Joint testing device for non-metallic anti-floating anchor multi-interface shear stress

An anti-floating anchor rod and joint testing technology, which is applied in the direction of measuring force components, etc., can solve problems that have not been involved in the mechanical properties of the anchor body and the bonded interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

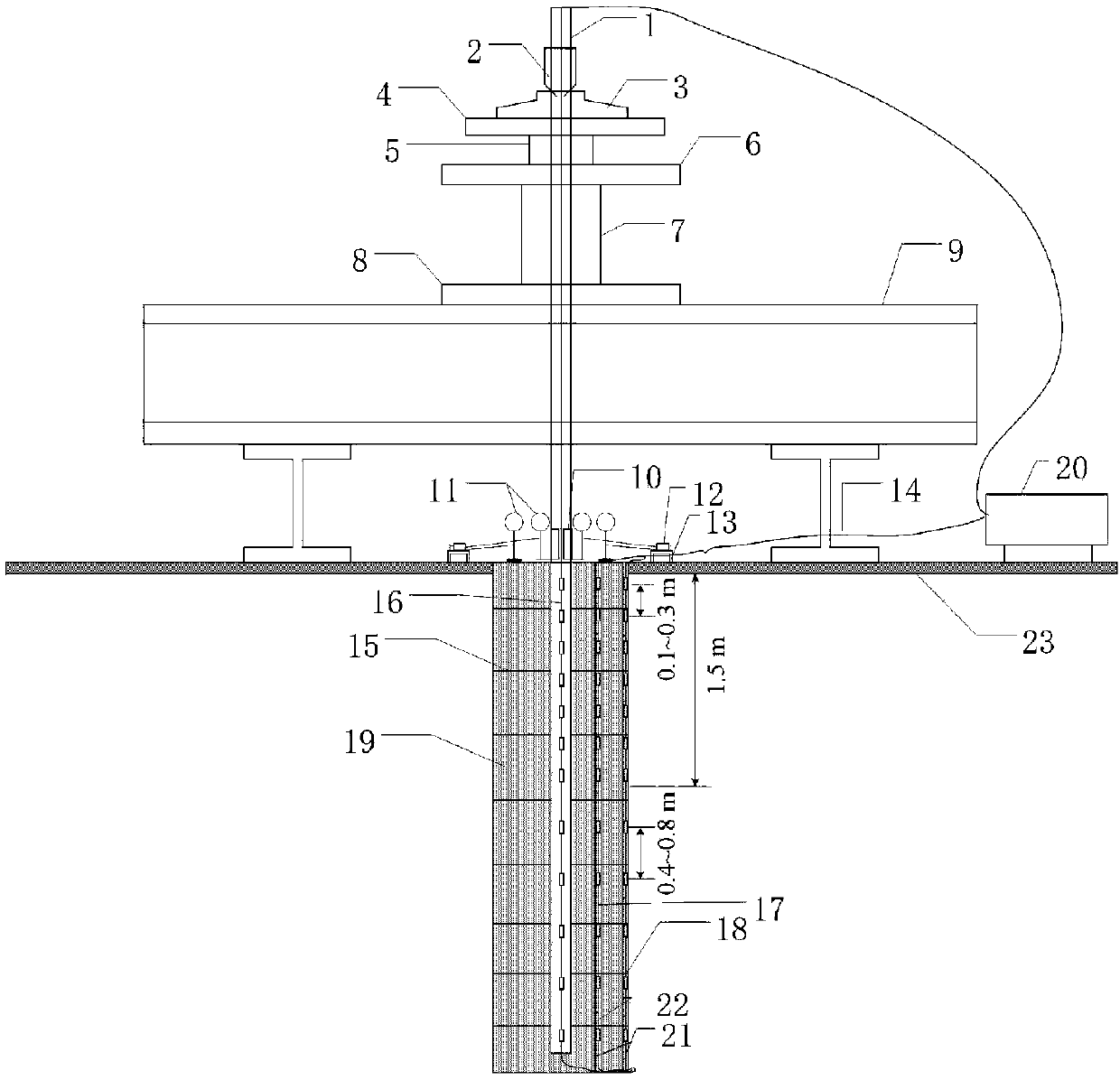

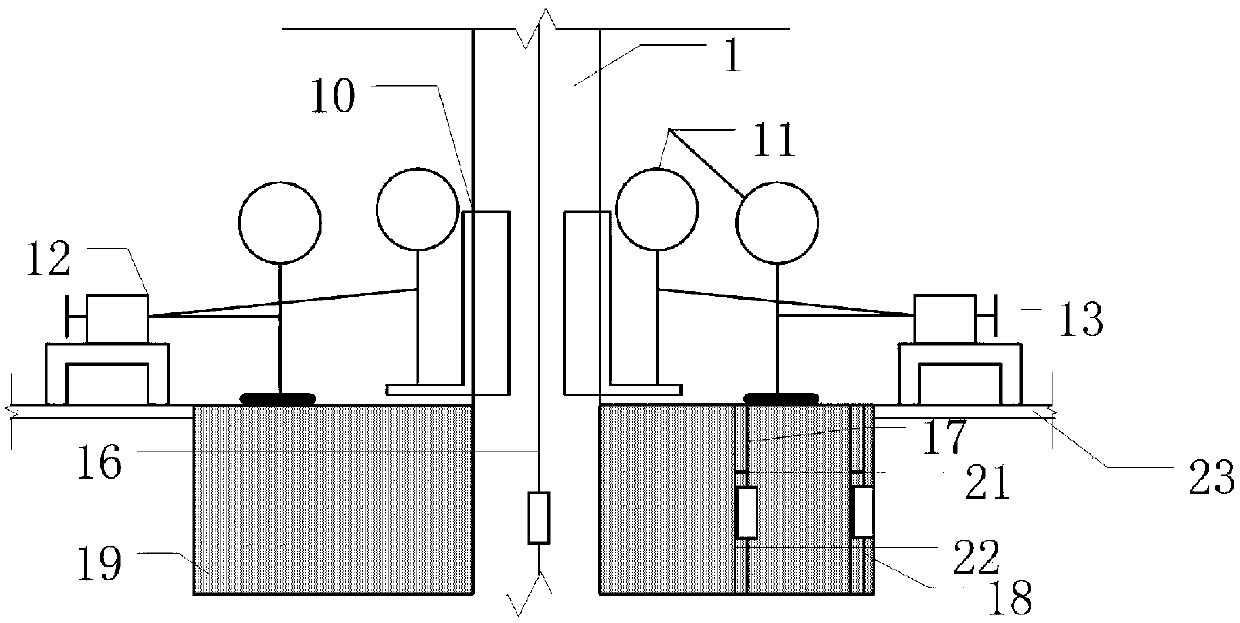

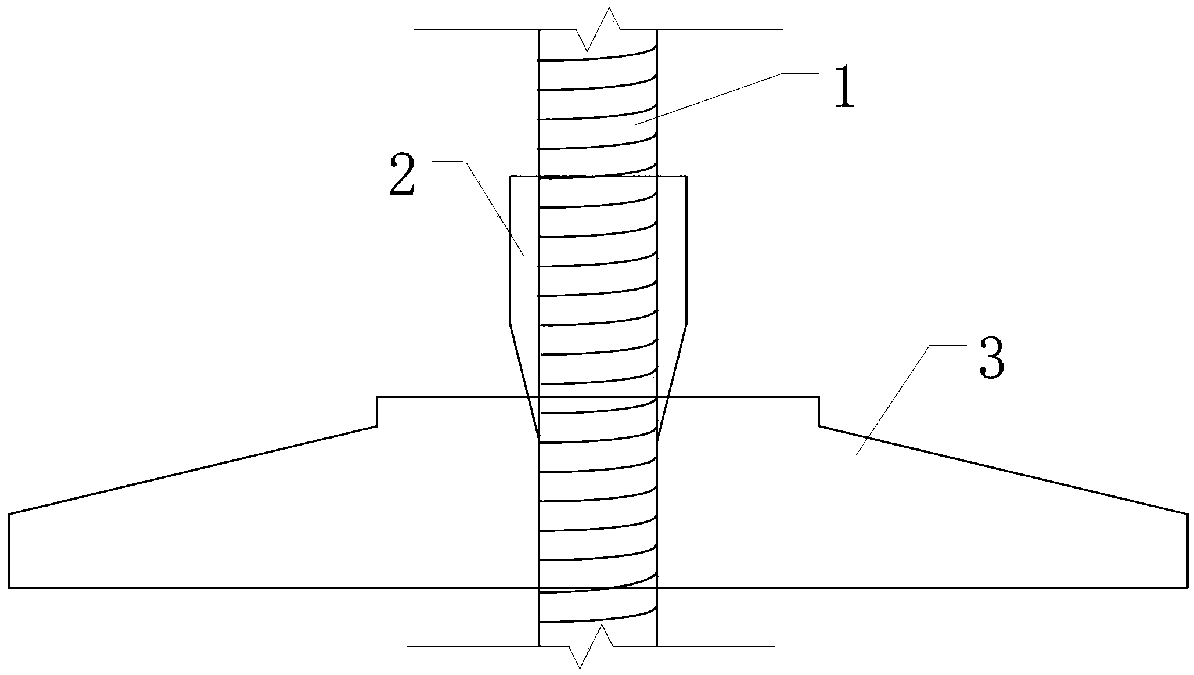

[0043] The main structure of the non-metallic anti-floating anchor multi-interface shear stress joint test device described in this embodiment includes an anchor rod body 1, a locking anchor 2, a stress diffusion tray 3, a first through-hole steel backing plate 4, and a load sensor 5 , second through-core steel backing plate 6, through-core jack 7, third through-core steel backing plate 8, through-core reaction beam 9, self-made displacement test device 10, optical fiber grating displacement meter 11, magnetic table base 12, reference beam 13. I-beam support beam 14, anchor rod bracket 15, self-compensating miniature FBG strain sensor string 16 in the rod body, self-compensating miniature FBG strain sensor string 17 in the anchor body, second interface self-compensating miniature FBG strain sensor string 18, Commodity mortar 19, fiber grating demodulator 20, binding wire 21, hard steel wire 22 and fine stone concrete cushion 23; anchor rod body 1 is a solid glass fiber reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com