A sealing and locking part for realizing high-pressure filling

A sealing lock and filling technology, which is applied to valve devices, engine components, valves used for inflation, etc., can solve problems such as no such products, and achieve the effects of simple structure, simplified filling structure, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

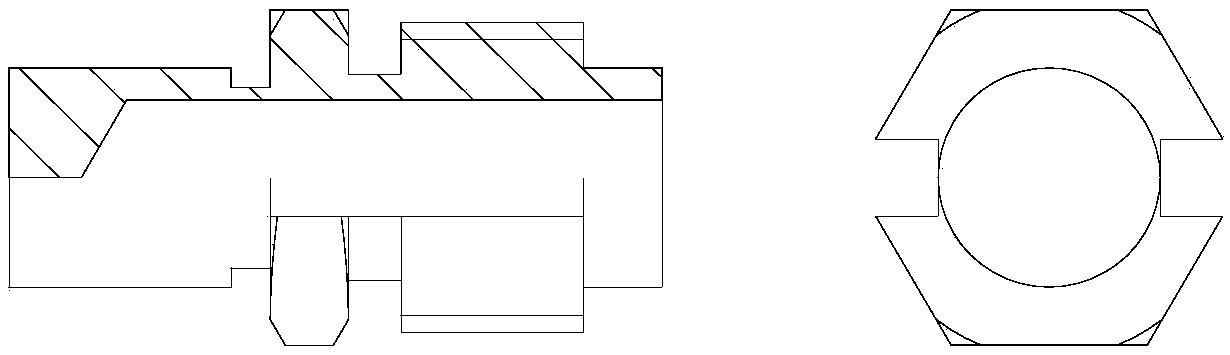

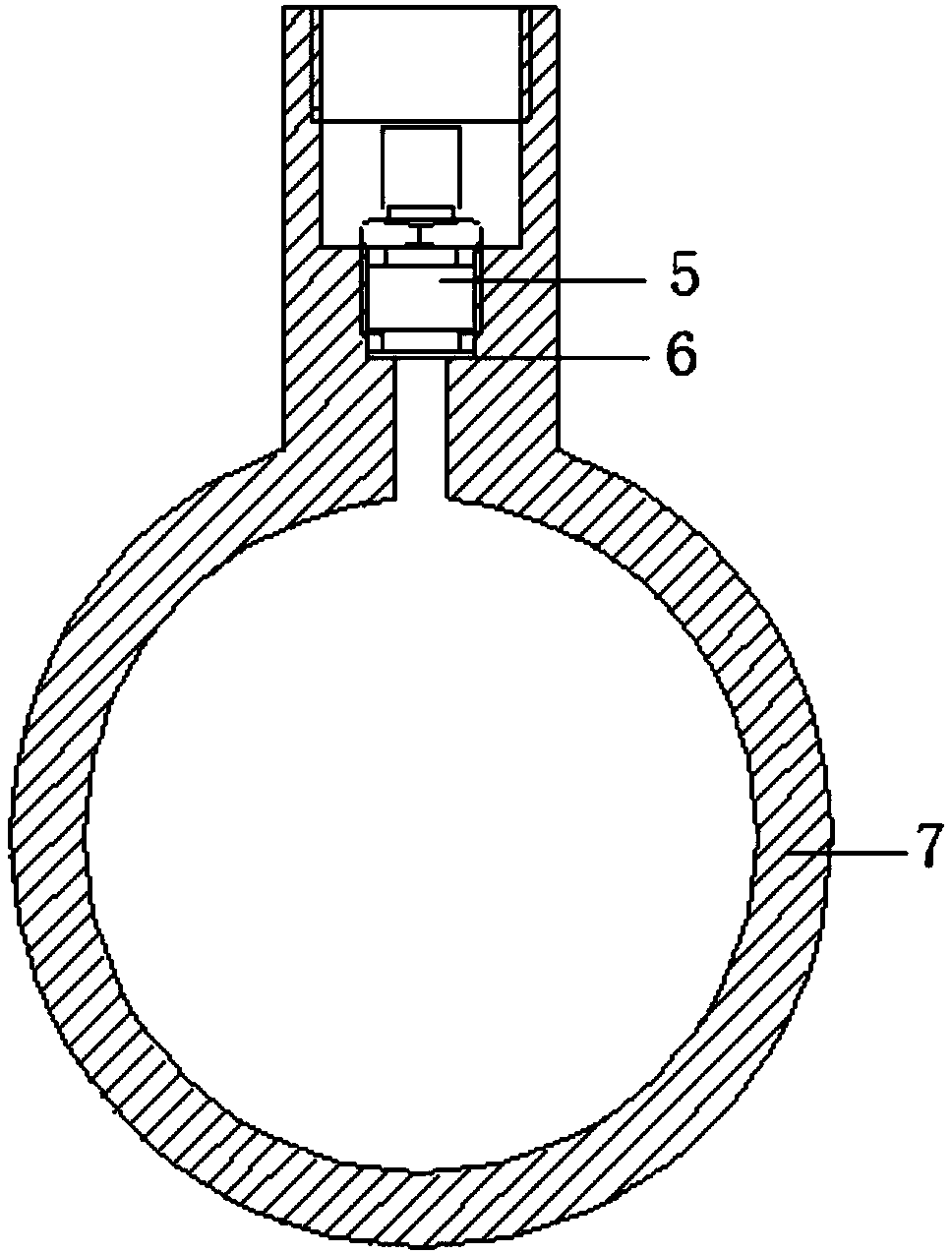

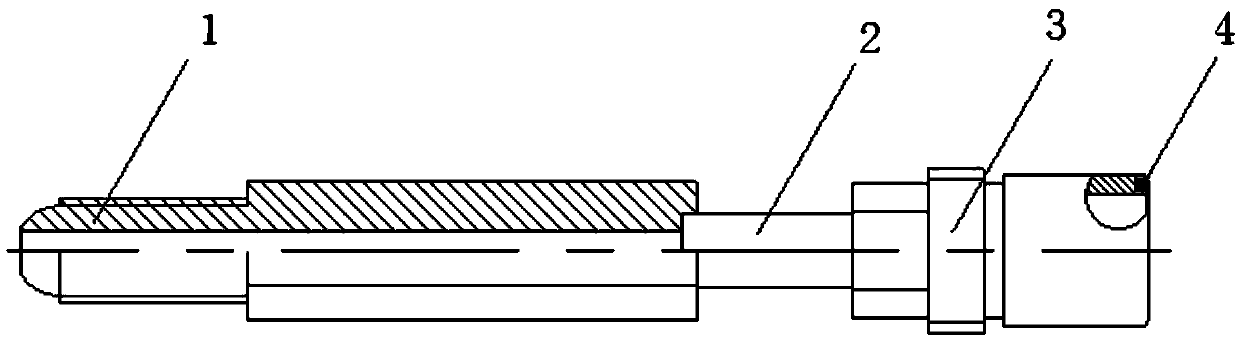

[0026] as attached figure 1 As shown, the present invention provides a sealing and locking member for high-pressure filling. The two ends of the sealing and locking member are cylindrical sections, and the part between the cylindrical sections is a hexagonal structure and a section of threaded section. The hexagonal structure is used to communicate with The external air inlet joint assembly cooperates to realize the transmission of rotational torque, and the threaded section is used to realize threaded connection with the bottle mouth of the bottle body 7; wherein, the diameter of the cylindrical section corresponding to one side of the hexagonal structure is smaller than the length of the opposite side of the hexagonal structure, and the threaded section one The diameter of the cylindrical section corresponding to the side is less than the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com