A joint test method for multi-interface shear stress of non-metallic anti-floating anchor

An anti-floating anchor and joint testing technology, which is applied in the direction of measuring force components, etc., can solve problems that have not been involved in the mechanical properties of the anchor body and the bonded interface, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

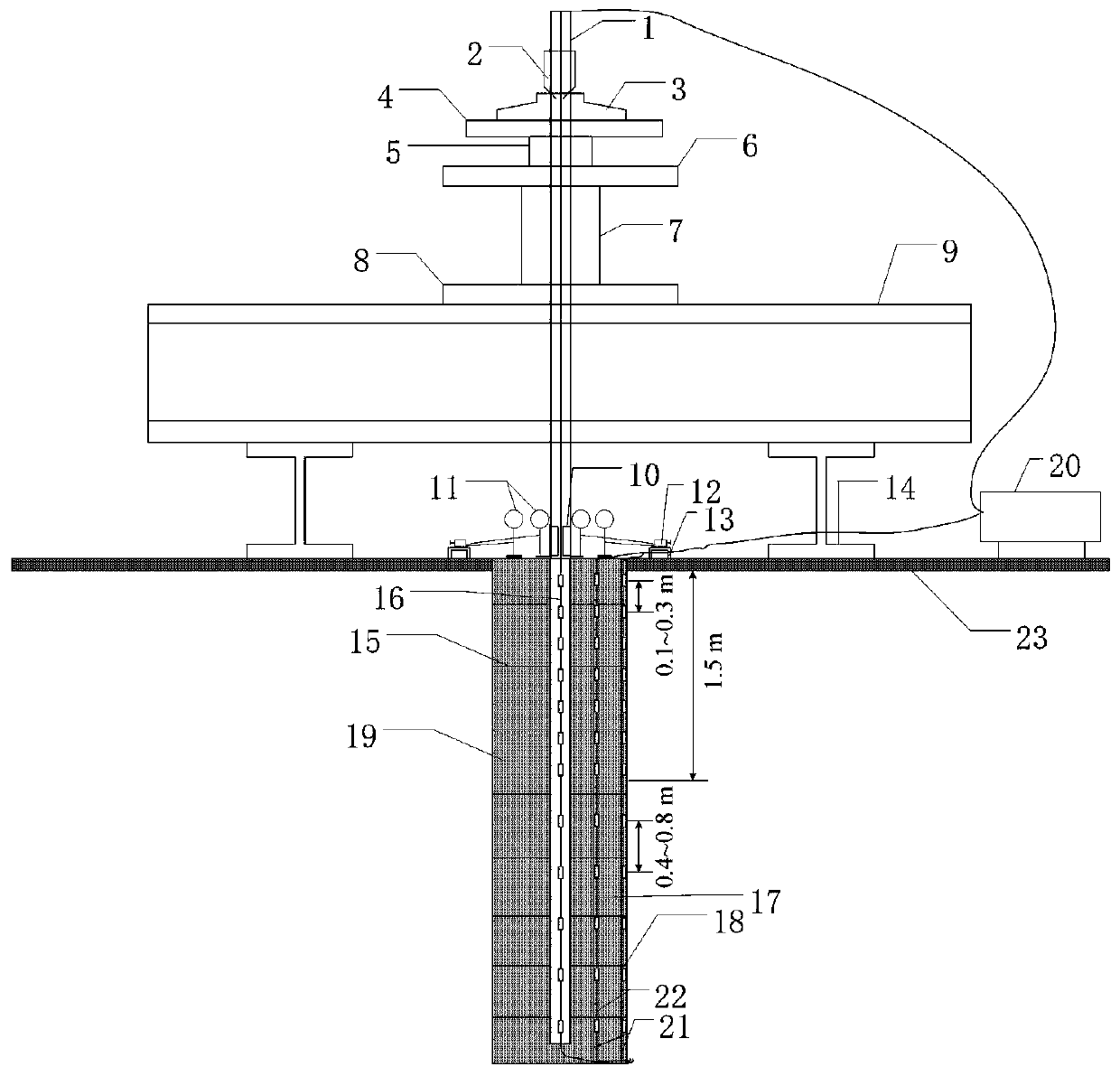

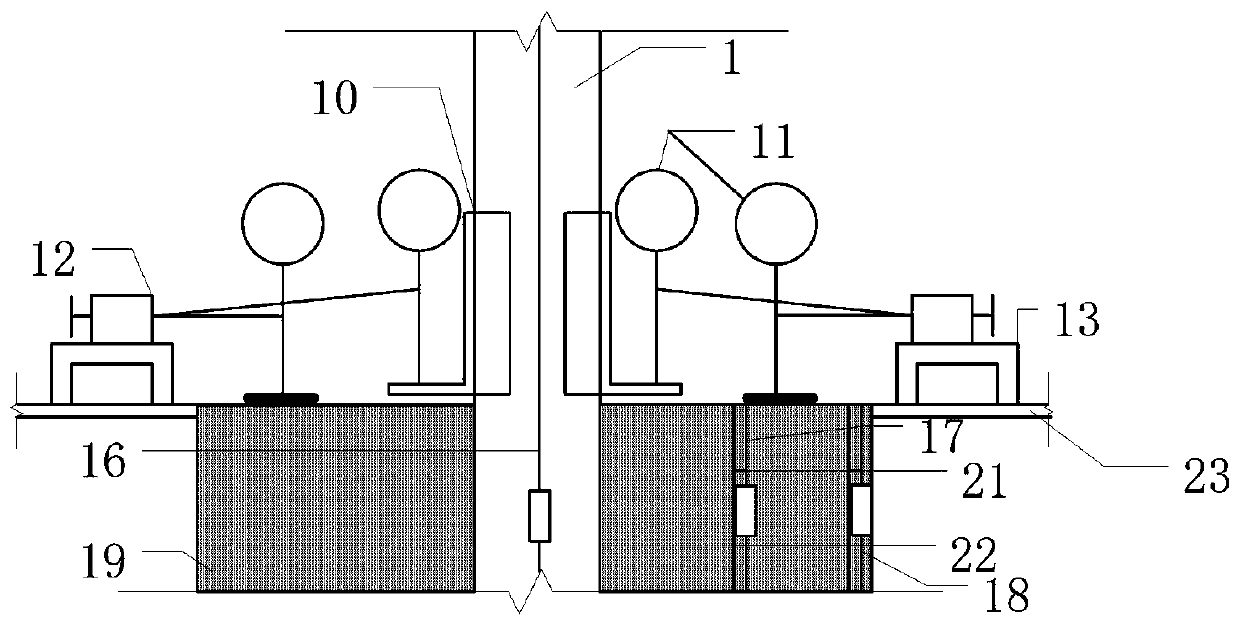

[0048] This embodiment is realized by using a multi-interface shear stress joint test device for non-metallic anti-floating anchor rods, and the specific process is as follows:

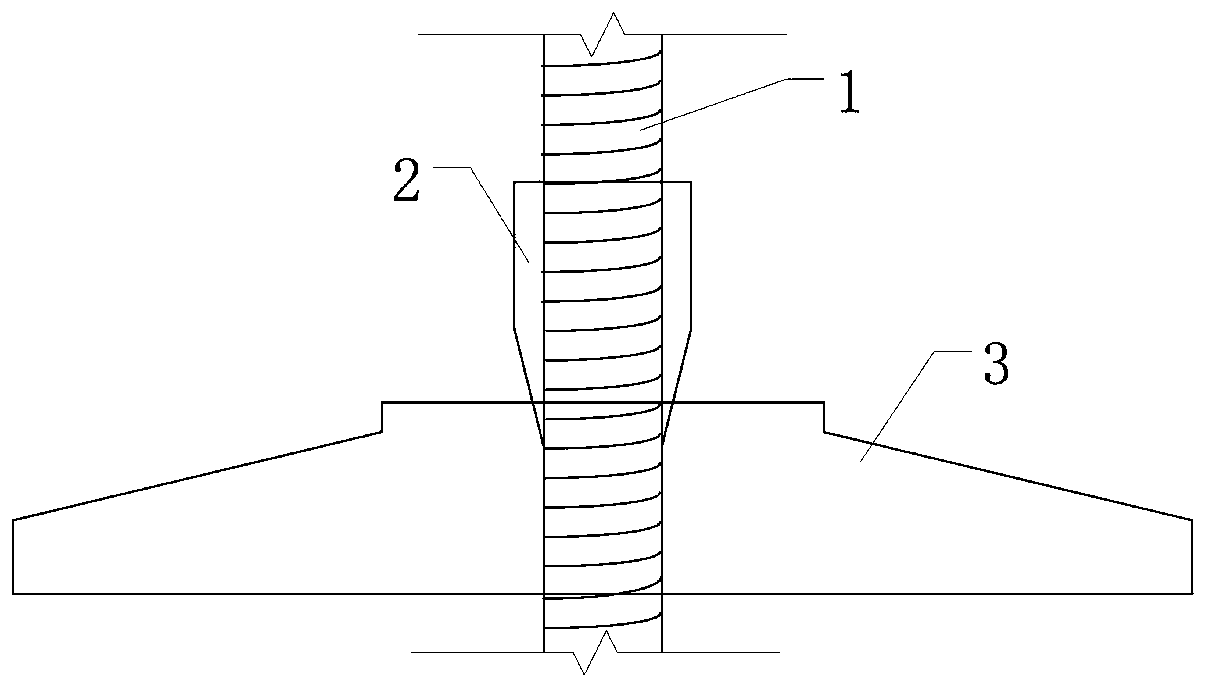

[0049] (1) Put the anchor rod body 1 implanted in the self-compensating miniature FBG strain sensor string 16 into the anchor rod bracket 15 every 0.5m, and tighten the fixing nuts to ensure that the anchor rod bracket 15 is firm and stable in the anchoring section of the rod body, Ensure not to move up and down (the self-compensating miniature FBG strain sensor string 16 in the rod body checks its survival rate (survival rate must not be lower than 90%) respectively before and after being implanted in the anchor rod body 1);

[0050] (2) Fix the hard steel wire 22 on the anchor bracket 15 with the binding wire 21 as required, and ensure that the hard steel wire 22 is respectively located in the middle position of the radial direction of the mortar anchor and the second interface (the outer surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com