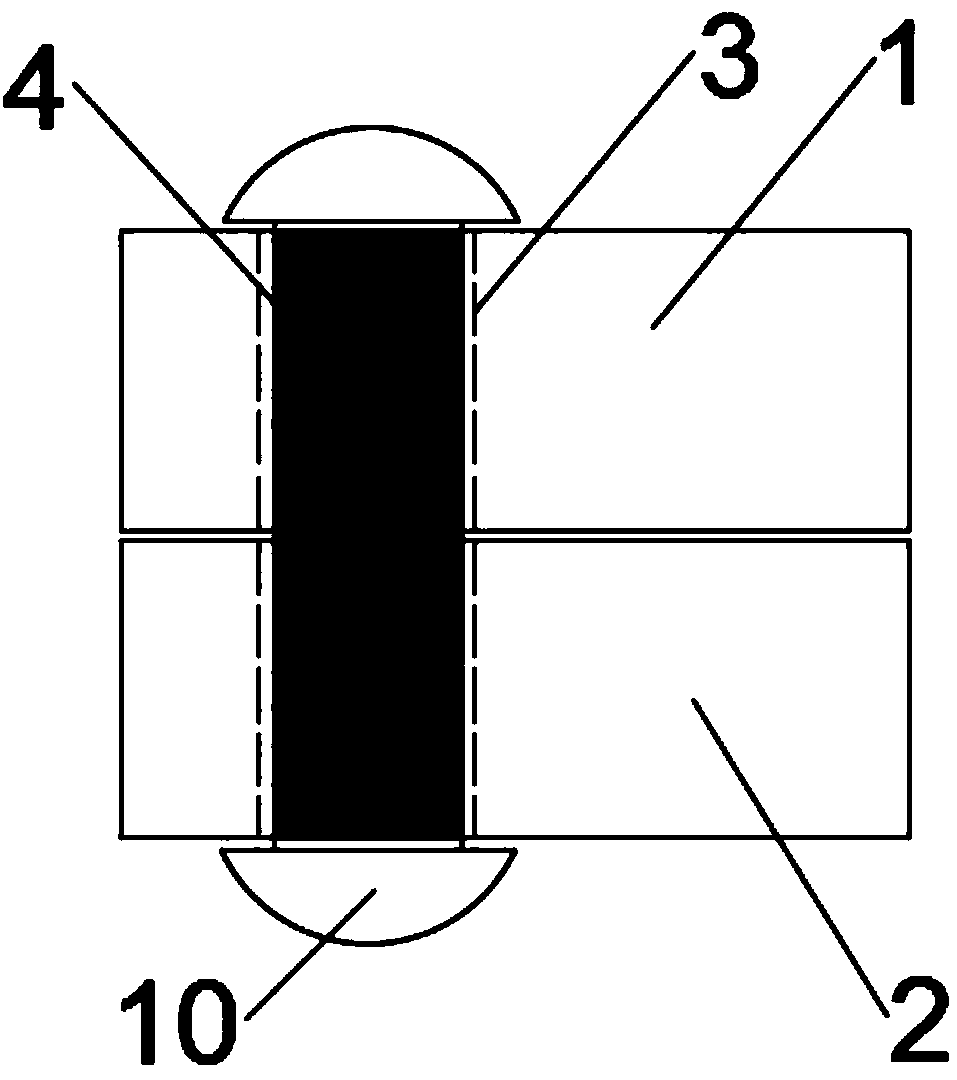

[0023] Such as Figure 1 to Figure 3 As shown, the present invention provides a curved-nose pliers suitable for automobile mechanical and electrical maintenance, including a first handle 1 and a second handle 2, the first handle 1 and the second handle 2 are flat arc-shaped structures, and The outer parts of the first handle 1 and the second handle 2 are covered with rubber sheaths 11, and the surface of the rubber sheaths 11 is provided with several protrusions 12, which can prevent electric shock and increase Large friction makes the use of curved nose pliers more convenient. The left end of the first handle 1 and the left end of the second handle 2 are all provided with through holes 3, and the two through holes 3 are on the same vertical line, and A rotating shaft 4 is inserted in the two through holes 3, the diameter of the rotating shaft 4 is slightly smaller than the diameter of the through hole 3, and the sum of the thickness of the first handle 1 and the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com