A kind of water-based rust conversion solution for steel structure

A rust conversion and steel structure technology, applied in the field of anti-corrosion coatings, can solve the problems of occupying anti-corrosion costs, etc., and achieve the effects of good salt spray resistance, accelerated surface drying and hard drying, and long storage time

Active Publication Date: 2019-10-15

ZHEJIANG UNIV +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the traditional method, the steel must be derusted in advance, and this work accounts for 40% of the entire anticorrosion cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

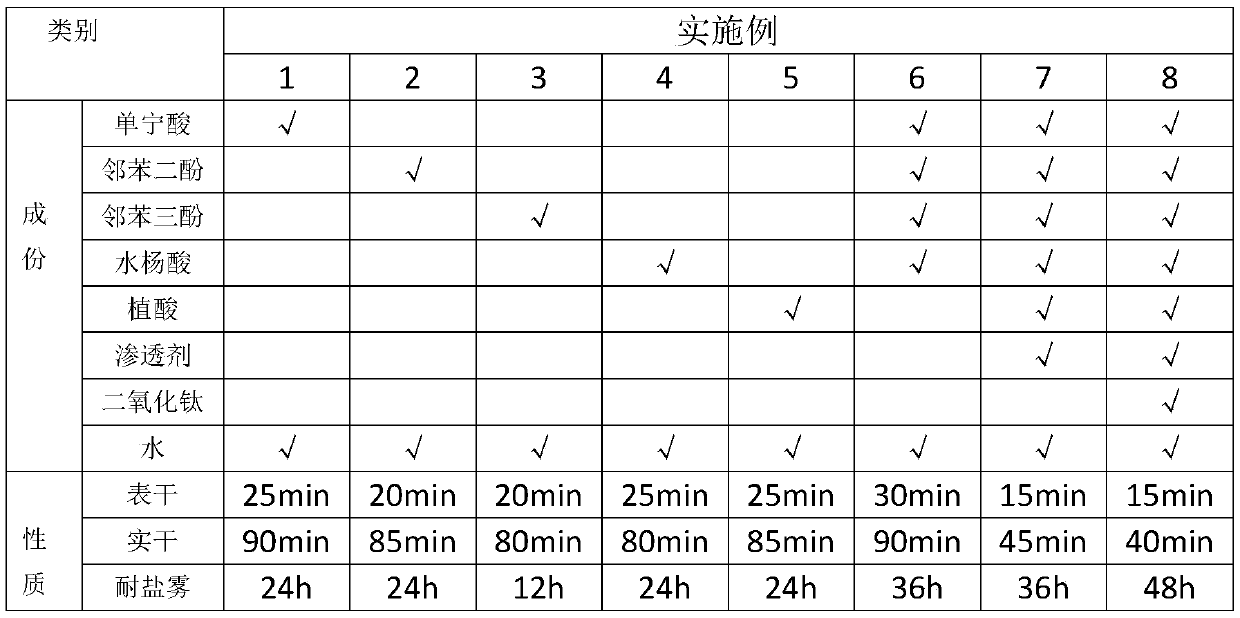

Embodiment 1

[0018] Take 50g of tannic acid and 50g of water (when tannic acid is dissolved in water, heat it slightly to dissolve) and mix;

Embodiment 2

[0020] Get catechol 50g, water 50g mix;

Embodiment 3

[0022] Get pyrogallol 50g, water 50g mix;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a novel steel structure water-based rust conversion solution. The novel steel structure water-based rust conversion solution comprises the following components: composite organic acid, a penetrating agent, nanometer titania and water. The novel steel structure water-based rust conversion solution is mainly used for a rusted steel structure surface, very good rust convertingcan be carried out on a rust layer on the steel structure surface, and after the rust conversion solution is dried, a primer continues to be sprayed. The steel structure water-based rust conversion solution is composed of the environmental-friendly components, and no toxic or harmful components (such as VOC) are contained. When the novel steel structure water-based rust conversion solution is used, the conversion solution and the water-based antirust coating are used successively, a steel structure can be protected to the maximum extent, the steel structure is prevented from being rusted again, the service life of steel is prolonged, large-scale rust removing work is not needed before construction, and a large number of financial resources and labor are saved.

Description

technical field [0001] The invention relates to a water-based rust conversion solution for steel structures, which belongs to the technical field of anti-corrosion coatings. Background technique [0002] With the development of my country's iron and steel industry, the application of steel structures in construction projects is increasing. Steel structure has a series of advantages such as high strength, good toughness, convenient fabrication, fast construction speed and short construction period. But there are also obvious weaknesses - easy to corrode. According to statistics, the annual economic loss caused by metal corrosion in the world is about 700 billion US dollars. Due to the incomparable advantages of other materials and methods such as excellent performance, convenient manufacturing and construction, and low price, paint coating anticorrosion often becomes the object of priority when selecting anticorrosion measures. [0003] For rusty steel, it is also a good m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23G1/08

Inventor 朱明乔古望军曹海荣吕汉龙尹建荣丁智俊陈滨周洋王泽辉姜永民

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com