Plug-in connecting square bar structure

A technology of plug-in type and square rod, which is applied in the direction of handle connection, building structure, and the spherical handle of wing leaf, etc., which can solve the problems of increased use cost, large waste, and unsafety, and achieves simple structure, convenient use, and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

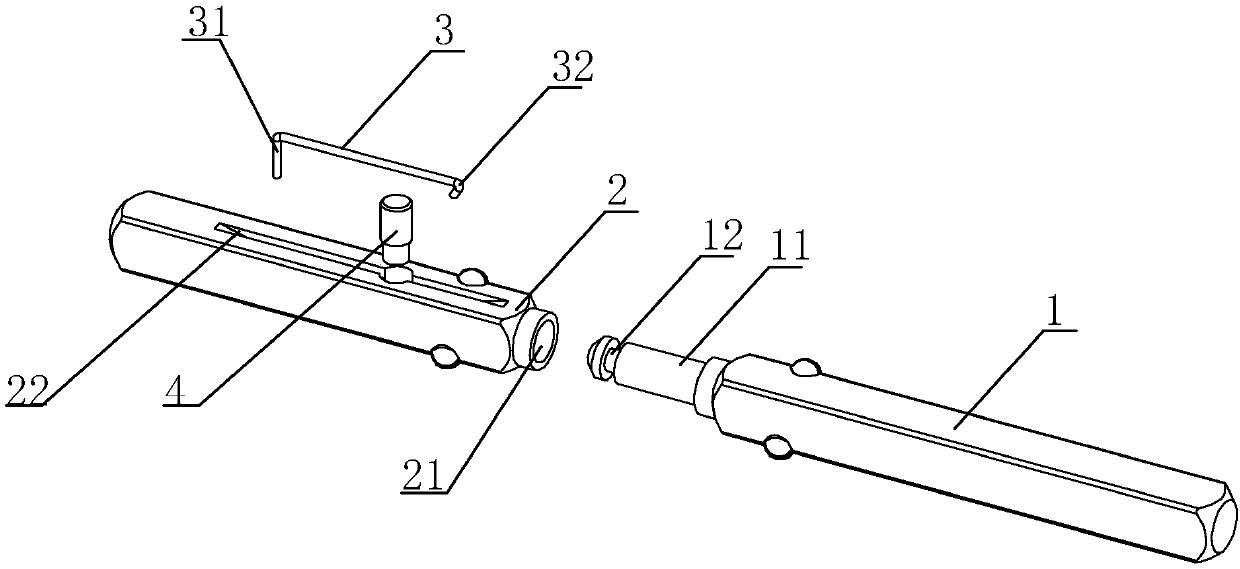

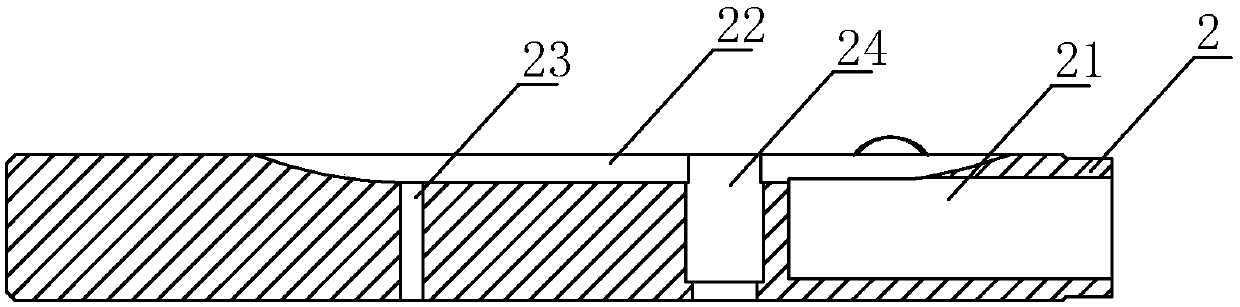

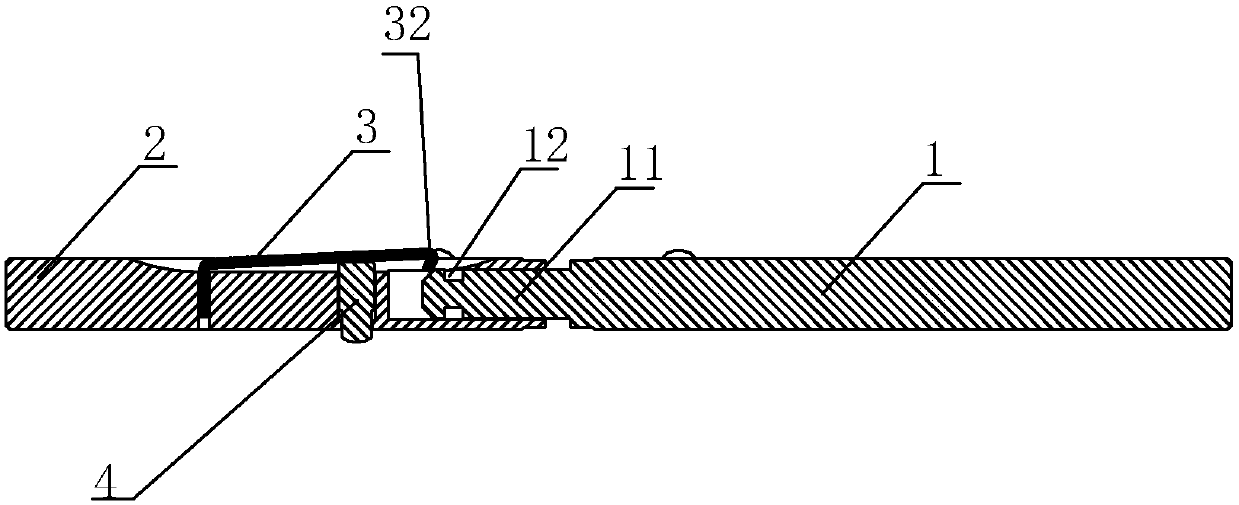

[0018] Refer to attached Figure 1 to Figure 5 A plug-in connection square rod structure of the present invention will be further described in detail.

[0019] A plug-in connection square rod structure, comprising an outer square rod 1 and an inner square rod 2, one end of the inner square rod 2 is provided with a socket hole 21 for connecting the outer square rod 1, and one of the ends A groove 22 is provided on the side, and the groove 22 extends forward to communicate with the socket hole 21, and an elastic groove 3 is arranged in the groove 22; one end of the elastic groove 3 is bent to form a mounting foot 31, A mounting hole 23 for fixing the mounting foot 31 is provided in the groove 22, and the mounting foot 31 is riveted and installed in the mounting hole 23 to prevent the elastic groove 3 from loosening; the other end of the elastic groove 3 is extended forward and placed In the socket hole 21, and the end is provided with a locking pin 32; the outer square rod 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com