Device for synchronously feeding multiple inserts into mold

A technology of inserts and driving devices, which is applied in the field of multi-inserts synchronously entering the mold, can solve the problems that the inserts cannot be connected closely when inserted into the mold, it is inconvenient to overhaul and replace parts, and it is inconvenient for users to disassemble. The effect of better effect and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

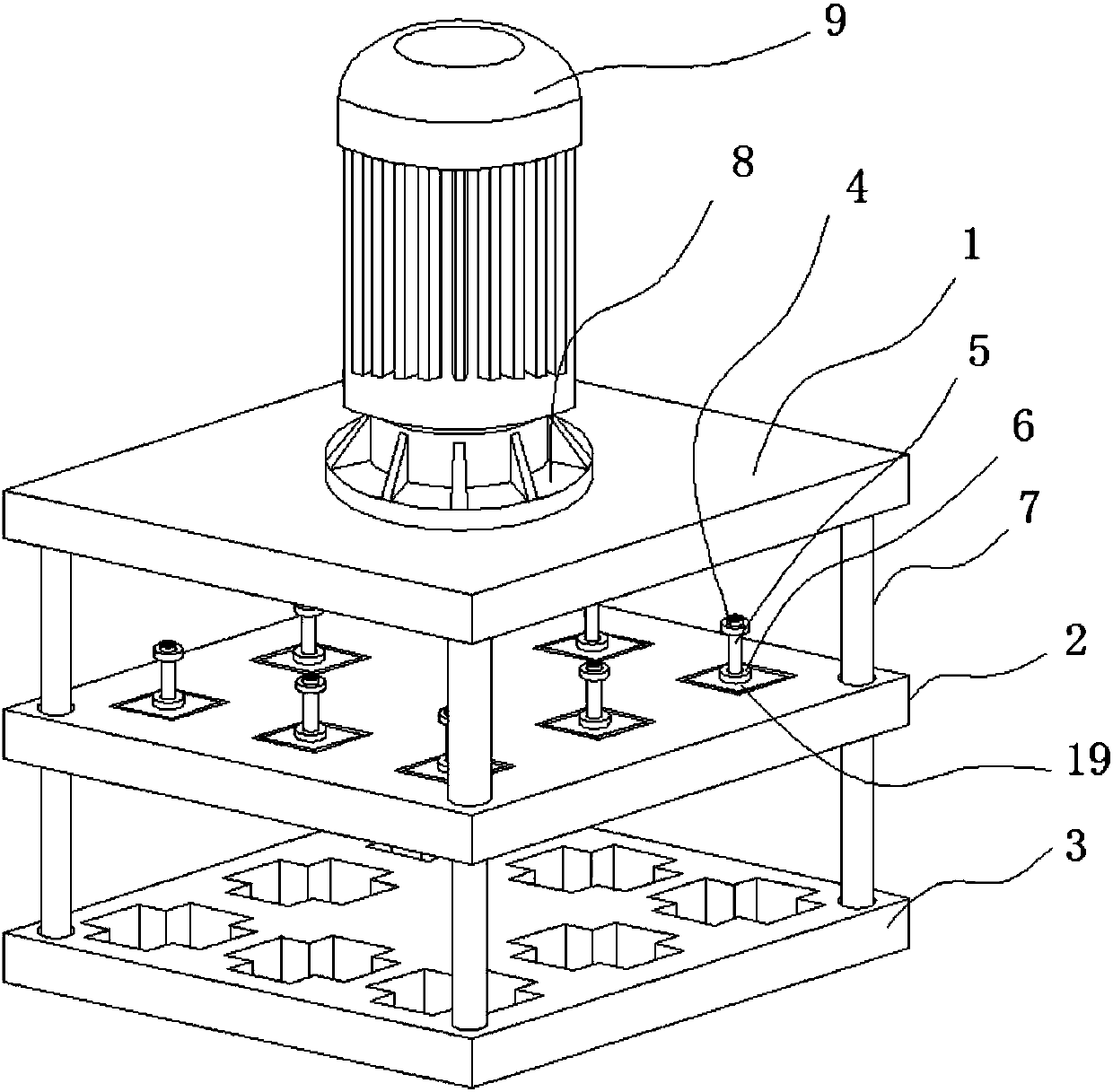

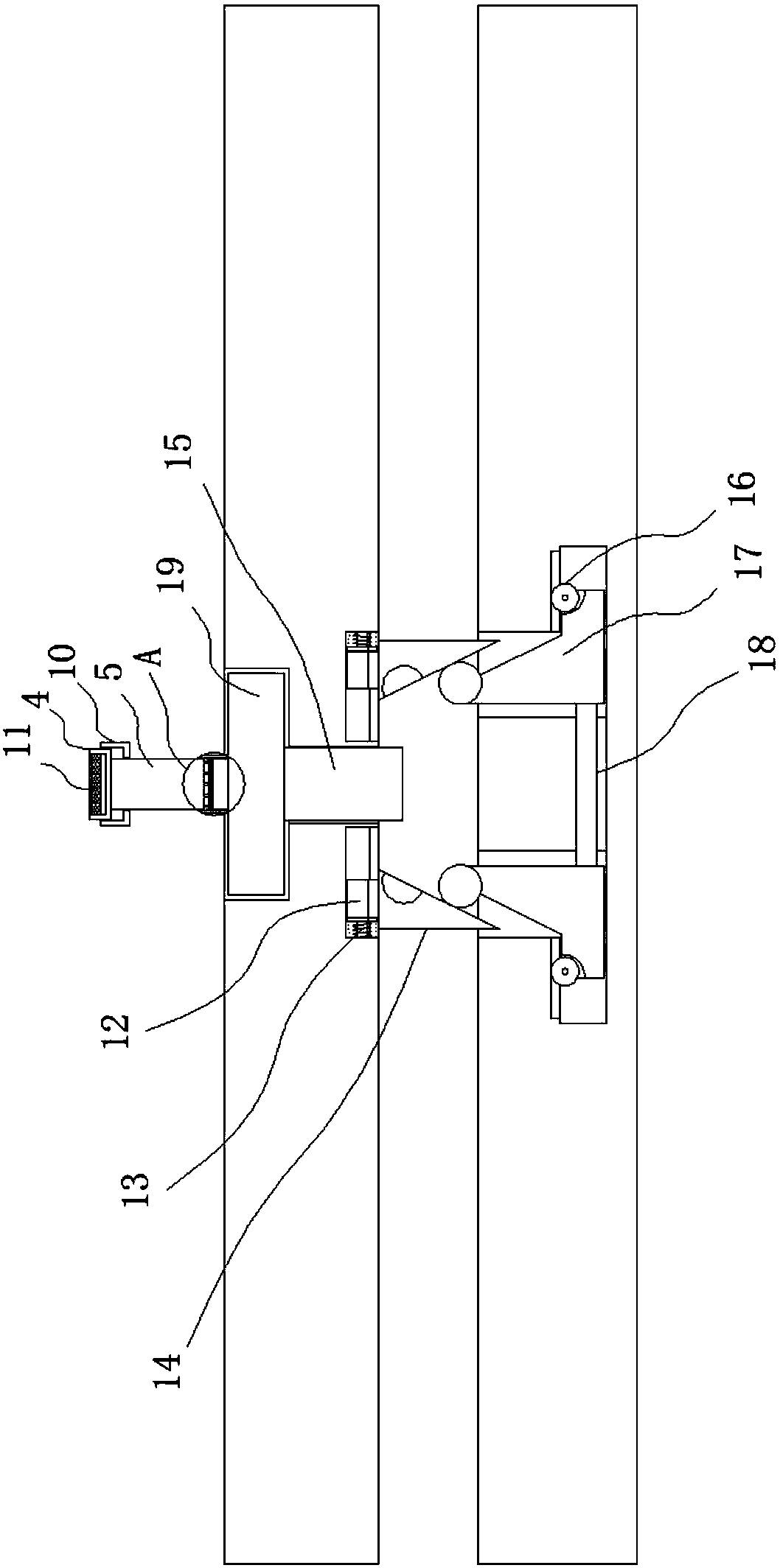

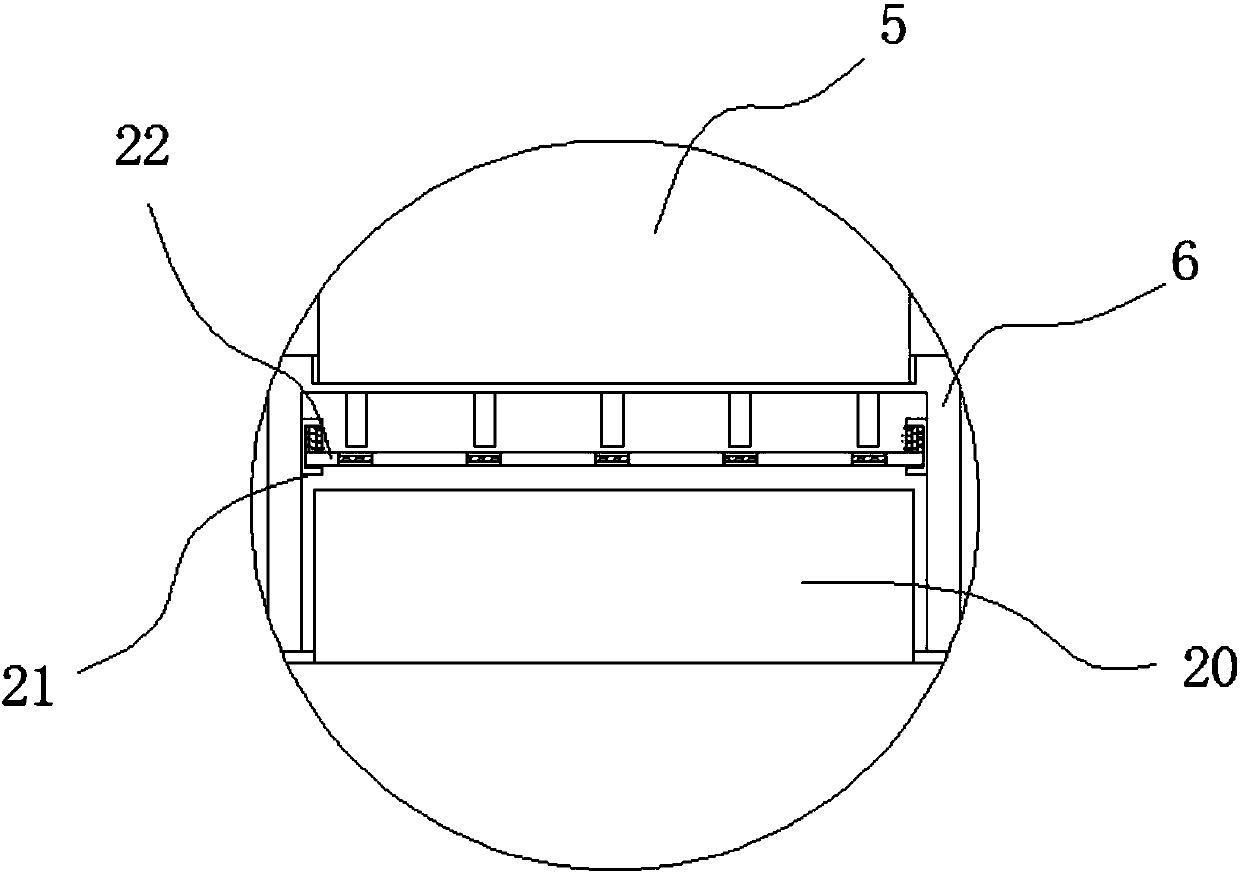

[0020] A multi-insert synchronous molding device, including a mounting plate 1, an upper template 2, and a lower template 3 arranged sequentially from top to bottom, and the four corners below the mounting plate 1 are provided with limit posts 7, which are far away from the mounting plate 1 One end passes through the upper formwork 2 and is extended and connected to the lower formwork 3. The upper middle part of the installation plate 1 is provided with a mounting seat 8, and a driving device 9 is installed on the mounting seat 8 through a fixing piece. The upper middle part of the installation plate 1 is provided with a mounting port. , the driving end of the driving device 9 passes through the installation port and is connected to the upper formwork 2, the upper formwork 2 is provided with an insertion port for interspersing the limit column 7, and the top of the upper formwork 2 is provided with a plurality of clamping grooves, and the upper formwork The bottom of 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com