Belt type drying machine feeding frame with adjustable feeding amount

A belt dryer, feed rate technology, applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of danger, easy ejection of the conveyor belt, affecting the drying effect, etc., to achieve strong practicability, use Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the description of the drawings and specific implementations:

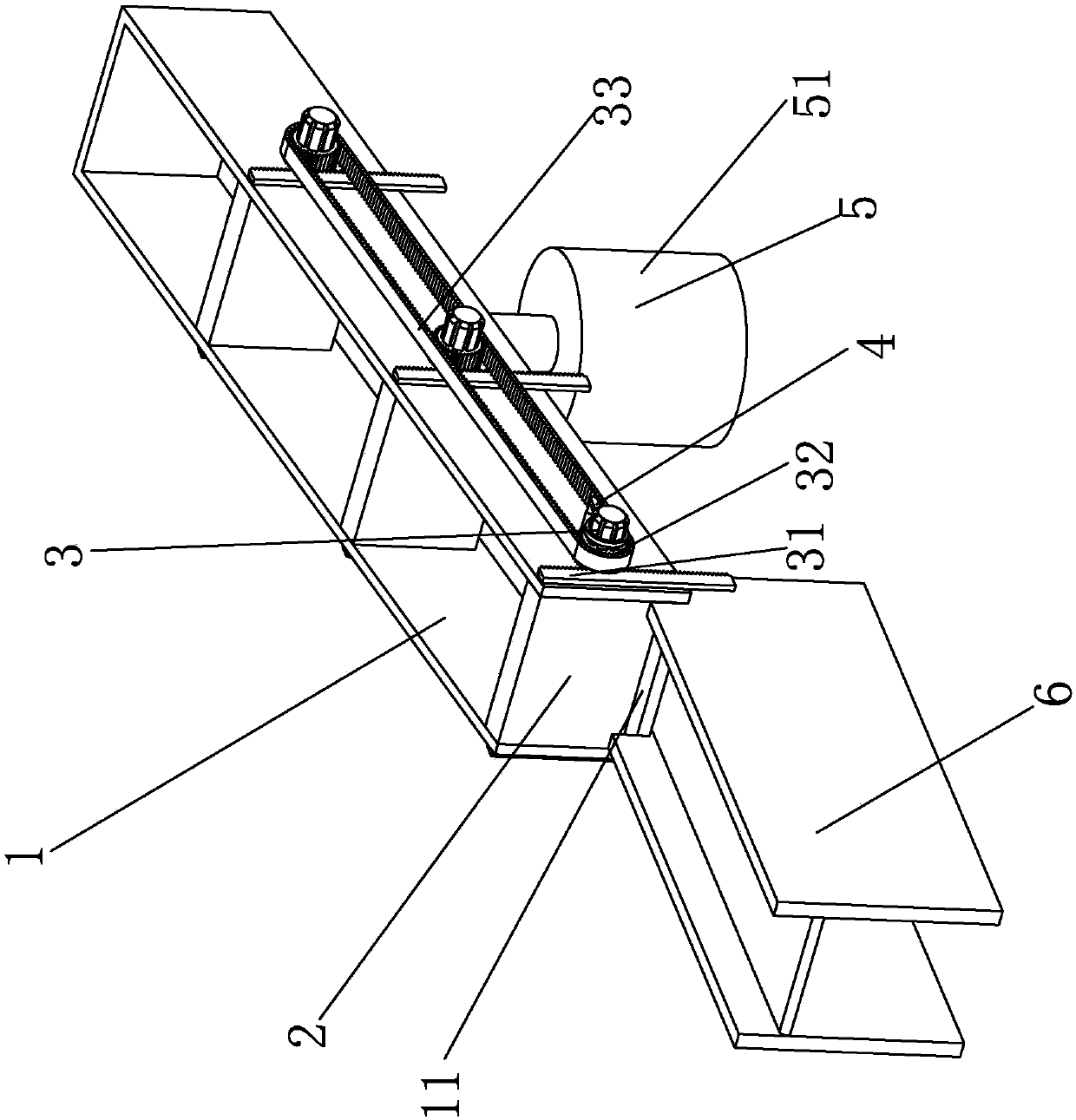

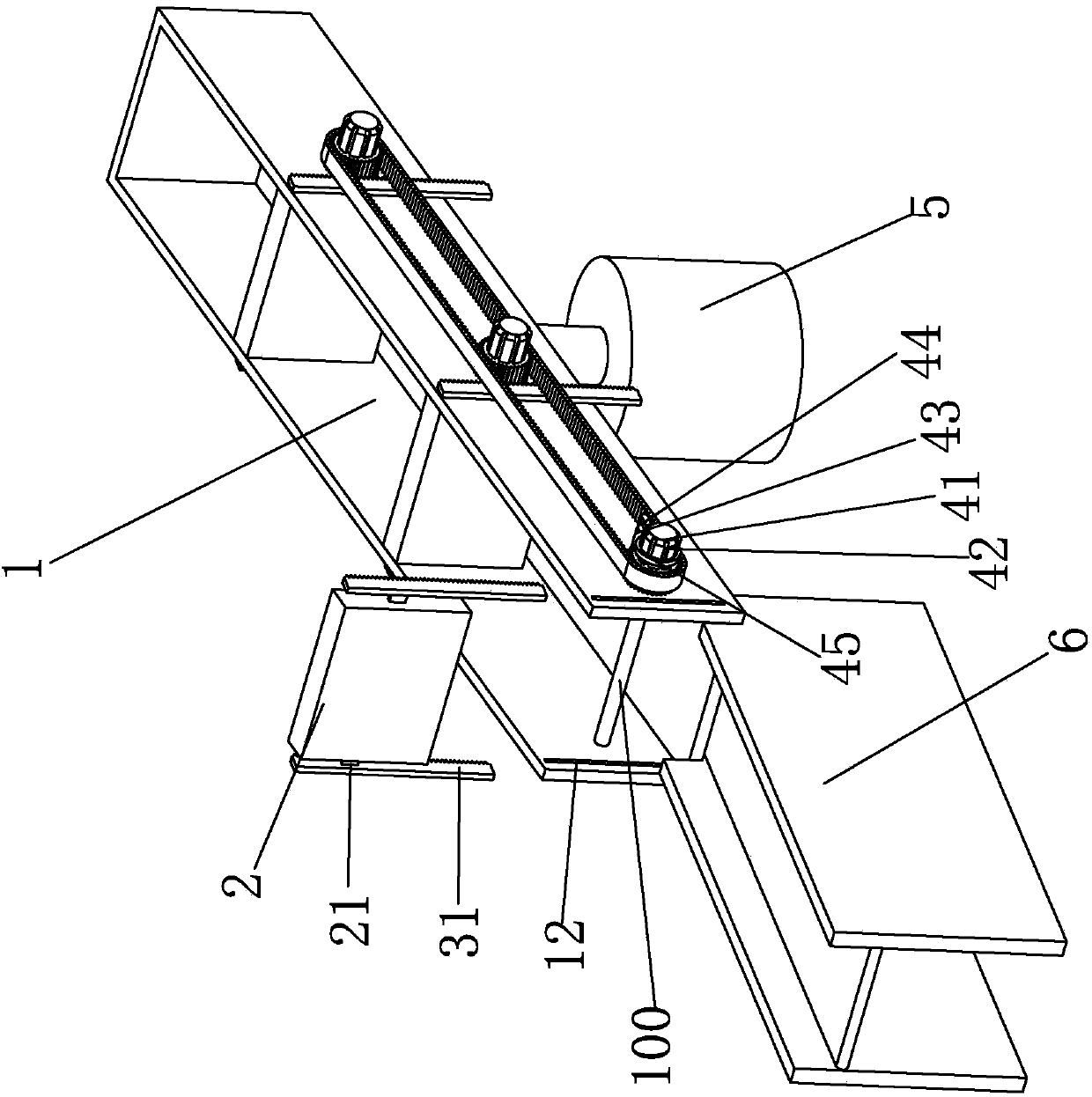

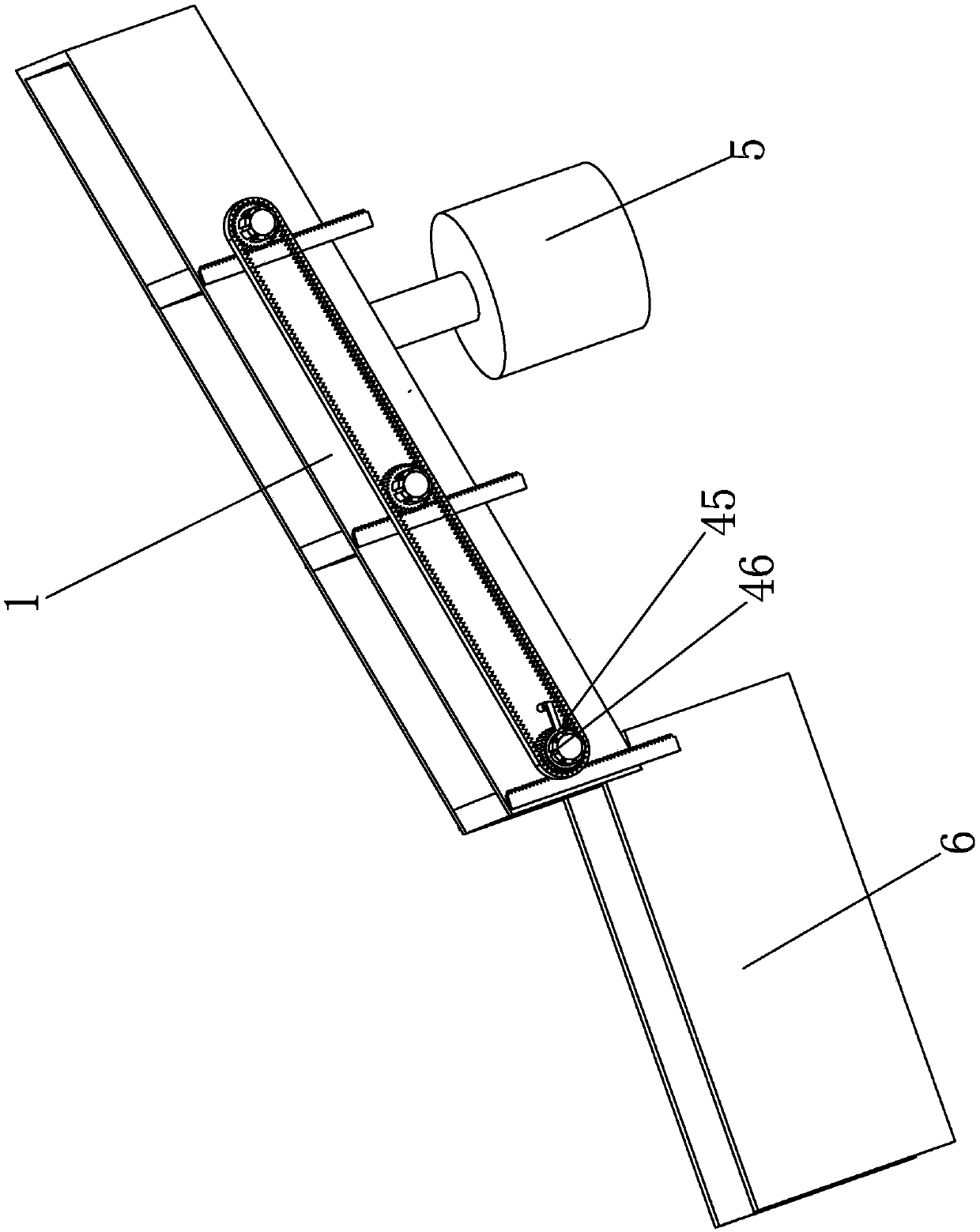

[0018] Such as Figure 1 to 3 The feeding rack of a belt dryer with adjustable feeding amount shown includes a feeding rack 1. A conveyor belt 6 is provided at the front end of the feeding rack 1, and the feeding rack 1 faces one end of the conveyor belt 6 Opening, a plurality of partitions 2 are provided in the feeding rack 1, and an adjustment mechanism 3 that can drive the partitions 2 to move up and down to adjust the height of the feed opening is provided on the side of the feeding rack 1. The lower end of the rack 1 is provided with a vibration mechanism 5 that can drive the feeding rack 1 to vibrate. By providing multiple partitions, the adjusting mechanism drives the partitions to adjust the height of the partitions, thereby adjusting the height of the inlet, so that the materials are more uniform. It will not accumulate, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com